Happy HCS2-1201 Troubleshooting guide

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 1

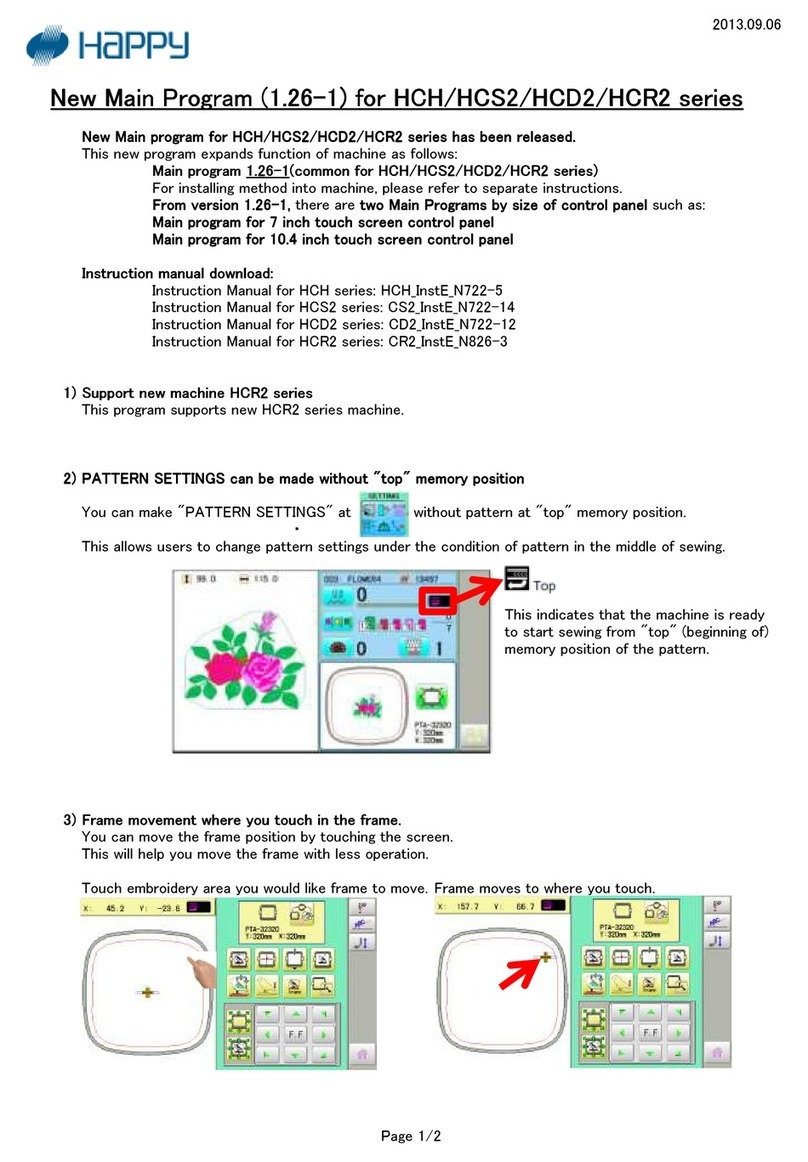

Training:

