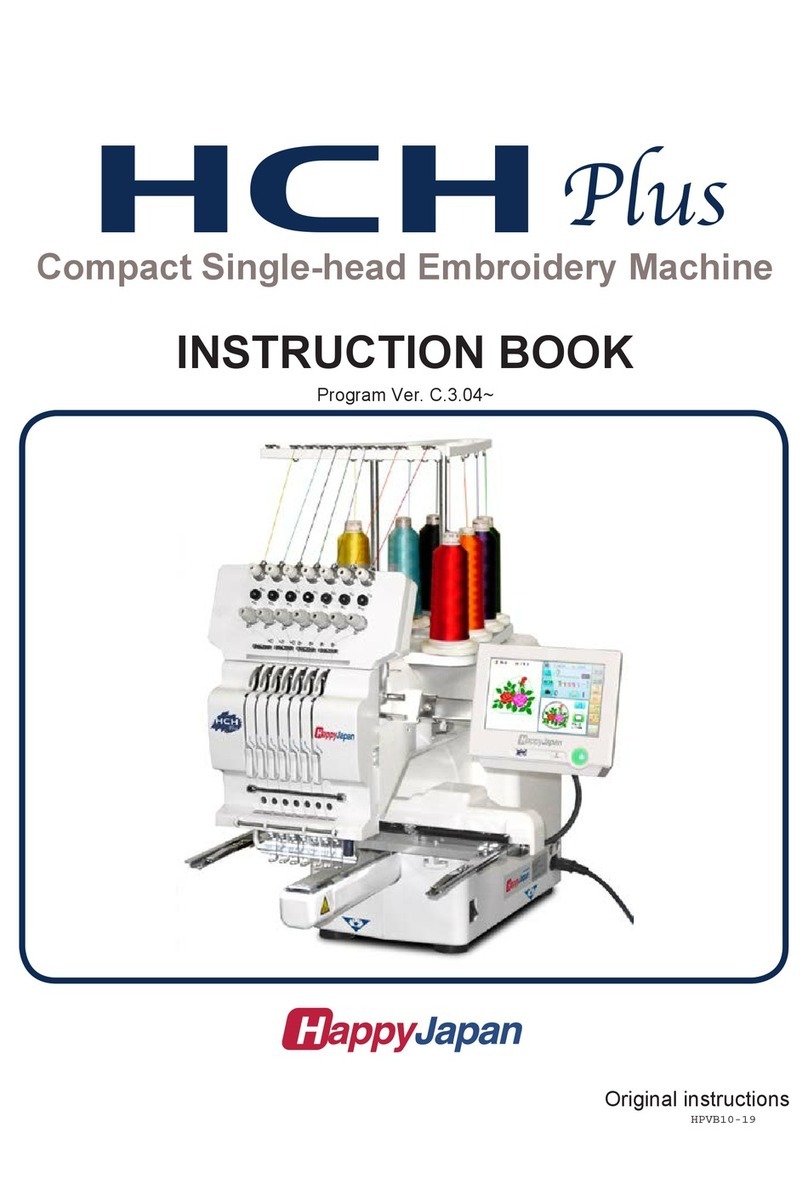

HappyJapan HCH(Puls) User manual

FCRC20-4

HCH(Puls)

,HCS2,

HCD2,HCD3

Side Clamp Frame

INSTRUCTION MANUAL

Program Ver. *1.60 ~

IMPORTANT SAFETY INSTRUCTIONS

Use this Manual together with Instruction Manual of embroidery machine for mounting this appliance and for

operating.

Use this appliance only for its intended use as described in this manual. Use only attachments recommended

by the manufacturer as contained in this manual.

Keepngersawayfromallmovingparts.Specialcareisrequiredaroundthesewingmachineneedle.

Do not pull or push fabric while stitching. It causes damage.

Do not modify this appliance.

SAVE THESE INSTRUCTIONS

0

-FC -2

INDEX

BASICINFORMATIONOFSIDECLAMPFRAME .. 1-1

ACCESSORIES........................................................ 1-2

ADJUSTMENTOFEMBROIDERYAREA................ 2-1

ADJUSTMENTOFUPPERARM ............................. 2-2

INSTALLINGTHEFRAME ....................................... 3-1

HOOPINGMATERIAL.............................................. 4-1

STARTINGTOEMBROIDER ................................... 5-1

ETC.

