Hansung XH-KG55B User manual

R

X H - K G 5 5 B

R

X H - K G 5 5 B

XH-KG55B Temperature Controller

USER’S MANUAL

一 OVERVIEW

X H -KG55B is a in te l ligent te mpera t u re con t r o ller,

desig n ed by ob ject’s c h a rac te r is tics, contro l ling

programmed te mperature according to pr o c ess cu rs e

It s i mp l ifie s sys tem op er a tio n o f KG66 and decrea s e s

output in terface, to going to smaller and more

in t elligen t d irection A nd i t is st r o n g versat i le , fit for

controlled tempera ture which is le s s than 150

℃

, i e

wa s h ing mechanis m an d ele ctric hea t e r

二 MAIN SPECIFICTIONS

2.1

I/O interfaces

1 input channe l f o r temperature mea su r e me n t

3 output chann e ls wi th switching var i a b le o f which :

2 heating c o nt ro ls 1 cal l c o n tr o l

relay output : AC 2 4 0 V / 3 A

2 2 Temp erature control specif ications

te mp era ture measu r e me n t c o mponent

:

Pt100 platin u m t h e rmo -resistor

1

R

X H - K G 5 5 B

R

X H - K G 5 5 B

te mp era ture measu r e me n t r ange

: 000.0℃ ~ 153.0℃

te mp era ture contro l ra nge

: 030.0℃ ~ 150.0℃

te mp era ture contro l a ccuracy

:

sta ble error

≤ ±

1 2

℃

2.3

Programma le Funct i on s

programmab le p rocess No

.:

(0

~

9)

,

to tal 10

P

rogra mma ble p ro c e s s s teps of each p rocess is t e n

Each s tep is b e set objec t te mp era ture, gradi e n t and

iso t h e rm time

2.4

Temperature Control Method:

optimize self-adaptive method

2.5

Temperature p ara m e t ers setting range

object t e mp e r atu re

:(

030 0

~

150 0

) ℃

gradien t

:(

0 2

~

9 9

) ℃

/min

time of iso t h e rmic phase

:(

00

~

99

)

mi n

2.6

Programming Checkout Functions

Press

“△”

key to ch ec k w heth er se tt in g

parameters cor r e s p o n d with pa r a me t ers in the

process flo wcha r t or not

2.7

Safekeeping

(

1

)

Suddenly power cu t o ff , a r u n ning con tro ller

can continual l y ru n in retr ie vi n g the old proc ess step

data after p o we r is o n again

2

R

X H - K G 5 5 B

R

X H - K G 5 5 B

Reader’s Card

Dear Sir

,

Thank you for accep ting our p roduct.

Please fill in Re ader’s Card and se nd to us.

We ’d like to give you excelle n t s e rvice.

✄

Type of Controller

ty.

Da t e

Company

Conta c t Pers on

Te l.

Add

P.C.

Advice

Add:Building1NanhaiTiananCyberPark,FoshanGuangdong

Tel

:

0757-81230666 Fax

:

0757-81230666

1 4

(2) Du ring running probe is

broken,

th e con t r oller

calls 18 t i m e s , th e n it s t o p s

(3) When te mp e ra ture is hi g her than 150

℃ ,

th e

controller ca ll s a n d auto mat ica lly stops

2.8

Power Range

AC

(

180

~

250

)

V

、

50/60HZ Power consumption

≤3W

2.9

Dimension of Apparatus

W( 96) ×H( 96) × ( 100) mm

3

2.10

Dimension of Install ation

W( 92) ×H( 92) mm

2

2.11

Work Env i ronment

Te mpera t u r e

≤

50

℃

re l a tive humidi t y

≤

90

%

三 OPERATING GUIDE

3.1

Functional Keys

( 1)

RST

— —

— —— —

— —

When press it,”P” wi l l flash on pan e l In

runnin g state pu sh S TOP a t fi rs t, then push R S T

( 2)

PRG

— —

— —— —

— —

P r e s s i t t o g o t o p r o g r a m mi n g s t a t e

( 3)

RUN

— —

— —— —

— —

In rese t sta te press it to displa y

F*L*

F*L*F*L*

F*L*

, it

me a n s pro c e s s No & s t e p No A f ter en t e r

F*L*

F*L*F*L*

F*L*

it

sta rt t o run During r u n n i n g pr e ss i t to displa y

process No & s t e p N o for 3 sec s

3

R

X H - K G 5 5 B

R

X H - K G 5 5 B

(4)STOP

— —

— —— —

— —

In op erating s t a te press it to pause

controller

(5)

— —

— —— —

— —

(Page up

)

Press it to page u p d ata of each s te p

in sequence and me mo r ize paramete rs And ch e c k

program step b y s te p

(6)

— —

— —— —

— —(

((

(

Page down

)

Press it to pa g e do wn data of ea ch

ste p in sequen c e And c heck program i n n e g a tive s t ep

(7)

“

0

00

0~

~~

~ 9

99

9

”

— —

— —— —

— — (

((

(

number

)

Enter decimal number

0

00

0~

~~

~9

99

9.

