5

GENERAL DESCRIPTION

The units required under these specifications shall be mounted to the side of the dump body,

below floor level and beneath the tailgate. During the maintenance operations it shall permit the

dumping of materials to the left or right without interfering with the operation of the tailgate.

The conveyor shall be capable of being controlled by the truck hydraulic system to vary the

amount of material being conveyed to the roadway surface. Bidders must submit with bids

complete detailed specifications on the units they propose to furnish. Bids with exceptions to

these specifications shall be considered unresponsive. Shall be capable of right or left discharge

Has 18” belt over chain D667X , 96” wide riveted, with 3/8”x1-1/4” crossbars, H.D. hot asphalt

type to withstand heat of 350 degrees Fahrenheit. Reversible with hydraulic hoses. Discharge

gates to be rack & pinion and shall be located on left and right sides of spreader. Feed gate

openings 16-1/4”x13” minimum. 6 tooth drive and idler sprockets flame cut steel plate, keyed

and timed with 1-1/2” shafts. ¼” wiper belting seals off front and rear end panels to conveyor.

Hydraulic reservoir and filter, hydraulic quick disconnect couplings, hydraulic hose and fitting

for truck and spreader, hydraulic in cab control valve and hydraulic pump. Pin mount type using

four pins for quick disconnect.

Optional Attachments:

Spinner attachment for spreading.

HYDRAULIC CROSS CONVEYOR

MOUNTING INSTRUCTIONS FOR AC-1820A

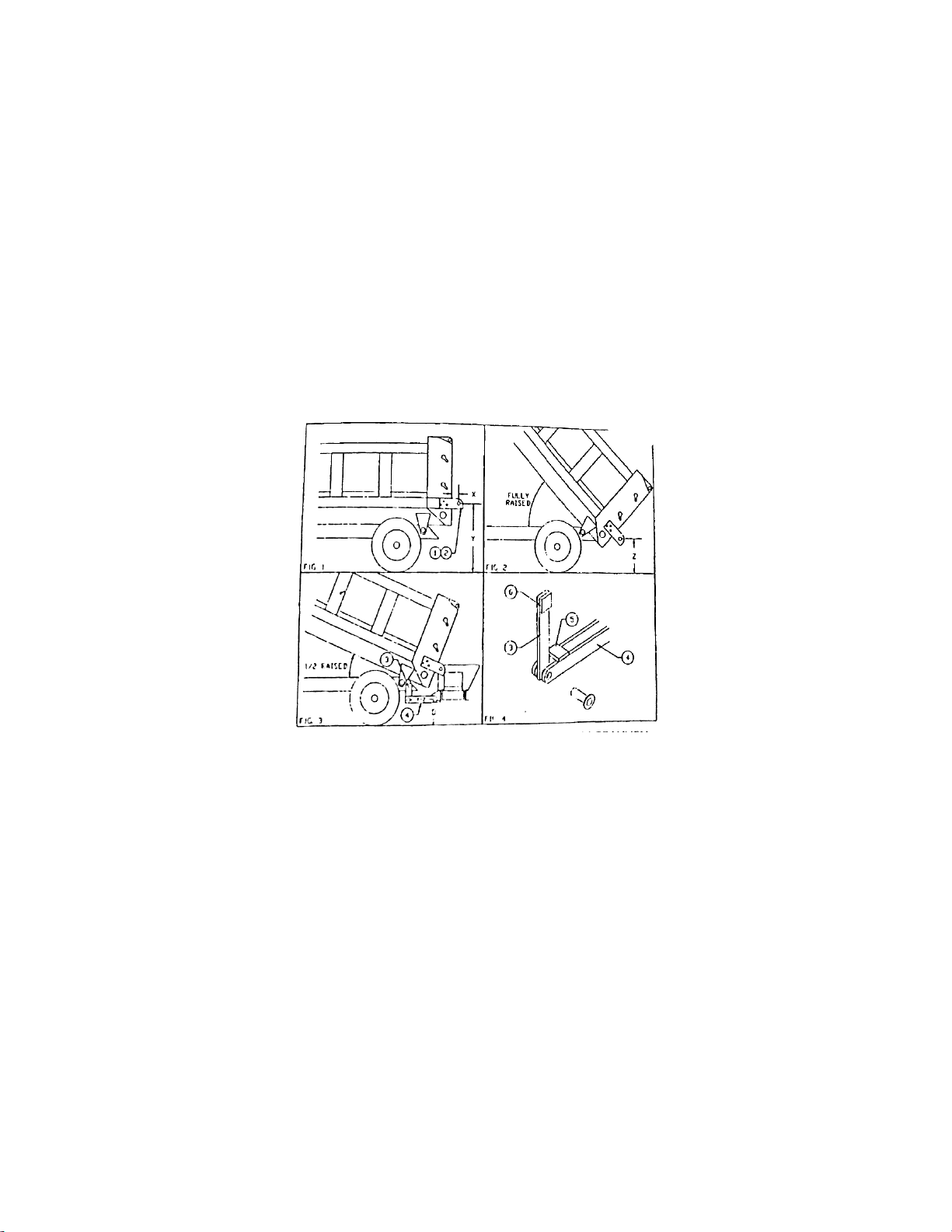

STEP 1. Place one inside upper mounting bracket, (Fig. 1, Item 1, Part No. 200536-19), on side

of the dump box rub rail with the bot- tom edge of the bracket even with the bottom edge of the

rub rail. Measure 2 1/2" from the back of the dump box to the center of the 1" hole in bracket, X,

and clamp bracket in place. Drill three 1/2" holes in the dump box to match the holes in the

bracket. Repeat this process for the other side of the dump box. Using the 1/2" x2 1/2* bolts in

the shipping kit, insert bolt from the inside of the rub rail outward. Attach the bracket to the

dump box with a lock washer and nut. Measure the outside distance between both brackets,

keeping this distance approximately 1/4" greater than the inside distance between the end panels

of the cross conveyor. The brackets may need to be spaced out evenly on both sides to attain the

proper distance. Before tightening down the inside brackets, place a flat washer on each bolt and

attach the outside bracket, (Fig. 1, Item 2, Part No. 200536-18), with a lock washer and nut.

Insert the 1" pin x 2 1/4" long, Part No. 220343- 05, through the hole in the brackets and tighten

the inside nut, then the outside nut. Measure the distance from the center of the pin to the ground,

Y.

STEP 2. Raise the dump box to the top position and measure the distance from the center of the

pin to the ground, (Fig. 2, Z). Determine the angle of the dump box that is half-way between