HAPPY HCS2-1201 Operations & Maintenance

For HCS Voyager2 with Touch Screen

Chapter 1: Introduction: The Machine, Needle, and Thread

–Introduction to your machine p.2

• Diagram of major parts p. 2

• Diagram of major systems: Pantograph, sewing machine, color change/cut p.3

• The Sewing Cycle p. 4

• Machine environment p.5

–Control Panel Introduction & Orientation p.6

• Power on/off / emergency stop

• Power-on & navigating to the main sewing screen

–Important Screens: A brief introduction p.7

• Drive screen 7

• Important Sub Screens 8

• Main menu, 9

–Additional Basics p.10

• About stitches, sewing quality, stitch file formats

–Embroidery Thread p. 11

• Installing thread p. 12

• Bobbin thread p. 14

–Embroidery Needles p. 15

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 2

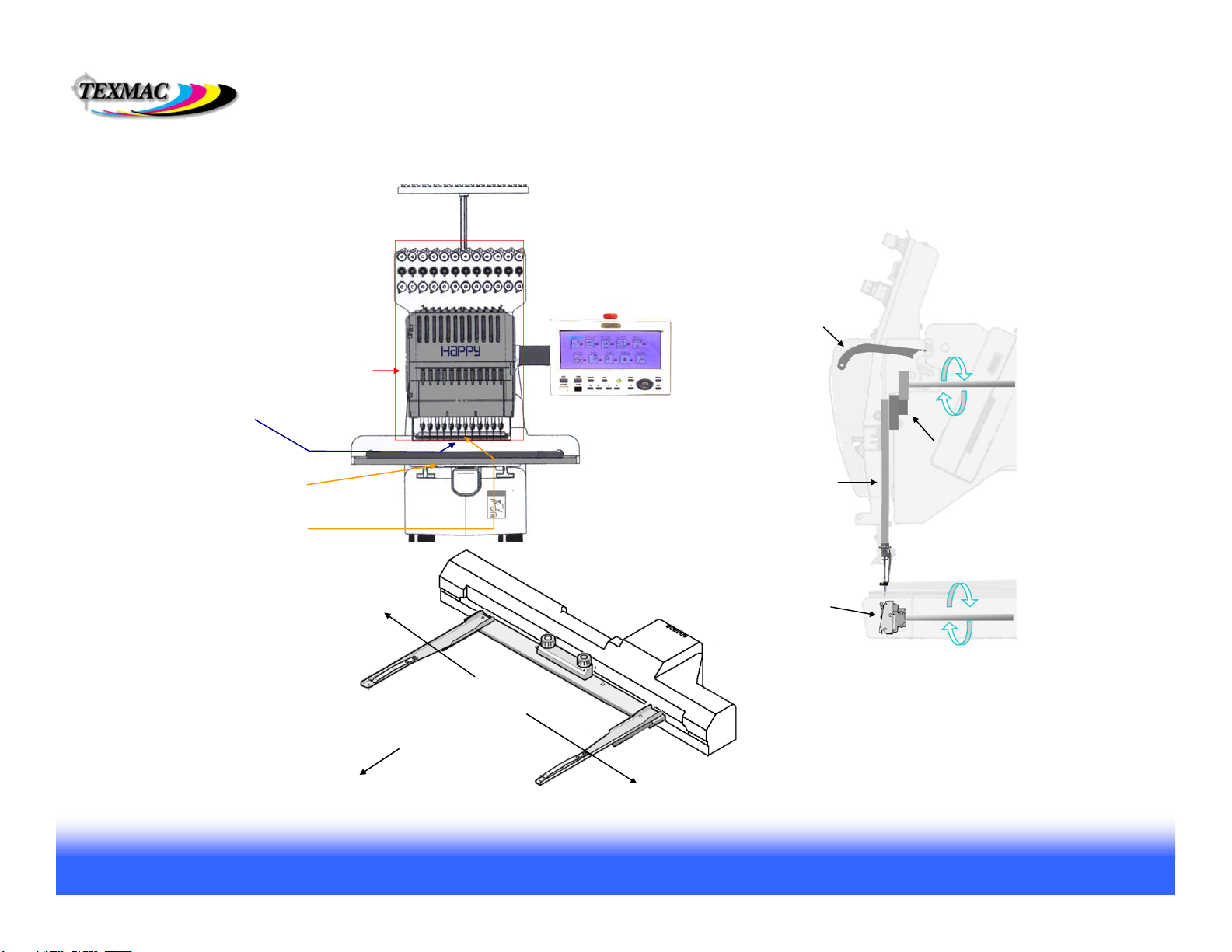

Introduction: A Quick Tour of the Machine

Fuses

power

base

tree

Emergency

Stop Switch

upper-tensioning knobs

thread break sensors

lower tensioning knobs

Main power switch: Press and

hold continuously for 1-2 sec. to

power on

cylinder arm

Rotary hook door /

bobbin cover

Oiling guide/

instructions

Manual needle

selector knob

Table area beneath cylinder arm:: for tubular goods, table or other object

under cylinder arm can provide support for the garment. However, the cap

driver requires that the surface under the arm be at least 4” below level of feet.

X-carriage

tubular arm

Thread posts

Take-up

lever

Safety

Cover

USB jump drive port

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 3

Introduction: 3 key mechanical systems

x-carriage

X-direction

Y-direction

Moving head

Currently selected needle

is the one directly over

the presser foot.

During a thread trim:

(1) Needle descends, and thread is

cut below needle plate between a

fixed & moving knife.

(2) Then, when needle comes back

up, the “catcher” hook grabs the

cut end and “docks” it into the

thread holder.

Side view of machine:

head and sewing arm

take-up lever

rotary hook spins

on lower shaft

needle bar

lower shaft

“crank” cam converts

spinning motion to up-

and-down motion of

needle bar

bobbin sits in basket

of rotary hook

1. Color Change System

Moving head

Thread cut system

2. Sewing System

Take-Up Lever

Needle bar

Rotary hook / bobbin

3. X-Y Pantograph

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 4

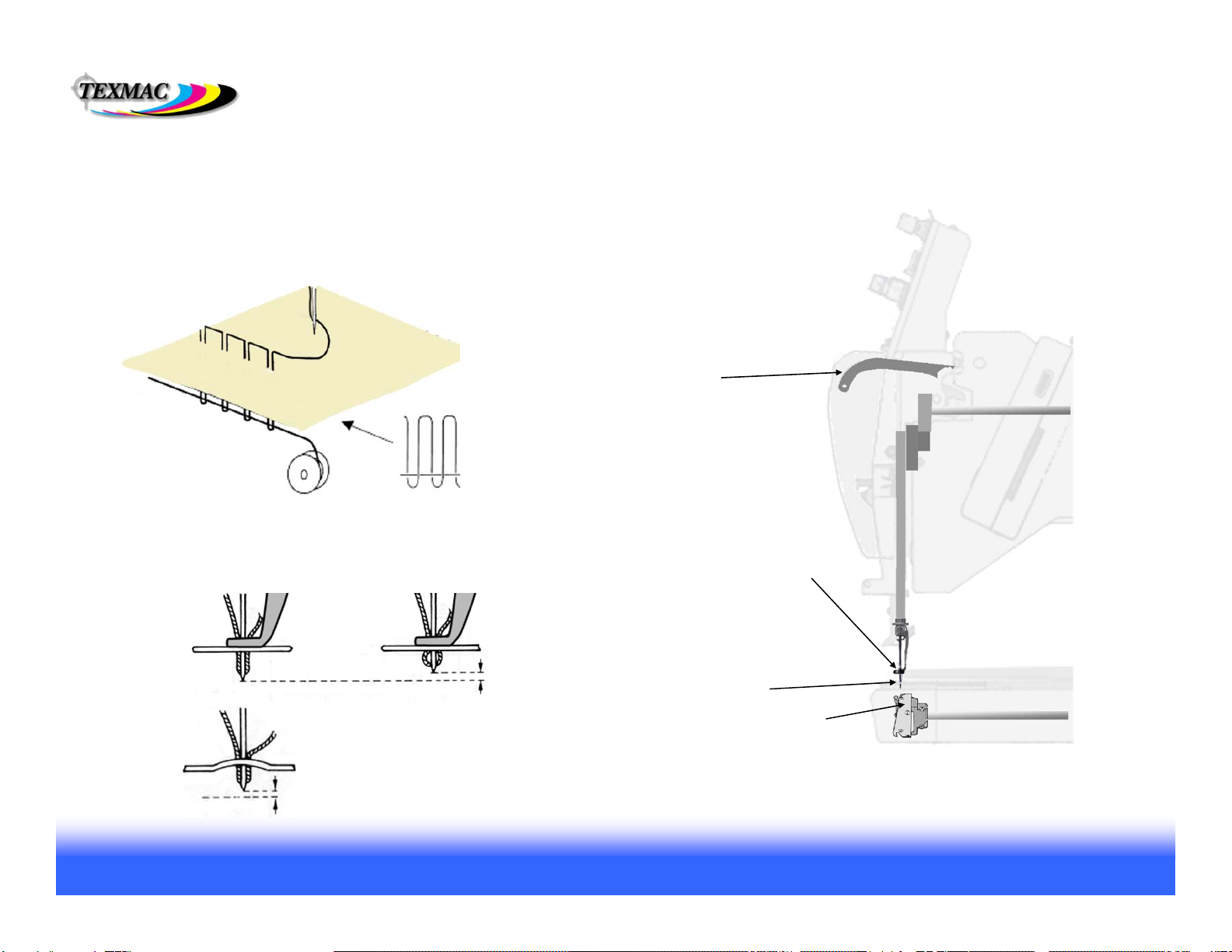

Basics: Lock Stitch Formation (sewing cycle)

bobbin thread

Take Up Lever:

At the start of the cycle, the take-up

lever lowers to allow enough slack

for the loop to form. After the hook

catches the colored thread and makes

the half-twist, it pulls back up to take

up the slack and close the loop to

finish the stitch.

Rotary Hook – spinning point reaches

behind the needle eye, hooks the colored

thread, spins/twists it around the bobbin

thread to form the loop.

Needle – Pushes a half-loop of thread

below the garment surface. Then, as it

starts back up, the slack causes the

loop to open, allowing the rotary hook

(below) to pass behind the needle and

grab the thread.

Presser Foot – presses down on the

garment surface to allow cleaner entry

of the needle. Also remains still as the

needle starts to lift to help the loop

form (see illustration at left.)

Lock Stitch Illustrated.

Notice how the top thread only half-loops with the bobbin

thread for every stitch

How Each Part of the

Cycle Works

The key parts of the sewing

cycle.

Role of the Presser Foot in Loop Formation

Note how the presser foot (shown in grey) helps the loop

open as the needle starts back up.

needle at

bottom needle

coming up

upper (colored)

thread

Without the presser foot, loop

may not form, as material and

thread rises with needle coming

back up.

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 5

Proper Machine Environment

Temperature and Humidity-Controlled Environment

Set up/store your machine in a temperature and humidity-controlled environment to prevent

long-term corrosion and to protect the electronics. Don’t keep your machine anywhere you

wouldn’t keep a laptop or desktop computer !

Clean, Protected Electrical Power

grounded outlets: Your machine uses standard 110v household

current. Be sure you connect it to a grounded 3-prong outlet like

the one shown here. This is standard in most homes and

businesses today, but some older buildings may only have 2-

prong outlets.

Steady Table / Mounting Surface

Your machine will perform better (especially at higher speeds)

when operated on a strong, level and steady mounting surface.

Although on wheels, the optional stand provides plenty of

stability, and even more when the wheels are rotated to their

outermost positions and the brakes are applied at all 4 corners.

surge protection: Protect your machine against occasional power

spikes (from electrical storms or electrical wiring problems) with at

least a basic surge protector. The electronics on your machine

can be very expensive to replace. Higher-end surge protectors

and UPS units are able to protect against higher energy strikes,

and often come with a guarantee.