EXCHANGESPONGEANDSHEET..................... 6-1

PARTSLIST ............................................................. 7-1

0_1 PB19

0-1

-FC -31_1 PB19

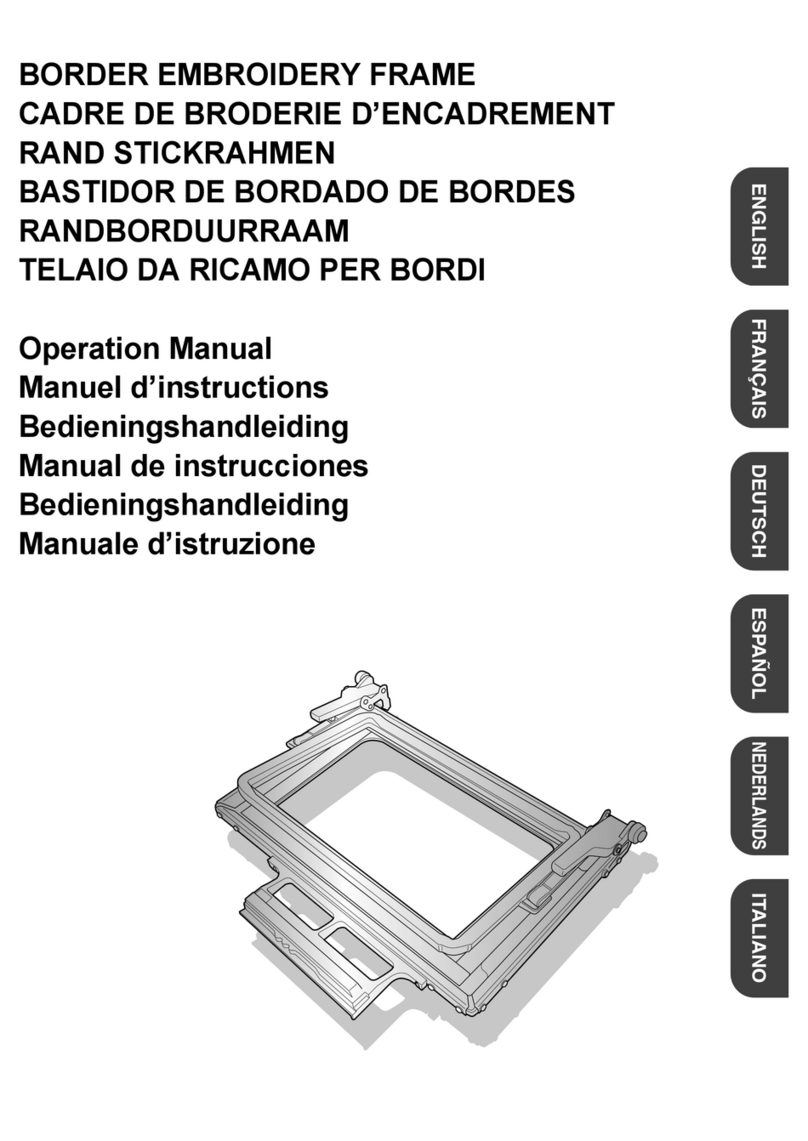

BASIC INFORMATION OF SIDE CLAMP FRAME 1-1

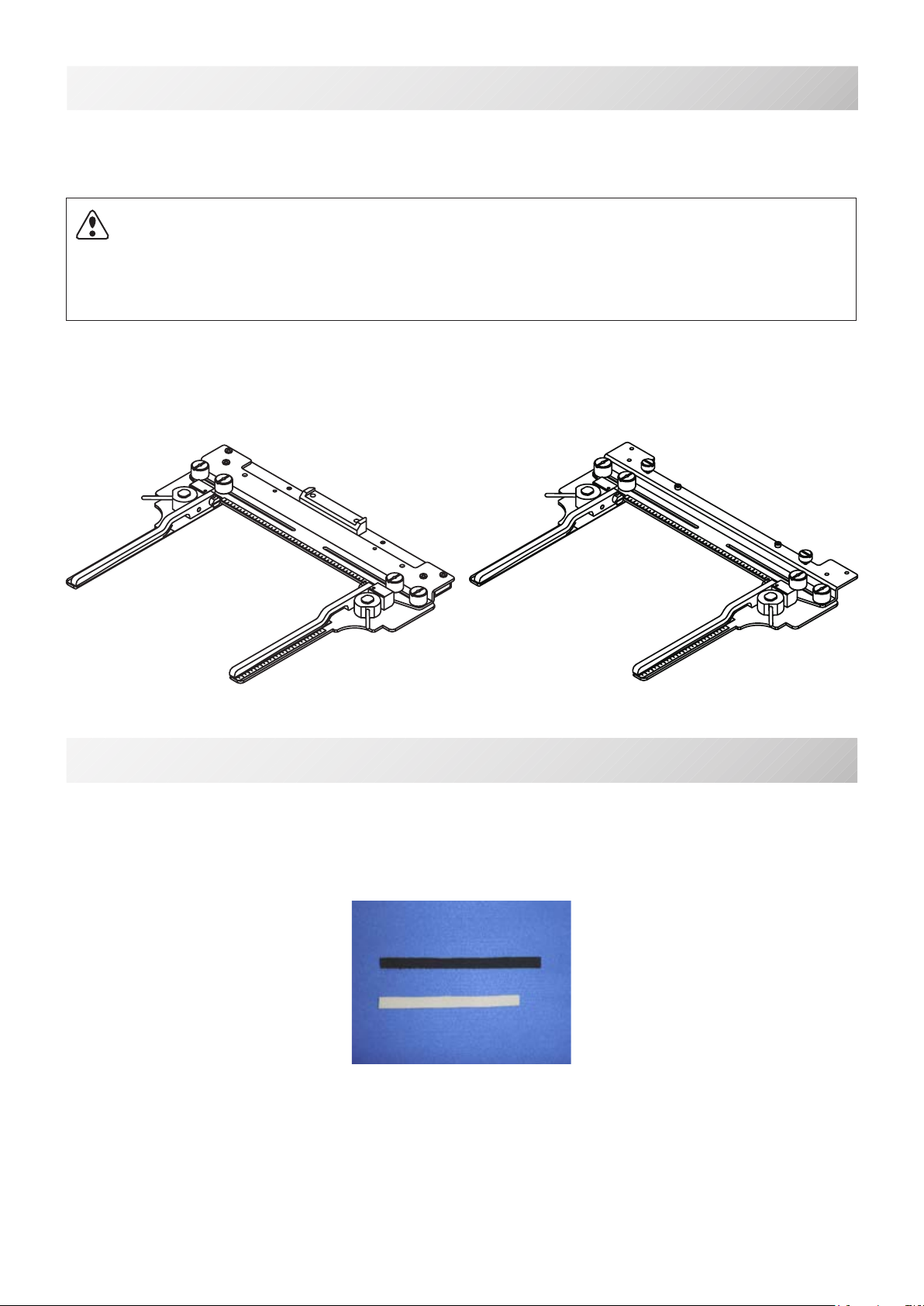

The types of side clamp frame are described below.

Use correct type of side clamp frame for your embroidery machine.

FRA21G0

Side Clamp Frame (for HCH, HCS2)

FRA21G1

Side Clamp Frame (for HCD2, HCD3)

CAUTION: To avoid problems.

To use side clamp frame , select “Special frame” from frame selection menu.

Please note that the following functions will be canceled at “Special Frame” mode.

* Frame conrmation (embroidery area of frame)

* Auto stop function when frame movement exceeds the carriage limit.

