Sentera RXTP Series Service manual

Mounting and operating instructions

RXTP ROOM TEMPERATURE

CONTROLLER WITH

PICONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 2 - 9

Table of contents

SAFETY AND PRECAUTIONS 3

PRODUCT DESCRIPTION 4

ARTICLE CODES 4

INTENDED AREA OF USE 4

TECHNICAL DATA 4

STANDARDS 4

OPERATIONAL DIAGRAMS 5

WIRING AND CONNECTIONS 5

MOUNTING & OPERATING INSTRUCTIONS IN STEPS 5

MODBUS REGISTER MAPS 8

VERIFICATION OF INSTALLATION INSTRUCTIONS 9

TRANSPORT AND STOCK KEEPING INFORMATION 9

WARRANTY INFORMATION AND RESTRICTIONS 9

MAINTENANCE 9

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 3 - 9

back to the table of contents

SAFETY AND PRECAUTIONS

Read all information, the datasheet, mounting instructions and wiring scheme

before working with the product. For personal and equipment safety, and for

optimum product performance, make sure you entirely understand the contents

before installing, using, or maintaining this product.

For safety and licensing (CE) reasons, unauthorised conversion and/ or modifications

to the product are not permitted.

e product must not be exposed to abnormal conditions, such as: extreme

temperatures, direct sunlight or vibrations. Chemical vapours with high concentration

in combination with long exposure times can affect the product performance. Make

sure the work environment is as dry as possible; check for condensation spots.

All installations shall comply with the local health and safety regulations and local

electrical codes. is product can only be installed by an engineer or a technician

who has an expert knowledge of the product and safety precautions.

Avoid contacts with energised electrical parts; always treat the product as if it

is life. Always disconnect the power source before connecting the power cables,

servicing or repairing the product.

Always verify that you apply appropriate power supply to the product and use wires

with appropriate size and characteristics. Make sure that all the screws and nuts are

well tightened and fuses (if any) are fitted well.

Recycling of equipment and packaging should be taken into consideration and

disposed in accordance with local and national legislation/regulations.

In case there are any questions that are not answered, please contact your technical

support or consult a professional.

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 4 - 9

back to the table of contents

PRODUCT DESCRIPTION

e RXTP is a room temperature controller with Modbus RTU communication. It

regulates a PI controlled analogue output and a relay output, in two modes – Heat

and Cool.

ARTICLE CODES

Code Supply Connection

RXTPG 15—24 VAC ± 10 %

18—34 VDC 3 - wire

RXTPF 18—34 VDC 4 - wire

INTENDED AREA OF USE

■Monitoring and maintaining temperature and relative humidity in HVAC applications

■For indoor use only

TECHNICAL DATA

■1 analogue output: 0—10 VDC/0—20 mA

■1 relay output, C/O (230 VAC/2 A)

■Power consumption:

►no load: max. 25 mA

►full load: max. 45 mA

■Load resistance:

►0—10 VDC mode > 500 Ω

►0—20 mA mode < 500 Ω

■Selectable temperature ranges: 0—30 °C/10—40 °C/20—50 °C/0—50 °C

■Free selectable temperature range via Modbus: 0—50 °C

■Selectable switching points: via trimmers or Modbus

■Selectable temperature hysteresis: 1 / 2 / 3 / 4 / 5 °C

■Auto-tuning function in Heat mode with three-second light indication (see Fig. 8

Operating indication)

■Enclosure:

►rear lid: plastic ABS, black (RAL9004)

►front cover: ASA, ivory (RAL9010)

■Protection standard: IP30 (according to EN 60529)

■Operating ambient conditions:

►temperature: 0—50 °C

►rel. humidity: < 95 % rH (non-condensing)

■Storage temperature: -25—50 °C

STANDARDS

■Low Voltage Directive 2014/35/EC

■EMC Directive 2014/30/EC: EN 61000-6-2: 2005/AC:2005,

EN 61000-6-3:2007/A1:2011/AC:2012, EN 61326-2-3:2013

■WEEE Direc tive 2012/19/EC

■RoHs Directive 2011/65/EC

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 5 - 9

back to the table of contents

OPERATIONAL DIAGRAMS

Heat mode Cool mode

SetpointSetpoint -Hysteresis T, [

0

C]

ON

(COM

NO)

Relay

output 1

OFF

(COM

NC)