Basic surge

protector

Standard

3-prong

110v

outlet

Optional machine stand with accessory

shelf, casters and wheel brakes

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 6

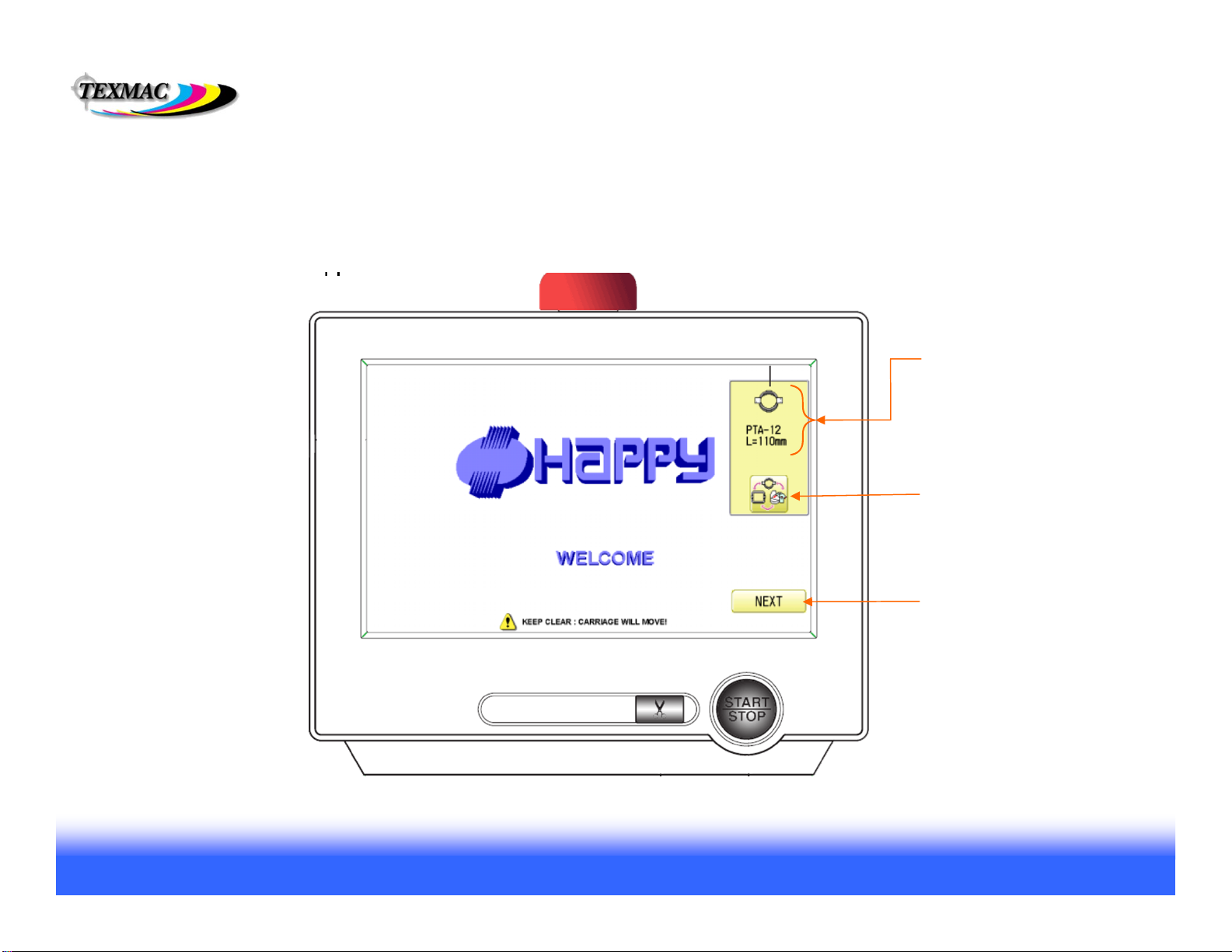

Control Panel Intro: Power On to the Main (Drive) Screen

Power On

Power on your machine with the black switch located on the side of the machine.

The screen below appears.

Press to continue

to the sewing

(drive) screen

Currently Selected

Hoop

Press if you wish to

select a different

hoop.

