Happy HK634020XB User manual

Maintenance Manual for Embroidery Machine

(Color Display Additional Manual)

HCS-1201-30

Version 1.0

HAPPY Industrial Corporation

2

# For safe adjustment and repair #

In order to conduct adjustment and repair safely and surely,

please be sure to abide by what is mentioned in this manual to prevent trouble.

1. When you conduct adjustment and repair of this embroidery machine or handle electric related parts,

you are required to take technical lesson in advance.

2. When you conduct adjustment and repair using this manual, please be sure to use together with instruction

with it in hand.

# Please conduct in accordance with work process in this manual.

# In case there are no specific instructions or explanations in work process.

please be sure to unplug cord from receptacle.

# When you exchange parts, please be sure to use genuine parts designated by us.

# Please never remodel the embroidery machine.

When you handle circuit boards:

# In order to prevent troubles from static electricity, please remove earth from human body.

# Please don't touch metal part of circuit board with bare hand as it will short-circuit

and threaten to break circuit boards.

# When you removed circuits boards from the machine or you store or transport them,

please wrap them in static electricity preventive bag and avoid to give shock.

3

Index

page

cover 1

For safe adjustment and repair 2

Index 3

1 Parts Replacement in control panel and setting 4

1-1 Open and remove front panel from control box

1-1-1 Open the front panel on the control box 5

1-1-2 Remove ATA LCD board 6

1-2 Dip switch setting for ATA LCD board 7

2 Initialization of system 8

2-1 Notice for update and Initialize machine systems 9

2-2 Operation order for update and Initialize machine systems. 10

2-3 Detail operation order for update machine systems

2-3-1 How to Update Program for Control of ATA LCD Board. 11

2-3-2 How to Change Language Setting. 12

2-3-3 How to Update CPU Board Program (from EP-ROM) 13

2-3-4 How to Update CPU Board Program (from CF card) 14

2-3-5 How to Update Internal Monogramming Data 15

2-4 Initialization of memory

2-4-1 Initialization ATA LCD board memory 16

2-4-2 Initialization CPU board memory 16

2-5 Setting of Revolution 17

2-6 Setting to detect needle position (for 12 needles). 18.19

3 Maintenance mode. 20

3-1 How to enter maintenance mode 21

3-2 Machine Machine movement 22

3-3 Memory Memory (Machine and Design) check and all erase. 23

3-4 Record Opereration data display

3-4-1 Thread Pattern Number of thread brake times in relation to pattern data 24

3-4-2 Thread Needle Accumulated total of thread break of a needle 25

3-4-3 Error Error occurred and the accrual date 26

3-5 Setup Machine setting. 27

4 Electric system diagram(Color Display) 28

4-1 Electrical connection diagram. 29

4-2 List of electrical connection diagrams 30

4

1 Parts Replacement in control panel and setting

1-1 Open and remove front panel from control box

1-1-1 Open the front panel on the control box

1-1-2 Remove ATA LCD board

1-2 Dip switch setting for ATA LCD board

5

Open and remove front panel from control box 1-1

Open the front panel on the control box 1-1-1

<Check> Please check down machine power completely.

1. Remove four setscrews behind of control panel

2. Open control panel like following picture.

(Open the cover from right side)

<Note>

Please do not wide open on the left side.

(Possible, make damage to wiring cable and electric board)

Please do not turn on power when inverter cover (refer to

the bellow), otherwise the machine might be damaged.

3. Disconnect Inverter power cable.

4. Disconnect for LCD-SW cable

5. Disconnect LCD-S cable.

1. Pull stopper on CN7 (ATA LCD Board)

2. Pull out the LCD-S cable.

Finish of procedures

For assemble and close this panel: Please opposite steps of

this procedure.