1-2

ACCESSORIES

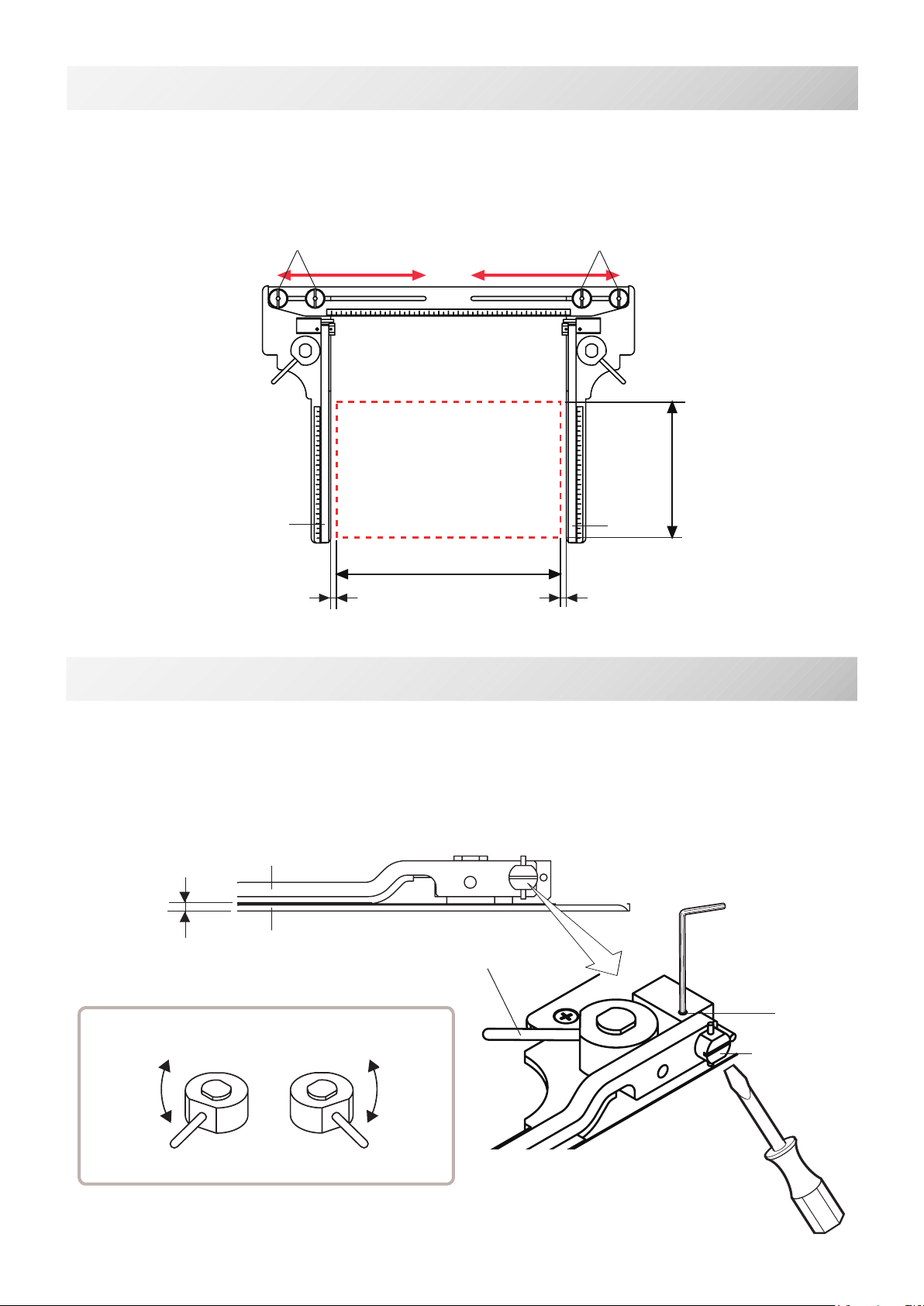

FRA21181 Sponge (2 pcs)

FRA21191 Sheet (2 pcs)

(packed with frame)

-FC -4

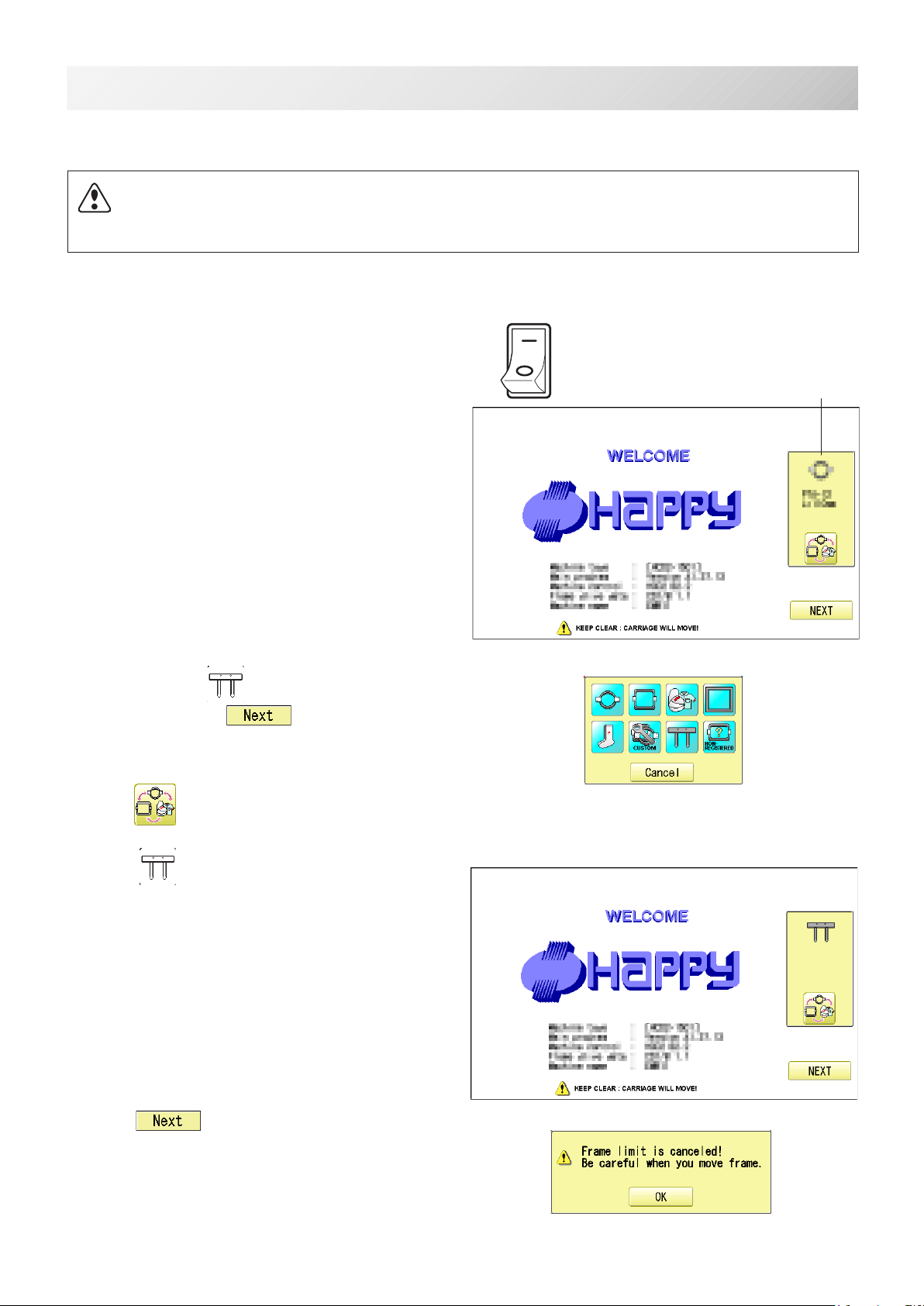

ADJUSTMENT OF EMBROIDERY AREA 2-1

Adjust width of the upper arm to meet size of material and embroidery design.

