Extruder GM-50-FU

Page 4/15 Issue 12.2009/Rev. 01 MUNSCH Kunststoff-Schweißtechnik GmbH

1 General

These operating instructions must always

be available at the place of use of the extruder.

The objective of these operating instructions is to

support operators in familiarizing themselves with

the extruder and in using its functions for the

intended service.

These operating instructions provide important

information for the safe, workmanlike and

economical operation of the extruder. Their

observance helps avoid danger, minimize repair

costs and downtimes, enhance reliability, and extend

the service life of the extruder.

These operating instructions must be observed by all

persons working with/on the extruder. Such work

includes, for instance:

•operation,

•maintenance, inspection and repair

•transport.

The extruder may only be mounted, operated and

maintained by trained personnel.

In addition to the operating instructions and the

national and local accident prevention regulations

applicable at the place of use, the acknowledged

technical rules for safe and proper working practices

must be observed.

These operating instructions provide basic

information to be observed for operation and

maintenance. For this reason, it is imperative that

they be read by the specialist personnel/Operator

prior to placing the hand extruder in service and that

they always be available at the place of use.

Apart from the general safety instructions under

section “Safety“, also the special safety instructions

given under the respective sub-sections must be

adhered to.

Non-observance of the safety instructions

may cause hazards to persons and the environment

or damage to the extruder.

Moreover, failure to observe the safety instructions

may lead to the forfeiture of any damages.

Non-observance of the safety instructions may in

particular involve the following risks:

•failure of important extruder functions,

•hazards to persons due to electrical and

mechanical impacts including risk of burns,

•hazards to the environment due to vapour-phase

hazardous substances,

•risk of fire.

2 Safety

These operating instructions provide basic

information to be observed for operation and

maintenance. For this reason, it is imperative that

they be read by the specialist personnel/Operator

prior to placing the extruder in service and that they

always be available at the place of use.

Safe operation of the extruder presupposes that the

instructions under section 1 – General – of these

operating instructions are complied with. In no case

must the limit values indicated be violated.

Intact and unaltered extruders conform to the

applicable codes and standards and meet all

regulatory limit values regarding EMC

(electromagnetic discharges and interference

immunity). For the country-specific limit values to be

observed, the Operator should consult the local

electric utility. Nevertheless, the extruders emit

electromagnetic fields within the acceptable limits.

Electromagnetic fields may interfere with the

operation of vital electronic devices (e.g. cardiac

pacemakers). Persons wearing a cardiac pacemaker

should therefore consult their physician before using

the machine.

In addition to the operating instructions and the

national and local accident prevention regulations

applicable at the place of use, the acknowledged

technical rules for safe and proper working practices

must be observed.

Apart from the general safety instructions under

section “Safety“, also the special safety instructions

given under the respective sub-sections must be

adhered to.

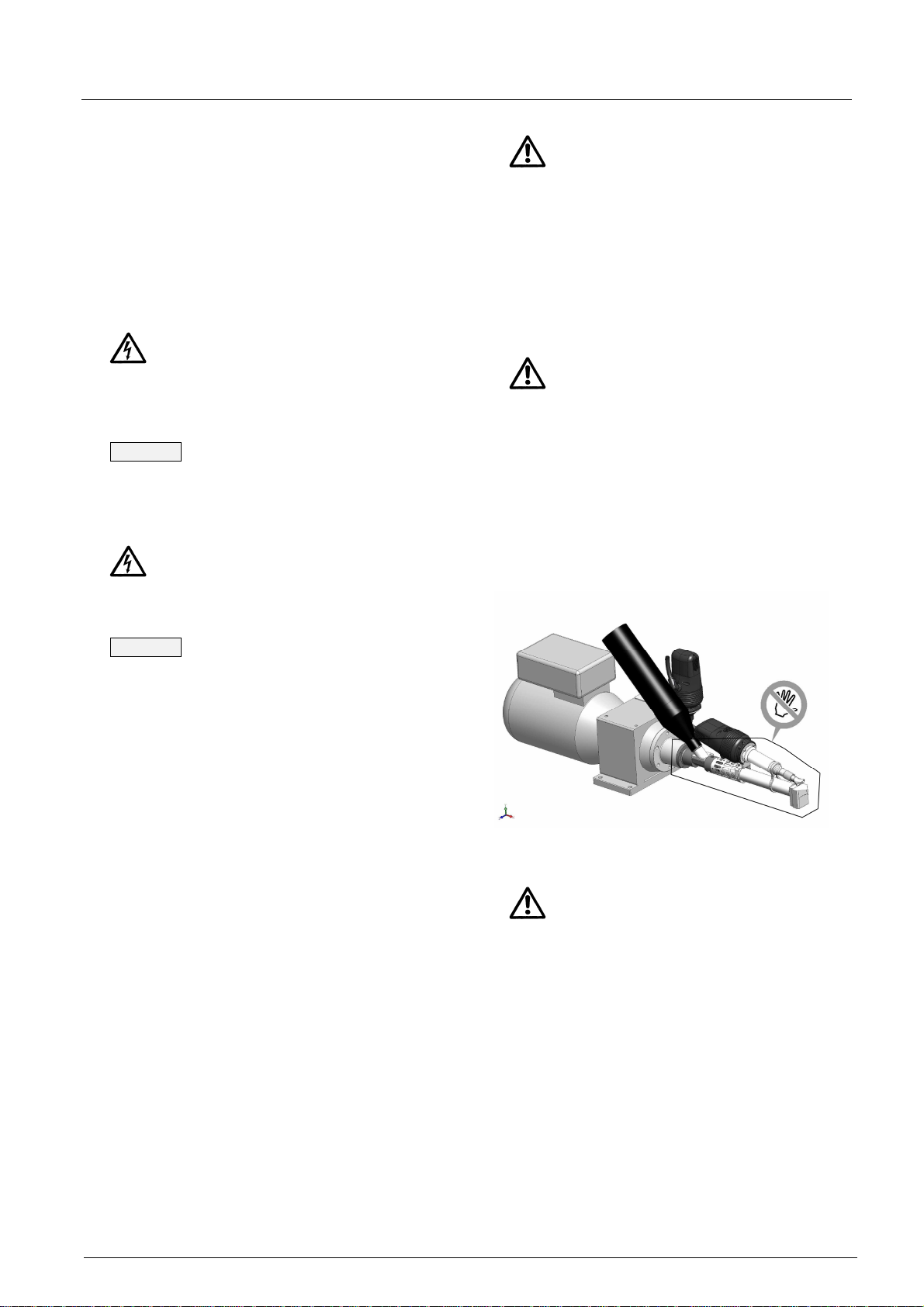

Any working practices posing a safety risk are

prohibited.