SIAM SIDDOS-automat 3M User manual

Limited Liability Company

Tomsk Scientific Introduction Innovation Company “SIAM”

DYNAMOGRAPH

«SIDDOS-automat 3М»

OPERATION MANUAL

Russia

2019

2

3

CONTENTS

1. OVERVIEW........................................................................................................... 4

2. BASIC SPECIFICATIONS .................................................................................. 5

3. COMPONENTS AND DELIVERY SET............................................................. 6

3.1. BASIC SET .............................................................................................................. 6

3.2 LOAD CELL KIT ....................................................................................................... 6

4.1 GENERAL PROVISIONS (REGULATORY FRAMEWORK).............................................. 7

4.1.1 Requirements to Personnel.............................................................................. 7

4.1.2 Requirements to the test object ....................................................................... 8

4.2 SAFETY MEASURES DURING THE OPERATION ........................................................ 10

4.2.1 Basic requirements........................................................................................ 10

4.2.2 Preparation of surface facilities..................................................................... 12

4.3 SAFE ASSEMBLY FOR THE DYNAMOGRAPH............................................................ 12

4.4 THE PROCEDURE OF SAFE DISASSEMBLY OF THE DYNAMOGRAPH ......................... 13

4.5. SCHEDULED MAINTENANCE AND REPAIR WORK................................................... 14

4.6. STORAGE AND TRANSPORTATION......................................................................... 15

5. ENSURING EXPLOSION-PROOFNESS OF THE PRODUCT. ................... 16

5.1. EXPLOSION-PROOFNESS OF THE PRODUCT............................................................ 16

5.2. MEASURES TO ENSURE AND KEEP THE DEVICE EXPLOSION-PROOFNESS DURING THE

ASSEMBLY,DISASSEMBLY AND REPAIR OF THE DYNAMOGRAPH................................. 17

6. GENERAL INFORMATION ON THE TOOL ................................................ 19

6.1 DESIGN AND USE OF DYNAMOGRAPH COMPONENTS.............................................. 19

6.2 DYNAMOGRAPH OPERATING PRINCIPLE ................................................................ 20

7. DYNAMOGRAPH OPERATION DESCRIPTION......................................... 20

7.1 SWITCHING ON AND SWITCHING OFF..................................................................... 21

7.2 WORK WITH THE GAUGES IN THE "SIAM SERVICE"APPLIED SOFTWARE.............. 21

7.3 BATTERY CHARGE................................................................................................. 24

8. DEVICE STORAGE AND TRANSPORTATION ........................................... 24

9. CLAIM INFORMATION................................................................................... 26

4

1. OVERVIEW

Dynamograph “SIDDOS-automat 3M” is a complex of electronic

devices and application software that provides automation of the

dynamogram control process, primary study processing and database

maintenance.

Testing process is conducted in an automatic mode. All the research

types require no more than one operator (two operators at use of the gauge

without the lifting mechanism). Graphs and numeric data of the studies are

visualized using an external terminal (smartphone/tablet/well pad data

collection modem).

The devices are explosion-proof designed (type of protection -

intrinsically safe circuit) in accordance with the requirements of GOST

31610.0-2014 (IEC 60079-0:2011), GOST 31610.11-2014 (IEC 60079-

11.), GOST 31610:2011), and have 1Ex ib IIB T3 Gb Хexplosion proof

mark. The devices are intended for indoor and outdoor installation in

potentially explosive gas atmosphere where atmospheric explosives of IIA,

IIB categories and T1, T2, T3 groups can form according to GOST R IEC

60079-20-1-2011 in the operating temperature range from -40 ºC to +50

ºC. The device design is comply with the assigned explosion proof mark,

with the requirements of GOST IEC 60079-14-2013 and other regulatory

documents governing the use of electrical equipment in hazardous areas.

The recommended interval between device calibration test is 1 year.

To check the device transmission characteristics for compliance with the

requirements of technical specification and to reduce the device to the

technical specification the device is recommended to be calibrated at the

dynamograph control stand after the calibration period has expired.

