Hardinge FlexC Low Profile Dead-Length Collet System Style... Datasheet

1

65mm FlexC™ Collet System Style DL Instructions B-177

Hardinge Inc. One Hardinge Drive, Elmira, New York U.S.A. 14902-1507 800.843.8801 www.ShopHardinge.com

Part No. B 00095000177

Hardinge FlexC™ Low Prole

Dead-Length®Collet System

Style DL — 65mm

Installation Instructions and Parts Lists

GENERAL SAFETY INFORMATION

Before installing the Hardinge®FlexC™Collet System on your

machine tool, thoroughly read this manual and understand the

information. If you are uncertain about any of the information,

see your immediate supervisor. Also make certain that you

understand the information in your machine tool operator’s,

programmer’s and maintenance manuals.

NOTICE

• Damage resulting from misuse, negligence or accidents is not

covered by the Hardinge FlexC™warranty.

• Information in this document is subject to change without

notice.

• In no event will Hardinge Inc. be responsible for indirect or

consequential damage resulting from the use or application of

the product, or any of the information in this document.

• This product is only to be used by trained machinists skilled in

the use and operation of collet systems and collet chucks on

metal cutting machines.

SAFETY REQUIREMENTS TO THE TURNING MACHINE

• Check to see that the workpiece is properly gripped and seated

in the collet head before beginning the machining cycle.

• Do not unclamp the workpiece until the machining cycle has

come to a complete stop.

• Observe all safety precautions indicated in the machine manual

when operating the machine including the use of guards and

keeping the door closed during machining.

• Do not exceed the maximum operating force and RPM for the

Hardinge FlexC Collet Systems indicated below:

– Maximum operating force: 10,100 lb (45KN)

– Maximum RPM: 6,000

2

65mm FlexC™ Collet System Style DL Instructions B-177

Hardinge Inc. One Hardinge Drive, Elmira, New York U.S.A. 14902-1507 800.843.8801 www.ShopHardinge.com

Part No. B 00095000177

PRODUCT DESCRIPTION AND USE

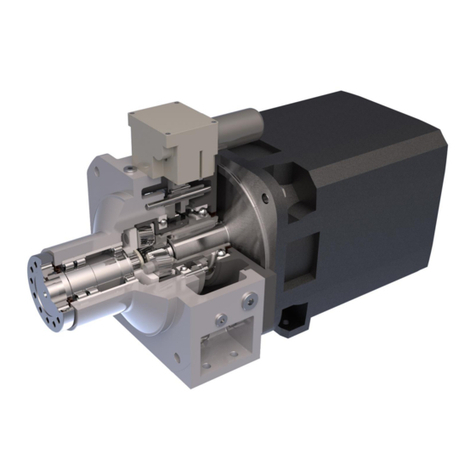

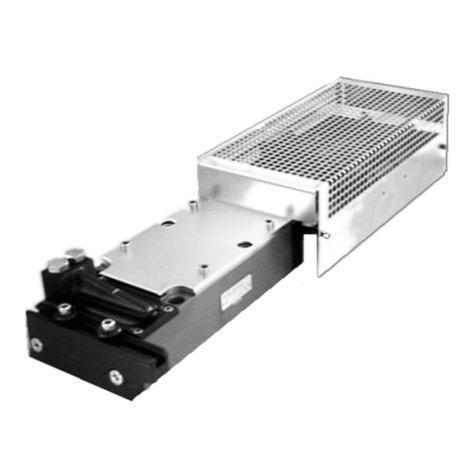

The Hardinge FlexC style DL Collet System consists of a spindle

mount assembly. Vulcanized collet heads and wrenches are

purchased separately. The style DL Dead-length®Collet System

can be used as a thru-hole for bar work or with a work stop for

chucking. The clamping heads consist of hardened steel segments

that are joined together by a vulcanization process. Their

outstanding characteristics include parallel workpiece clamping,

superb accuracy with a minimum of deformation of the work

piece, and quick-change capability. If the Hardinge FlexC style DL

Collet System is used as a dead-length system the work stop is

inserted into the body and secured with three set screws. When

part length control is not required the work stop can be removed.

The Hardinge FlexC style DL 65mm Collet Systems use a

push-to-close design with an axially-xed collet head. They are

ideally suited for sub-spindles to maintain length control during

secondary operations. The push-to-close design also avoids axial

stress between the spindles. The collet head is xed in the body,

while the drawbar moves forward and closes the collet head.

CAUTION

Make sure that the workpiece is adequately gripped so that the

workpiece will not come loose during the machining process.

