Hardinge SUPER-PRECISION HC User manual

«*'•

■

£

,

w.

.

•

.

!

•

•

J

/

/

J

\

$

1

!

9

i

.

<n

m

MAINTENANCE

MANUAL

FOR

AUTOMATIC

THREADING

UNIT

ON

HARDINGE

SUPER-PRECISION

”

CHUCKING

MACHINE

MODELHC

mm

■

READ

MANUAL

CAREFULL

BEFORE

STARTING

MAIN

TENANCE

OR

REPAIR

ON

AUTOMATIC

THREADING

UNIT

When

this

manual

was

printed,

the

information

given

was

cur

rent.

However,

since

we

are

constantly

improving

the

design

of

our

machine

tools,

it

is

possible

that

the

illustrations

and

descriptions

may

vary

from

the

automatic

threading

unit

you

received.

This

means

that

the

unit

you

received

is

the

latest

improved

model

to

better

fulfill

your

requirements.

It

is

assumed

those

who

use

this

manual

will

have

a

general

knowledge

of

machine

maintenance

and

repair.

This

general

knowl

edge

coupled

with

the

following

manual

will

greatly

reduce

or

elimi

nate

down

time

to

allow

you

to

receive

maximum

production

from

your

Hardinge

Automatic

Threading

Unit.

HARDINGE

BROTHERS,

INC.

ELMIRA,

NEW

ORK

CONTENTS

V

PAGE

'

!

3

Air

Connections

Chasing

Head

—

Disassembly

8

11

Reassembly

:

7

Cycle

Stop

Micro

Switch

—

Replacement

6

Cylinder

Housing,

Chasing

Head

”

!

V

7

Disassembly

7

Reassembly

Electrical

Connections

4

Electric

Control

Functions

5

Feed

Rate

Adjusting

Screw

—

Removal

6

Replacement

6

A

14

Gib

Adjustment,

Tool

Post

Slide

I

Installation,

Automatic

Threading

Unit

3

Knockout

Control

—

Disassembly

14

Reassembly

15

Lubricant

Vendors

2

Lubrication

14,

19

Lubro-Control

Unit

19

Maintenance,

Preventive

2

Mounting

Bracket

and

Chasing

Bar

Assembly

18

—

i

Removal,

Automatic

Threading

Unit

5

14

Serial

Number

Slide

Travel

Adjusting

Screw

—

Removal

6

6

Replacement

5

Tool

Post

—

Disassembly

FOR

OPERATION

AND

RELATED

ADJUST ENTS,

SEE

“

OPERATOR

S

ANUAL

FOR

AUTO ATIC

THREADING

UNITS

ON

ODEL

HC

CHUCKING

ACHINES

”

1

PREVENTIVE

MAINTENANCE

DAILY

PAGE

14

Clean

and

Lubricate

Lead

Screw

and

Follower

.

14

Clean

and

Lubricate

Guide

Bar

.

WEEKL

PAGE

14

Fill

Oil

Cup

on

Chasing

Head

14

Cycle

Threading

Unit

20

Drain

Filter

Reservoir

SE I-ANNUALLY

PAGE

20

Clean

Air

Filter

Element

DEPENDING

ON

USE

PAGE

20

Maintain

Oil

in

Lubricator

Reservoir

Note:

Oil

Base

Cutting

Fluids

are

Recommended

for

Maximum

Life

of

Automatic

Threading

Unit.

LUBRICANTS

(Use

Recommended

Product

or

Equivalent)

Product

Vendor

Standard

Die

Set

Co.

(Div.

of

Dieco.)

Die

Makers

Grease

Molylube

#M-88 Alpha-Molykote

Corporation

Mobil

Oil

Corporation

Velocite

No.

6

2

I

©

©_J

Figure

1

—

Threading

Unit

Mounting

Pads

Figure

4

—

Rear

View

of

Threading

Unit

INSTALLATION

ON

EXISTING

MACHINES

1.

Remove

any

paint

or

burrs

from

pads

“

A

”

,

Fig

ure

1,

and

keyways

in

pads.

2.

Position

base

plate

“

B",

Figure

2,

and

as

semble

eight

screws

“

C

”

.

3.

Set

four

T-Bolts

“

D

”

and

“

E

”

,

Figure

3,

in

base

plate

as

shown.

Bolts

“

D

”

are

the

longer

ones

supplied.

4.

Position

threading

unit

on

base

plate

with

hoist

and

sling

and

assemble

four

washers

and

nuts

“

F

”

,

Figure

4.

DO

NOT

OVERTIGHTEN

NUTS

“

F

”

,

SNUG

IS

SUFFICIENT.

Figure

2

—

Base

Plate

Mounting

Figure

5

—

Air

Control

Unit

Location

AIR

CONNECTIONS

1.

Drill

two

3

/s"

diameter

holes

5

Vs"

apart

at

left

rear

of

oil

pan

and

mount

air

regulator

“

G

”

,

Figure

5.

2.

Fill

lubro-control

unit

with

oil

per

instructions,

Page

19.

Connect

air

line

from

threading

unit

to

lubro-control

unit.

3.

Connect

lubro-control

unit

to

air

supply.

If

ex

cessive

water

problem

exists,

add

heavy

duty

filter

to

air

line.

3

r

!

___

J

4.

Set

pressure

regulator

knob

“

J

”

,

Figure

7

to

provide

a

minimum

of

65

pounds

and

a

maximum

of

75

pounds

of

air

pressure.

Tighten

lock

screw

“

H

”

against

control

knob

to

maintain

setting.

5.

Follow

steps

1

&

2

on

this

page

under

“

Elec

trical

Connections

’

’

.