4 set screws

Closing the left side

Inverter cover

Inverter power cable

LCD-SW cable

1

2

Stopper

LCD-S cable

6

Open and remove front panel from control box 1-1

Remove ATA LCD board 1-1-2

1. Disconnect emergency SW cable

2. Disconnect DISP cable. (Please off stopper first)

3. Remove ATA LCD board

Remove four setscrews

Finish of procedures

Emergency SW cable

CN1

DISP cable

Four setscrews

7

Dip switch setting for ATA LCD board 1-2

1 ------ON Initialize back up data

OFF. Non Initialize(Regular)

2 ------OFF. Regular

3 ------OFF. Regular

4 ------ON

5 ------ON

6 ------OFF.

7 ------OFF.

8 ------OFF.

9 -----OFF. Regular

10 ---OFF. Regular

Color LCD Size

External

Regular

Regular

Detail of External switch (Normally, dose not use at maintenance)

7 8

ON ON Forbid

ON OFF Erase of language data.

OFF ON Forbid

OFF OFF Normal machine work(Regular)

8

2 Initialization of system

2-1 Notice for update and Initialize machine systems

2-2 Operation order for update and Initialize machine systems

2-3 Detail operation order for update machine systems

2-3-1 How to Update Program for Control of ATA LCD Board

2-3-2 How to Change Language Setting

2-3-3 How to Update CPU Board Program (from EP-ROM)

2-3-4 How to Update CPU Board Program (from CF card)

2-3-5 How to Update Internal Monogramming Data

2-4 Initialization of memory

2-4-1 Initialization ATA LCD board memory

2-4-2 Initialization CPU board memory

2-5 Setting of Revolution

2-6 Setting to detect needle position (for 12 needles)

9

Notice for update and Initialize machine systems 2-1

* Please install program when update (Machine system program, Internal Monogram data) and Replace circuit board (CPU board,

ATA LCD board) and indication language.

* Contents of system program for HCD are as follows:

CPU Board

OS. : HCS/H **** (program for control of CPU board )

Letter : LTR*** (Internal Monogramming data)

LCD Board

Control. : LCDH**** (program for control of LCD board )

Language. : H_ENG*** (English)

: H_JPN*** (Japanese)

* System program above will be shown as below on PC screen

Program for control of CPU board : HCS/H ****----------------->.CHCS***.bin

Internal Monogramming data : LTR***----------------------->.LTR***.bin

Program for control of LCD board : LCDHA***------------------> LCDHA***.upi + LCDHA***.bin : 2 files required

Language (English and others) : H_ENG***------------------> H_ENG***.upi + H_ENG***.bin : 2 files required

<NOTE>

Pleasedo not write system program in folder in CF card when you upgrade machine by writing system program in CF card by

PC as machine becomes unable to recognize version up program (please write system program on route of subject media).

* In case, upgrade plural programs same time, please keep following priority install order.

1:LCDH****( program for control of LCD board )

2:H_ENG*** or H_JPN*** (language)

3:HCS/H ****( program for control of CPU board )

4:LTR***( Internal Monogramming data)

<NOTE>

* After replace board and upgrade program, please operate following items.

1. After upgrade LCD board program (Control and Language), please operate chapter [2-4-1 Initialization ATA LCD board

memory LCD] for clear a memory.

2. After update CPU board program (OS and Letter), please reference following chapters for set Memory clear, set machine

speed, needle position, system initialize and calendar set.

1: [2-4-2 Initialization CPU board memory ]

2: [2-5 Setting of Revolution]

3: [2-6 Setting to detect needle position (for 12 needles)]

4: [3-3 memory (Machine and Design) check and all erase]

5: In an Instruction book [25-1.2 Initialize machine] and [3-7 Calendar setting]

3. You can install and update all program from CF card.

But, in case of you have problem of electricity whole program install, possible loose CPU operation program completely. In this

time you need install CPU operation program from EP-ROM tip only.

10

Operation order for update and Initialize machine systems 2-2

* Work sequence of Updating Program are described below.

If you need more detail information fro each sequence, please reference each manual

1. Insert CF card saved update program to slot of control panel.

Press and keep [MENU] button and turn on the machine

2. Go to maintenance mode and practice install.

3. Update [CPU board program] from EP-ROM tip.

(In case, Machine program brake completely, you can re-install CPU board program

only from EP-ROM tip)

Turn off machine and connect EP-ROM saved machine program tip to socket on CPU board.