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 7

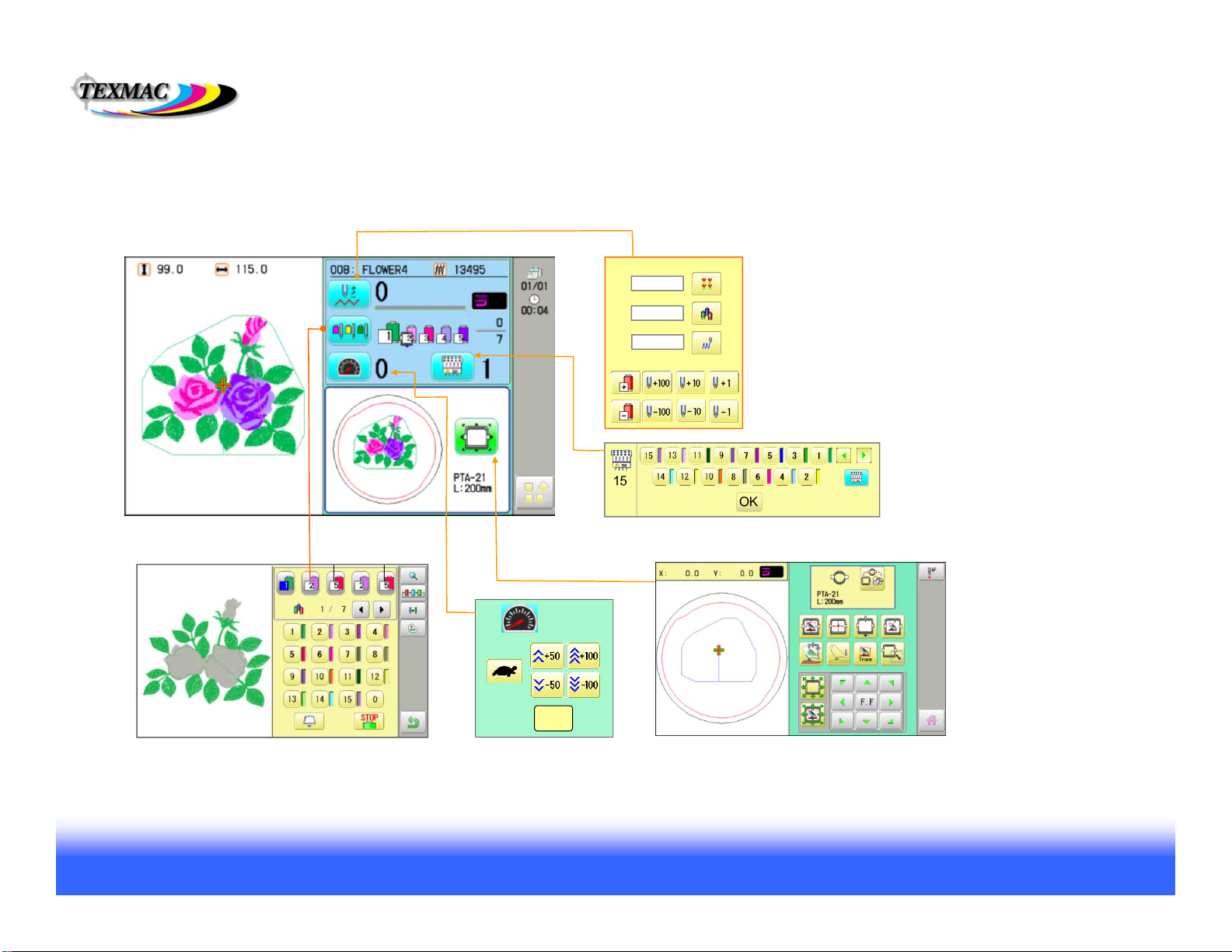

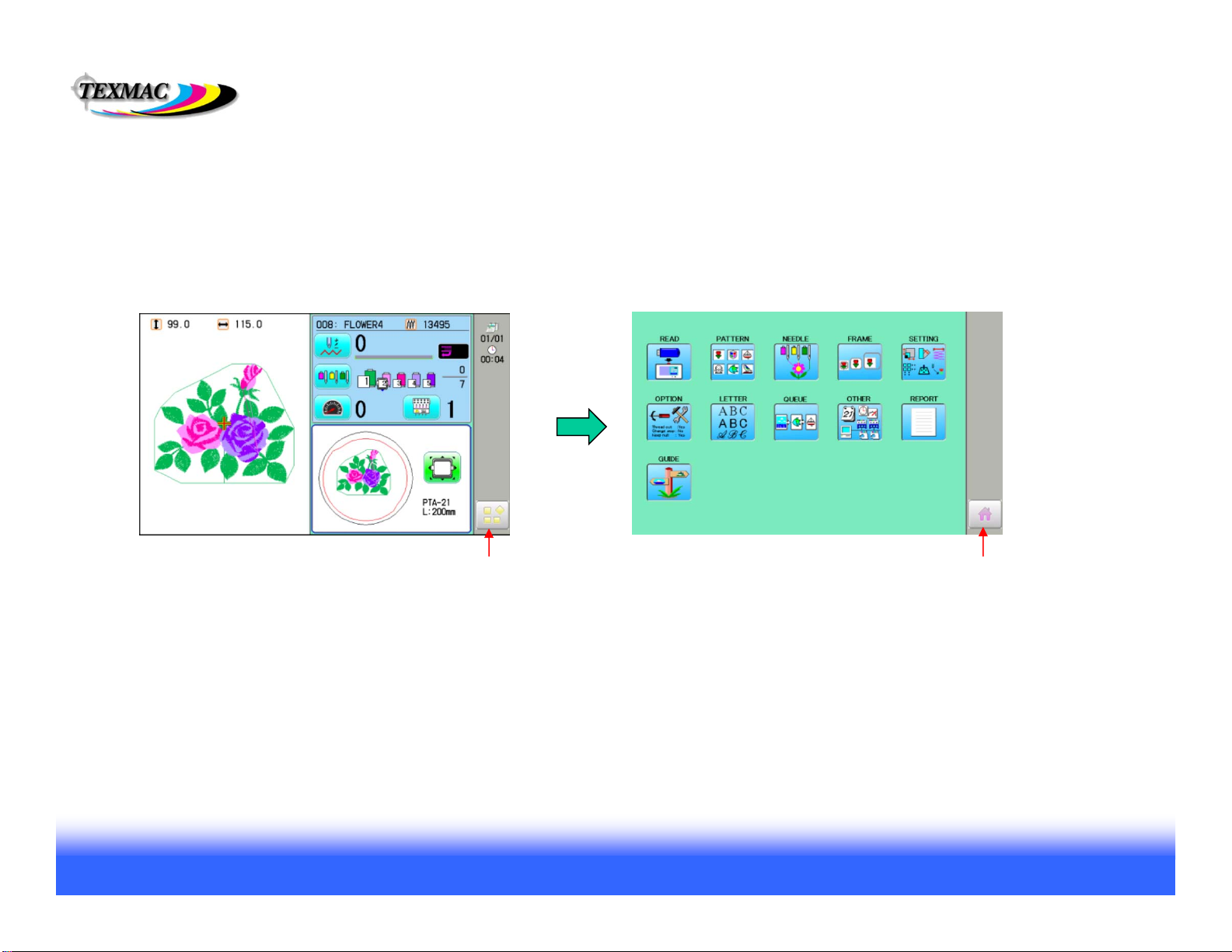

Control Panel Intro: Power On to the Main (Drive) Screen

The Sewing/Drive Screen

This is the main “drive” screen. The machine needs to be in this mode to sew or to accept design transfers

by PC connection. Note the important information shown in the Drive screen here. This is the only screen

where this information is displayed.

-Current stitch position # is 0

-Current color block # is 1

-Current sewing speed is 0

Origin Symbol:

means the sewing

position is at the

origin (beginning).

Current Hoop:

shows what type of

hoop has been

selected.

Design position and fit in the hoop

Lights in green

when the machine

is ready to sew.

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 8

Control Panel Intro: Other Important Screens

Shown below are the important subscreens directly accessible from the Drive screen by a single button:

OK

700

7

1

1

Sewing Position Screen

Jump to any position in the design

using this screen, by piece #, by

color block# or by stitch#.

Adjust Max Speed

During sewout or

while stopped.

Select hoop, Adjust Sewing Position

By selecting the hoop you’re being used, the

machine accurately displays the position in the

hoop.

Set Colors for Current Design

Assign needle (color) numbers, applique

stops, frame out commands in the design.

Needle Selector

Select a different

needle, toggle

jump/drive mode.

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 9

Control Panel Intro: Other Important Screens

Summary of Main Menu Sub-screens:

READ – read in designs from thumb drive or from PC via network cable

PATTERN – view/select/delete/rename etc designs in memory

NEEDLE – set design colors (can be done from Drive screen as well)

FRAME – select hoop (can be done from Drive screen as well)

SETTING – perform basic edits/adjustments to the current design

OPTION – adjust settings for machine, designs and stitch data

LETTER – onboard lettering feature

QUEUE – queue a sequence of designs to be sewn.

OTHER – date/time, network, machine reset, version/update

REPORT – machine production report

GUIDE – onboard help

iCUSTOM – Customize drive screen icons (like a tablet or smart phone)

SCREEN – screensaver settings – select your own images, time, etc.

The Main Menu

The other - and most important - menu is the Main Menu, accessed from the main Drive screen by

pressing MENU as shown below.

Press this menu

button to get to

the main menu.

Press the Home

button to exit to the

main (drive) screen.

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 10

Other Basics

•About Stitches :

–Max and minimum length: Must be between 1mm (.04 inch) and 12.7mm (1/2 inch). Too short causes thread

breaks. Too long, stitches are too loose.

•Major Factors Affecting Sewing Quality that you can control:

–Tension – once properly set, should rarely require re-adjustment. We will cover this in class.

–Hooping – proper hooping is a must. Not too tight, not too loose. We will cover this in class.

–Digitizing – hire a digitizing service and/or learn how to digitize in digitizing classes.

–Machine Adjustments – we will show (Chapter 4) how check key adjustments to maintain performance.

•Sewing file format used in commercial embroidery: DST

– All commercial machines read this format

– Does not have color information – must load the design into the machine AND tell it which colors to sew.

– Limited in editability. Not resized or adjusted easily for different types of garments without compromising

quality.

– Happy machines will also read HAPPY (.TAP) and Melco (.EXP) format.

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 11

Embroidery Thread

•Upper (colored) thread

– Can be polyester or rayon, usually polyester. Standard is 40 weight

– Comes in several sizes: 5,000 meter cones to 1,000 meter cones.

– Handle carefully: physical contact, oil, dust, humidity, moisture can

prevent it from unspooling smoothly, and cause it to “hang up”

– Use thread cone stabilizers (plastic springs) to minimize cone movement

during sewing

•Bobbin thread

– L-type, approximately 350 yards per spool. Bobbin thread will have to

be changed more frequently than upper thread.