5

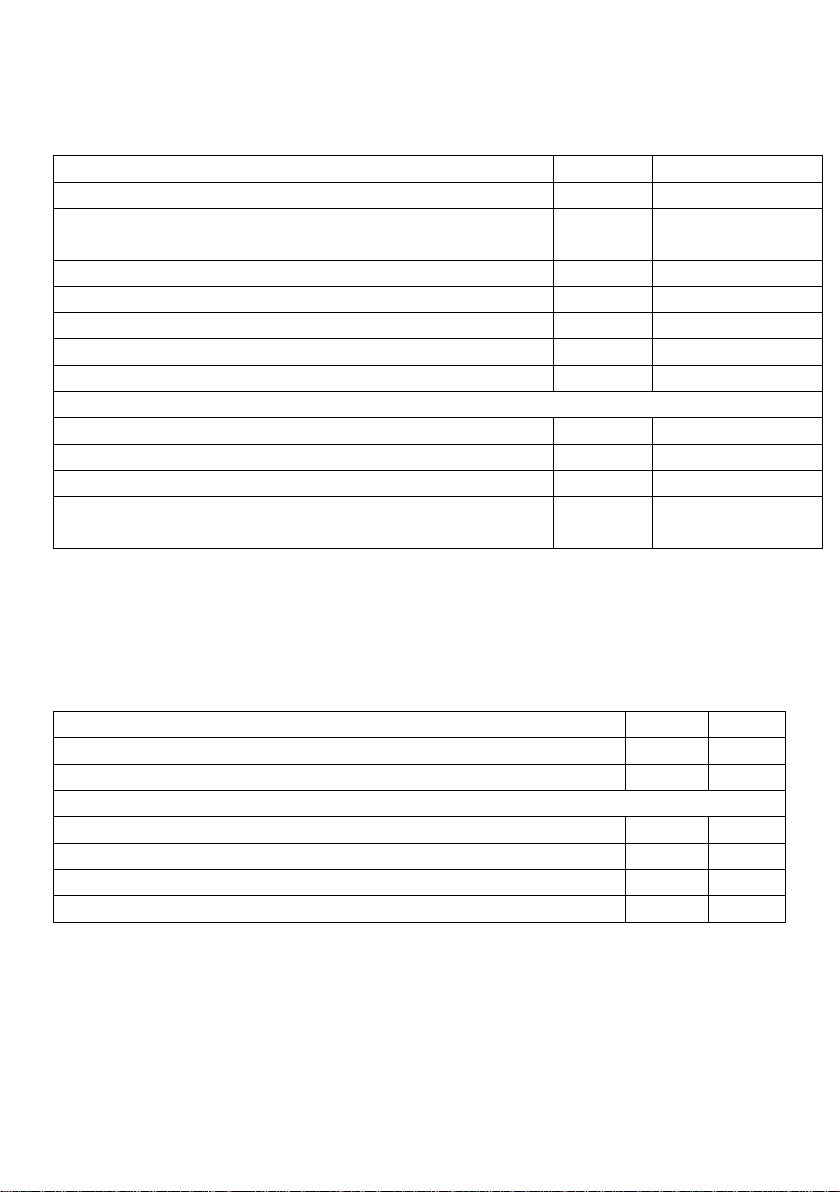

2. BASIC SPECIFICATIONS

Parameter name

Norm on specifications

Explosion proof mark according to GOST 31610.0-

2014 (IEC 60079-0:2011)

1Ex ib IIB T3 Gb X

IP degree of protection according to GOST 14254-

2015

up to IP54

Load monitoring range

0 10 000 kgf

Displacement monitoring range

0,5 9,999 mm

Available pump speed of the sucker rod pump

horsehead

1.5 15 SPM

Load monitoring resolution

10 kgf

Displacement monitoring resolution

50 mm

Time of continuous operation (1-2 measures per 24

hours), up to

720 h.