Flip dipswitch [DSW2 to OFF] and [DSW4 to ON], then turn on machine.

Start copy of CPU board program automatically.

After a copy, Please turn off machine power and flip back dipswitch [DSW2 to ON] and

[DSW4 to OFF].

4. [Update LCD board control program]

Flip dipswitch [DSW1 to ON] on ATA LCD board. And turn on machine.

Starts initialize

5. [Update LCD board control program]

Turn off machine power And Flip back dipswitch {DSW1 to OFF}.

6. Flip dipswitch [DSW1 to OFF] on CPU board. And turn on machine.

Starts initialize memory.

7. Turn off machine and flip back dipswitch [DSW1 to ON] on CPU board.

Press and keep [MENU] button and turn on machine power.

8. Memory checks at maintenance mode.

9. Re-turn on the machine

Come up [E-120] on display, and press [SET] button for turn off machine power.

10. Press and keep [MENU] button and turn on machine power.

11. Needle setting at maintenance mode.

(”D”for 1st needle ,”E”for 12th needle ,”F”for check)

12. Exit maintenance mode.( Press [ESC] button for back to drive mode)

Check moving head working correctly.

13. Initialize machine system

14. Machine speed teaching

15.Calender setting

16.end of process

2-4

Initialize memory

2-6

Needle position setting

Instruction book

25-1.2 Initialize machine

Instruction book

3-7 Calendar setting

3-3

Check and all clear a

memory

2-3

UPDATE PROGRAM

11

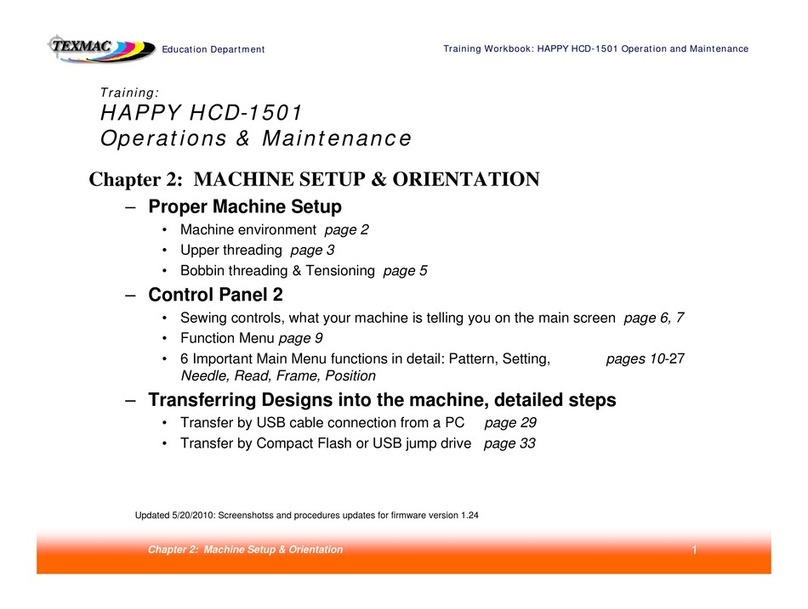

How to Update Program for Control of ATA LCD Board 2-3-1

1. Update of ATA LCD board program

Insert CF card contains data for version up into CF card

insertion slot

2. .Refer to “3-1 How to enter maintenance mode”and enter

maintenance mode. Display comes as below.

3. Place cursor at [ Install ] by button and press SET

button.

4. Showing menu on right side of screen.

Select [ install ] by button and press SET button.

5. Display comes as below after reading data in CF card

6. Press SET button for update of ATA LCD board program

<NOTE>

* Please do not take out CF card during installation.

* Will show following message

* For cancel, press ESC button and back to last menu

7. Completely, and re-boot machine.

If you have [ Error ] message, please operate from step 1 of

this process again.