Widthofthearmshouldhaveenoughmarginsforembroideryarea.

Loosenbothsideknobnutsforadjustmentofarm.

Tightenallknobnutsafteradjustment.

Knob nut

Arm

0 ~ 220mm

140mm

Knob nut

2_1 PA13

Pleasenotethatbasicallytheupperarmandthelowerarmshouldbeparallelatlockingposi-

tion.

Incasethethicknessofthematerialisuneven,useadjustingsetscrewandeccentricpinto

changeangleoftheupperarmtogiveholdingpressureevenly.

Lowerarm

Setscrew

Eccentricpin

Upper arm

Parallel

2-2

ADJUSTMENT OF UPPER ARM

Open

Close

Open

Close

RightLeft

Lever

Arm

5mm ~ 5mm ~

-FC -5

3-1

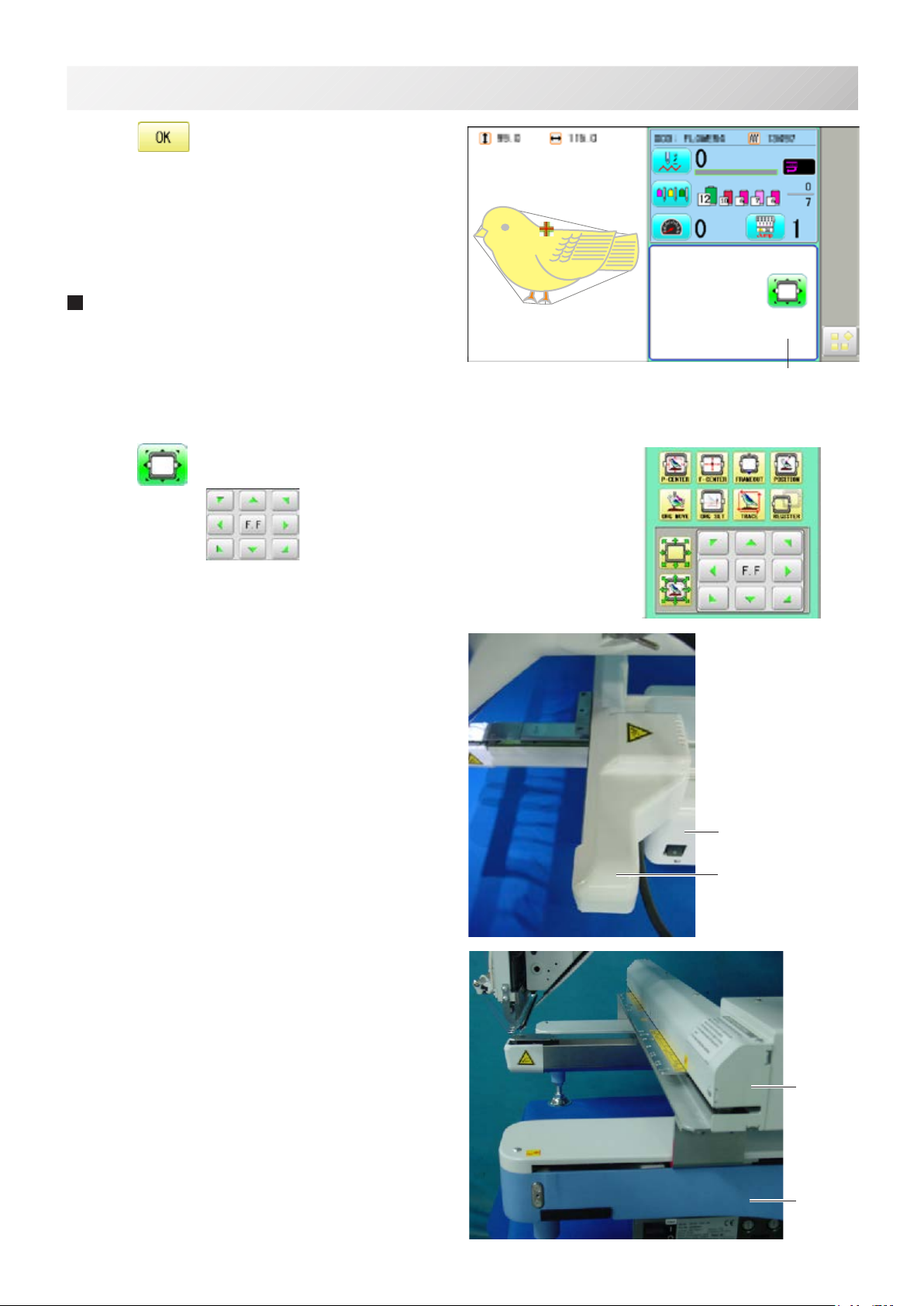

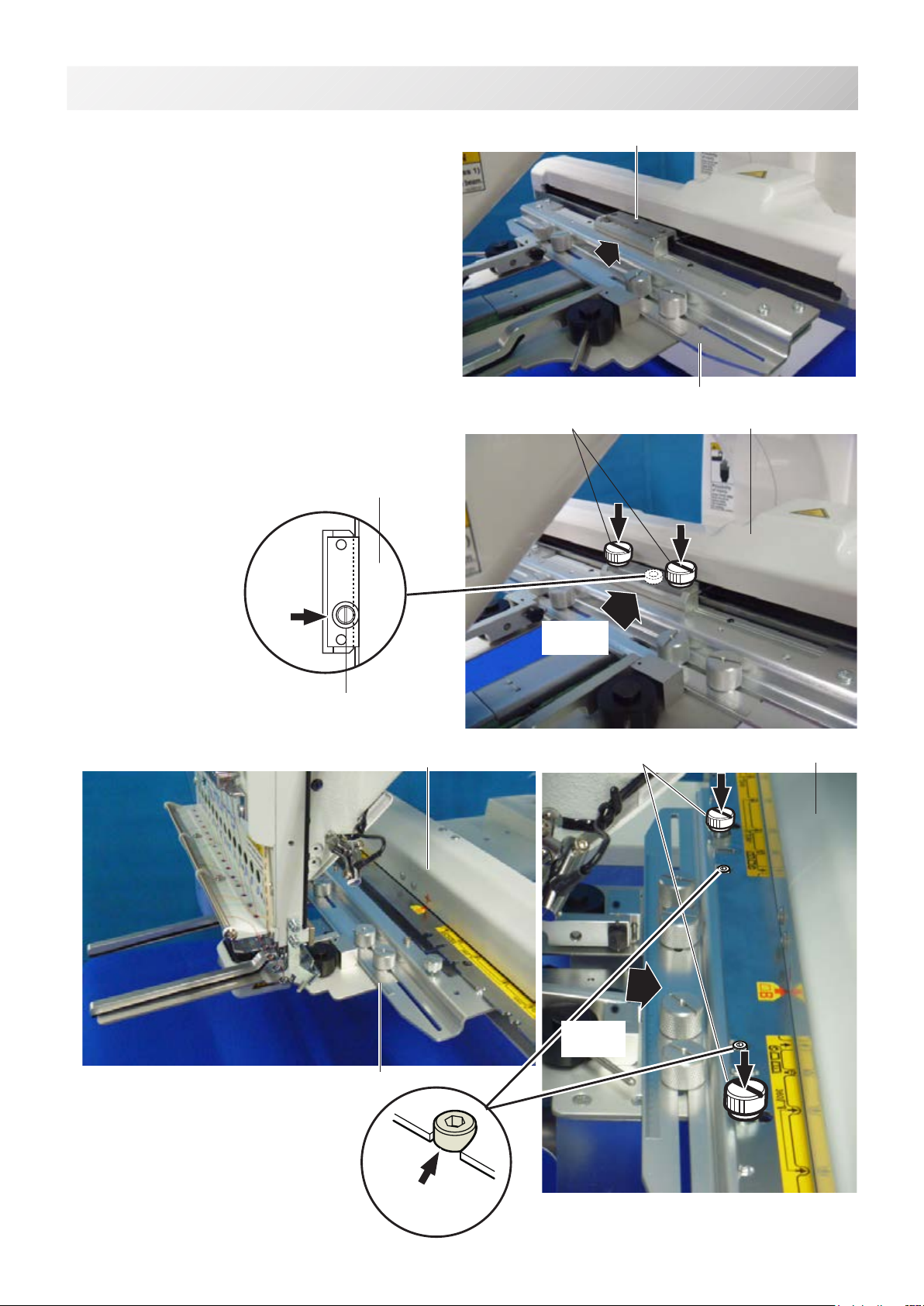

INSTALLING THE FRAME

Whenyouusesideclampframe,pleasemakemachinesettingaccordingtoframetypeselected.

CAUTION: To avoid problems.

Themachineand/orframemaybedamagediftheincorrectframesettingsareused.

ON

OFF Selectedframe

1. Turnonthepowerswitch.

Indicates the selected frame.

2. Incaserequired “Specialframe”isalready

selected,pressthe and jump to operation

no.4.

Incaseselectedframetypeisnot“Specialframe”,

press .

3. Select “Specialframe”.

4. Press .

3_1 PA13

-FC -6

3-2

INSTALLING THE FRAME

5. Press .

Iindication of frame type disappears.

It means that “Special frame” is selected.

When you need to change from Special frame to oth-

er type of frame, please powor machine off and start

again.

Without re-starting machine, machine will move in-

correctly.

6. Press and move the carriage to the position

shown by press .

Frame Iindication disappears

HCD2,

HCD3

HCH, HCS2

3_2 PA13

Machine

Carriage

Machine

Carriage

-FC -7

3-3

INSTALLING THE FRAME

7. Insertshoeframetobelowthexingbaseof

carriage by sliding on bed.

Fixknobscrewsashittingthebearing

against the carriage while pressing the side

clamp frame to the carriage.