Weight, not exceed

3,2 kg

Service life

5 years

6

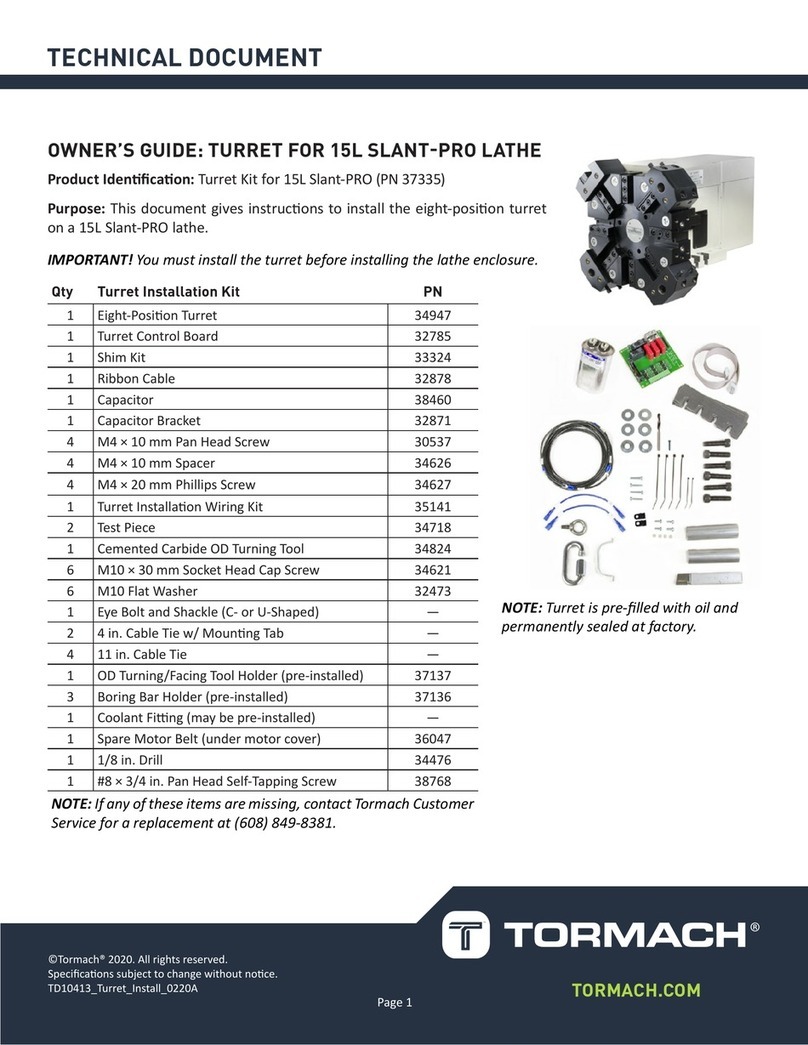

3. COMPONENTS AND DELIVERY SET

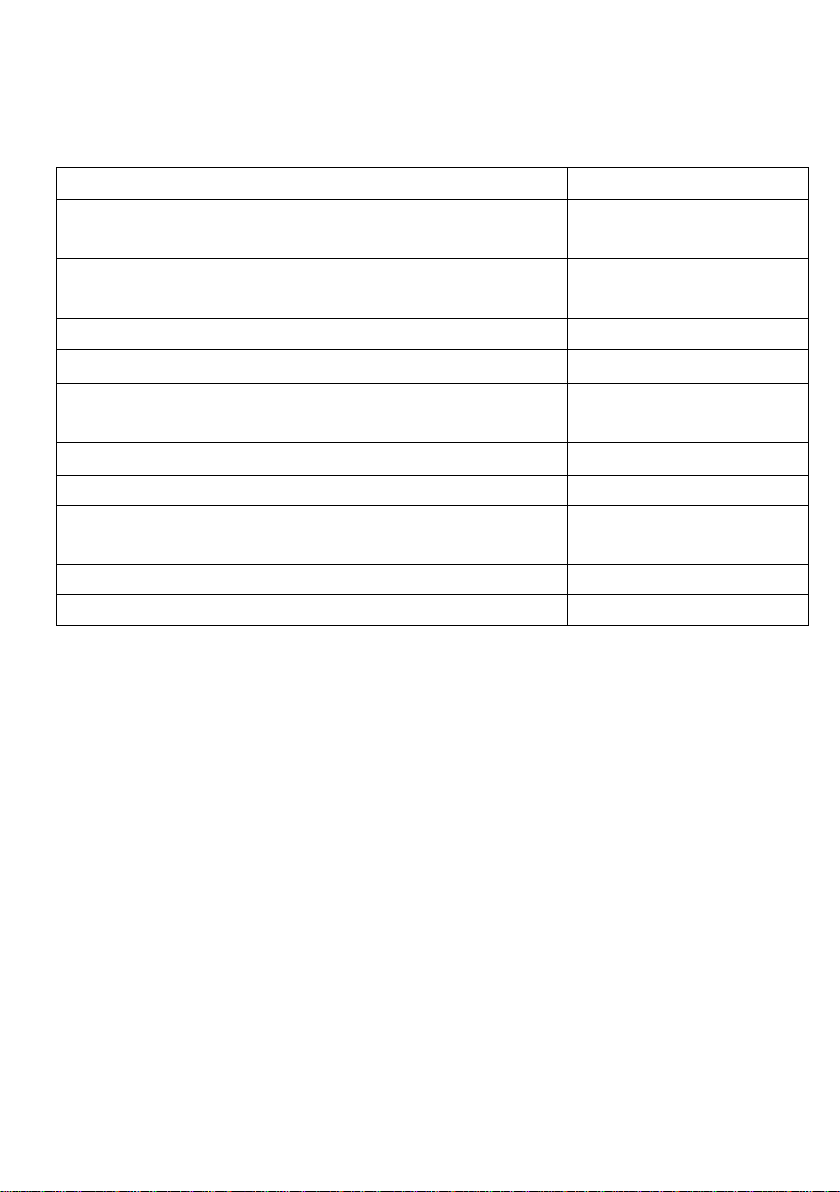

3.1. Basic set

Item

Quantity

Note

1. SIDDOS-automat 3M gauge

1

2. Load cell kit

1

See more variants

in 3.2.

3. AC adapter

1

4. Charge cable

1

5. Bag for the dynamograph

1

6. Load cell supporting plate

2

7. «DB SIAM» and/or SiamService software

1

8. Operating documentation:

8.1. SIDDOS-automat 3М. Certificate

1

8.2. SIDDOS-automat 3М. Operation manual

1

8.3. DB SIAM/SiamService software user’s guide

1

8.4. Sucker rod pumping unit diagnostic with the use

of dynamograph “SIDDOS”. Dynamometry manual

1

3.2 Load cell kit

3.2.1 Version of dynamograph with DN-10M gauge (dynamograph

with built-in jacks)

Item

Quantity

Note

1. Load cell DN-10M with expanded jacks

1

2. Ratchet handle wrench for the expanded jacks

1

3. Spare parts and accessories

3.1. Shim

1

3.2. Bottom jack housing

1

3.3. Left jack spring

1

3.4. Right jack spring

1

7

4. SAFE OPERATION GUIDELINES

4.1 General Provisions (regulatory framework)

The design of the wellhead equipment is to be approved by the

Russian Technical Surveillance Agency (RTSA).

Preparation of the well for tests should be conducted in accordance

with the requirements of the current Manual and internal guidelines

for maintaining and testing wells approved by the head of the

company.

Test equipment is to be operated according to the operating

instructions supplied with the equipment.

Measures to ensure safety are regulated by labor protection

instructions for respective types of work approved by the

Company’s Department of Labour Protection and the Safety

Regulations in Oil and Gas Industry approved by the RTSA.

4.1.1 Requirements to Personnel

Well tests are to be carried out by individuals above 18 who have

secondary education and who are medically cleared for work.

Qualification requirements to the personnel:

-not below category 5 for oil and gas production operators;

-not below category 4 for well test operators.

The personnel must attend professional training in accordance with

the requirements of local instructions on well operation,

organization and study conduction. The professional stuff must also

study Safety rules in the oil and gas industry (by Federal

Environmental, Industrial and Nuclear Supervision Service of

Russia, - Federal Rules and Regulations (FNP) №101); Operational

Code for Electrical Installations (PUE), Chap. 7.3 “Electric

installations in hazardous areas”; Regulations for Technical

Maintenance (PTE) and safety regulations PTB, Chap. 3.2.

8

"Electrical installations in hazardous areas”. The personnel is

required to pass the relevant examinations.

Personnel must participate in on-the-job training session on

research equipment operation. The training session is given by the

manufacturing company.

The personnel quantity to operate the dynamograph is about 1-2

people.

4.1.2 Requirements to the test object

- Researches are carried out on producing wells equipped with

bottomhole rod pumps of any type and any design with drive from a sucker

rod pumping unit of SKN series according to GOST 5866-56, SK

according to GOST 5866-76, SKD according to OST 26-16-08-87 of all

standard sizes, and similar foreign production.

- Column of rods of any length and configuration should end with

polished rod with diameter 19 - 36 mm.

- Packing of the polished rod should be made by sealing SUS1 or

SUS2.

