Happowa Spreader 4000 User manual

2021

Rev 2.0

Happowa Oy

www.happowa.fi

USER MANUAL

Acid applicator

Spreader 4000 & Spreader 6000

2 3

Contents

Eu Declaration of conformity................................................3

1. Safety...........................................................................................4

1.1 General safety instructions ................................................... 4

1.2 Handling of acids ........................................................................5

1.3 Personal protection ...................................................................5

1.4 First aid instructions ................................................................ 6

1.5 Restrictions on use.................................................................... 6

2. Technical specifications......................................................7

3. Assembly ..................................................................................8

3.1 Pump connection...................................................................... 8

3.2 Connecting cable...................................................................... 9

3.3 Controller connection ............................................................ 9

4. Controller usage and key functions ............................ 10

4.1 Controller buttons and their functions.......................10

4.2 Default settings ........................................................................13

4.3 Changing the default settings........................................14

5. Taking into use ..................................................................... 16

5.1 Testing..............................................................................................17

6. Additional equipment ....................................................... 18

7. Maintenance and storing ................................................. 19

8. Trouble shooting................................................................. 20

9. Terms of guarantee.............................................................22

10. Responsibilities...................................................................23

Spare parts................................................................................. 24

Eu Declaration of conformity

Happowa Oy

Kankaantie 563, 62150 Ylihärmä

We declare under our sole responsibility that the acid

applicators Spreader 4000 and Spreader 6000 starting

from production number 3200 are in conformity with the

relevant Union legislation Machinery Directive 2006/42/

EC.

These products are also in conformity with the relevant

safety requirements of the following directives:

Directive 89/392/EEC

Directive 91/368/EEC

Directive 93/44/EEC

Directive 93/68/EEC

The following standards have also been considered in

designing the products, as applicable:

EN 292-1

EN 292-2

EN 294

EN 349

EN 811

EN 1152

SFS 5091

In Ylihärmä 4.1.2019

__________________________

Johannes Holkkola, managing director

4 5

1. Safety

Spreader acid applicators are primarily intended for

pumping and dosing fluid agricultural preservatives in

silage production. The pump feeds the preservative to

the nozzles through the hoses and the preservative is

mixed to the fodder by the nozzles.

The acid applicator can also be used as a transfer pump,

in which case the pump feeds the preservative straight

to another container through the hose.

1.1 General safety instructions

• In addition to the instructions given in the manual,

you must obey all the general safety rules concerning

mechanical working.

• Before using the applicator, make sure that the device

has been connected correctly and that covers are at

place.

• Before using the applicator, make sure that all the

hoses, couplings and nozzles connected to the system

are suited for the preservatives used.

• All operating personnel must be familiar with the

operating functions and the manual of this machine.

• Keep children and unauthorised people away while

using, assembling or maintaining the machine.

• Always stop the tractor prior to maintenance or

repairs. Apply the parking brake, remove the ignition

key and disconnect the dosing machine before

leaving the cab.

• Keep the rear window of the tractor closed while

using the acid applicator.

• Always keep enough clean rinse water on hand.

• Pump a large amount of clean water through the

system before maintenance. Always handle acids with

caution. Always use acceptable personal protective

equipment.

• Inspect the condition of the hoses and the couplings

regularly. Replace any damaged parts with new ones

immediately. Notice that even a small detrition or

corrosion may cause danger.

1.2 Handling of acids

• Familiarise yourself with the safety and handling

instructions of the preservative manufacturers.

• Always handle the acid applicator with caution and

use appropriate personal protective equipment.

• Only use the acid applicator outdoors or in spaces

with adequate ventilation.

• An acid applicator that has not been cleaned can only

be placed on a surface that is acid resistant.

1.3 Personal protection

• Use an appropriate respirator if ventilation is

inadequate.

• Use tight-fitting safety goggles to protect your eyes

and keep clean water in a bottle for rinsing out eyes.

• Use protective clothing or an apron of a sufficient size

and boots to protect from any splashing.

• Use neoprene or PVC gloves to protect hands.

6 7

1.4 First aid instructions

• Inhalation of acid fumes: move to fresh air, keep warm

and calm. Consult a doctor if necessary.

• Acid splashing on skin: rinse splashes from the skin

immediately using plenty of water and take off

stained clothes.

• Acid exposure to eyes: rinse eyes immediately with

plenty of water, also under the eyelids. Consult a

doctor.

• If acid gets into mouth: rinse your mouth immediately

with plenty of water. A few glasses of water may be

drunk. Consult a doctor if necessary.

1.5 Restrictions on use

• The operator of the acid applicator must not be

under the influence of narcotics, alcohol or powerful

medications.

• In case of illness or disablement, the operation of

the machine must be authorized by the attending

physician.

• The acid applicator must not be used dry.

• Pumping inflammable liquids, liquids for human

consumption, or additives is forbidden.

• Do not pump acid that has been diluted with water

unless specifically permitted by the manufacturer.

2. Technical specifications

You can find the identity information of the machine in

the machine plate shown in the picture below. With this

information it is easier to maintain the product and order

spare parts.

Type the information of your machine to the pattern

below to be able to find it easily.