HCD2, HCD3

HCH, HCS2

Carriage

Knob screw

Fixingbase

Side clamp frame

Carriage

Knob screw

Fixingbase

Side clamp frame

3_3 PA13

Pushing

against

Positioning bolt

Pushing

against

Bearing

Carriage

-FC-8

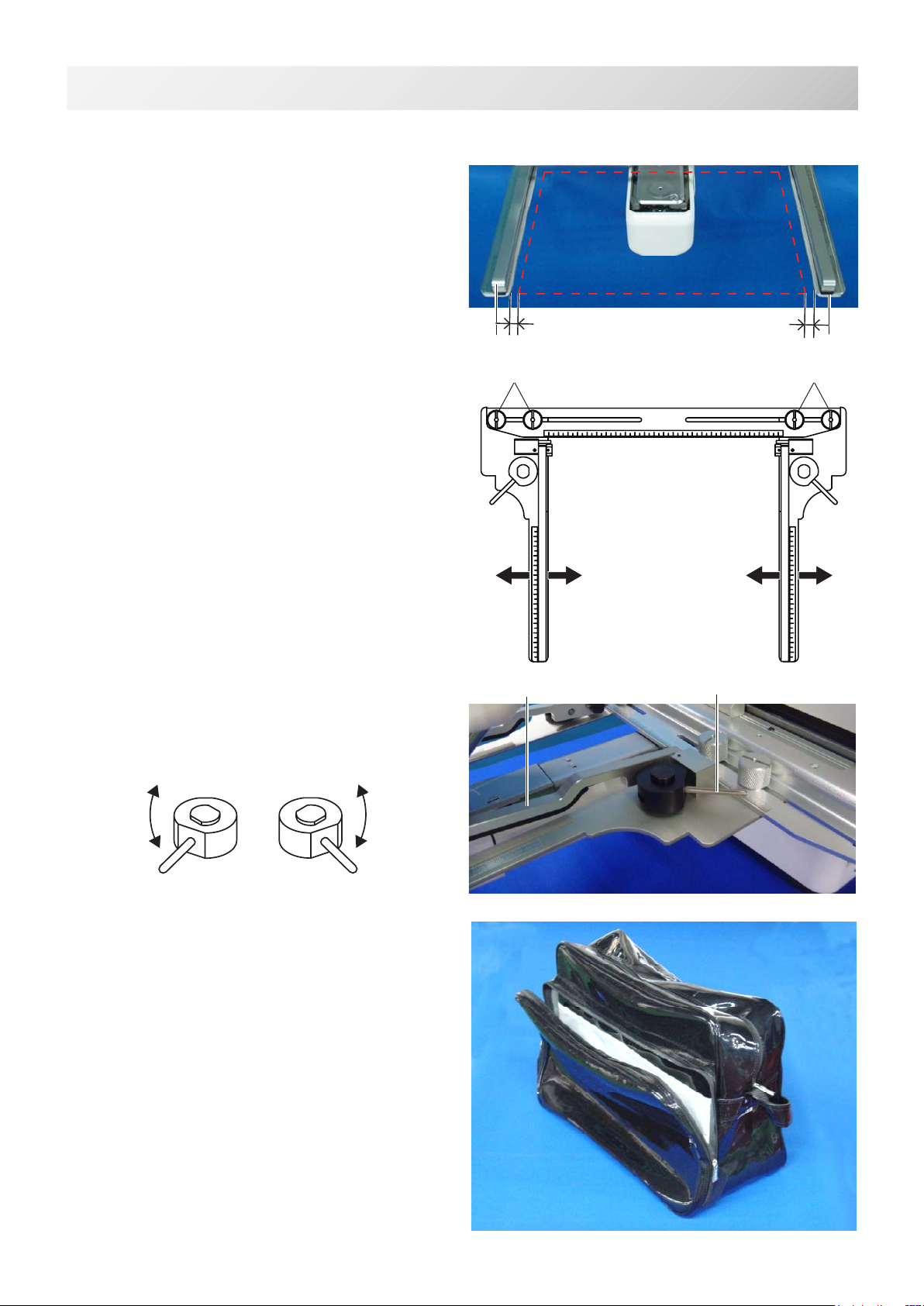

4-2

HOOPING MATERIAL

Lever

1. Adjust width of the arm to meet size of ma-

terial and embroidery design.

Widthofthearmshouldhaveenoughmar-

gins for embroidery area.

Loosenbothsideknobnutsforadjustment

of arm.

Tightenallknobnutsafteradjustment.

2. Turnrightandleftlevertoopentheupper

arm.

3. Takeoffallremovablepartslikeinsoleto

reduce weight of the bag.

Openallsidezipperstokeepthematerial

exible.

Upper arm

Knob nut Knob nut

Arm Arm

Thefollowingisanexampleforbagembroidery.

4_1 PA13

Open

Close

Open

Close

RightLeft

5mm ~ 5mm ~

-FC -9

4-2

HOOPING MATERIAL

4. Turnrightandleftlever,thenthebagwillbe

locked.

Pleasemakesurethatthematerialinsideof

embroideryareaissetat.

Pleasealsocheckthatnohardmaterial

likemetalhookislocatedintheembroidery

area.

Edgeofbagshouldbesetinthespacebe-

low upper arm.

Ifthebagistooheavy,usesupporttableto

preventthearmfromslantingdown.

4_2 PA13

Embroideryarea

Spacebelowupperarm

Lever

Table (HCS2)

-FC -10

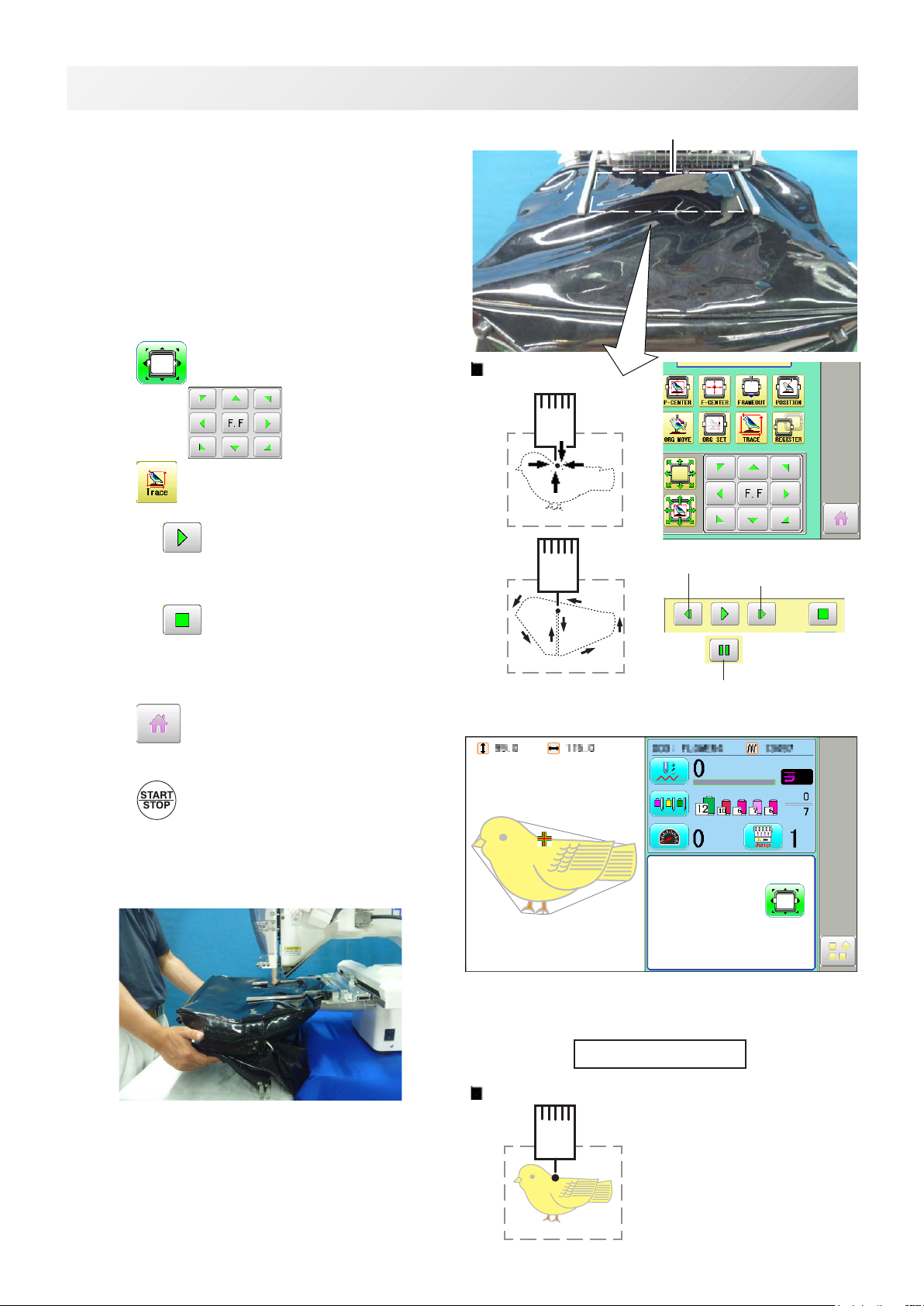

5-1

STARTING TO EMBROIDER

:Originalpoint

(Startpoint)

1. Press andmovetheframetotheoriginal

point with the .