ELECTRICAL

CONNECTIONS

1.

Disconnect

power

source.

Feed

cable

“

J

”

,

Fig

ure

4,

through

hole

“

K

”

,

Figure

6.

2.

Attach

white

wire

to

terminal

8

and

black

wire

to

terminal

37

of

terminal

board.

Tighten

cable

grip

at

“

K

”

.

Figure

7

—

Lubro-Control

Unit

4

NOTE:

THREADING

UNIT

REQUIRES

ONL

10

VOLTS

FOR

OPERATION.

Machines

manufactured

after

Serial

No.

100A

are

wired

to

include

10

volt

tap

on

transformer.

FOR

INITIAL

SETTING

OF

AUTO ATIC

THREADING

UNIT,

SEE

OPERATOR

’

S

ANUAL

FOR

AUTO ATIC

THREADING

UNITS

ON

ODEL

HC

CHUCKING

ACHINE.

ELECTRIC

CONTROL

FUNCTIONS

(Figure

6)

L

—

Fuse

for

automatic

threading

unit.

(FRN

1-

1

A

)

M

—

Control

voltage

transformer

(115

volt

output

with

10

volt

tap

for

automatic

threading

unit).

Figure

10

—

Fine

Adjustment

Dial

Assembly

AUTOMATIC

THREADING

UNIT

REMOVAL

1.

Disconnect

electrical

power

source

and

remove

wires

at

terminals

8

and

37,

Figure

6.

2.

Loosen

cable

grip

at

“

K

”

and

remove

cable

from

main

switch

case.

3.

Disconnect

air

pressure

and

remove

air

line

from

threading

unit

at

lubro-control

unit.

4.

Remove

four

nuts

and

washers

“

F'\

Figure

4,

and

remove

complete

threading

unit

with

hoist

and

sling.

5.

If

necessary,

remove

the

T-Bolts

“

D

”

and

“

E

”

Figure

3,

and

base

plate

“

B

”

,

Figure

2.

TOOL

POST

DISASSEMBL

Figure

8

—

Tool

Post

Assembly

1.

Remove

bolt

“

A

”

,

Figure

8.

washer

and

tool

block

“

B

”

.

2.

Loosen

nuts

“

C

”

and

“

D",

Figure

8,

and

slide

tool

post

assembly

down

keyway

to

remove.

3.

Unscrew

fine

adjustment

dial

assembly,

Figure

9.

NOTE:

FINE

ADJUSTMENT

SCREW

HAS

LEFT-

HAND

THREADS.

4.

To

disassemble

fine

adjustment

dial

assembly:

(a)

Remove

taper

pin

“

E

”

,

Figure

10,

and

unscrew

dial

“

F

”

.

(b)

Remove

adjusting

bolt

“

G

”

,

nut

"H

”

and

T-

Bolt

“

J

”

.

5.

Remove

nut

“

K

”

,

Figure

11,

washer

and

spring

“

L

”

,

Figure

12.

Remove

T-Bolt

‘

‘

M

”

,

Figure

11.

6.

Unscrew

adjusting

nut

“

N

”

,

Figure

11,

from

tool

post

support

“

O

”

.

7.

Reassemble.

NOTE:

Fine

adjustment

dial

as

sembly

which

has

left-hand

threads,

can

be

threaded

into

either

one

of

two

threaded

holes,

depending

on

set

up.