- The connection between the rod and the sucker rod pumping unit

should be made by polished rod carrier bar of a PCSH-type wellhead rod.

When using a DN-10 load cell, the limits of the suspension configuration

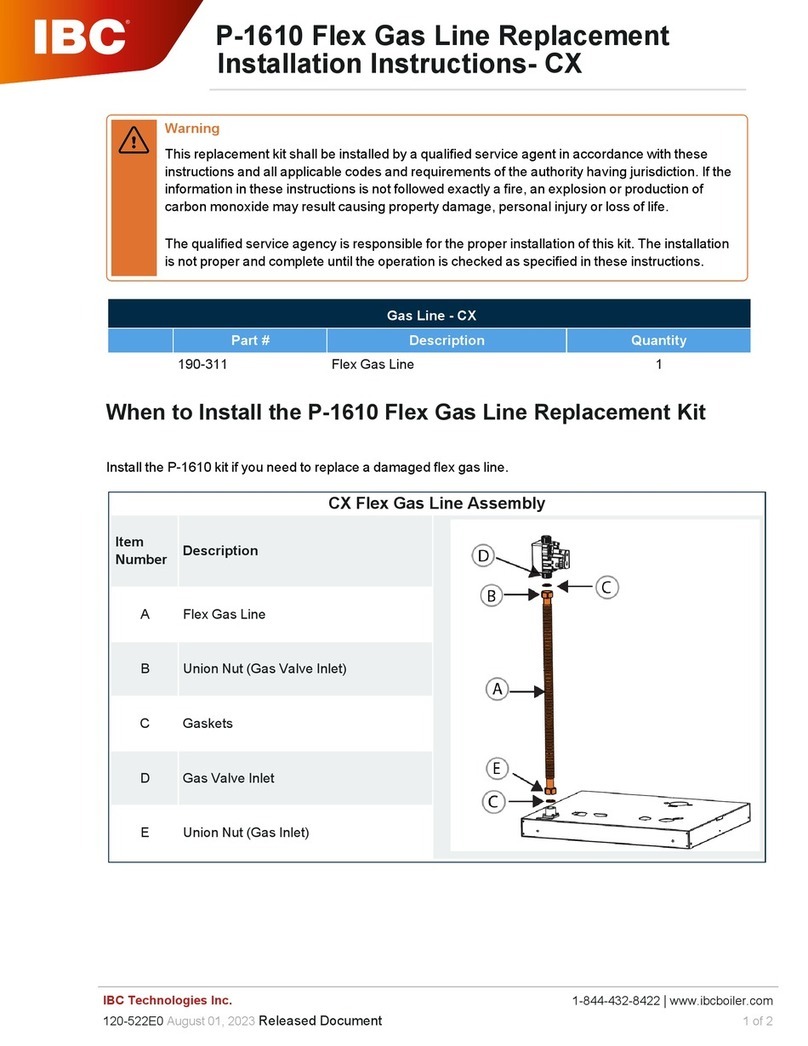

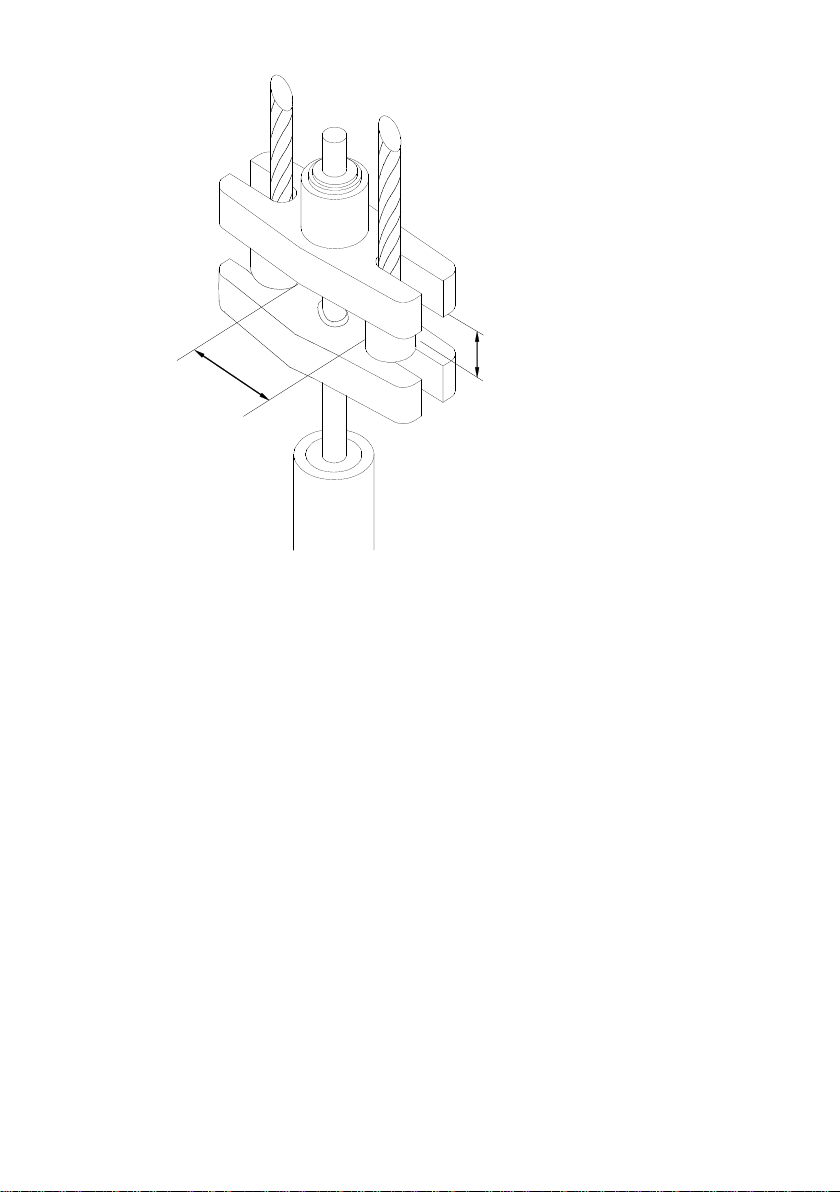

are shown in Figure 1.