Spreader 4000 Spreader 6000

Operating voltage 12 V 12 V

Max. required

current 7 A 13 A

Max. pressure 3 bar 3 bar

Max. pumping

capacity 6 l/min 12 l/min

Weight 3,1 kg 3,1 kg

8 9

3. Assembly

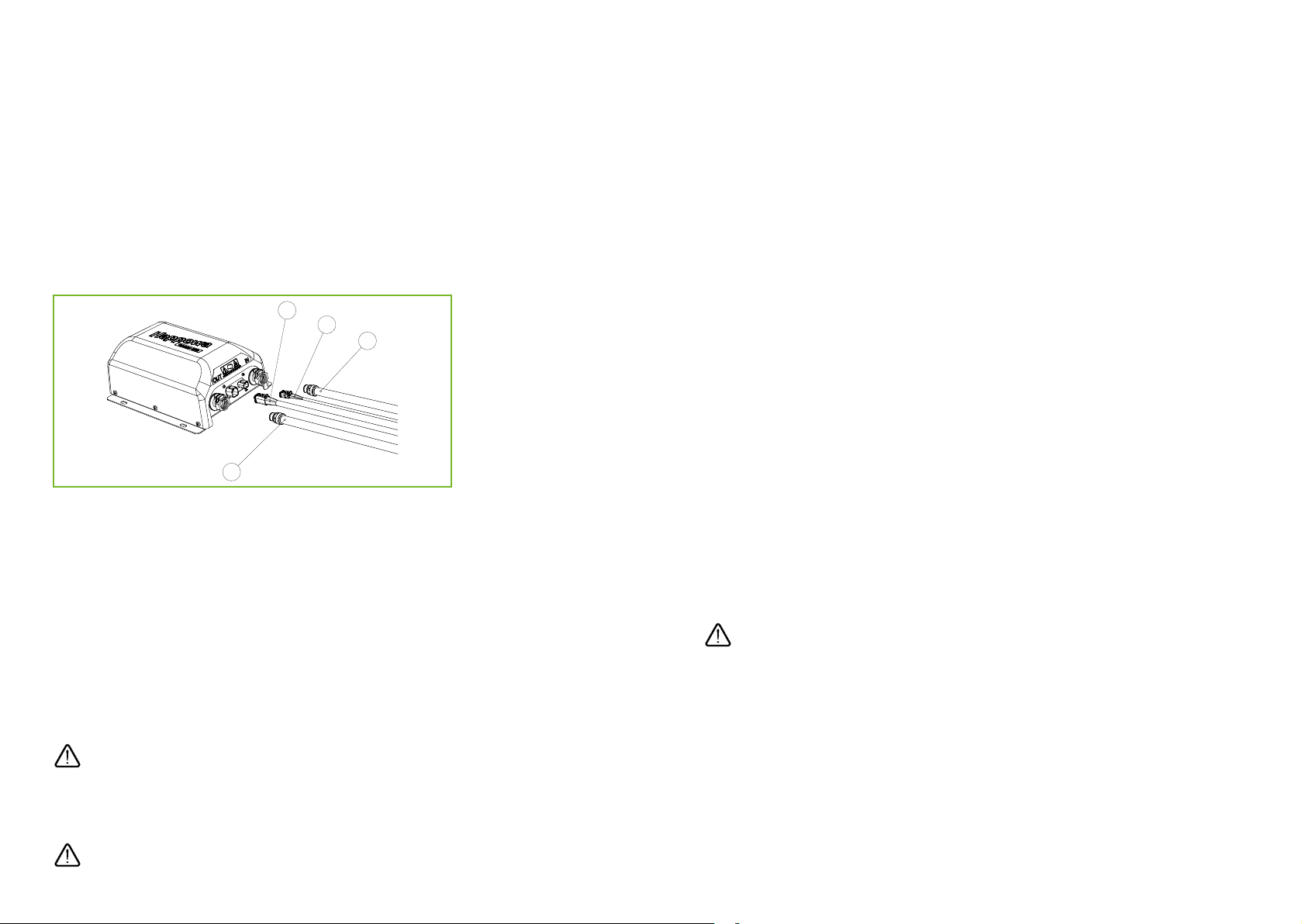

3.1 Pump connection

The pump unit should be mounted as near the tank

as possible. This improves the functions of the pump

especially with a tank that is not full and after filling it

up. The pump unit can be mounted either horizontally or

vertically (couplings downwards only).

Mount the pump unit firmly with four hex head screws to

a suitable place where it is not exposed to unnecessary

vibration.

Connect the suction hose (1), limit switch (2, additional

equipment), power cable (3) and pressure hose (4) to

the analogous couplings of the pump. Make sure that

the quick couplings of the hoses are locked, and the

couplings of the power cables are firmly attached.

MAKE SURE THAT ALL THE HOSES, COUPLINGS AND

NOZZLES CONNECTED TO THE SYSTEM ARE SUITED FOR

THE PRESERVATIVE USED.

DO NOT USE THE PUMP DRY

3.2 Connecting cable

The sequence of the pins of the cable connecting the

pump to the controller:

1. Motor + 12 V

2. +10 V to the sensor

3. Flow meter signal

4. Limit switch signal

5. Sensor 0 V

6. Motor –

3.3 Controller connection

Mount the controller securely into the cabin so that it is

not exposed to unnecessary vibration. Connect the cable

and the limit switch (optional). The limit switch may be

connected either to the pump or to the controller.

Connect the controller’s power cable to the tractor’s

tripolar power outlet (red +, yellow –), the voltage of the

fuse being max. 15 A.

INCORRECT WIRING MAY DAMAGE THE

CONTROLLER!