– Lasts approximately 25,000 to 60,000 stitches, depending on fabric

thickness, thread tension and other factors.

These stabilizers

help prevent thread

from unraveling or

catching.

Typical 5000

meter “king”

cone of thread

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 12

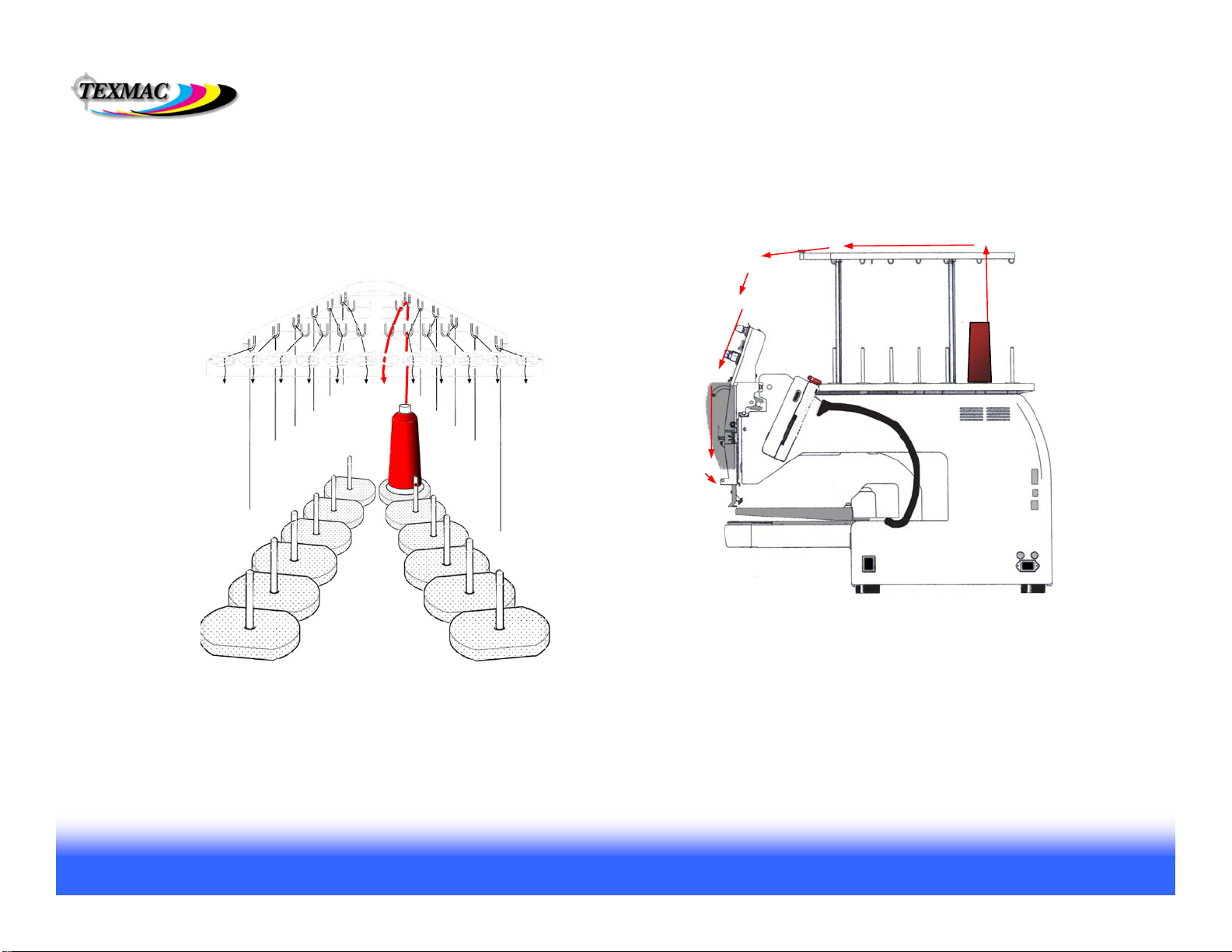

Embroidery Thread

General Thread Path

Thread should be properly, perfectly routed from cone to

needle or it will not feed properly and stop the machine.

Installation of upper thread on your machine

Layout of Cone/Needle Sequence

Needle numbers are arranged right to left, lowest number to highest.

needle 1

needle 2

needle 3

needle 4

needle 5

needle 6

needle 12

needle 11

needle 10

needle 9

needle 8

needle 7

Thread

must not be

allowed to

slack here

or catch.

Thread must

be docked

in the spring

here, not

hanging

loose.

Replacement cones can be tied in here and pulled

through so the thread doesn’t have to be run manually

through the thread path. (See next page)