Figure

9

—

Fine

Adjustment

Dial

Removal

5

i

r

Figure

11

—

Tool

Support

and

Components

Figure

13

—

Chasing

Head

Cylinder

Housing

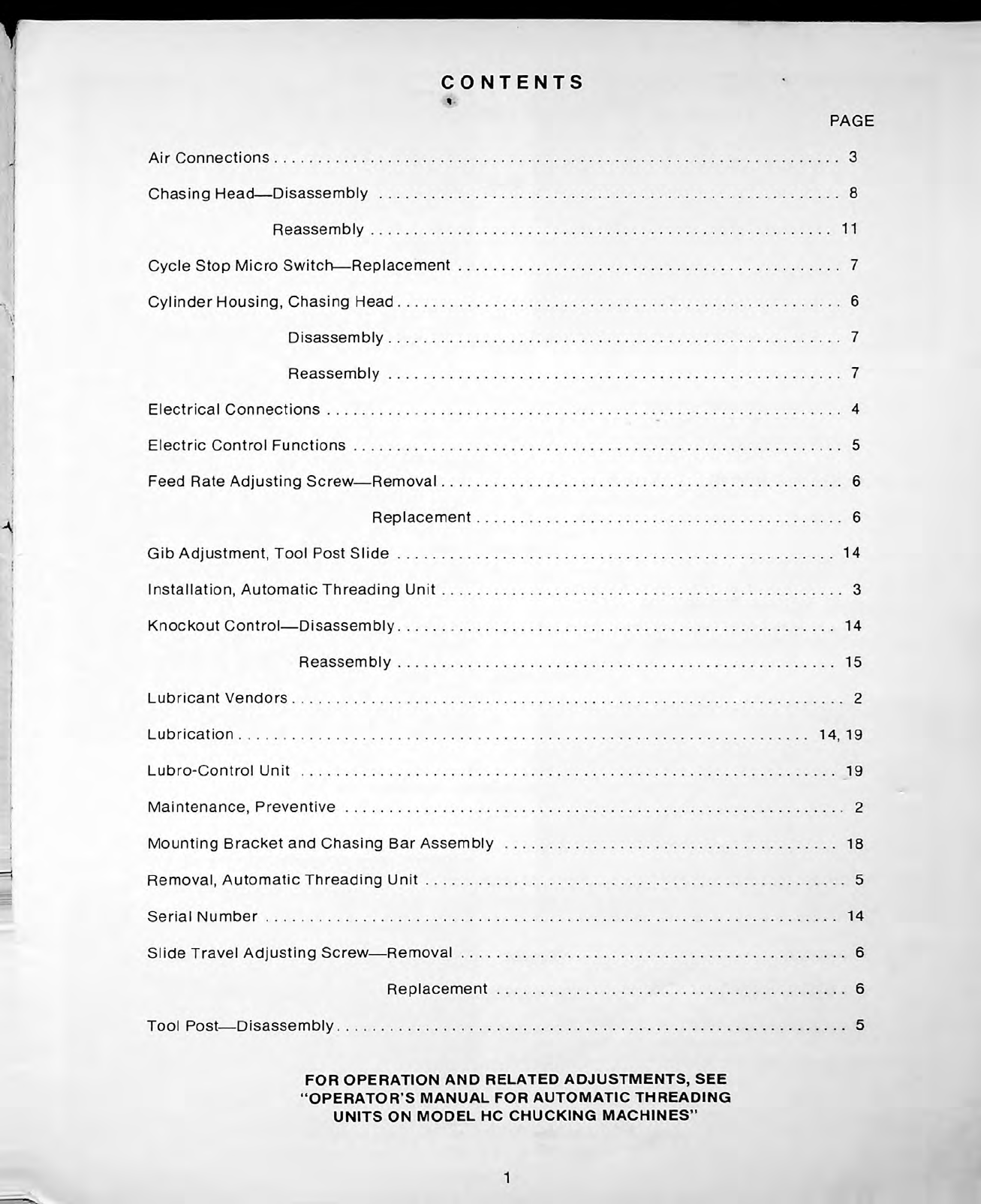

Feed

Rate

Adjusting

Screw

Replacement

1.

Replace

O-ring

“

F

”

,

Figure

14,

adjusting

nut

“

E

”

,

knob

“

D

”

and

roll

pin

“

C

”

.

2.

Thread

piston

stop

assembly

“

B'\

Figure

13

into

casting

until

adjusting

nut

“

E

”

,

Figure

14,

is

flush

with

casting.

Turn

knob

“

D

”

down

until

it

just

contacts

nut

“

E

”

.

Connect

air

pressure

at

control

unit.

3.

Cycle

threading

unit.

If

unit,

fails

to

cycle

and

slide

to

advance,

turn

large

white

dial

clockwise

by

hand

to

stop

passes.

Thread

adjusting

nut

“

E

”

out

gradually

per

following

instructions

until

pawl

can

enter

ratchet

and

operate

chasing

head.

(a)

Turn

knob

“

D

’

\

Figure

14,

counter-clock

wise

until

adjusting

nut

“

E

”

moves

a

frac

tion

of

a

turn.

Tighten

set

screw

under

lock

screw

“

A

”

.

Turn

knob

“

D

”

down

until

it

just

contacts

nut

“

E

”

.

Cycle

threading

unit.

4.

When

chasing

head

cycles,

tighten

set

screw

under

lock

screw

“

A

”

,

Figure

13,

and

replace

screw

“

A

”

.

Figure

12

—

Spring

for

Tool

Post

CHASING

HEAD

C LINDER

HOUSING

Feed

Rate

Adjusting

Screw

Removal

Slide

Travel

Adjusting

Screw

Removal

1.

Disconnect

air

pressure

at

control

unit.

Loosen

set

screw

“

G

”

,

Figure

13.

Do

not

misplace

brass

plug

under

set

screw.

2.

Remove

adjusting

screw

“

H

”

,

Figure

15,

and

remove

O-ring

“

J

”

.

NOTE:

Feed

rate

adjusting

screw

“

B

”

,

Figure

13,

is

factory

set

and

sealed.

Removal

is

not

recommended

unless

absolutely

necessary.

1.

Disconnect

air

pressure

at

control

unit.

Remove

wax

seal

from

screw

“

A

”

,

Figure

13,

and

remove

lock

screw

“

A

”

.

Loosen

set

screw

under

lock

screw

“

A

”

.

2.

Unscrew

piston

stop

assembly

“

B

”

.

Remove

roll

pin

“

C

”

,

Figure

14,

knob

“

D

”

,

adjusting

nut

“

E

”

and

O-ring

“

F

”

.

Do

not

misplace

brass

plug

under

screws

“

A

”

,

Figure

13.

Slide

Travel

Adjusting

Screw

Replacement

1.

Replace

O-ring

“

J

”

,

Figure

15,

and

start

ad

justing

screw

“

H

”

.

Connect

air

pressure

at

control

unit.

2.

Set

thread

depth

control

dial

at

70.

Turn

ad

justing

screw

“

H

”

,

Figure

15,

slowly

to

its

limit

under

normal

pressure

and

back

off

Vs

turn.

Relock

set

screw

“

G

”

,

Figure

13.

6

9.

Replace

cover

“

L

”

,

Figure

13,

and

seven

screws

“

K

”

.

10.

Connect

air

pressure

at

control

unit.