10 11

3 4 5 6 7 8

1 2

10

9

11

12

13

14

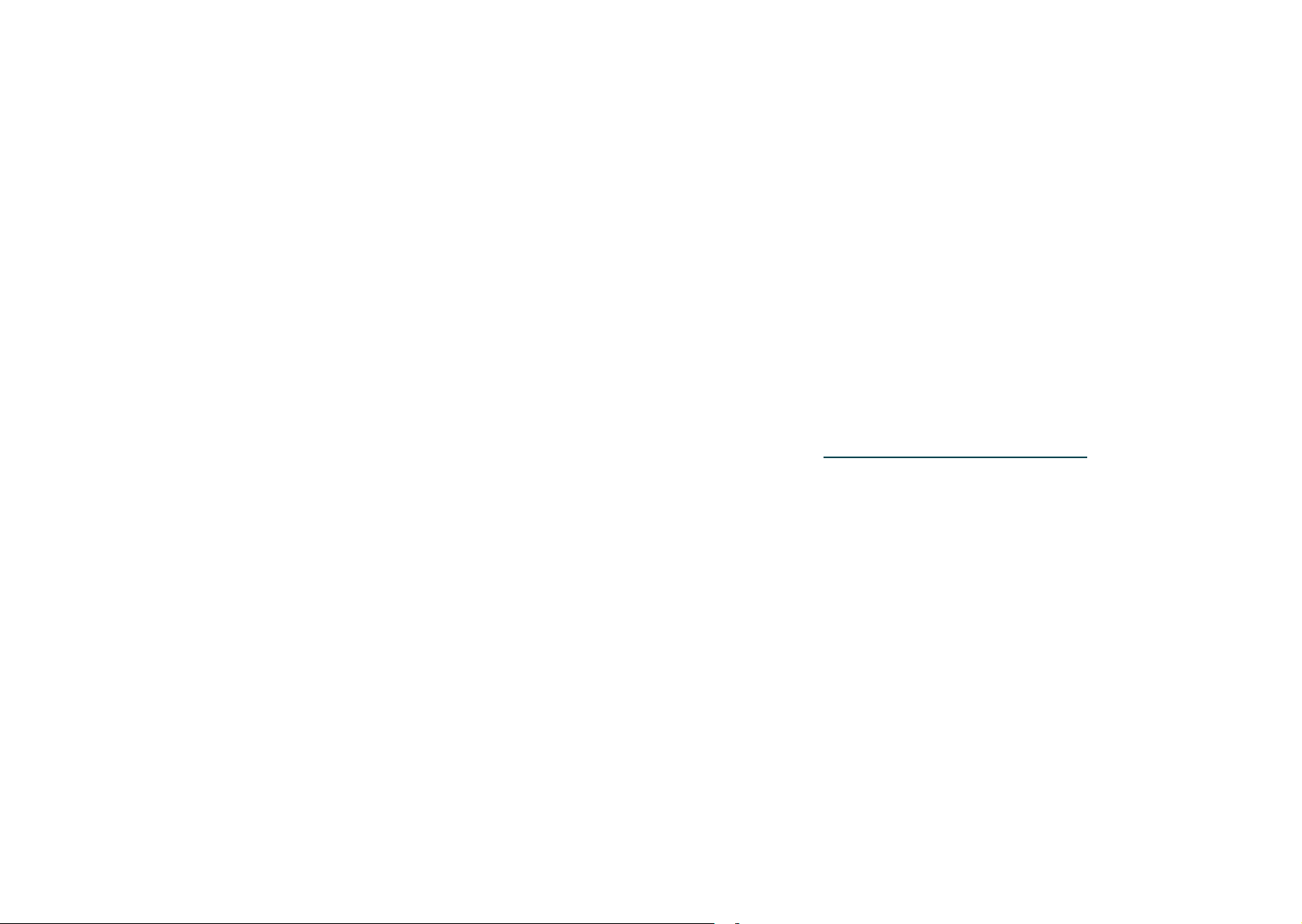

4. Controller usage and key functions

4.1 Controller buttons and their functions

1. On/off -switch

2. Power adjustment

3. Flow button

4. Trip button

5. Total button

6. Reset button

7. Shift button

8. Pump: start/stop

9. Pump: signal light

10. Limit switch: signal light

11. Digital display

12. Flow: signal light

13. Trip: signal light

14. Total: signal light

As the controller is switched on using the on/off

switch (1), the default settings are displayed in the

following order:

- The pulse rate of the flow, pulses/litre

- The level of flow alarm, litres/minute

- The hysteresis of flow alarm, litres/minute

After this the controller enters the basic mode and is

ready to operate.

The Flow button (3) is used to choose the flow metre. The

reading on the screen shows the actual liquid flow (litres/

minute) and the signal light ”Flow” (12) is on.

The Trip button (4) is used to observe the amount of

pumped litres. The number on the screen shows the

amount of pumped litres and the signal light ”Trip” (13)

is on. The calculator can be reset to zero by pressing the

Reset button (6) for 3 seconds. The Trip calculator can be

used e.g. for monitoring the consumption of preservative

per load.

The Total button (5) is used to switch on the Total

calculator that shows the amount of the pumped liquid

in litres while the signal light ”Total” (14) is on. The

calculator can be reset to zero by pressing the Reset

button (6) for 3 seconds. The Total calculator can be used

e.g. for monitoring the consumption of preservative per

container.

12 13

When the Shift button (7) is pressed and held down the

pump operates with full power regardless of the power

adjustments and the position of the limit switch. Can be

used e.g. for removing air from the system.

The Pump button (8) is used to start or stop the

pumping. When the pump is switched on the signal light

”Pump” (9) is on. The power may be adjusted steplessly

with the potentiometer (2).

If the limit switch gets activated the signal light ”Cut”

(10) is switched on and the pumping stops. As the limit

switch is released the signal light is switched off and the

pumping continues according to the adjustments.

Flow alarm

When the flow lowers below the alarm level the

controller gives the alarm signal. The buzzer goes off and

the text ”FLO” flashes on the screen. If the increase of the

flow does not reach the hysteresis level in ten seconds,

the controller automatically stops the pump. In this

case the buzzer goes out and the text ”FLO” stays on the

screen. Usually the alarm is caused by the draining of the

container. If there is still preservative left in the container,

see chapter “Trouble shooting” (p. 20).

The new

pulse rate

The amount calculated by the controller

The actual amount of litres pumped

The current

pulse rate

×

=

4.2 Default settings

PULSE RATE

The pulse rate indicates the amount of pulses in one

litre of liquid. The pulse rate has been calibrated in the

factory. If the flow calculators of the controller do not

correspond to the actual consumption, the pulse rate

can be adjusted as follows:

Check the current pulse rate. Reset the Trip calculator to

zero and pump plenty of liquid (e.g. 100 litres) through.

The new pulse rate can be calculated by comparing the

amount calculated by the controller to the the actual

amount using the following formula:

After changing the pulse rate, the reading of the Trip

calculator should indicate the actual amount of litres

pumped.

THE LEVEL OF FLOW ALARM

The default setting of the flow alarm is 1,5 l/min. If the

flow decreases below the set level for more than five

seconds, the alarm will be activated.

14 15

THE LEVEL OF HYSTERESIS

The level of hysteresis indicates the amount of increase

in the flow above the alarm level required to stop the

alarm automatically. The default setting is 0,3 l/min. In

the default setting mode, the flow alarm will be activated

when the flow decreases below 0,5 l/min for more

than five seconds. It will be deactivated when the flow

increases by more than 0,8 l/min.