When clamping very short workpieces, the minimum clamping

lengths must be observed. They depend on the selected clamping

head size and shape – call Hardinge for guidance. Do not clamp

tapered work pieces. In general the collet system should never be

rotated without a clamped workpiece. Never rotate the collet

system over 2,000 RPM without a clamped workpiece. When

actuating the changing wrench, never reach inside the moving

parts for risk of severely damaging your hand.

DRAWBAR LINKUP

The Hardinge FlexC Collet System requires a drawbar linkup to

mate the specic machine drawbar (varies by machine brand and

model) to the FlexC clamping sleeve. This linkup can be ordered

from Hardinge or can be made by the customer.

INSTALLATION

The spindle adapter and collet seat assembly are shipped

assembled. The spindle adapter must be separated from

the body by removing the six mounting screws. Inspect

the six fastening screws to ensure a torque of 7.375 ft-lb

(10Nm). Tighten if necessary.

Clean and inspect the machine spindle and the spindle

adapter. Mount the spindle adapter to the machine spindle

using the six fastening screws. For A2 style spindles, orient

the spindle adapter with the drive button. Tighten the

fastening screws in a criss cross pattern to the appropriate

torque shown in the parts list. Flat back spindles must be

indicated before you torque the bolts to specication.

Check the concentricity and face runout of the spindle

adapter before mounting the collet seat assembly. Neither

should exceed .0002" (5µm). If the indicator reading is

more than .0002" (5µm), remove the spindle adapter and

clean the surfaces again before remounting.

Reduce the clamping pressure of the machine to a minimum

and extend the drawbar to the forward position. Carefully

screw the collet seat assembly onto the drawbar clockwise

until it bottoms out or until you have .203" gap between

spindle adapter and body. DO NOT TIGHTEN. Rotate

the body counterclockwise until the clearance holes in the

body line up with the threaded holes on the spindle adapter.

Carefully move the drawbar backwards and seat the collet

seat assembly into the spindle adapter. Insert and tighten the

six mounting screws equally to 26 ft-lb (36Nm) torque in a

criss cross pattern.

Increase the clamping pressure to sufcient force for the job.

spindle

adapter

collet seat

assembly

3

65mm FlexC™ Collet System Style DL Instructions B-177

Hardinge Inc. One Hardinge Drive, Elmira, New York U.S.A. 14902-1507 800.843.8801 www.ShopHardinge.com

Part No. B 00095000177

CHECKING THE FINAL CONCENTRICITY

OF THE COLLET CLOSING TAPER

Locate the probe to touch the inside closing taper of the body to

verify concentricity. Remove the body and clean the surfaces of

the spindle adapter and the body again before remounting. Check

the concentricity again and repeat this step until the desired

reading is met. Concentricity may be affected if using stock beyond

the nominal gripping range.

CLEANING AND MAINTENANCE

The spindle, collet head and the spindle mount mating surfaces

must be cleaned and free of chips and sludge whenever mounting

to the spindle or changing out a collet head. Visually inspect

collets for tearing or separation of rubber on a regular basis

during long job runs and during setup. If you are using a high

pressure coolant in your machining processes, you need to inspect

the collets more frequently. Do NOT clean an open spindle with

an air hose as chips and sludge may be forced into the spindle

drawbar area. Clean and lubricate all moving parts with Chevron

Ultra-Duty EP NLGI 2, Dow Corning BR-2-Plus, or Kluber

ALTEMP Q NB 50 grease. Store all unused products properly

to prevent corrosion and keep free of dust and environmental

particles.

Check to see that all mounting screws are in good condition

and replace when worn. All components must be replaced with

original Hardinge replacement parts.

INSTALLING A COLLET HEAD

Installing or changing of the collet head is possible only when the

chuck is in the unclamped position. Prior to inserting the collet

head you must clean the taper of the collet seat and the mating

taper of the collet head.

Fully insert the pins of the manual wrench into the holes in the

face of the collet head. Actuate or pull the lever to collapse the

segments before inserting it into the collet seat. Insert applying

light pressure. Orient the keyway in the collet head with the key in

the collet seat. To release the collet head from the manual wrench

you must press on the release button.

CAUTION

When actuating the manual wrench never reach inside the moving

parts where there is risk of injury to your hand. Clean and lightly

oil the collet head and the body before installing.

REMOVING OR CHANGING THE WORK STOP

Follow the previous instructions to remove the collet head before

changing the work stop. The collet head must be in the unclamp

position. Reach in and remove the seal and set it aside.