9

НЕ МЕНЕЕ 45 мм

НЕ МЕНЕЕ 105 мм

Figure 1. Carrier bar of wellhead polished rod

- Installation and operation of the sucker rod pumping unit and its

electrical equipment shall be carried out in accordance with the

"Regulations on Labor Safety in Oil and Gas Industry".

- The control station of the sucker rod pumping unit must have a

mode switch for manual operation.

- Moving parts of the sucker rod pumping unit (crank-connecting rod

mechanism, multiple V-belt drive) should have a proper standard fence.

- The SC gearbox must have a proper hand brake.

- The wellhead shall be equipped with a service platform for the

wellhead polished rod packing so that the upper end of the packing is not

more than 1 meter above the site, and the cable hanger cross-beams in the

extreme lower position of the horsehead are not more than 1.5 meters. The

distance between the lower hanger cross-beam and the cap of the head of

the wellhead should be at least 20 cm. (Figure 2).

10

Figure 2. Wellhead equipment

- The service site must meet the requirements of the "Oil and Gas

Industry Safety Regulations". The diagram of the site is shown in the

picture.

- If the height of the wellhead rod packing is low (up to 2 m above

the ground), portable sites may be used provided that they meet the above

requirements.

4.2 Safety measures during the operation

4.2.1 Basic requirements

When preparing, conducting research, assembling and

disassembling the equipment the personnel should be guided by the

“Safety rules in the oil and gas industry”, Operational Code for Electrical

Installations (PUE), Chap. 7.3 “Electric installations in hazardous areas”;

Regulations for Technical Maintenance (PTE) and safety regulations

(PTB), Chap. 3.2. "Electrical installations in hazardous areas”.

The following is prohibited:

-operation of a sucker rod pumping unit without a crank-

11

connecting rod mechanism and a V-belt drive;

- operating without stopping the sucker rod pumping unit;

- locating people under the sucker rod pump and its horsehead;

- turning the pulleys manually and braking them with non-standard

devices (pipes, scrap, etc.);

- using of non-standard means of switching the motor on and off;

-carrying out testing on a defective handbrake of a sucker rod

pumping unit;

- open fire using, smoke, use of non-explosive safety devices and

equipment.

Installation of the dynamograph should be performed only from the

sites intended for work with wellhead equipment.

Handle careful of all instruments of the complex. Carry and transport

the parts of the complex packed in standard cases. Avoid shock loads on

sensors.

Do not allow the presence of unauthorized persons at the site of the

investigated well during installation of the dynamograph and

measurements. It is prohibited to use non-standard installation tools and

technologies.

Before mounting the dynamograph, make sure that there are no

mechanical damages and make a total dynamograph function check.

If the space between cross-beams or the gauge is soiled, remove the

dirt with a rag.

The attachment of the cable to the wellhead assembly must ensure

that it does not collapse during start-up and operation of the sucker rod

pumping unit. When dismounting, the cable is removed from the mount

and, when stretched, is fed smoothly into the dynamograph reeling.

Start and stop of the sucker rod pumping unit is performed

according to the operating instructions of the sucker rod pumping unit.

During assembly, disassembly and operation, do not stand in front of

the dynamometer or place vehicles or other equipment in the danger area.

Operators and equipment must be located sideways on the windward side

12

of the well.

4.2.2 Preparation of surface facilities

Check the availability and serviceability of the handbrake, horsehead

holder, protective fences and service platform.

If the sucker rod pumping unit is operated in remote control mode or

in automatic mode, switch the control to manual according to the

instructions.

Hang up a sign on the starter: “Do not switch on, the operation is

under way”.

Make sure that the wellhead packing has no fluid passes at any rod

position.

4.3 Safe assembly for the dynamograph

Stop and brake the sucker rod pumping unit at the lower position of

the rod.

Align the gauge jacks so that they can fit freely between the cross-

beams.

Place the gauge in the cross-beam space with the jack screws

towards the balancer. Fasten the gauge with a safety chain to the

cable hanger elements. The jack's lower supports should rest on the

lower cross-beam in the entire plane. If the beam has an uneven

surface, a steel gasket of appropriate thickness and configuration

must be used.

Align the gauge with the cross-beam and polished rod in two

directions:

-the pier axis of the jack must match the longitudinal axis of the

top beam;

-the polished rod should be positioned symmetrically with

respect to the jacks.

Using the jacks, with the handle wrench, lift the top beam over

the thrust sleeve, successively twisting one or the other jack

13

until the wedges are completely brought together. As a result,

the upper crosshead should rise above the hanger thrust sleeve

and transfer the entire load to the gauge prism. It must be

ensured that the upper beam only transfers the load to the gauge

prisms and does not come into contact with the jack housing. A

gap of at least 2 mm between the beam and the jack housing

should remain.

4.4 The procedure of safe disassembly of the dynamograph

Stop the sucker rod pumping unit in the lower position.

Switch off the device if it is on.

Release the dynamo by successively loosening the jacks.

Unscrew the safety chain, remove the dynamo from the cross-

beam space, clean the dirt and place the device in the

transport box.

14

4.5. Scheduled maintenance and repair work

In case of malfunctions, please contact the manufacturer of the

complex or specialized organizations that have a certificate for repair

work from the manufacturer. Disassembly of the dynamograph and

other products of the complex leads to the loss of warranty.