..

.

(8)

— —

— —— —

— —

(

shif t ri g h t

)

Digital d i sp l ayin g place s h if ts

to w a rds righ t

3.2

Operat i ng Flowchar t

(1)program

F

FF

F

—

process No

.

L

LL

L

—

step No

.

i e pro c e s s No

.

F2,

step No

.

1

4

Problem Reason Troubleshooting

Can’t

program

Don’t push RST or

PRG key Don’t enter

finish code 00000000

in programming mode

Program again

Or turn on

controller to

program again

When

controller is

on, it’s in

isothermic

phase STOP

and RST key

can’t be

operated

Up-gradient rate and

down-gradient rate is

set 00 in

programming mode

Quickly push

STOP and RST

key, it can

return to

normal state

Check error

parameter and

program again

operation

error

Can’t run to

next step

Set data is unsuitable,

i e , set temp is 30

℃ ,

set time is 10

min But actual temp

is higher than 30

℃

in summer

Readjust

parameters

Abnormal

Don’t display

Press STAET key of

sampling dyeing

machine, but keys

can’t run rightly It

results in wrong initial

state

Cut off power

for 8-10

seconds, then

power on again

八 Service

A wa rran t y of time fo r o u r produc t i s one ye a r We

provid e ou r customers w ith cons i s te n t bes t a fter- s a le s

support If you h a ve an y p roblem, p lea s e don ’t hes i ta t e to

contact with u s

1 3

p r e s s

【

RST

】

to display P

press

【

P R G

】

to display F0L0

enter

【

F2

】

,press

【

►

】

to input

【

L1

】

enter data & next step

press

【

▲

】

memorize

ente r e n d co d e 00000000

press

【

RST

】

press

【

▲

】

memorize and page up

R

X H - K G 5 5 B

R

X H - K G 5 5 B

8.0 Trou leshooting

Problem Reason Troubleshooting

Display 000

℃

or 153

℃

P

robe circuit is short

or cut

Probe flex connected

wrongly

Check probe

and lines

Instable temp

during up-

gradient phase

Joins in probe line or

three-core insulating

line can’t be

connected or bad to

ground

Probe wet

Probe

Circu

it

Temp

inaccurate

which is up to

95

℃

Water come into

probe It become

vapor at high temp

Vapor influences

probe

Check and

connect probe

line again

Blow out water

in probe, then

seal and fix it

If necessary,

change new

one

Can’t increase

or decrease

temp when

controller runs,

but lights is on

Output is ok

AC contactor can’t

run or heated flex is

burnt out

Maintain

external electric

apparatus

Increase temp

slowly

Power of heated flex

is smaller

Val

ve

Increase temp

rapidly Temp

continually rise

in isothermic

phase

AC contactor is bad

or can’t run

change a new

one

1 2

( 2) Check Program

( 3) Run process(F2L1)

:

( 4) Re-run process after halt

ru n n i n g s t at e

pr e s s S TO P

pr e s s R N

( 5) Process Step Jump:

running state

press STOP

press

△

towards object process

push RUN twice

( 6) Process Parameters Correction:

d i s p l a y

P

PP

P

pr e s s P RG t o d i s p l a y

F0L0

F0L0F0L0

F0L0

enter

F

FF

F*

**

*L

LL

L*

**

*

press △ modify data press △

press

【

RST

】

5

display P

press

【

0

~

~~

~

9

】

to display F0L0

enter F*L*

p r e s s

【

▲

】

to check

press

【

RST

】

display P

press

【

R N

】

to display F0L0

enter F2 L1

press

【

R N

】

to start

R

X H - K G 5 5 B

R

X H - K G 5 5 B

3.3

Su routine Fun c t i o n

(1) Ru n n in g p a u se sub 161 0 0 0 0 0 & e nd sub 00000 0 0 0

,

th e c o ntrolle r s to p s and calls

(2)Temperatur e co r r e c ti o n

:

i e enter F9L9, see

corre ction func ti on a s belo w,

1 6 2 0 0 0 0 9 press

△

△△

△

to memo rize

subroutine No 0—positive correction

1—negative correction

Note

:

A

、

During run n in g pu sh

(

0

~

9

)

key to d i s p lay

corre cted te mp, i e + 5

℃

displa y 5

,

-5

℃

displa y - 5

B

、

If c h an ge new IC, r e-s e t temp cor rec tion program

If n eedn’t correct te mp , p l e ase set 16200000

C

、

Temperature deflection of KG55B is less than

±

0 6

℃

And temperature correction subroutine is 16200000 Only there

is old apparatus and bad probe, we have to correct temperature

The corrected temp value is used under 99

℃

after the controller

is in isotherm time 20mins It is right correction method that 6

bits standard resistor corresponds with standard temperature

Moreover, three-core insulating line can’t effect measured

temperature within 50 meters

6

Temperature (

℃

℃℃

℃)

))

)

PT100 resistor(

Ω

ΩΩ

Ω)

))

)

24 109 352

26 110 230

28 110 904

30 111 670

40 115 540

50 119 400

60 123 240

70 127 070

80 130 890

90 134 700

100 138 540

110 142 290

120 146 060

130 149 820

140 153 580

148 156 570

150 157 310

Start cont ro ll er to pre-heat f o r 3mins

Then calibrat e low p oint 50

℃

and high p o in t

130

℃

Pri mar i l y ca lib rate th i s two points and

th e n o thers Te mpe r a tu r e deflection o f each

point is les s than 0 6

℃ 。

11

0

~

9: max corrected temp is 9

℃

R

X H - K G 5 5 B

R

X H - K G 5 5 B

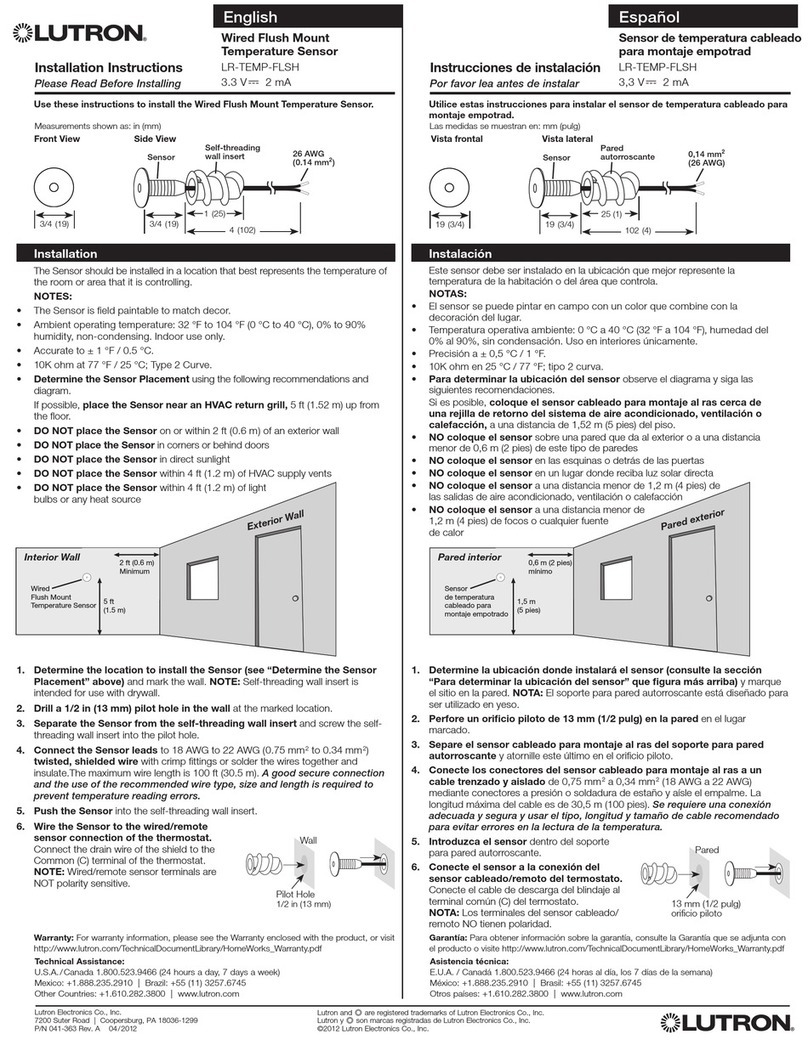

K G55 B B a c k Pan e l

diagram 2

7.0 Method of Temperature Cali ration

Repla c e P T100 with 6 b i ts standard re s i st or

Temperature (

℃

℃℃

℃)