2. Press .

Press ,andtheembroideringframemoves

for the design trace.

Youcanconrmoutlinetraceandthepositionof

the design.

Press ,andtraceisstopped.

Goontostep4ifyouwanttostartembroidering

without tracing.

3. Press after the trace is completed.

Theembroideringframehasmovedtotherst

stitch point of the pattern.

4. Press .

Theembroiderywillstart.

Handsupportisalsohelpfulwhenthearmis

slanted down due to weigh of the bag.

5. Afterembroideringyourdesigniscomplete,show

“>>End”andthemachinewillstop.

Theembroideryframereturnstotheoriginal

pointautomaticallyifthe“Autoorigin”function

hasbeenactivated.

:Originalpoint(Startpoint)

Forward only when pressing

Backwardonlywhenpressing

Youcanconrmtheoutline

and position of design.

>>End

Embroideryarea

5_1 PA13

(HCS2)

Pause button

-FC -11

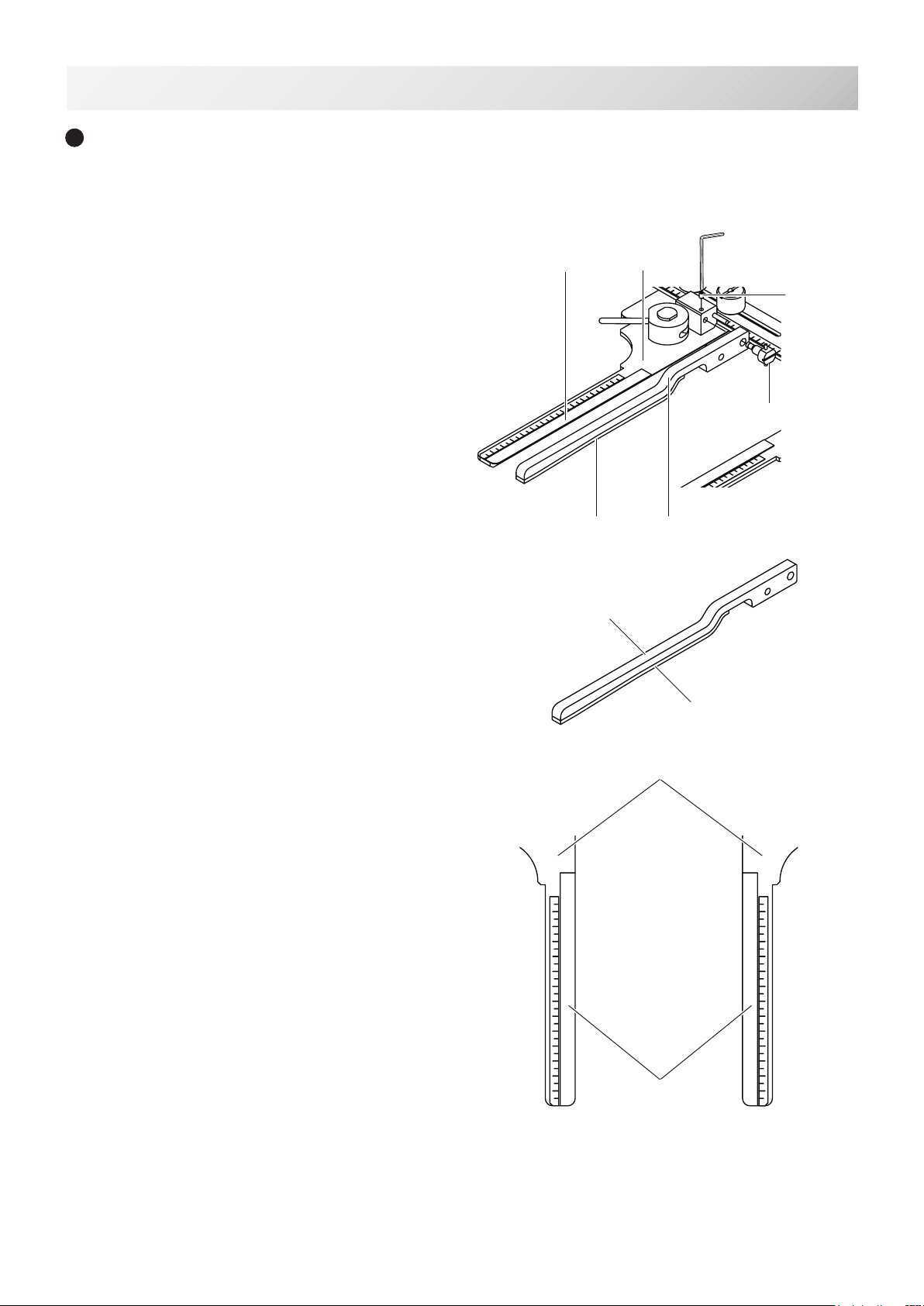

6-1

ETC.

EXCHANGE SPONGE AND SHEET

Spongeandsheetarelocatedundertheupperarmandonthelowerarmtoholdfabricrmly.

Whenspongeorsheetarewornordamaged,pleaseexchangespongeorsheet.

1. Removethesetscrewanddisassemblethe

eccentric pin.

2. Removetheupperarm.

3. Removethespongeorsheetfromthe

upper arm or the lower arm.

4. Attachthespongetotwiththeedgeof

the upper arm as shown.

5. Attachthesheettotwiththeedgesofthe

lower arm as shown.

Cuttotaroundthecorner.

4. Inthereverseorderofdisassembling,x

the upper frame by screw.

Afterxtheupperframe,adjusttheupper

frameinaccordancewith“ADJUSTMENT

OFUPPERARM2-2”.