* End of process

[Maintenance]

> Machine : A

Angle. : 0

Memory. :

Display : 1

Install. :

Record :

[Maintenance]

Machine : A

Angle. : 0

Memory. :

Display : 1

> Install :

Record :

[Maintenance]

Machine : A

Angle : 0

Memory .:

Display : 1

>. Install :

Record :

> install

prog

lettr font

[Maintenance]

[ Install mode ]

> 1 : LCD/H **.**

LCD Control Program Installing

12

How to Change Language Setting 2-3-2

1. Change language of LCD panel

Insert CF card included language data to card slot of

control panel. Refer to “3-1 How to enter maintenance

mode”and enter maintenance mode. Display comes as

below.

2. Set cursor at [ Install ] by button and press SET

button.

3. Will show the menu on right side.

Set cursor at [ install ] by button and press SET

button.

4. Display comes as below after reading data in CF card

5. Select your language and press SET button. Start install

automatically.

* File name of language

English H_ENG***

Japanese H_JPN***

German H_GER***

Danish H_DAN***

<NOTE>

* Please do not take out CF card during installation.

For cancel, press ESC button and back to last menu.

6. Indicate [ complete ], then return to drive menu

automatically.

Please retry when you have display as “Error ”by mistake

of writing.

* end of process

[Maintenance]

Machine : A

Angle : 0

Memory :

Display : 1

> Install :

Record :

[Maintenance]

Machine : A

Angle : 0

Memory :

Display : 1

> Install :

Record :

> install

prog

lettr font

[Maintenance]

[ Install mode ]

> 1 : H_ENG***

2 : H_JPN***

[Maintenance]

[ Install mode ]

- - - - - Installing Data - - - -

[Maintenance]

[ Install mode ]

- - - - - Complete - - - -

13

How to Update CPU Board Program (from EP-ROM) 2-3-3

1. Update of CPU board program

Insert ROM in socket with power off

Control-program

[HCS/H **.**]

Dented side on the bottom.

2. Set No.4 of [DS1] to [ON] and No.2 to [OFF] to

turn power on.

Indicating process

3. Display [complete]

When you make wrong writing, message of "error" will be

displayed. Please write again

<Judgment by circuit board itself>

Lighting condition of LED4 on the CPU Board enables you to

distinguish the result.

Normal complete : 8times blinking --- lighting

Writing error : 8times blinking --- blinking

Retry if writing error occurs.

4. Turn power off and set No.4 of DS1 to OFF, No.2 to ON.

5. Remove ROM.

* End of process

HCS/H

A*.**

Load 2.01

[> > > > ]

Load 2.01

- - - - - > Complete

14

How to Update CPU Board Program (from CF card) 2-3-4

1. Update of CPU board program

Insert CF card contains data for version up into CF card

insertion slot

2. Refer to “3-1 How to enter maintenance mode”and enter

maintenance mode. Display comes as below.

3. Place cursor at [Install] by button and press SET

button.

4. Display menu on right side below.

Select [ prog ] by button and press SET button.

5. .Display comes as below after reading data in CF card

6. Press SET for start program update

<NOTE>

* Please do not take out CF card during installation.

* For cancel, press ESC button and back to last menu.

* Display comes as below.

12. When completed, reboot machine automatically

Please retry when you have display as “Error”by mistake

of writing.

* End of process.

[Maintenance]

> Machine : A

Angle. : 0

Memory. :

Display : 1

Install. :

Record :

[Maintenance]

Machine : A

Angle. : 0

Memory. :

Display. : 1

> Install. :

Record. :

[Maintenance]

Machine : A

Angle. : 0

Memory. :

Display : 1

> Install. :

Record :

install

>. prog

lettr font

[Maintenance]

[ Program install ]

> 1 : CHCSA***

Load 2.01

- - - - - > Complete

15

How to Update Internal Monogramming Data 2-3-5

1. Update for Internal Monogram data.

Insert CF card saved update data. Refer to “3-1 How to

enter maintenance mode”and enter maintenance mode.

Display comes as below.

2. Place cursor at [ Install ] by button and press SET

button.

3. Showing menu on right side of screen

Select [ letter font ] by button and press SET button.

4. Display comes as below after reading data in CF card

5. Press SET button for start update of monogram data.

<NOTE>

Please do not take out CF card during installation

For cancel, press ESC button and back to last menu.