To remove the work stop you must turn the 3 pipe plugs

counterclockwise to remove them. Loosen the 3 set screws

counterclockwise 2 full turns. Grasp the stop rod and pull

forward.

Make any adjustments for the next job and insert the work stop

using the rod. Now carefully tighten the 3 set screws clockwise

until you feel resistance. Hand tightening is sufcient, DO NOT

over tighten. Applying to much pressure can damage the set

screws. If you are not using the worktop, remove the 3 set screws

and insert the 3 pipe plugs. Remember to replace the seal before

inserting you collet head. Failure to use the seal may cause

malfunction of the collet system.

release

button

keyway

4

65mm FlexC™ Collet System Style DL Instructions B-177

Hardinge Inc. One Hardinge Drive, Elmira, New York U.S.A. 14902-1507 800.843.8801 www.ShopHardinge.com

Part No. B 00095000177

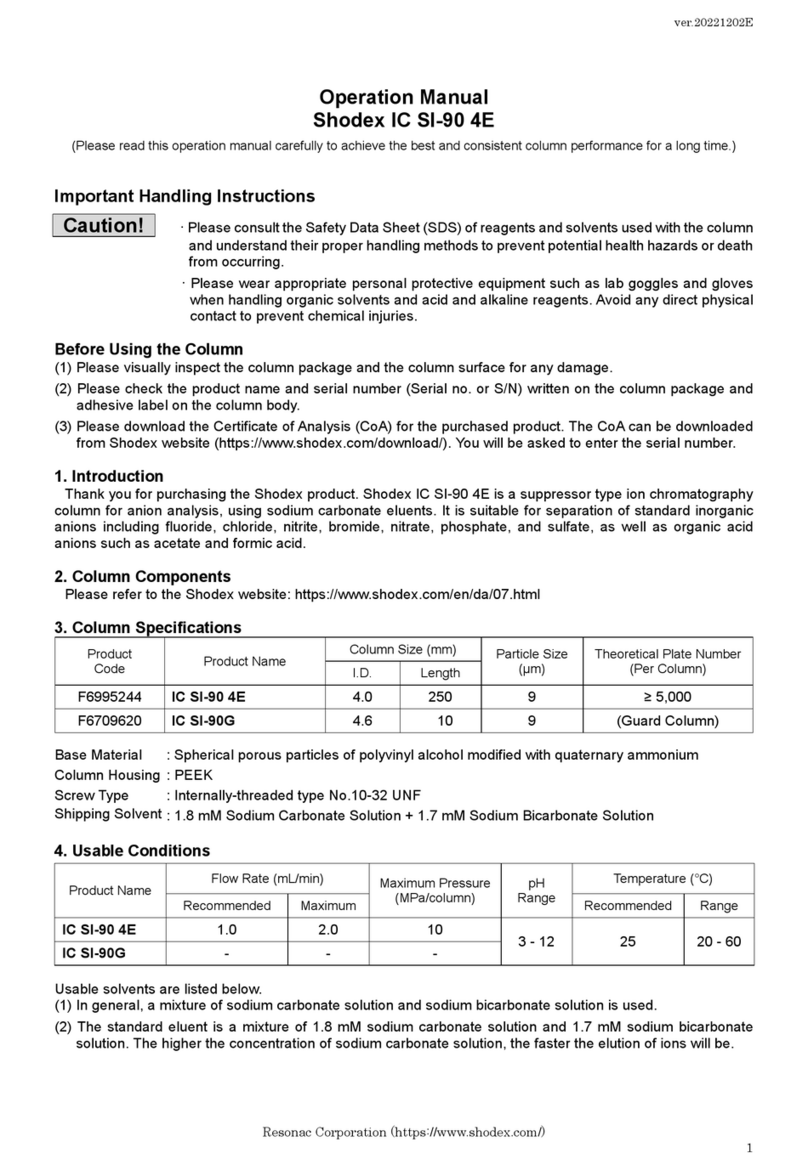

1 V65 6DL05832 Body

2 V65 6DL05837 Spacer

3 V65 6DL05833 Closing sleeve

4 MS 0103818 Screw, shcs, M8x1.25x20mm

5 V65 01237 Key screw

6 5-0001467 1/8-27 NPT pipe plug

7 V65-6DL11601 Seal for FlexC 65 Dl

8 OR 0007678 Parker 2-048 o-ring

9 OR 0006571 Parker 2-156 o-ring

10 OR 0004446 Parker 2-039 o-ring

13 MS 0103527 Screw shcs M5X.8X65mm

14 V65 6DL05836 Threaded part stop