T, [

0

C]

Setpoint

ON

(COM

NO)

Relay

output 1

OFF

(COM

NC)

Setpoint +Hysteresis

T, [0C]

Setpoint

t, [s]

PI control

T, [%]

Setpoint

t, [s]

PI control

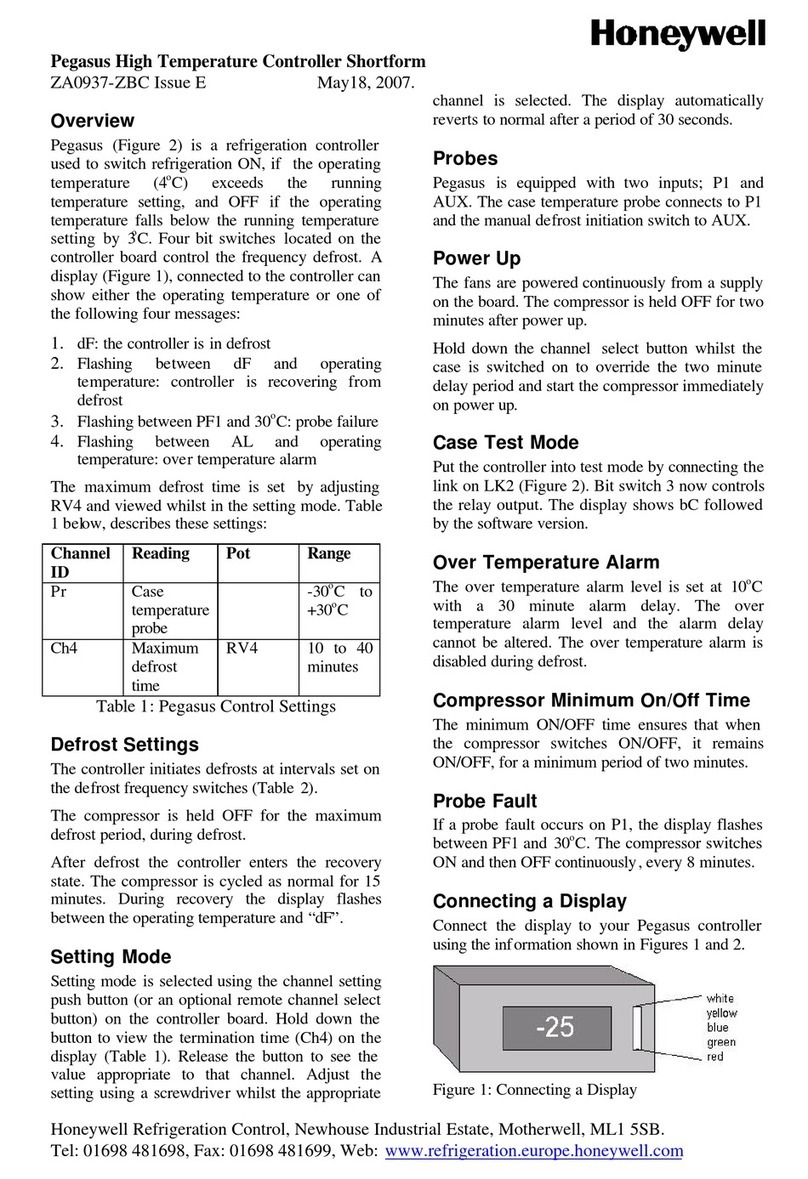

WIRING AND CONNECTIONS

Vin Positive DC voltage/AC ~

GND Ground/AC ~

A Modbus RTU (RS485), signal A

/B Modbus RTU (RS485), signal /B

Ao1 Analogue output (0—10 VDC/0—20 mA)

GND Ground

NO1 Normally open contact

COM1 Common contact

NC1 Normally closed contact

Connections Cable cross section: max. 1,5 mm2

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 6 - 9

back to the table of contents

MOUNTING & OPERATING INSTRUCTIONS IN STEPS

Before you start mounting the RXTP controller, read carefully “Safety and

Precautions”. Choose a smooth surface for an installation location (a wall,

panel and etc.).

Follow these steps:

1. Open the white cover by releasing the locking plates on both sides of the cover

and remove it. (See Fig. 1 Locking plates release.)

2. Insert the cables through the cable opening of the enclosure rear lid. (See Fig. 2

Mounting dimensions.)