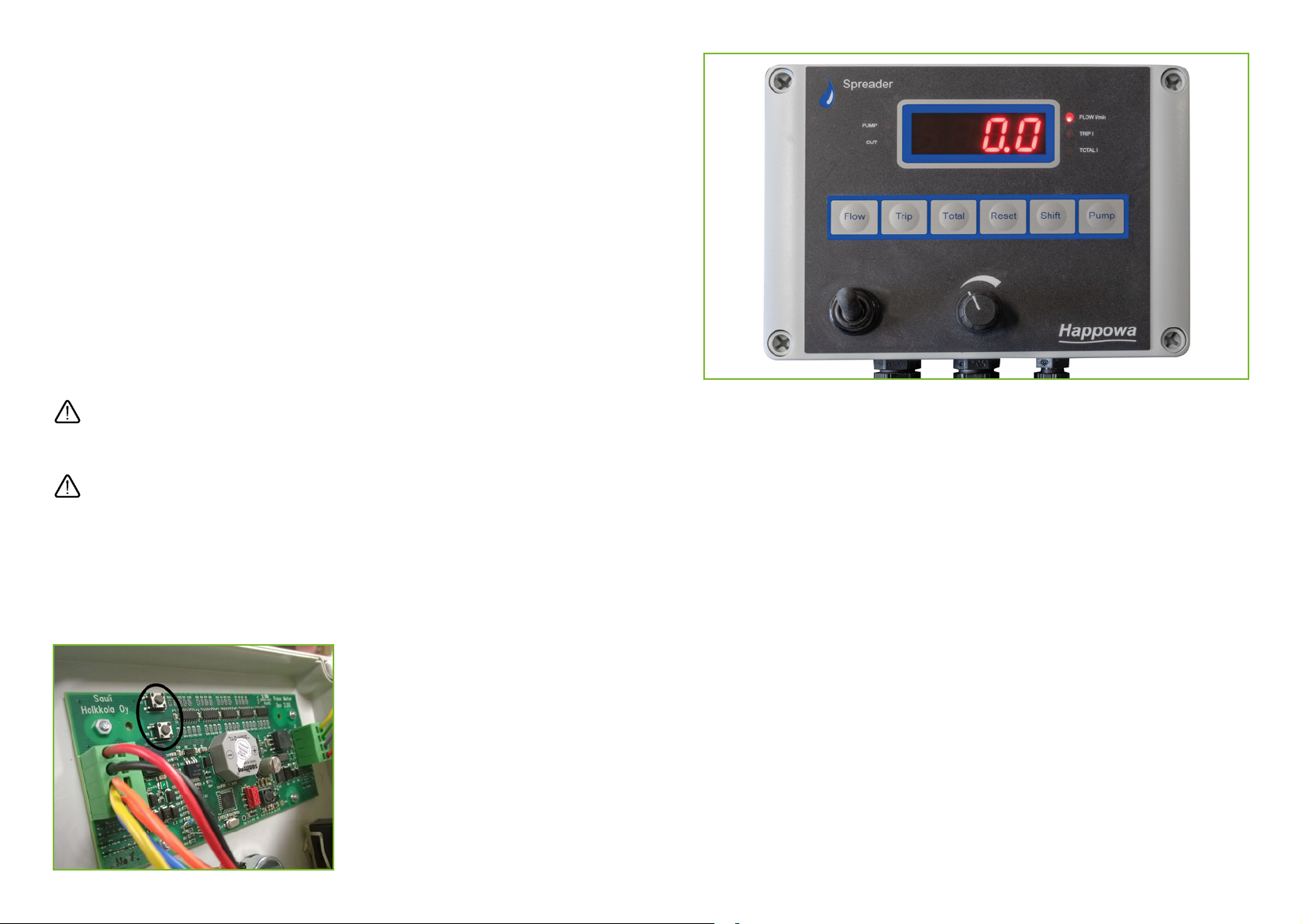

4.3 Changing the default settings

To change the default settings, open the plastic case of

the controller.

Turn the power off using the on/off switch prior to

opening the case!

Proceed with great caution!

Behind the controller’s circuit card there are two

programming buttons that can be used to change the

default settings. See the picture.

Pulse rate HysteresisAlarm level

-+-+-+

The default settings can be changed by obeying the

following instruction:

1. Press both programming buttons and hold them down.

Switch on the controller by using the on/off switch.

2. Set new values using the buttons of the panel on the

front.

• Flow: the pulse rate decreases

• Trip: the pulse rate increases

• Total: the alarm level decreases

• Reset: the alarm level increases

• Shift: the hysteresis decreases

• Pump: the hysteresis increases

3. Release the programming buttons.

16 17

5. Taking into use

Connect the hoses between the pump unit and the

suction pipe and between the pump unit and the

nozzles. Mount the anti-drip valve as near the nozzles as

possible. The direction of flow is indicated by the arrow

on the valve frame.

Choose the nozzles according to the amount of litres you

are going to pump. With nozzles too large the flow may

be distributed unevenly which may weaken the power of

the flow. With nozzles too small the counter pressure of

the system increases, and the desired flow level may not

be achieved. The liquid may also disperse into spray that

is easily blown away by the wind.

The acid applicator is equipped with a pressure switch.

If the pressure of the system increases above the set

level, the pressure switch will stop the pump. The default

setting of the pressure switch is 3 bars.

5.1 Testing

Prior to acid pumping the system must be tested by

pumping clean water through the pump. The testing is

easier to do after the pump has been mounted to the

harvesting machine as the conditions are then similar to

the actual use.

The following should be observed during the pumping

test:

- The operating of the pump

- The operating of the flow sensor

- The evenness of the distribution of the flow from the nozzles

- The durability of the equipment and all the joints

A test run is also recommended prior to the beginning of

the harvest season.

18 19

6. Additional equipment

Different kinds of limit switches can be used to control

the operating of the Spreader applicators. There are

three options: a mechanical limit switch, a magnetic limit

switch and a control relay.

The limit switch can be mounted e.g. to the pick-up of

the silage machine.

A control relay can be used if there is an available signal

coming from the silage machine for controlling the

applicator. Check the availability of signal in the manual

of the silage machine.

The limit switch can be connected either to the controller

or to the pump’s limit switch coupling.

NB: Only use the original components.

NB: Supplying the limit switch coupling with voltage not

allowed!

7. Maintenance and storing

The acid applicator must always be cleaned after use

by pumping clean water through the whole system.

External cleaning is also necessary. During cleaning, the

electronic components must be protected from water.

After cleaning, the pump and the electric couplings must

be carefully dried.

Do not use a pressure washer for cleaning the pump!

Use the appropriate personal protective equipment!

After use the acid applicator must be stored in a dry

place, protected from sunlight. If the acid applicator

is stored in a cold place, pump antifreeze through the

system before storing to prevent freezing.

20 21

8. Trouble shooting

Error Possible cause Solution

The pump does

not start.

The pump is out of

power.

The limit switch is

activated.

Check the power

cables and

couplings.

Release the limit

switch.

The pump starts

but then stops

immediately.

The counter

pressure is too high.

The pressure switch

stops the pump.

Remove the

possible block,

check the mounting

of the quick coup-

lings or widen the

nozzles.

There is no

suction.

A block in the

suction filter.

Air in the suction

pipe.

The suction fails

because of small

output caused by a

long suction hose.

The valves are worn

out.

Clean the filter.

Check the condition

of the suction pipe

and the joints.

Press the Shift

button and hold it

down until the the

suction begins.

Change the valves.

Error Possible cause Solution

The output is

weak.

The valves are worn

out.

The counter

pressure is too high.

Change the valves.

Remove the

possible block,

check the mounting

of the quick coup-

lings or widen the

nozzles.

“FLO” alarm. Flow alarm, flow

below the alarm

level

The controller does

not receive the

pulse data from the

flow sensors.

Make sure there is

still liquid left in the

container.

Remove the cause

of the counter

pressure.

Adjust the alarm

level.

Check the wires

and the couplings.

Damaged flow

sensor.

(Deactivating the

FLO-alarm: Set the

alarm rate to 0.)

“ERR1” alarm. Short circuit in the

sensors.

Check the wires and

the couplings.