:

Figure

14

—

Feed

Rate

Adjusting

Screw

Cylinder

Housing

Disassembly

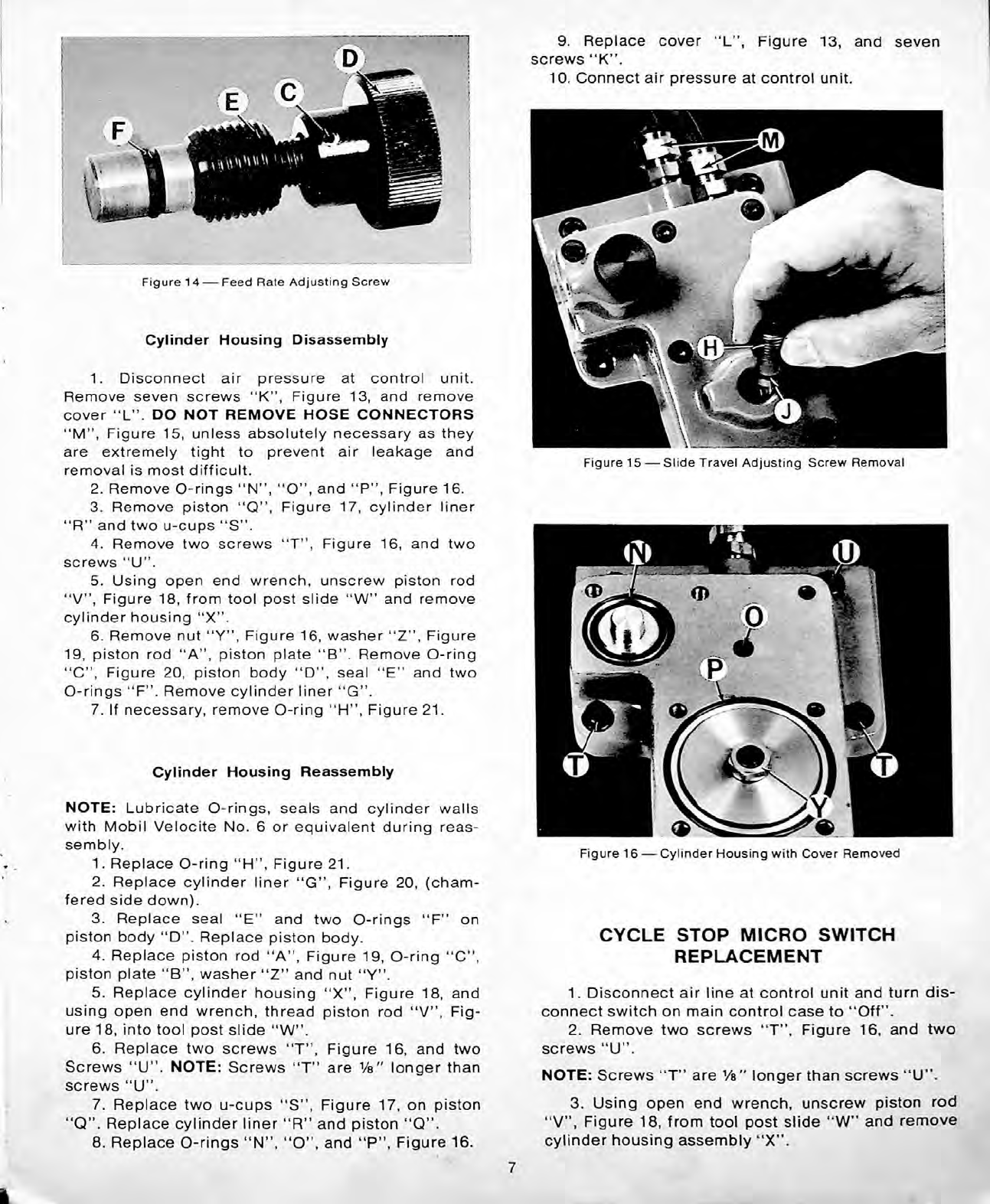

1.

Disconnect

air

pressure

at

control

unit.

Remove

seven

screws

“

K

”

,

Figure

13,

and

remove

cover

“

L

”

.

DO

NOT

REMOVE

HOSE

CONNECTORS

“

M

”

,

Figure

15,

unless

absolutely

necessary

as

they

are

extremely

tight

to

prevent

air

leakage

and

removal

is

most

difficult.

2.

Remove

O-rings

“

N

”

,

“

O

”

,

and

“

P

”

,

Figure

16.

3.

Remove

piston

“

Q

”

,

Figure

17,

cylinder

liner

“

R

”

and

two

u-cups

“

S

”

.

4.

Remove

two

screws

“

T

”

,

Figure

16,

and

two

screws

“

U

”

.

5.

Using

open

end

wrench,

unscrew

piston

rod

“

V

”

,

Figure

18,

from

tool

post

slide

“

W

”

and

remove

cylinder

housing

“

X

”

.

6.

Remove

nut

“

”

,

Figure

16,

washer

“

Z

”

,

Figure

19,

piston

rod

“

A

”

,

piston

plate

“

B

”

.

Remove

O-ring

“

C

”

,

Figure

20,

piston

body

“

D

”

,

seal

“

E

”

and

two

O-rings

“

F

”

.

Remove

cylinder

liner

“

G

”

.

7.

If

necessary,

remove

O-ring

“

H

”

,

Figure

21.

Figure

15

—

Slide

Travel

Adjusting

Screw

Removal

Cylinder

Housing

Reassembly

NOTE:

Lubricate

O-rings,

seals

and

cylinder

walls

with

Mobil

Velocite

No.

6

or

equivalent

during

reas

sembly.

1.

Replace

O-ring

“

H

”

,

Figure

21.

2.

Replace

cylinder

liner

“

G

”

,

Figure

20,

(cham

fered

side

down).

3.

Replace

seal

“

E

”

and

two

O-rings

“

F

piston

body

“

D

”

.

Replace

piston

body.

4.