3. Fix the unit to the wall / panel taking into account that the unit has to be installed

at a minimum height of 1,5 m and the air flow has to pass freely through it. Mind

the correct mounting position and unit dimensions. See Fig. 2 and Fig. 3.

Fig. 1 Locking plates release Fig. 2 Mounting dimension Fig. 3 Mounting position

2x Ø 6

59,8

9,8

74,5

104,5

74

,

5

1

0

4,5

20

104,5

25,6

70,5

Acceptable Not acceptable

Keep 1,5 m. minimum

distance from the floor

4. Do the wiring according to the wiring diagram (see Fig. 4) using the legend

information from section “Wiring and connections”.

Fig. 4 Wiring and connections

Power supply

15—24 VAC ± 10%/18—34 VDC

Relay 1 contacts

Normally closed

Common

Normally open

Modbus

RTU

A

/B

Analogue output

0—10 VDC/0—20 mA

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 7 - 9

back to the table of contents

5. Check if your unit starts or terminates the network (see Example 1 and

Example2). If it does not, remove the NBT jumper (see Fig. 5).

Example 1 Example 2 Fig. 5 Network bus

resistor jumper

Slave 1

RX

ТX

NBT

NBT

NBT

Slave 2

Master

Slave n Slave 2

Slave 1

RX

ТX

NBT

NBT

Master

Slave n

ATTENTION If an AC power supply is used with any of the units in a Modbus network, the

GND terminal should NOT BE CONNECTED to other units on the network or

via the CNVT‑USB‑RS485 converter. is may cause permanent damage to the

communication semiconductors and/or the computer!

6. Adjust the standalone settings:

6.1 To select the analogue output mode, use jumper JP4 (See Fig. 6 Analogue

output selection jumper).

6.2 To reset the Modbus settings, put and hold jumper P1 for 20 seconds. (See

Fig.7 Modbus reset jumper).

Fig. 6 Analogue output selection jumper Fig.7 Modbus reset jumper

0—10 VDC

0—20 mA

54321

Put and hold for 20 seconds

7. Close the enclosure and fix the cover.

8. Switch on the power supply.

ATTENTION Do not exceed the maximum power supply rating! Measure before installation!

Unregulated 24 VAC supply units provide higher nominal output voltage and

activate the integrated fuse protection.

ATTENTION If a G‑type article is using the same AC power supply source (transformer) as

F‑type article, a SHORT CIRCUIT may result when the power supply and analogue

signal terminals are connected to the same common ground! In this case always

connect different article types to separate AC transformers or use the same

article version.

9. You can customise the factory settings to the desired ones through the

3SModbus software (if necessary). For the default factory settings, see Table

Modbus register maps.

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 8 - 9

back to the table of contents

MODBUS REGISTER MAPS

INPUT REGISTERS

Data type Description Data Values

1Temperature signed int. Actual temperature level 0—500 250 = 25,0 °C

2-10 Reserved, returns 0

11 Analogue output value unsigned int. Value of the analogue output 0—1.000 0 =

1.000 =

0 %

100 %

12 Relay status unsigned int. Relay status. When it is On, the contact between COM1 and NO1 is closed. 0—1 0 =

1 =

Off

On

13 Temperature setpoint unsigned int. Temperature setpoint used for PI control 0—500 250 = 25,0 °C

14 Relay setpoint unsigned int. Relay switching setpoint 0—500 250 = 25,0 °C

15 Hysteresis unsigned int. Hysteresis for the relay switching 1—5

1 =

2 =

3 =

4 =

5 =

1,0 °C

2,0 °C

3,0 °C

4,0 °C

5,0 °C

16 Output mode unsigned int. Analogue and relay output mode (Heat/Cool) 0—1 0 =

1 =

Heat mode

Cool mode

17 Kp value unsigned int. Proportional gain value 1—1.000 10 = 1,0 gain

18 Ti value unsigned int. Integration period value 1—6.000 1 =

100 =

0,1 s

10 s

19-20 Reserved, returns 0

HOLDING REGISTERS

Data type Description Data Default Values

1Device slave address unsigned int. Modbus device address 1—247 1

2Modbus baud rate unsigned int. Modbus communication baud rate 1—4 2

1 =

2 =

3 =

4 =

9.600

19.200

38.400

57.600

3Modbus parity check unsigned int. Parity check mode 0—2 1

0 =

1 =

2 =

8N1

8E1

8O1

4Device type unsigned int. Device type (Read only) RXTPX = 1023

5HW version unsigned int. Hardware version of the device (Read only) XXXX 0 x 0110 = HW version 1.1