22 23

9. Terms of guarantee

• The warranty period for the machines manufactured

by Happowa Oy is 12 months.

• The warranty period begins on the date the

authorized dealer has delivered the new equipment.

• Warranty covers manufacturing and material defects.

• Damaged parts that have been made a complaint

about during the warranty period will be replaced

or repaired free of charge if they are returned to the

manufacturer, the shipping paid by the customer.

• The parts that have not been manufactured by

Happowa Oy, such as the circuit cards and electric

motors, are covered by the warranty of the supplier in

question.

• Warranty does not cover the operating and travelling

expenses.

• Warranty is only valid if the fault has been reported to

our dealer within 14 days from the delivery date.

Warranty does not cover:

• Damages caused by normal wear or incorrect

maintenance.

• Damages caused by incorrect use.

• Repairs or changes made without the consent of the

manufacturer and the damages caused by them.

• Secondary damages and the financial losses caused

by them.

• Damages caused by incorrect wiring.

Subject to change without notice.

10. Responsibilities

Manufacturer is not responsible if the acid applicator

is used contrary to safety regulations or this operating

manual. Since the use of the acid applicator may

cause situations for which there are no instructions or

regulations, the operators are recommended to follow

general machine safety instructions and directives.

Note that the incorrect use of acid may cause harm

to people, animals, bodies of water and soil. Follow

the instructions provided by the manufacturer of the

preservative and other experts regarding the handling

and use of preservatives.

Manufacturer is not responsible for the incorrect use of

preservatives or secondary damages caused by it.

Manufacturer is not responsible for damages caused by

the use of components manufactured by others.

Manufacturer is not responsible for damages to

other machines or equipment caused by the use of

preservatives.

The owner of the machine is responsible for its use, care

and maintenance.

The owner of the machine is responsible for making

sure that all people using the machine are sufficiently

informed of its handling and use.

Since the manufacturer cannot supervise the use

of the products we can only guarantee their quality. We

cannot take responsibility for the performance of the

products.