Replace

piston

rod

“

A

”

,

Figure

19,

O-ring

“

C

”

,

piston

plate

“

B

”

,

washer

“

Z

”

and

nut

“

".

5.

Replace

cylinder

housing

“

X

”

,

Figure

18,

and

using

open

end

wrench,

thread

piston

rod

“

V

”

,

Fig

ure

18,

into

tool

post

slide

“

W

”

.

6.

Replace

two

screws

“

T

”

,

Figure

16,

and

two

Screws

“

U

”

.

NOTE:

Screws

“

T

”

are

Vs"

longer

than

screws

“

U

”

.

7.

Replace

two

u-cups

“

S

”

,

Figure

17,

on

piston

“

Q

”

.

Replace

cylinder

liner

“

R

”

and

piston

“

Q

”

.

8.

Replace

O-rings

“

N

”

,

“

O

”

,

and

“

P

”

,

Figure

16.

Figure

16

—

Cylinder

Housing

with

Cover

Removed

on

C CLE

STOP

MICRO

SWITCH

REPLACEMENT

1.

Disconnect

air

line

at

control

unit

and

turn

dis

connect

switch

on

main

control

case

to

“

Off

”

.

2.

Remove

two

screws

“

T

”

,

Figure

16,

and

two

screws

“

U

”

.

NOTE:

Screws

“

T

”

are

Vs"

longer

than

screws

“

U

”

.

3.

Using

open

end

wrench,

unscrew

piston

rod

“

V

”

,

Figure

18,

from

tool

post

slide

“

W

”

and

remove

cylinder

housing

assembly

“

X

”

.

7

i

Wi

v?l|

4.

Remove

two

screws

“

B

”

,

Figure

22,

and,

remove

micro

switch

“

A

”

.

Remove

wires

from

micro

switch.

5.

Connect

wires

to

normally

closed

and

common

terminals

of

new

micro

switch.

Replace

switch

“

A

”

and

two

screws

“

B

”

.

Do

not

tighten

screws.

6.

Pull

cycle

start

knob,

set

micro

switch

with

ac

tivator

just

touching

plunger

“

C

”

and

tighten

screws

“

B

”

.

7.

Turn

disconnect

switch

on

main

control

case

to

“

On

”

.

When

threading

unit

is

lowered

to

operating

position

a

click

will

be

heard

from

solenoid

in

knockout

housing

with

cycle

start

knob

“

Out

”

and

will

not

be

heard

with

cycle

start

knob

“

In

”

,

if

micro

switch

“

A

”

is

operating

properly.

Turn

large

white

dial

right-handed

to

retract

cycle

start

knob.

8.

Reassemble

other

components

by

reversing

steps

1,2,

and

3.

Figure

19

—

Piston

for

Slide

Travel

Adjusting

Screw

Figure

20

—

Cylinder

Housing

and

Components

Figure

17

—

Piston

for

Feed

Rate

Adjusting

Screw

Figure

21

—

Cylinder

Housing

CHASING

HEAD

DISASSEMBL

1.

Support

guide

bar

bracket

“

F

”

,

Figure

23,

by

hand

and

loosen

two

bolts

“

G

”

.

Remove

guide

bar

bracket.

2.

Follow

steps

1,

2,

and

3

under

“

Cycle

Stop

Micro

Switch

Replacement

”

on

previous

page.

3.

Remove

two

screws

“

B

”

,

Figure

22,

and

remove

micro

switch

“

A

”

.

Remove

wires

from

micro

switch.

Remove

O-ring

seal

for

micro

switch.