6FW version unsigned int. Firmware version of the device (Read only) XXXX 0 x 0130 = FW version 1.3

7Operating mode unsigned int Reserved, returns 0

8Output overwrite unsigned int. Enables the direct control over the outputs. 0—1 00 =

1 =

Disabled

Enabled

9-10 Reserved, returns 0

11 Temperature setpoint unsigned int. Temperature setpoint used for PI control 0—500 250 500 = 50,0 °C

12 Relay setpoint unsigned int. Relay switching setpoint 0—500 250 500 = 50,0 °C

13 Hysteresis unsigned int. Hysteresis for the relay switching 1—5 4

1 =

2 =

3 =

4 =

5 =

1 °C

2 °C

3 °C

4 °C

5 °C

14 Kp value unsigned int. Proportional gain value 0—1.000 50 10 = 1,0 gain

15 Ti value unsigned int. Integration period value 1—6.000 100 1 =

100 =

0,1 s

10 s

16 Output mode unsigned int. Selects the analogue and relay output mode (Heat/Cool) 0—1 00 =

1 =

Heat mode

Cool mode

17-19 Reserved, returns 0

20 Autotune of analogue

output unsigned int. Starts autotune in PI control for the analogue output 0—1

1 =

0 =

Autotune start

(In progress)

Stop (Idle)

If you want to find out more about Modbus over serial line, please visit: http://www.modbus.org/docs/Modbus_over_serial_line_V1_02.pdf

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

www.sentera.eu

MIW-RXTP-EN-001 - 29 / 03 / 2017 9 - 9

back to the table of contents

VERIFICATION OF INSTALLATION INSTRUCTIONS

After switching on the unit, the blue ON/OFF LED should blink every 2 seconds

during the 30-second initialization period (SeeFig. 8 Operating indication). After this

period the LED indicator illuminates continuously if the unit is working properly. If

this is not the case, check the connections again.

If both LEDs (LEDTX and LEDRX) blink after you switch on your unit, your unit has

detected Modbus network (SeeFig.9 Communication detection indication). If this is

not the case, check the connections again.

Fig. 8 Operating

indication

Fig. 9 Communication

detection indication

ATTENTION e status of both LEDs (LEDTX and LEDRX) can be checked only when the unit

is energised. Take the relevant safety measures!

TRANSPORT AND STOCK KEEPING INFORMATION

Avoid shocks and extreme conditions; stock in original packing.

WARRANTY INFORMATION AND RESTRICTIONS

Two years from the delivery date against defects in manufacturing. Any modifications

or alterations to the product after the date of publication relieve the manufacturer

of any responsibilities. e manufacturer bears no responsibility for any misprints or

mistakes in this data.

MAINTENANCE

In normal conditions this product is maintenance-free. If soiled, clean with a dry or

dampish cloth. In case of heavy pollution, clean with a non-aggressive product. In

these circumstances the unit should be disconnected from the supply. Pay attention

that no fluids enter the unit. Only reconnect it to the supply when it is completelydry.

RXTP ROOM TEMPERATURE CONTROLLER

WITH PI CONTROL

This manual suits for next models

2

Table of contents

Popular Temperature Controllers manuals by other brands

Omega

Omega OS212-MT user guide

KT-Elektronik

KT-Elektronik SOL3-5 Quick installation and operating manual

E+E Elektronik

E+E Elektronik EE23 series Operation manual

Carrier

Carrier Atmosphera 42EM series Installation, operation and maintenance instructions

METER

METER RT-1 quick start guide

Carel

Carel Clima quick start guide

AirTouch

AirTouch ZoneTouch3 user manual

S+S Regeltechnik

S+S Regeltechnik HYGRASREG RH-30 Operating Instructions, Mounting & Installation

Elk

Elk ELK-M1ZTS quick start guide

OJ Electronics

OJ Electronics CPST10 instructions

Honeywell

Honeywell Pegasus 190937-ZBC quick start guide

Saunum

Saunum Base Solution User Manual and Installation Guidelines