24 25

Spare parts 103410 103420

1

2

3

4

5

Svenska

Pcs

Part

Suomi

Code

English

5 328945

Letkunkiristin 13-20 +RVHFODPS .OlPPDUH

2

4 337113

Pikaliitinpistoke 12 mm 6QDSFRXSOLQJPDOH 6QDEENRSSOLQJPDQ

2

3 322008

Spreader välikaapeli &DEOH .DEHO

1

2 322005

Spreader -ohjain &RQWUROOHU .RQWUROOHU

1

1 337440

Spreader4000 pumppuyksikkö 3XPSXQLW 3XPSKHW

1

Dimensions

103410

Spreader 4000 pumppupaketti

1

2

3

4

337440

322005

322008

337113

328945

Spreader-ohjain

Spreader 4000 -pumppuyksikkö

Spreader-välikaapeli

Pikaliitinpistoke 12 mm

Letkunkiristin 13-20 mm

Spr. 4000 pump unit

Spreader controller

Spreader jumper cable

Quick coupling plug 12 mm

Hose clamp 13-20 mm

Spr. 4000-pumpenhet

Spreader-kontroller

Spreader-mellankabel

Snabbstickkontakt 12 mm

Slangklämma 13-20 mm

1

1

1

2

2

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

5

1

2

3

4

5

Svenska

Pcs

Part

Suomi

Code

English

5 328945

Letkunkiristin 13-20 +RVHFODPS .OlPPDUH

2

4 337113

Pikaliitinpistoke 12 mm 6QDSFRXSOLQJPDOH 6QDEENRSSOLQJPDQ

2

3 322008

Spreader välikaapeli &DEOH .DEHO

1

2 322005

Spreader -ohjain &RQWUROOHU .RQWUROOHU

1

1 337460

Spreader 6000 pumppuyksikkö 3XPSXQLW 3XPSKHW

1

Dimensions

103420

Spreader 6000 pumppupaketti

1

2

3

4

337460

322005

322008

337113

328945

Spreader-ohjain

Spreader 6000 -pumppuyksikkö

Spreader-välikaapeli

Pikaliitinpistoke 12 mm

Letkunkiristin 13-20 mm

Spr. 6000 pump unit

Spreader controller

Spreader jumper cable

Quick coupling plug 12 mm

Hose clamp 13-20 mm

Spr. 6000-pumpenhet

Spreader-kontroller

Spreader-mellankabel

Snabbstickkontakt 12 mm

Slangklämma 13-20 mm

1

1

1

2

2

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

5

26 27

1

2

3

4

5

6

Svenska

Pcs

Part

Suomi

Code

English

6 111651

Pvc-letku 12mm 3YFKRVH 3YFVODQJ

1

5 328945

Letkunkiristin13-20 +RVHFODPS .OlPPDUH

6

4 337113

Pikaliitinpistoke 12 mm 6QDSFRXSOLQJPDOH 6QDEENRSSOLQJPDQ

1

3 113240

Tippumisenestoventtiili 12mm &KHFNYDOYH $QWLGURSYHQWLO

1

2 337112

Pikaliitinrunko 12mm 6QDSFRXSOLQJIHPDOH 6QDEENRSSOLQJNYLQ

2

1 337006

Imuputki 6XFWLRQKRVH 6XJVODQJ

1

Dimensions

320018

Spreader varustepaketti

1

2

3

4

5

337006

337112

113240

337113

328945

Imuputki

Pikaliitinrunko 12 mm

Tippumisenestoventtiili 12 mm

Pikaliitinpistoke 12 mm

Letkunkiristin 13-20 mm

Suction pipe

Quick coupling male

Anti-drip valve 12 mm

Quick coupling plug 12 mm

Hose clamp 13-20 mm

Sugrör

Snabbkoppling hane

Droppstoppsventil 12 mm

Snabbstickkontakt 12 mm

Slangklämma 13-20 mm

1

2

1

1

6

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

6111651 Pvc-letku 12 mm Pvc-hose 12 mm Pvc-slang 12 mm 1

320018 337440

16

1718

1

2

3

4

5

67

8

9

10

11

12

13

14

15

Svenska

Pcs

Part

Suomi

Code

English

18

SH1211144

Konekilpi 7\SHSODWH 7\SVN\OW

1

17

SH1902152

Spreader 4000 tarra 6WLFNHU .OLVWHUPlUNH

1

16

SH1211142

Varoitustarra 6WLFNHU .OLVWHUPlUNH

1

15 337027

Kansi &RYHU 3ODVWORFN

1

14 133020

Lukitusmutteri M6 1XW 0XWWHU

4

13 133028

Aluslatta M6 :DVKHU %ULFND

4

12 111651

Pvc-letku 12mm 3YFKRVH 3YFVODQJ

1

11 328945

Letkunkiristin13-20 +RVHFODPS .OlPPDUH

6

10 142210

Sähkösarja (OHFWULFNLW (OHNWULVNNLW

1

9 133141

Levyruuvi 3,5 x 9,5 6FUHZ 6NUXY

4

8 337109

Pikaliitinrunko 12mm 6QDSFRXSOLQJIHPDOH 6QDEENRSSOLQJNYLQ

2

7 113146 Kuusioruuvi M6 x 30 6FUHZ 6NUXY 4

6 133143

Uraruuvi M5 x 10 6FUHZ 6NUXY

6

5 113230

Virtausanturi )ORZVHQVRU )O|GHVVHQVRU

1

4 111651

Pvc-letku 12mm 3YFKRVH 3YFVODQJ

2

3 337017

Pohjalevy )RXQGDWLRQSODWH %RWWHQSODWWD

1

2 157206

Letkulähtö 12mm +RVHFRXSOLQJ 6ODQJVOXWQLQJ

2

1 157350

Kalvopumppu 2 mäntää 0HPEUDQHSXPS 0HPEUDQSXPS

1

Dimensions

337440

Spreader 4000 pumppuyksikkö

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

157350

157206

337017

111651

113230

133143

113146

337109

133141

142210

328945

111651

133028

133020

337027

SH1211142

Kalvopumppu 2-mäntäinen

Letkulähtö 12 mm

Pohjalevy

Pvc-letku 12mm

Virtausanturi

Uraruuvi M5 x 10

Kuusioruuvi M6 x 30

Pikaliitinrunko 12mm

Levyruuvi 3,5 x 9,5

Liitinpaneeli

Letkunkiristin 13-20 mm

Pvc-letku 12 mm

Aluslevy M6

Lukitusmutteri M6

Kansi

Varoitustarra

2-piston diaphragm pump

Hose coupling 12 mm

Bottom plate

Pvc-hose 12 mm

Flow sensor

Slot headed screw M5 x 10

Hexagonal bolt M6 x 30

Quick coupling plug 12 mm

Screw 3,5 x 9,5

Connector panel

Hose clamp 13-20 mm

Pvc-hose 12 mm

Washer M6

Nut M6

Lid

Warning sticker

2-kolvs memranpump

Slangkoppling 12 mm

Bottenplatta

Pvc-slang 12 mm

Flödesgivare

Spårskruv M5 x 10

Sexkantsskruv M6 x 30

Snabbstickkontakt 12 mm

Skruv 3,5 x 9,5

Kopplingsbord

Slangklämma 13-20 mm

Pvc-slang 12 mm

Bricka M6

Mutter M6

Lock

Varningsdekal

1

2

1

2

1

6

4

2

4

1

6

1

4

4

1

1

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

17

18

SH1902152

SH1211144

Spreader 4000 -tarra

Konekilpi

Spreader 4000 sticker

Machine plate

Spreader 4000 -dekal

Märkplåt

1

1

28 29

337460

1

2

3

4

337122

337124

337122

337126

Pumpun pääty

Alempi pumpunpesä

Pressure switch

Pump end mounting

Valve set, 2-piston

Lower pump housing

Tryckbrytare

Pumpbotten

Ventilserie, 2-piston

Nedre pumphus

1

1

1

1

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

1

2

3

4

337122

337134

337132

337136

Pumpun pääty

Alempi pumpunpesä

Pressure switch

Pump end mounting

Valve set, 2-piston

Lower pump housing

Tryckbrytare

Pumpbotten

Ventilserie, 2-piston

Nedre pumphus

1

1

1

1

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

1234 5

Svenska

Pcs

Part

Suomi

Code

English

5 337130

Moottori

1

4 337136

Alempi pumpunpesä

1

3 337132

Venttiilisarja 4 mäntää

1

2 337134

Pumpun pääty

1

1 337122

Painekytkin

1

Dimensions

157352

Kalvopumppu 4 mäntää

12345

Svenska

Pcs

Part

Suomi

Code

English

5 337120

Moottori

1

4 337126

Alempi pumpunpesä

1

3 337122

Venttiilisarja 4 mäntää

1

2 337124

Pumpun pääty

1

1 337122

Painekytkin

1

Dimensions

157350

Kalvopumppu 2 mäntää

1234 5

Svenska

Pcs

Part

Suomi

Code

English

5 337130

Moottori

1

4 337136

Alempi pumpunpesä

1

3 337132

Venttiilisarja 4 mäntää

1

2 337134

Pumpun pääty

1

1 337122

Painekytkin

1

Dimensions

157352

Kalvopumppu 4 mäntää

12345

Svenska

Pcs

Part

Suomi

Code

English

5 337120

Moottori

1

4 337126

Alempi pumpunpesä

1

3 337122

Venttiilisarja 4 mäntää

1

2 337124

Pumpun pääty

1

1 337122

Painekytkin

1

Dimensions

157350

Kalvopumppu 2 mäntää

5

5

Moottori Engine Motor 1

Moottori Engine Motor 1

337120

337130

Painekytkin

Painekytkin

Venttiilisarja 2-mäntäinen

Venttiilisarja 4-mäntäinen

157350

157352

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Svenska

Pcs

Part

Suomi

Code

English

18

SH1211144

Konekilpi

1

17

SH1902153

Spreader 6000 tarra

1

16

SH1211142

Varoitustarra

1

15 337027

Kansi

1

14 133020

Lukitusmutteri M6

4

13 133028 Aluslatta M6 4

12 111651

Pvc-letku 12mm

1

11 147151

Klemmari 12-22

6

10 142210

Sähkösarja

1

9 133141

Levyruuvi 3,5 x 9,5

4

8 337109

Pikaliitinrunko 12mm

2

7 113146 Kuusioruuvi M6 x 30 4

6 133143

Uraruuvi M5 x 10

6

5 113230

Virtausanturi

1

4 111651

Pvc-letku 12mm

2

3 337017

Pohjalevy

1

2 157210

Letkuliitin 1/2"