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 13

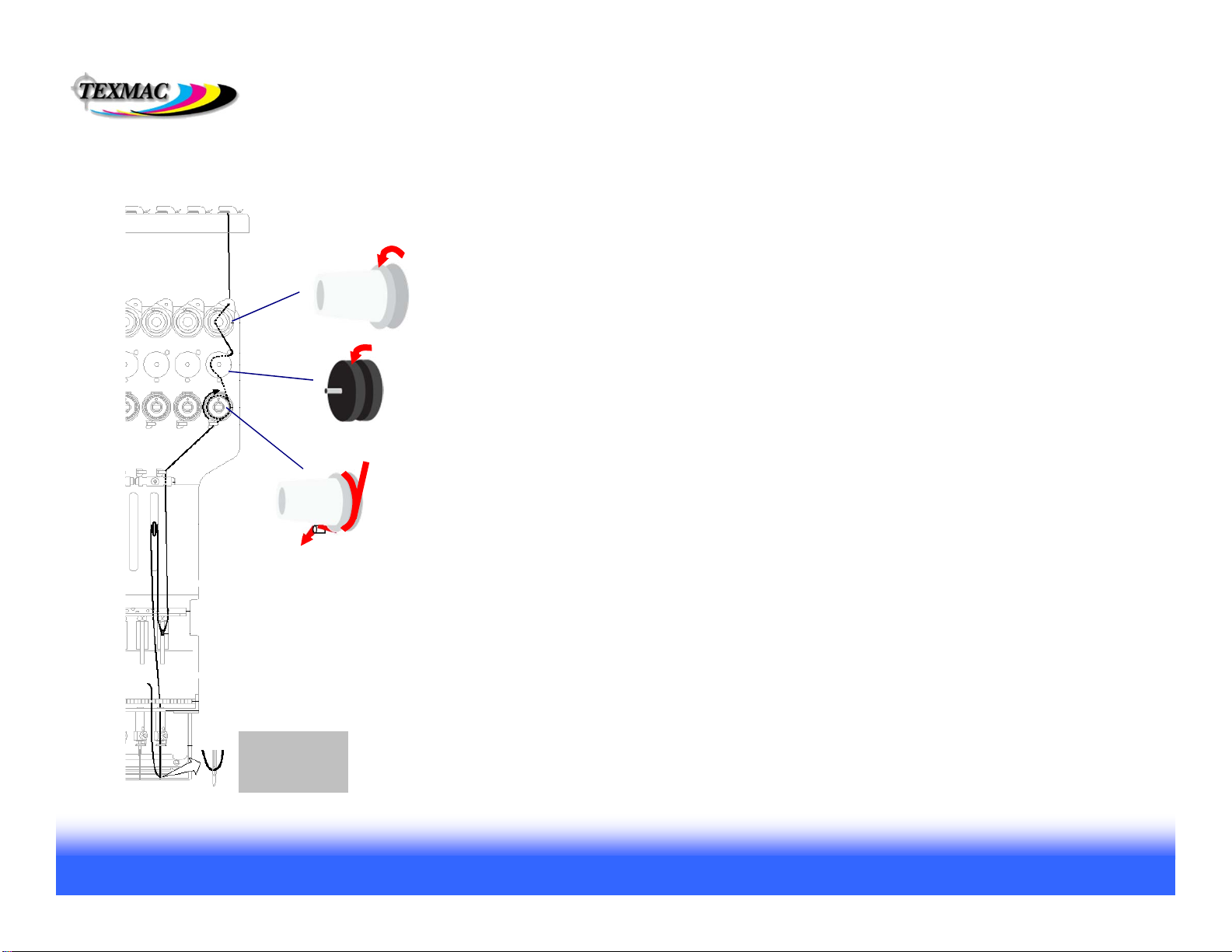

Embroidery Thread

Thread Path through the moving head

-Proper Thread Routing: All threads must be routed

correctly at all points along the path through the sewing

head.

-Practice good thread “Discipline”: After threading all

needles, ensure there is no slack anywhere along the

thread path. Make sure to:

-Pull all threads – to ensure thread feeds smoothly

and turns the break sensor, and all slack is removed

from around thread cones

-“Dock” all thread ends from each needle onto the

thread-holding spring. Prevents thread from coming

loose and catching where not desired.

Upper Tensioner

Thread only makes

½ turn – make sure

it passes to the left

between the 2 metal

discs.

Lower Tensioner

Thread makes 1 full turn

clockwise around the base of the

knob – make sure it runs in the

V-shaped groove of the spoked

wheel.

Thread Break Sensor

Thread this like the upper

tensioner – ½ turn to the left.

Make sure the thread falls in

the groove as shown.

Thread “docked”

in thread

holding spring

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 14

Embroidery Thread

Bobbin Loading and Tension Check/Adjustment

RE-LOADING THE BOBBIN CORRECTLY

The bobbin will need to be replaced frequently, allowing only 30,000 to 60,000 stitches per

spool. This has to be done correctly every time.

1.Ensure bobbin turns

clockwise. Pull thread

through this slit.

2. Feed thread through

eye at the end of the

tension flap.

4. Pass thread through the

wire loop at the top front of

the bobbin case. Do this

after you’re satisfied with

tension, and before

inserting into the machine.

1. Hold the bobbin case as shown in step 3, after feeding the thread through

the eye at the end of the tension flap.

2. “Cast” the bobbin case downward gently, very much like throwing a yo-yo.

3. Good tension: Upon stopping your hand, the slight downward momentum of

the bobbin case should cause it to unspool and continue downwards slightly

and stop. (If downward motion of your hand causes the bobbin to jump out of

the case, try again but more gently).

4. Wrong tension: If the bobbin doesn’t unspool at all, tension is too tight. If the

bobbin unspools on its own when held like in step 3, tension is too loose.

Make adjustments if needed as shown on the right.

With a working bobbin case and a properly loaded bobbin, this test reliably

tests to 25g on a bobbin tension gauge, precise within 1g. Perform this quick

check each time you re-load the bobbin until you are comfortable with tension. 5. TAKE CARE TO RE-INSERT THE RELOADED

BOBBIN CASE FULLY after re-loading or the machine

will not function correctly.

CHECKING TENSION WITH THE “DROP” TEST.

Make small adjustments if

you find it necessary. – no

more than a ¼ or ½ turn in

either direction before re-

checking tension.

3. Check tension with the

“drop” test (explained

lower left).