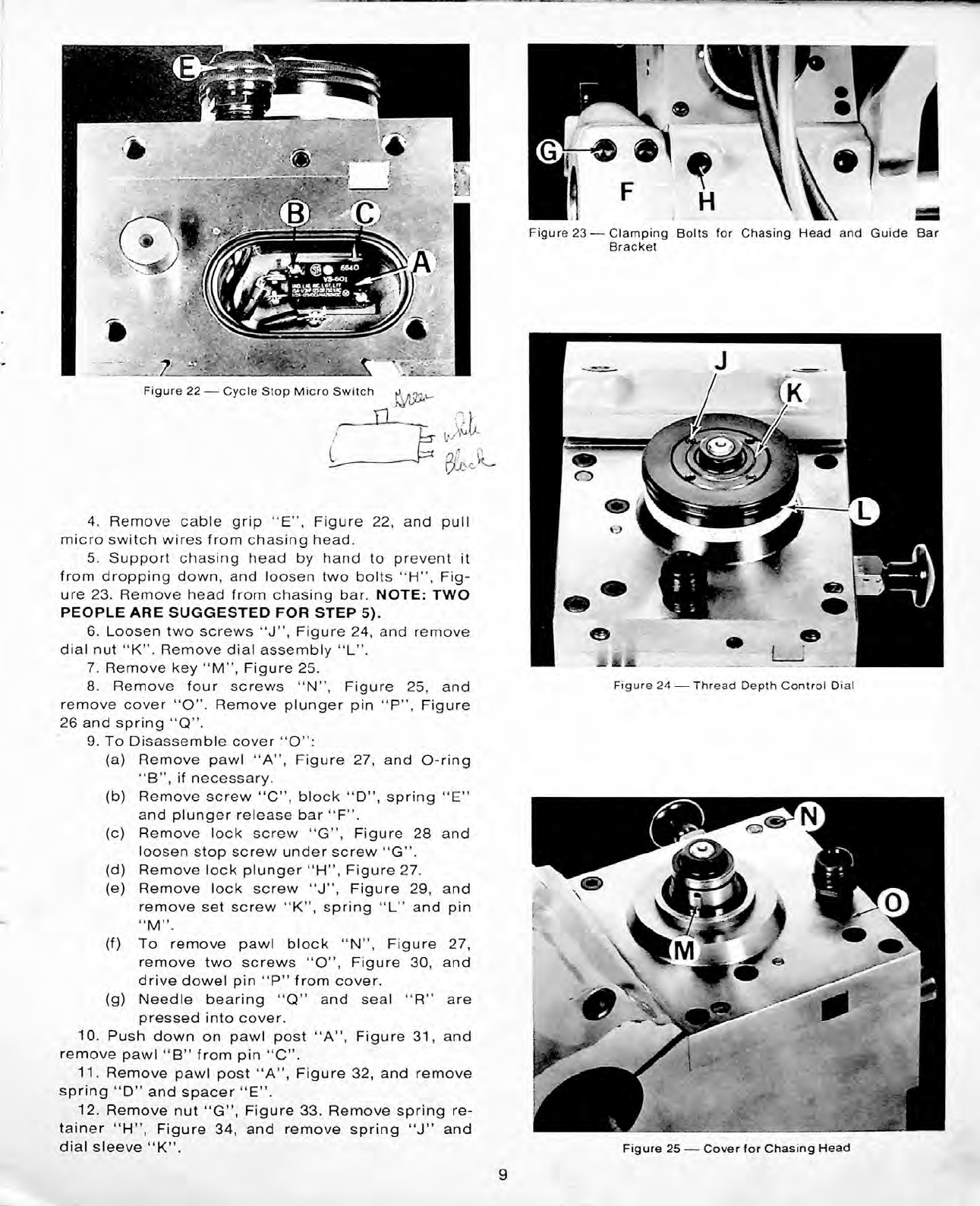

Figure

18

—

Piston

Rod

for

Slide

Travel

8

:

7]

r>

x\M

E

b

^

'

m

Figure

23

—

Clamping

Bolts

for

Chasing

Head

and

Guide

Bar

Bracket

w':

I

*

•

.

:

.

7

--^11

Figure

22

—

Cycle

Stop

Micro

Switch

■

n

i

4.

Remove

cable

grip

“

E

”

,

Figure

22,

and

pull

micro

switch

wires

from

chasing

head.

5.

Support

chasing

head

by

hand

to

prevent

it

from

dropping

down,

and

loosen

two

bolts

“

H

”

,

Fig

ure

23.

Remove

head

from

chasing

bar.

NOTE:

TWO

PEOPLE

ARE

SUGGESTED

FOR

STEP

5).

6.

Loosen

two

screws

“

J

”

,

Figure

24,

and

remove

dial

nut

“

K

”

.

Remove

dial

assembly

“

L

”

.

7.

Remove

key

“

M

”

,

Figure

25.

8.

Remove

four

screws

“

N

”

,

Figure

25,

and

remove

cover

“

O".

Remove

plunger

pin

“

P

”

,

Figure

26

and

spring

“

Q

”

.