2

1 157352

Flojet 18 R4300143

1

Dimensions

337460

Spreader 6000 pumppuyksikkö

7\SHSODWH 7\SVN\OW

6QDEENRSSOLQJNYLQ

6WLFNHU .OLVWHUPlUNH

6WLFNHU .OLVWHUPlUNH

&RYHU 3ODVWORFN

1XW 0XWWHU

:DVKHU %ULFND

3YFKRVH 3YFVODQJ

+RVHFODPS .OlPPDUH

(OHFWULFNLW (OHNWULVNNLW

6FUHZ 6NUXY

6QDSFRXSOLQJIHPDOH

6FUHZ 6NUXY

6FUHZ 6NUXY

)ORZVHQVRU )O|GHVVHQVRU

3YFKRVH 3YFVODQJ

)RXQGDWLRQSODWH %RWWHQSODWWD

+RVHFRXSOLQJ 6ODQJVOXWQLQJ

0HPEUDQHSXPS 0HPEUDQSXPS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

157352

157210

337017

111651

113230

133143

113146

337109

133141

142210

147151

111651

133028

133020

337027

SH1211142

Kalvopumppu 4-mäntäinen

Letkuliitin 1/2”

Pohjalevy

Pvc-letku 12 mm

Virtausanturi

Uraruuvi M5 x 10

Kuusioruuvi M6 x 30

Pikaliitinrunko 12mm

Levyruuvi 3,5 x 9,5

Liitinpaneeli

Klemmari 12-22 mm

Pvc-letku 12 mm

Aluslevy M6

Lukitusmutteri M6

Kansi

Varoitustarra

4-piston diaphragm pump

Hose coupling 1/2”