- It is forbidden to disassemble the dynamograph and other elements

of the complex and perform repair work on the well.

- It is prohibited to charge the dynamograph batteries with a non-

standard charger. Charge the batteries in accordance with the operating

instructions of the complex with careful following its requirements.

- The charger is powered by AC 220V, 50Hz industrial AC power, so

take general precautions: do not plug the charger into faulty electrical

outlets, do not use extension cords, and do not leave turned on

devices unattended.

- Do not heavily pollute the gauges, especially the jacks and

measurement pyramids built into them. Remove the dirt with a rag.

Gasoline may be used with subsequent lubrication of coupling

screws.

- Check the condition of the fastening screws of the dynamograph at

regular intervals. When loosening, tighten them and secure with

paint.

- Do not allow dirt or sand to enter the connectors of the

dynamogaph. If dirty, flush the connectors with ethyl alcohol or

alcohol-gasoline mixture (9 parts alcohol, 1 part gasoline) using a

brush. Alcohol consumption - 100g per month of operation. After

washing it is recommended to apply a small amount of CYATIM

GOST6267-80 grease to the connectors surface.

- At critical hang-up of the device and absence of any reaction from

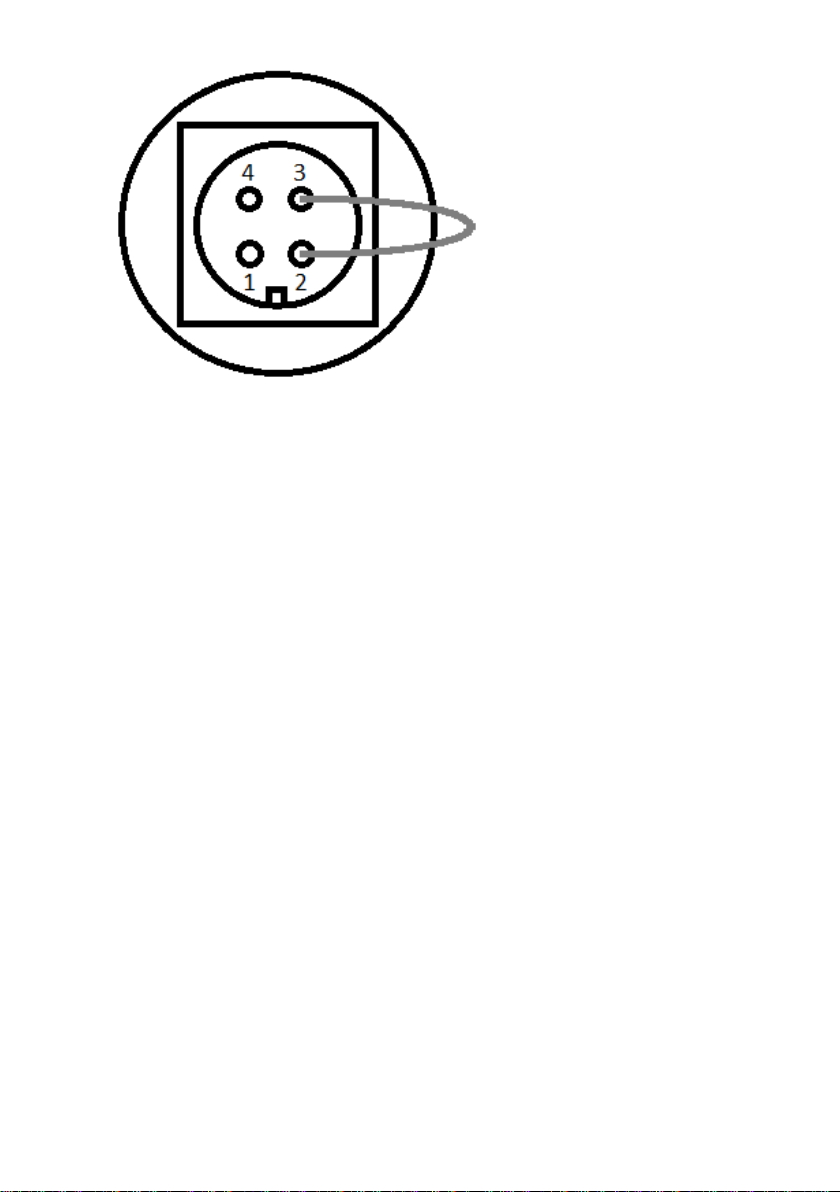

it the device could be restarted forcibly by closing 2 and 3 contacts of

the connector with a metal object (a paper clip/piece of a wire) as

shown in the figure:

15

Front view of the connector. Short circuit 2 and 3 for the forced

restart.

4.6. Storage and transportation

Please store the tool in its standard bag in dry heated rooms with the

–10oC to + 40oC temperature range and moisture content of 80% and

below. While storing the tool, check the battery voltage every 2 months

(Section 6.13).

The tool can be transported using any type of transport at the –40oC

to + 50oC temperature range.

16

5. ENSURING EXPLOSION-PROOFNESS OF THE PRODUCT.

5.1. Explosion-proofness of the product

Explosion-proofness of the device is provided by the type of

protection "intrinsically safe electric circuit" “ib” level, according to the

requirements of GOST 31610.11-2014 (IEC 60079-11:2011), which is

achieved by the following:

Basic circuit diagram includes the protective component “Fib”. The

protective component “Fib” is an intact spark protection unit with the

short-circuit current limitation at 0.07 A (maximum), using current limiting

resistors and semiconductor fuses in series. Double redundancy is used in

the “Fib” protective component to ensure greater reliability. The “Fib”

component is integrated into the battery compartment of the device. The

design of the protective component “Fib” is met with the requirements of

GOST 31610.11-2014 (IEC 60079-11:2011), including leakages and

clearances. The minimum width of conductors on the PCB is 0.2 mm,

copper thickness is not less than 18 µm. Thus, the electrical circuit coming

out of the battery compartment of the device is intrinsically safe.