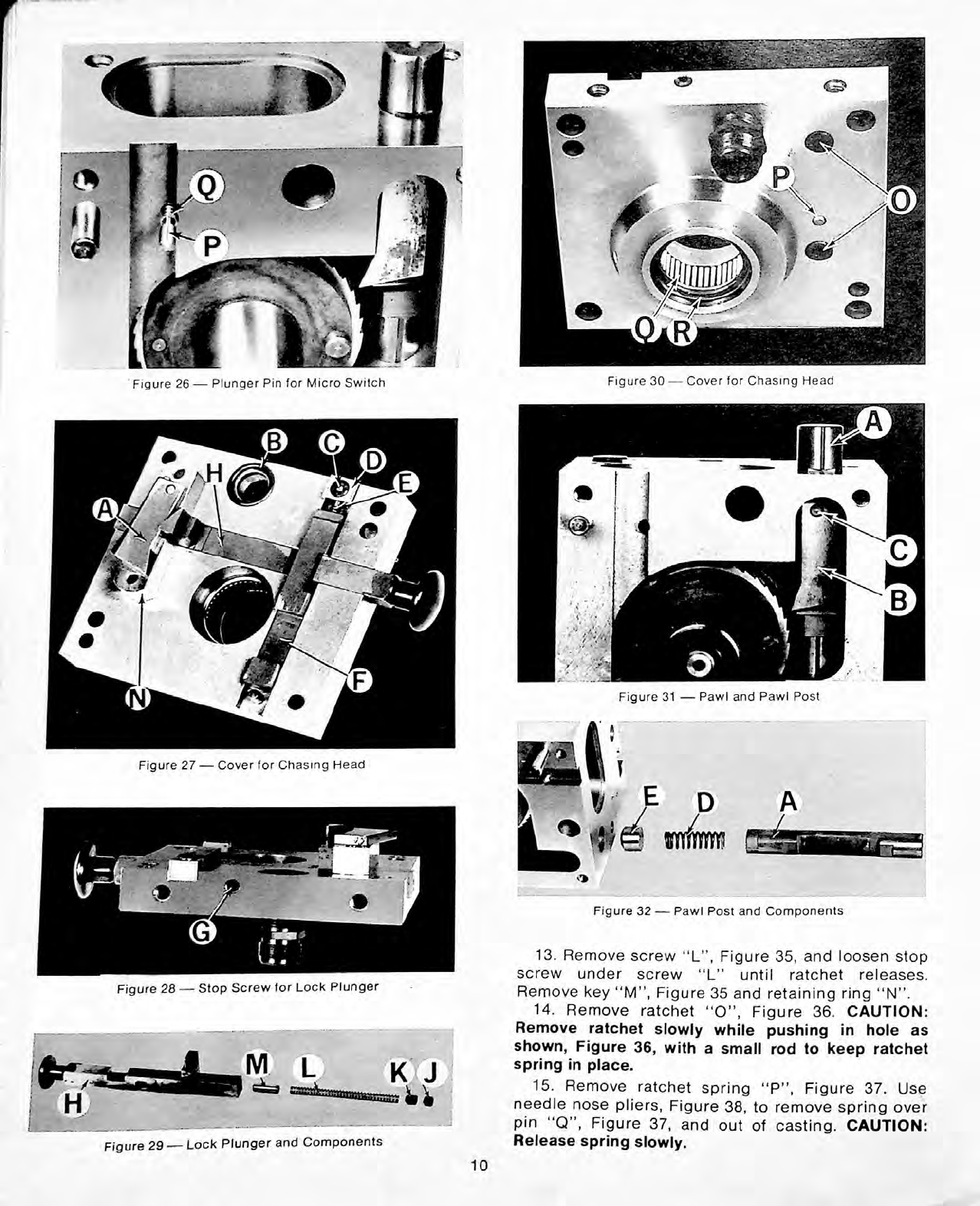

9.

To

Disassemble

cover

“

O

”

:

(a)

Remove

pawl

“

A

”

,

Figure

27,

and

O-ring

“

B

”

,

if

necessary.

(b)

Remove

screw

“

C

”

,

block

“

D

”

,

spring

“

E

”

and

plunger

release

bar

“

F

”

.

(c)

Remove

lock

screw

“

G

”

,

Figure

28

and

loosen

stop

screw

under

screw

“

G

”

.

(d)

Remove

lock

plunger

“

H

”

,

Figure

27.

(e)

Remove

lock

screw

“

J

”

,

Figure

29,

and

remove

set

screw

“

K",

spring

“

L

”

and

pin

“

”

.

(f)

To

remove

pawl

block

“

N

”

,

Figure

27,

remove

two

screws

“

O

”

,

Figure

30,

and

drive

dowel

pin

“

P

”

from

cover.

(g)

Needle

bearing

“

Q

”

and

seal

“

R

”

are

pressed

into

cover.

10.

Push

down

on

pawl

post

“

A

”

,

Figure

31,

and

remove

pawl

“

B

”

from

pin

“

C

,

\

11.

Remove

pawl

post

“

A

”

,

Figure

32,

and

remove

spring

“

D

”

and

spacer

“

E

”

.

12.

Remove

nut

“

G

”

,

Figure

33.

Remove

spring

re

tainer

“

H

”