6. When completed, comes as below display [ complete] and

reboot machine automatically.

Please retry when you have display as “Error”by mistake of

writing.

* End of process

[Maintenance]

Machine : A

Angle. : 0

Memory. :

Display : 1

> Install :

Record :

[Maintenance]

Machine : A

Angle. : 0

Memory. :

Display : 1

> Install. :

Record :

install

prog

>. lettr font

[Maintenance]

[ Lettr install ]

> 1 : LTR * * *

Write 1.01[ * * * * ]

- - - - - > Complete

16

Initialization of memory 2-4

At time of start-up, this is to initialize work memory to specified value. Initialization takes place

Initialize “work memory”. Please practice when you have problem example, strange display, strange machine working. After

initialize “working memory”, Please set machine speed and needle position setting.

Initialization ATA LCD board memory 2-4-1

1. Please flip dipswitch DS1-1 on ATA LCD board. Then turn on the machine

2. End of initialize. Please turn off machine and flip back dipswitch DS1-1 to [OFF].

Initialization CPU board memory 2-4-2

1. Set DS1-1 on CPU board to [OFF] to turn power on.

2. You will have no problem in starting and finishing initialization. Please turn power off to set DS1-1 to ON after initialization

3. Please set as refer following process.

1. [2-5 Setting of Revolution]

2. [2-6 Setting to detect needle position (for 12 needles)]

3. Instruction book [25-1.2 Initialize machine] and [3-7 calendar setting]

<NOTE>

You are unable clear pattern memory area. If you want to clear, Please refer to [3-3 memory (Machine and Design) check and all

erase ].

DS1-1

DS1-1

17

Setting of Revolution 2-5

Setting of revolution of main shaft, which is suitable to the

machine is required.

If setting is not done, the revolution may not speed up.

1. Turn on the power. After the program start up, press MENU

button.

2. Press to select OTHER window and press SET

button.

Displayed as bellow.

3. Press to select Speed and press SET button.

Press to select [OK] and press SET button.

5. Main shaft adjusts its revolution speed automatically.

Message complete will be displayed when setting is

finished and it goes back to drive mode.

End of process.

Speed setting OK?