Training Workbook: HAPPY HCS2-1201 Voyager Operation and Maintenance

Education Department

Chapter 1: Introduction and Basics 15

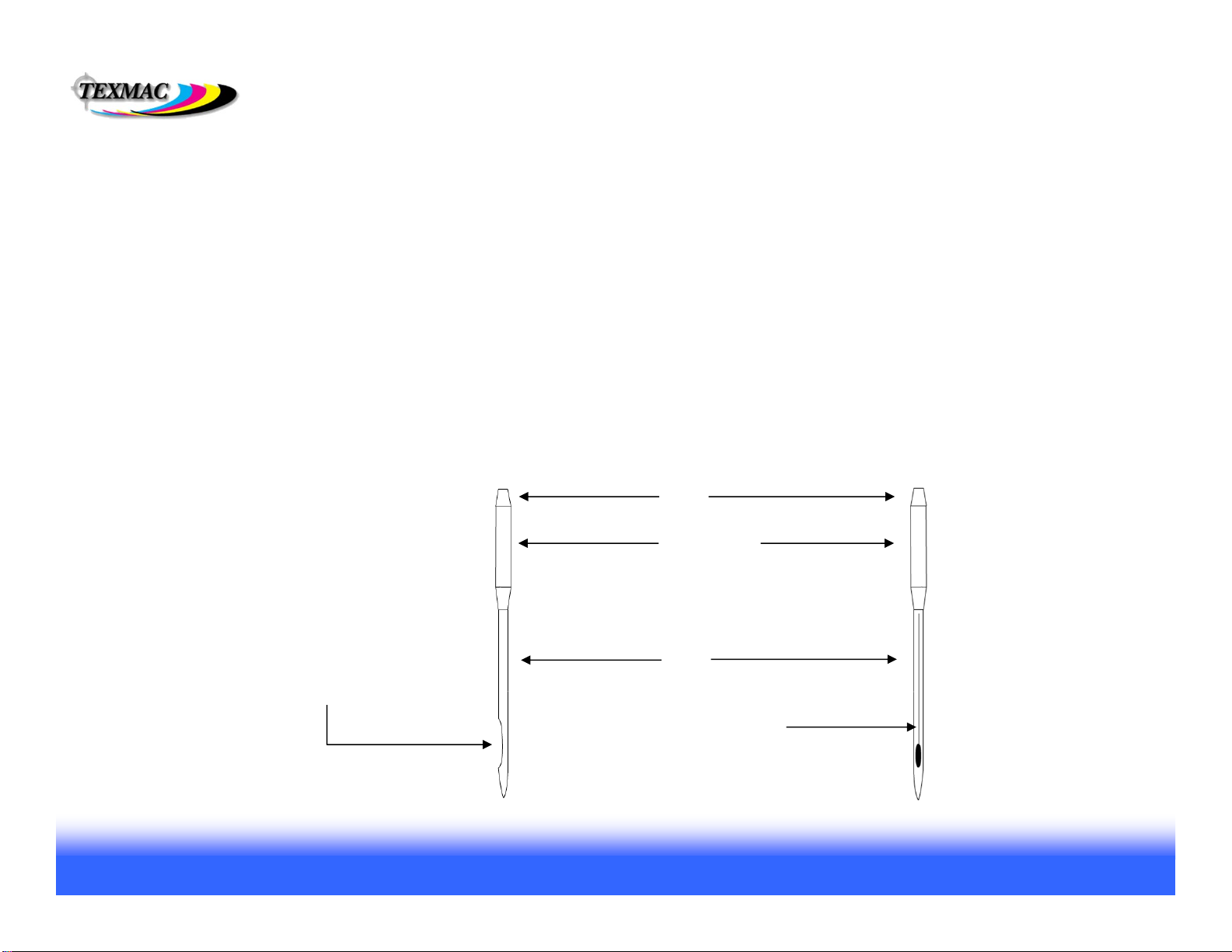

Embroidery Needles

Shank –

rounded. Does

not have a flat

spot

butt

blade or

shaft

Groove – allows you to find the

front of the needle by feel.

Scarf – faces towards the back

of the machine

–Type DB-K5, standard size is 75/11 ballpoint for most applications. Alternate needle for

sewing caps and other tightly-woven goods (heavy canvas) is 80/12 sharp point for better

penetration

–The width of the shaft of an embroidery needle limits the the finest possible detail (the

smallest possible stitch). Standard size (75/11) needles are .75 mm across, so stitches must be

at least a little wider than the hole that the needle punches in the fabric (minimum distance

1mm)

–Needles are subject to wear! Over time, burred surfaces and other wear can cause problems.

Be prepared to change needles frequently especially with heavy use.

Side

view

Front

view

Table of contents

Other Happy Sewing Machine manuals

Happy

Happy HCD Instruction sheet

Happy

Happy HCH User manual

Happy

Happy HCH Series User manual

Happy

Happy HCH-701 User manual

Happy

Happy HCS2-1201-30 User manual

Happy

Happy HCH User manual

Happy

Happy HCS User manual

Happy

Happy HK634020XB User manual

Happy

Happy HCG Series User manual

Happy

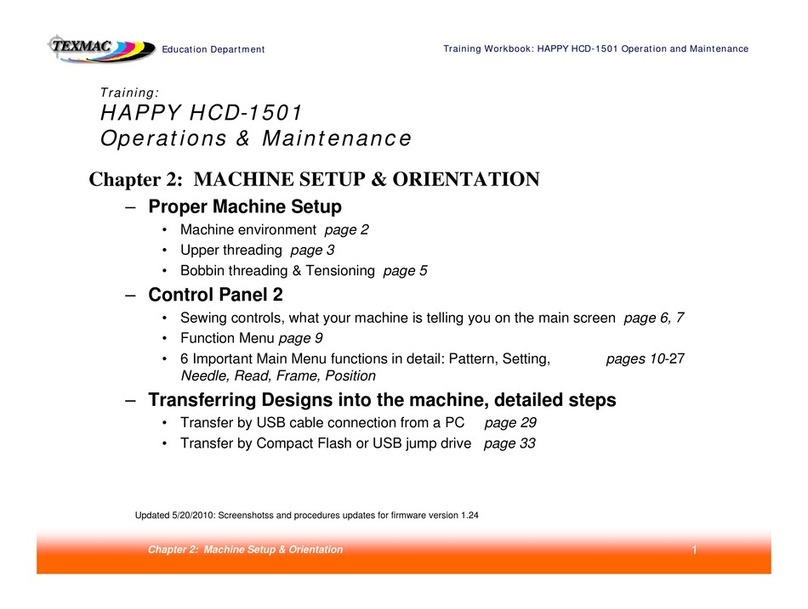

Happy HCD-1501 Installation guide

Popular Sewing Machine manuals by other brands

Pfaff Industrial

Pfaff Industrial POWERLINE 2231 Adjustment manual

Leather Machine

Leather Machine COBRA CLASS 3 MAINTENANCE AND TIPS

Janome

Janome MC 200E - brochure

Duerkopp Adler

Duerkopp Adler 510 operating instructions

Singer

Singer 4843116 instruction manual

Baby Lock

Baby Lock Katherine BL210A Getting to know