The electrical circuit principal and applied third party components

provide maximum power consumption not more than 1.5 W from the

internal battery with maximum possible voltage on it 7.2 V. The total

maximum capacity of the electrical circuit is 20 μF, maximum inductance

is not more than 200 µGn. The maximum current in the circuit during

normal operation is not more than 200 mA.

The battery has special made contacts which exclude the possibility

of its incorrect switching on (polarity reversal) and is located in the internal

battery compartment of the device. The design of the battery compartment

ensures that the battery does not fall out of the device. Do not replace the

battery and do not charge it in the hazardous area. For this reason, in order

to inform the user about special conditions of use of the device, the

identification plate of the device is marked with an "X" sign indicating

special conditions of safe operation.

17

The maximum temperature of overheating of components and

connections in the circuit diagram during normal operation is 15 °C max.

Thus, the surface temperature of conductors and elements during operation

and at maximum operating temperature plus 50 ° C is not more than 65 °

C. Device enclosures are made with the degree of protection against

external influences not lower than IP54 according to GOST 14254-2015.

5.2. Measures to ensure and keep the device explosion-proofness

during the assembly, disassembly and repair of the dynamograph.

5.2.1 Measures to ensure explosion-proofness before the production

process:

- The elements used in the protective component of “Fib”are

subjected to an acceptance test:

- resistors are tested for their nominal resistance;

- the fuses are checked against the short-circuit current limit;

- Materials used for casting the protective component “Fib”are

subjected to an acceptance test according to the certificates presented.

5.2.2 Measures to ensure explosion-proofness during production:

- The protective component “Fib”with the installed battery is

subjected to an outgoing inspection:

- the short-circuit current and open circuit voltage at the output of

the protective component are checked;

- visual inspection of the filling location is carried out in order to

confirm the absence of any foreign inclusions, bubbles, cracks or

stratification.

5.2.3 Measures to ensure explosion-proofness during operation:

- Check that the cover of the battery compartment and the

compartment itself (including the threaded connection) are free from

mechanical damage and corrosion. In case of corrosion or mechanical

damage, do not operate the device;

18

- meet the requirements specified by the "X" sign in the explosion

proof mark (see item 1.3.2 of TU 4273-004-20690774-2018).

5.2.4 Measures to ensure explosion-proofness during repair:

- the device must be repaired only by the employees of the

manufacturer.

Repair by third parties or individuals is prohibited.

- the protective component “Fib” is not to be repaired. It is made

intact and must be replaced in case of failure. Repair of the “Fib”

component is not permitted.

- after repair, the device must be tested according to the test

procedure, with the “Fib”component tested for short-circuit current and

open-circuit voltage (together with the battery installed).

19

6. GENERAL INFORMATION ON THE TOOL

6.1 Design and use of dynamograph components

Dynamograph "SIDDOS-automat 3" (hereinafter a dynamograph)

designed for integrated control of sucker rod pumping units (SGNU). It

provides automatic control of dynamograms such as "load - position of the

rod" in operating condition and when the well is start up, as well as valves

test in static condition. The special feature is the monoblock design of the

dynamograph. The design allows to exclude the connecting cable, which

increases the efficiency and safety of the test.