CAUTION! <Main shaft turns>

Cancel

OK

- - - Complete - - -

18

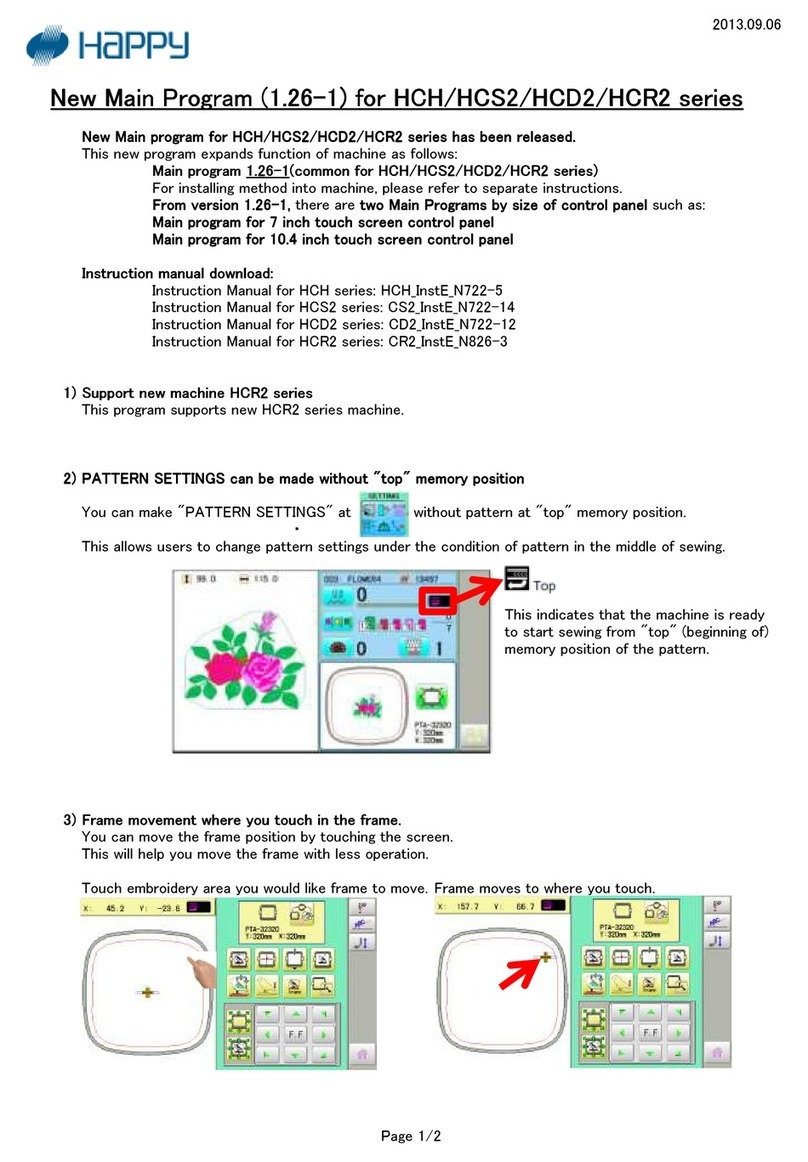

Setting to detect needle position (for 12 needles) 2-6

It is necessary to store value of needle selection sensor

according to number of needles. If this setting is not made,

normal needle selection may not be made.

1. Sift moving head to first needle by hand turning knob

2. Refer to “3-1 How to enter maintenance mode”and enter

maintenance mode.

3. Place cursor at [ machine ] by button and press

SET button

4. Press button and select “D ”then press SET

button. Memory first needle position to machine.

<Check>

When you press SET button, comes up “# ”mark split

second for proof memory needle position to machine

completely.

5. Slide moving head to 12th needle by hand.

[Maintenance]

> Machine : A

Angle. : 0

Memory. :

Display : 1

Install. :

Record :

[Maintenance]

> Machine : #D

Angle. : 0

Memory. :

Display : 1

Install. :

Record. :

19

Setting to detect needle position (for 12 needles) 2-6

6 Press button and select “E ”then press SET

button. Memory 12th needle position to machine.

<Check>

When you press SET button, comes up “# ”mark split

second for proof memory needle position to machine

completely.

7. Press button and select “F ”then press SET

button.

8. Right side of [ : F ] Indicate present needle number on

display.

Please slide moving head by hand and confirm 1 to 12 all

needle displayed number and present needle number

9. Press SET button for return to top menu of maintenance

mode.

10. Press ESC button for back to drive mode.

End of process

[Maintenance]

> Machine : #E

Angle. : 0

Memory. :

Display : 1

Install. :

Record. :

[Maintenance]

> Machine : F

Angle. : 0

Memory. :

Display : 1

Install. :

Record. :

[Maintenance]

> Machine : #F 12

Angle. : 0

Memory. :

Display : 1

Install. :

Record. :

[Maintenance]

> Machine : F

Angle. : 0

Memory. :

Display : 1

Install. :

Record. :

20

3 Maintenance mode

3-1 How to enter Maintenance mode

3-2 Machine Machine movement

3-3 Memory Memory (Machine and Design) check and all erase

3-4 Record Opereration data display

3-4-1 Thread Pattern Number of thread brake times in relation to pattern data

3-4-2 Thread Needle Accumulated total of thread break of a needle

3-4-3 Error Error occurred and the accrual date

3-5 Setup Machine setting

This manual suits for next models

1

Table of contents

Other Happy Sewing Machine manuals

Happy

Happy HCS2-1201 Troubleshooting guide

Happy

Happy HCS-1201-30 User manual

Happy

Happy HCS2-1201-30 User manual

Happy

Happy HCH-701 User manual

Happy

Happy HCG Series User manual

Happy

Happy HCH User manual

Happy

Happy HCH User manual

Happy

Happy HCD Instruction sheet

Happy

Happy HCD-1501 Installation guide

Happy

Happy HCH Series User manual