Rightside Eccentricpin

Setscrew

Upper armSponge

Sheet Lowerarm

Sheet

Upper arm

Sponge

Lowerarm

6_1 PB19

I

17

19

I

22

23

J

20

J

22

21 I

21

1

2

24

K

15

13

12

9

10

4

B

3

16

16

A

15

14

12

10

5

25

11

HCH, HCS2 HCD2, HCD3

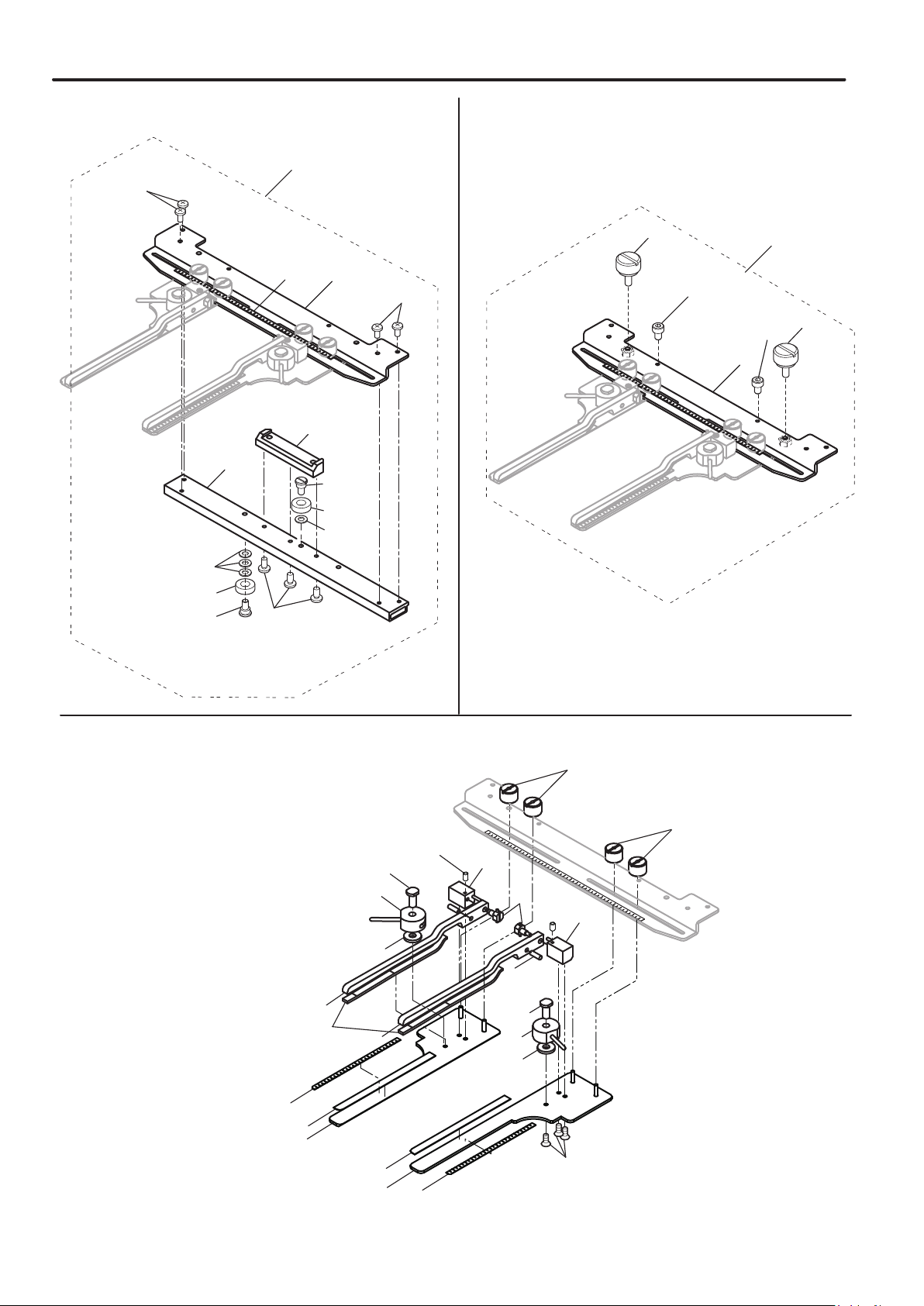

SIDE CLAMP FRAME 7-1

FCPA13

7

18

24

K

25

5

6

8

SIDE CLAMP FRAME サイドクランプ枠 7-2

指図 部品番号 部品名 FCPA15 備考

Ass'y El't Parts No. Parts Names Note

1FRA21G0 Side clamp frame ass'y (for HCH, HCS2) サイドクランプ枠組(HCH, HCS2用)

2FRA21G1 Side clamp frame ass'y (for HCD2) サイドクランプ組(HCD2, HCD3用)

3FRA21I00 Lower arm long ass'y (right) 下アームロング組(R)

4FRA21I10 Lower arm long ass'y (left) 下アームロング組(L)

5FRA21191 Sheet long 滑り止めシートロング

6FRA21F40 Fulcrum block (right) ass'y 支点ブロック(R)組

7FRA21F50 Fulcrum block (left) ass'y 支点ブロック(L)組

8FRA21I20 Upper arm long ass'y (right) 上アームロング組(R)

9FRA21I30 Upper arm long ass'y (left) 上アームロング組(L)

10 FRA21181 Sponge long 滑り止めスポンジロング

11 FRA21F60 Eccentric pin ass'y 偏心ピン組

12 MPZ04730 Washer 金属ワッシャ

13 FRA21F20 Cam (right) ass'y 溝カム(R)組

14 FRA21F30 Cam (left) ass'y 溝カム(L)組

15 FRA21340 Shaft シャフト

16 FRA21102

Knob nut

ノブナット

17 FRA21152 Connecting plate 靴枠連結板

18 FRA21B51 Connecting plate ass'y 靴枠連結板組

19 FRA21200 Scale sticker A (250mm) メモリテープA

20 HCB40041 Screw ベアリング止めネジ

21 HCB40121 Arm 連結アーム

22 HCB40132 Bracket 取付け板

23 MPB00250 Bearing (L1680ZZ) ミニチュアベアリング

24 HCD37092 Knob screw ノブネジA

25 FRA21210 Scale sticker B (140mm) メモリシールB

ASGAK04010 Flat head screw (phillips, M4x10) 十字穴付き皿小ねじ (M4×10)

BSSAA03005 Hex socket screw (M3x5) 六角穴付き止めねじ (M3×5)

ISBBK04008 Bind head screw (phillips, M4x8) 十穴付きバインド小ねじ (M4×8)

JSCAD04006 Hex socket head cap screw (M4x6) 六角穴付きボルト (M4×6)

KWPAD05000 Plain washer (M5)

平座金 (M5)

OA01E

HEAD OFFICE 3-3515, Tachiyagawa, Yamagata-city, 990-2251, Japan

Phone: +81-23-686-2272 Fax: +81-23-686-2243

TOKYO OFFICE 2-9-5, Taito, Taito-Ku, Tokyo 110-0016, Japan

Phone: +81-3-3834-0711 Fax:+81-3-3835-8917

Other manuals for HCH(Puls)

1

This manual suits for next models

3

Table of contents

Other HappyJapan Sewing Machine manuals