Bottom plate

Pvc-hose 12 mm

Flow sensor

Slot headed screw M5 x 10

Hexagonal bolt M6 x 30

Quick coupling plug 12 mm

Screw 3,5 x 9,5

Connector panel

Hose clamp 12-20 mm

Pvc-hose 12 mm

Washer M6

Nut M6

Lid

Warning sticker

4-kolvs memranpump

Slangkoppling 12 mm

Bottenplatta

Pvc-slang 12 mm

Flödesgivare

Spårskruv M5 x 10

Sexkantsskruv M6 x 30

Snabbstickkontakt 12 mm

Skruv 3,5 x 9,5

Kopplingsbord

Slangklämma 12-20 mm

Pvc-slang 12 mm

Bricka M6

Mutter M6

Lock

Varningsdekal

1

2

1

2

1

6

4

2

4

1

6

1

4

4

1

1

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

17

18

SH1902153

SH1211144

Spreader 6000 -tarra

Konekilpi

Spreader 6000 sticker

Machine plate

Spreader 6000 -dekal

Märkplåt

1

1

30 31

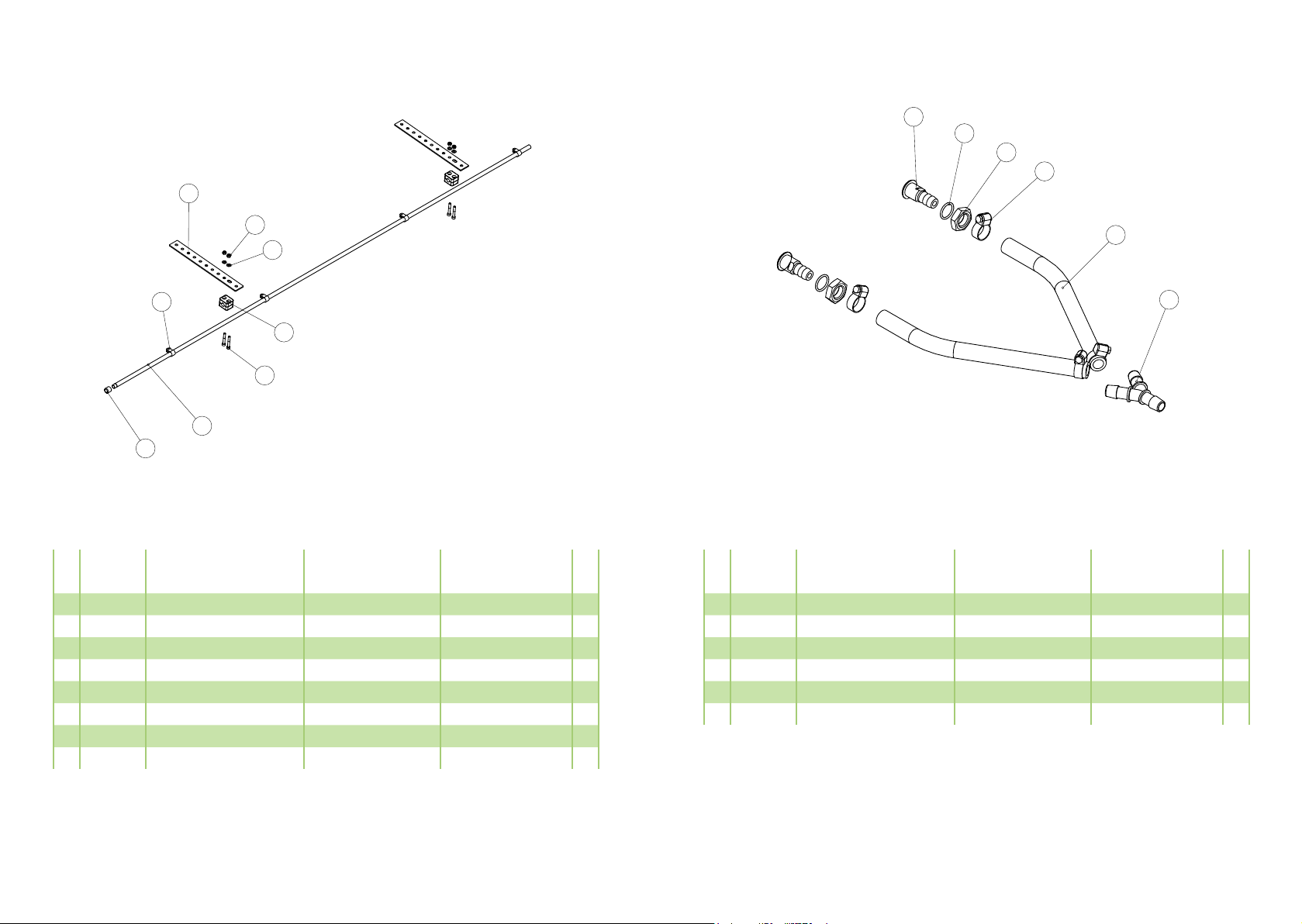

1

2

3

4

5

6

Svenska

Pcs

Part

Suomi

Code

English

6 337108

Pikaliitinpistoke 3/8" 6QDSFRXSOLQJPDOH 6QDEENRSSOLQJPDQ

1

5 320032

Tynnyrisovite&DS.RUN

1

4 111651

Pvc-letku 12mm 3YFKRVH 3YFVODQJ

1

3 328990

Letkunkiristin A4 12-22 +RVHFODPS .OlPPDUH

2

2 313287

Letkuliitin 3/8" -13mm +RVHFRXSOLQJ6ODQJVOXWQLQJ

2

1 337202

Imusihti koottu 6WDLQHU 6LO

1

Dimensions

337006

1

2

3

4

5

337202

313287

328990

111651

320032

Imusuodatin koottu

Letkuliitin 3/8” 13mm

Letkunkiristin A4 12-22

Pvc-letku 12 mm

Tynnyrisovite

Suction filter, complete

Slangkoppling 3/8” 13 mm

Hose clamp A4 12-22

Pvc-hose 12 mm

Barrel adapter

Sugfilter, monterat

Hose coupling 3/8” 13 mm

Slangklämma A4 12-22

Pvc-slang 12 mm

Fatadapter

1

2

2

1

1

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

6337108 Pikaliitinpistoke 3/8” Quick coupling plug 3/8” Snabbstickkontakt 3/8” 1

337006

1

2

3

4

10

7

8

9

11

5

6

12

Svenska

Pcs

Part

Suomi

Code

English

12 313289

Putkiteippi 6HDOWDSH 7lWQLQJWHMS

1

11 133630

Kuusiokoloruuvi M6x40 6FUHZ 6NUXY

4

10 337420

Putken kiinnikepari 13,5mm 3LSHIDVWHQHUSDLU 5|UIlVWSDU

2

9 133028

Aluslatta M6 :DVKHU %ULFND

4

8 133020

Lukitusmutteri M6 1XW 0XWWHU

4

7 1666

Kiinnityslatta )DVWHQLJQSODWH )lVWSODWWD

2

6 313298

Viuhkasuutin 2,2 l/min 9508 1R]]OH 0XQVW\FNH

3

5 313293

Viuhkasuutin 1,1 l/min 9504 1R]]OH 0XQVW\FNH

3

4 313283

Kulmanippa$QJOHQLSSOH 9LQNHOQLSSHO

1

3 337403

Väliputki3LSH5|U

2

2 313282

T-nippa 7QLSSOH 7QLSSHO

2

1 313284

Letkuyhde +RVHFRXSOLQJ 6ODQJVOXWQLQJ

1

Dimensions

337400

Viuhkasuutintanko

1

2

3

4

5

6

7

8

9

10

11

313284

313282

337403

313283

313293

313298

1666

133020

133028

337420

133630

Letkuyhde

T-nippa

Väliputki

Kulmanippa

Viuhkasuutin 1,1 l/min 9504

Viuhkasuutin 2,2 l/min 9508

Kiinnityslevy

Lukitusmutteri M6

Aluslevy M6

Putken kiinnikepari 13,5 mm

Kuusiokoloruuvi M6x40

Hose coupling

T-adapter

Pipe

Elbow adapter

Flat spray nozzle

Flat spray nozzle

Mounting plate

Nut M6

Washer M6

Pipe fastener 13,5 mm

Hex. socket head screw

Slangkoppling

T-koppling

Rör

Vinkelkoppling

Spaltspridarmunstycke

Spaltspridarmunstycke

Fästplatta

Mutter M6

Bricka M6

Rör fästdon 13,5 mm

Sexkanthålsskruv

1

2

2

1

3

3

2

4

4

2

4

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

12 313289 Putkiteippi Tape Tejp 1

337400

32 33

1

2

3

4

5

6

7

8

Svenska

Pcs

Part

Suomi

Code

English

8 303115

Asennusside +RVHFODPS .OlPPDUH

4

7 337414

Tulppa3OXJ 3URSS

1

6 337412

Pistesuutinputki3LSH5|U

1

5 133630

Kuusiokoloruuvi M6x40 6FUHZ 6NUXY

4

4 337421

Putken kiinnikepari 12mm 3LSHIDVWHQHUSDLU 5|UIlVWSDU

2

3 133028

Aluslatta M6 :DVKHU %ULFND

4

2 133020

Lukitusmutteri M6 1XW 0XWWHU

4

1 1666

Kiinnityslatta )DVWHQLQJSODWH )lVWSODWWD

2

Dimensions

337410

Reikäsuutintanko

1

2

3

4

5

6

7

8

1666

133020

133028

337421

133630

337412

337414

303115

Kiinnityslevy

Lukitusmutteri M6

Aluslevy M6

Putken kiinnikepari 12 mm

Kuusiokoloruuvi M6x40

Pistesuutinputki

Tulppa

Klemmari

Mounting plate

Nut M6

Washer M6

Pipe fastener 12 mm

Hex. socket head screw

Spridarrör

Plug

Clamp

Fästplatta

Mutter M6

Bricka M6

Rör fästdon 12 mm

Sexkanthålsskruv

Spray bar

Propp

Klämmare

2

4

4

2

4

1

1

4

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

337410

1

2

3

4

5

6

Svenska

Pcs

Part

Suomi

Code English

6 113011

6LOSSXULVXXWLQ 1R]]OH 0XQVW\FNH

2

5 144981

O-rengas 16 x 22ULQJ 2ULQJ

2

4 133116

Matala mutteri M16 x 1,5 7KLQQXW 7XQQPXWWHU

2

3 328945

Letkunkiristin13-20 +RVHFODPS .OlPPDUH

4

2 111651

Pvc-letku 12mm 3YFKRVH 3YFVODQJ

2

1 157302

T-haara7FRQQHFWRU 7NRSSOLQJ

1

Dimensions

113351

SLOSSXULVuutinsarja

1

2

3

4

5

157302

111651

328945

133116

144981

T-haara

Pvc-letku 12 mm

Letkunkiristin 13-20

Matala mutteri M16 x 1,5

O-rengas 16 x 2

T-connector

Pvc-hose 12 mm

Hose clamp 13-20

Nut M16 x 1,5

O-ring

T-koppling

Pvc-slang 12 mm

Slangklämma 13-20

Mutter M16 x 1,5

O-ring

1

2

4

2

2

Osa

Nr.

Tunnus

Code

Suomi English Svenska Kpl.

Pc.

St.

6113011 Silppurisuutin Chopper nozzle Flismaskin munstycke 2

113351

Happowa Oy

www.happowa.fi

tel. +358 400 863 514

myynti@happowa.fi

This manual suits for next models

1

Table of contents

Other Happowa Spreader manuals

Popular Spreader manuals by other brands

Cub Cadet

Cub Cadet 125 lb Spreader & 10 Gallon Sprayer Operator's manual

SnowEx

SnowEx SP-1675 owner's manual

Warren

Warren AC-1820A Owner / Operator Manual & Parts Reference Guide

Tatu Marchesan

Tatu Marchesan DCA2 MC 2500 Operator's manual

Echo

Echo RB-60 Operator's manual

Amazone

Amazone SUPER-JET 1600 H-18 Operator's manual