))

)

PT100 resistor(

Ω

ΩΩ

Ω)

))

)

10 103 900

20 107 790

22 108 576

1 0

4.0 Operation Attention

(1)The last bit flashes in isotherm phase, not flashing in up-

gradient temperature phase It is to identify if setting

temperature is equal with real temperature or not

(2)

It is easy to s t ar t at a n y proc es s No ( F) & s te p

No (L)

(3) Handle a b n o rma l situation : If a b n ormal s i tu a tio n

happens i n opera t ion , c u t off power f or 5 s e c s

before the con t ro ller runs aga i n o r press R S T

(4) Opera ti o n o f keys s h o u ld be on for one se cond to

avoid er r o r

(5) When programming, set temperature had better to be

integer(set zeroes after decimal point)

(6) In ru n n i n g state p u s h S TOP to o nl y display te mp r a -

tur e o f dyeing ta n k

(7) If c o r r ec t in g process p a r a me ters, needn ’t shif t la s t

place to press

“

△

”

to pa g e up

.

( 8 )

We pr o vide cu s to mers with ge n e ral software

wi th o u t temperature correc t io n If c u st o me rs ha ve

special o r d e r, we can g ive you te mpe r a tu re

corre ction sof t w a r e

7

CALL

CALLCALL

CALL

PT100

HEAT 1 COM

HEAT 2

17

18

19

20

0

21

22

23

24

25

1

2

3

4

5

6

7

R

X H - K G 5 5 B

R

X H - K G 5 5 B

5.0 Explanation of Programming

i e process No

F2

F2F2

F2

,

ste p No

.

L0

L0L0

L0.

..

.

Diagram of Programming

No

act i o n set t i n g

te mp

(

℃

)

gr ad

(℃

/min

)

i s o t h e r m

t i m e

(

min

)

Process

No

F *

Step No

L*

1

2

3

4

5

6

7

8

press

RST

RSTRST

RST

press

PRG

PRGPRG

PRG

press

0

0 0

0~

~~

~9

9 9

9

press

△

set parameters

press

△

set end program

press

RST

RSTRST

RST

P

PP

P

F0L0

F0L0F0L0

F0L0

F2L0

F2L0F2L0

F2L0

000.0

000.0000.0

000.0

0 8 0

0 8 00 8 0

0 8 0.

..

.0

00

0

000.0

000.0000.0

000.0

000.0

000.0000.0

000.0

P

0.0

0.00.0

0.0

1

11

1.5

.5.5

.5

0.0

0.00.0

0.0

0.0

0.00.0

0.0

0 0

0 00 0

0 0

3 0

3 03 0

3 0

0 0

0 00 0

0 0

0 0

0 00 0

0 0

enter F*L*

enter F2

enter data

F2L1

enter data

F2L2,set 0

end

8

6.0 Diagram of KG55B Output Connection

KG 5 5 B F r o nt P a n el

Diagram 1

9

XH

-

KG

55B

DYEING CONTROLLER

TEMP (℃) *GRAD

(℃

/min)

*TIME

(min)

*

HEAT HOLD CALL RUN

R

FO

SHAN HAN

SU

NG AUTOMATION Co., Ltd.

R N

STOP

PRG

RST

0

~

~~

~

9

holding te mpe r at u re

80℃

for 30

END

up-gradient

1.5℃ /

mi n

amb i e nt temperatu r e

Table of contents

Popular Temperature Controllers manuals by other brands

Tzone

Tzone TZ-Tag06 user manual

Autonics

Autonics KPN Series User Manual for Communication

DirekTronik

DirekTronik LSN50v2-D20 user manual

Autonics

Autonics TM Series user manual

Viessmann

Viessmann Vitotrol 100 UTDB-RF2 Installation and service instructions

Middleby Marshall

Middleby Marshall 37626 Installation, programming and troubleshooting instructions

TE Technology

TE Technology TC-48-20 instruction manual

Autonics

Autonics TK Series User Manual for Communication

Sentera

Sentera RXTP Series Mounting and operating instructions

Gira

Gira KNX/EIB operating instructions

dixell

dixell XH360L operating instructions

Lutron Electronics

Lutron Electronics LR-TEMP-FLSH installation instructions