A2-5 Assembly

11 V65 5DL05731 Mounting plate

12 V65 6DL05838 Clamp sleeve

15 MS 0104018 Mounting bolts (40 ft/lb.)

A2-6 Assembly

11 V65 6DL05831 Mounting plate

12 V65 6DL05848 Clamp sleeve

15 MS 0104218 Mounting bolts (60 ft/lb.)

A2-8 Assembly

11 V65 8DL06031 Mounting plate

12 V65 6DL05834 Clamp sleeve

15 MS 0104621 Mounting bolts (60 ft/lb.)

140 mm Assembly

11 V65 140DL02431 Mounting plate

12 V65 6DL05838 Clampling sleeve

15 MS 0104019 Mounting bolts (40 ft/lb.)

Other Hardinge Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Simplex

Simplex Full-Size Fuelport manual

optimax

optimax ECOPAX CP316S24MM operating instructions

Hella Gutmann

Hella Gutmann CSC-Tool SE operating instructions

SUHNER MACHINING

SUHNER MACHINING AG 12-2 installation instructions

Agilent Technologies

Agilent Technologies ESG series Manual supplement

Festo

Festo BV-200 Series operating instructions

Servomex

Servomex SERVOTOUGH Laser SP 2930 Operator's manual

SCHUNK

SCHUNK Vario F Series operating manual

Eaton

Eaton EU1E-SWD Series Instruction leaflet

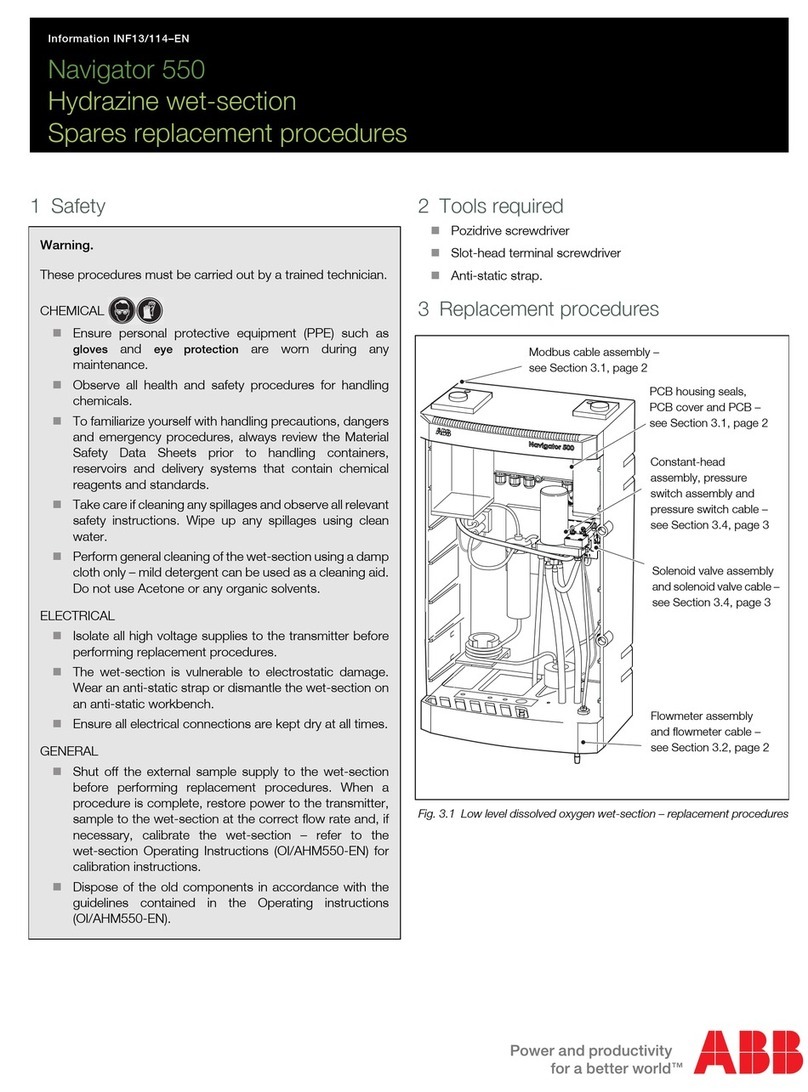

ABB

ABB Navigator 550 Spares Replacement Procedures

SEW-Eurodrive

SEW-Eurodrive X Series Assembly and operating instructions

Siemens

Siemens SINAMICS G120P operating instructions