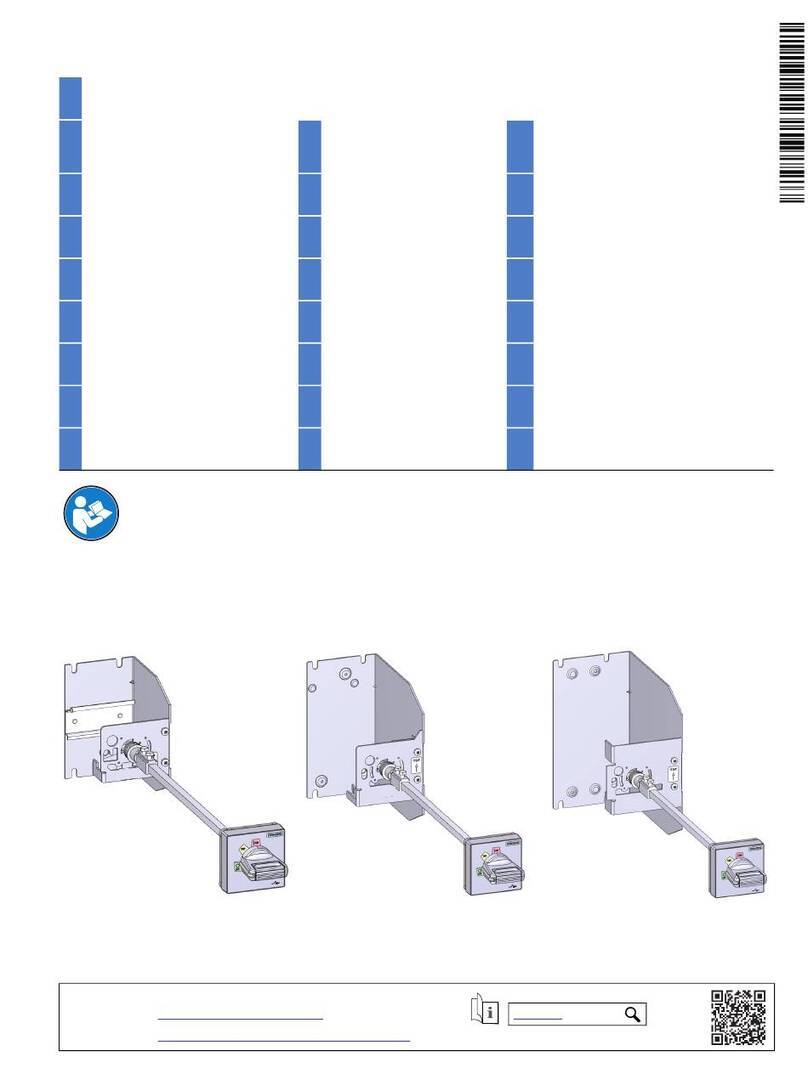

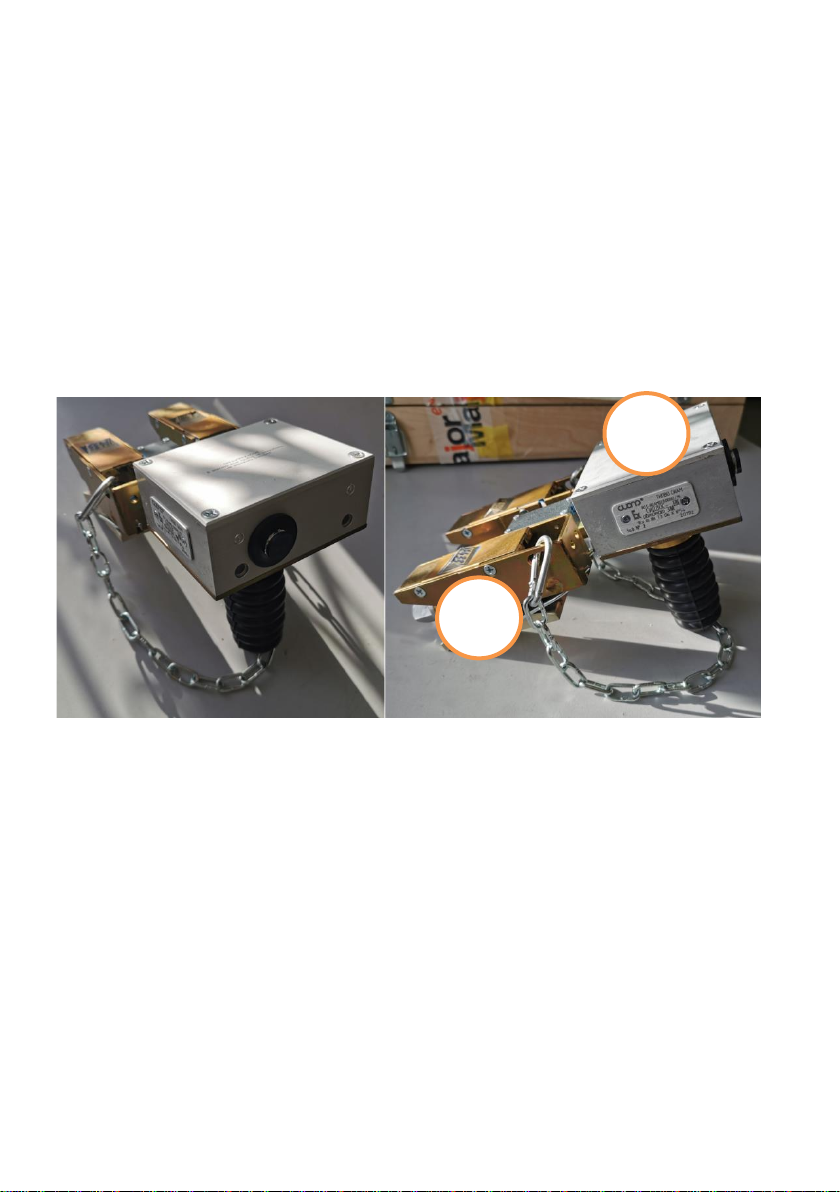

Figure 3 - Appearance of the gauge

The dinamograph consists of two modules: an electronic unit and a

load cell. The electronic block (1) is a microprocessor-based controller that

sets the algorithm of the complex, receives and processes data from the

displacement cell and load cell (2), and provides communication with

external devices wirelessly. The electronic block is connected to the cross-

beam load cell.

1

2

20

6.2 Dynamograph operating principle

The dynamograph operating principle is to simultaneously record the

change in time of load on the polished rod and its displacement at different

operating modes of the rocking machine.

In the dynamograph the type of test "DYNAMOGRAM" is

implemented - recording the dependence of load-position of the rod.

All the tests are conducted in automatic mode. The research

parameters are set by the operator. They can be changed at any time using

the external terminal software depending on the purpose of the test. The

last parameter setting is saved each time, thus simplifying the algorithm of

operating strictly on the well as much as possible.

All test results are memorized in the terminal software. They can be

viewed and transferred to a PC at any time.

Batteries are used as power cells to ensure long operating time. The

dynamograph monitors their status and is equipped with an integrated

charging controller.

7. DYNAMOGRAPH OPERATION DESCRIPTION

The dinamograph is equipped with two indicators. The indicator

"Сharging" shows the status of the device battery: battery is charged

(green), battery is empty (red), battery is charging (orange).

The "Power" indicator shows the status of the device: the device is in

operating mode (green), measurement is performed (flashing or burning

red), measurement error (flashing red after finishing deleting the

dynamograph).

A connector on the front panel is provided for charging the device

battery.

Table of contents

Other SIAM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Badger Meter

Badger Meter ER-10 user manual

Alfa Network

Alfa Network CR6 Original instruction

Signode

Signode GRIPPACK Original Operation, Parts & Safety Manual

Hillco

Hillco CS9030 Operator's manual

IEMCA

IEMCA BOSS 552 - IC Manual for use and maintenance

SCHUNK

SCHUNK TCU-P Series Assembly and operating manual