,

Figure

34,

and

remove

spring

“

J

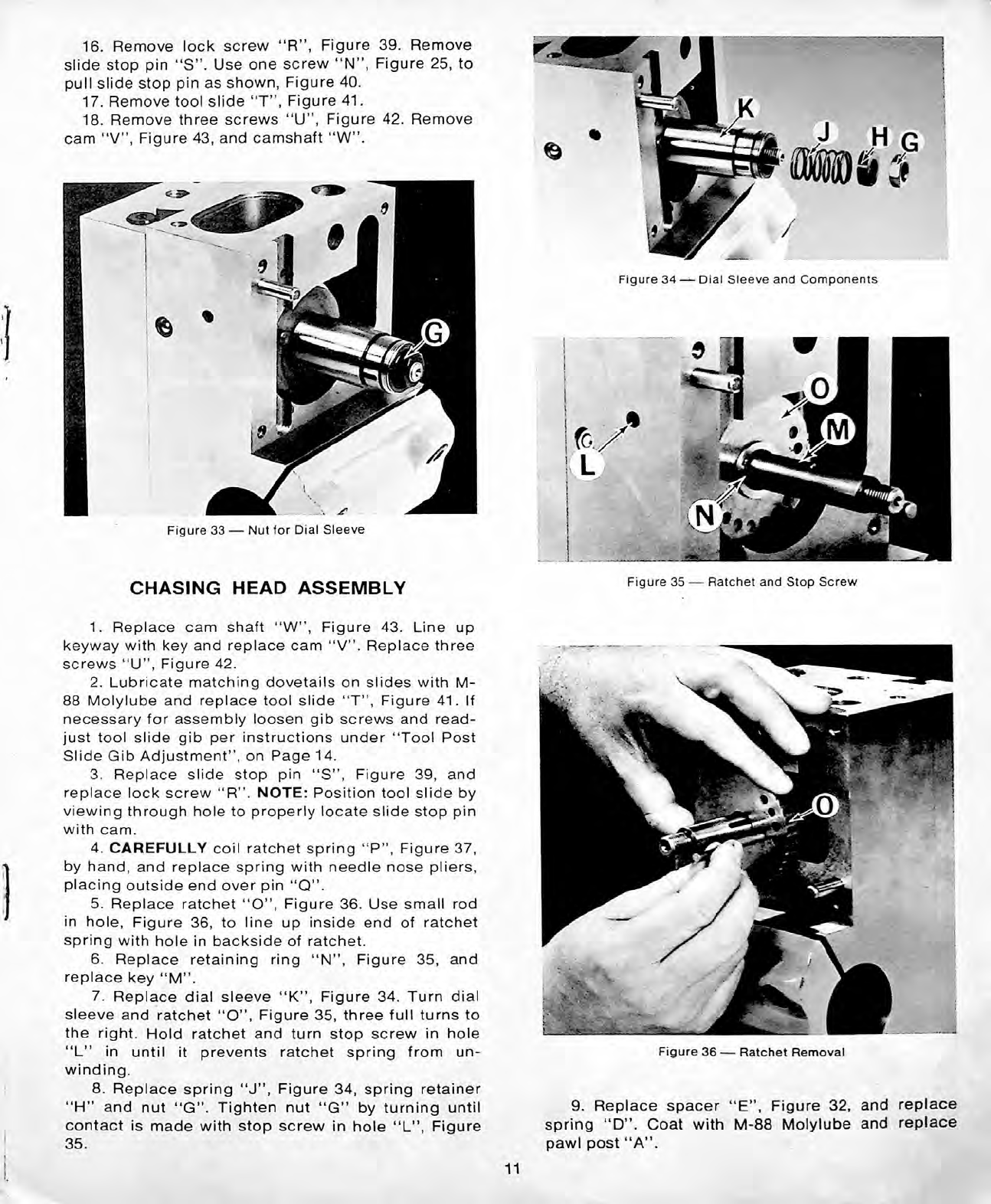

”

and

dial

sleeve

“

K

”

.

Figure

24

—

Thread

Depth

Control

Dial

Figure

25

—

Cover

for

Chasing

Head

9

r

i

Figure

30

—

Cover

for

Chasing

Head

'

Figure

26

—

Plunger

Pin

for

Micro

Switch

C

B

•s-

-

Figure

31

—

Pawl

and

Pawl

Post

ft

mi

’

*

Figure

27

—

Cover

for

Chasing

Head

}

V

j-

p

A

Figure

32

—

Pawl

Post

and

Components

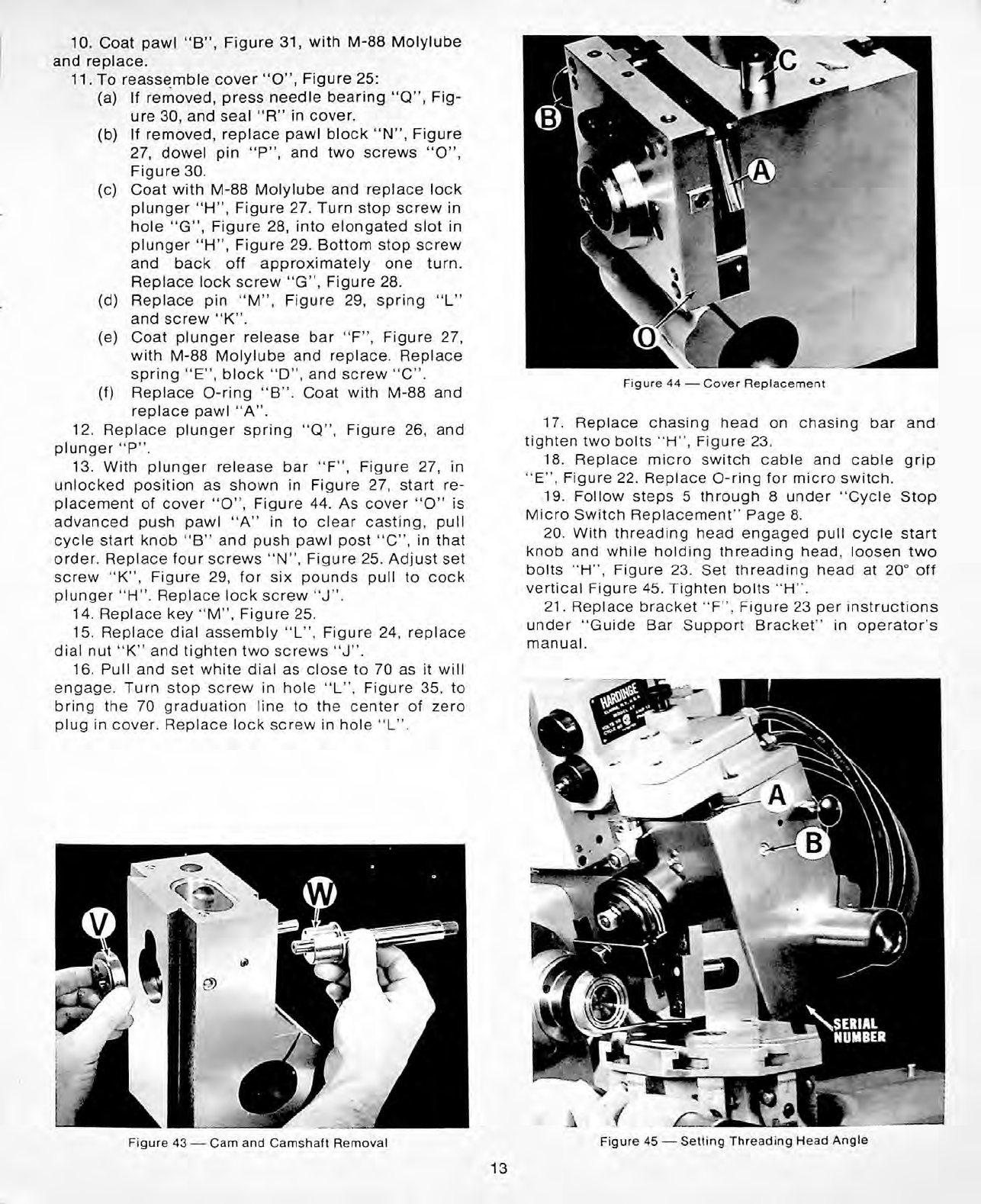

13.

Remove

screw

“

L

”

,

Figure

35,

and

loosen

stop

screw

under

screw

“

L

”

until

ratchet

releases.

Remove

key

“

M

”

,

Figure

35

and

retaining

ring

“

N

”

.

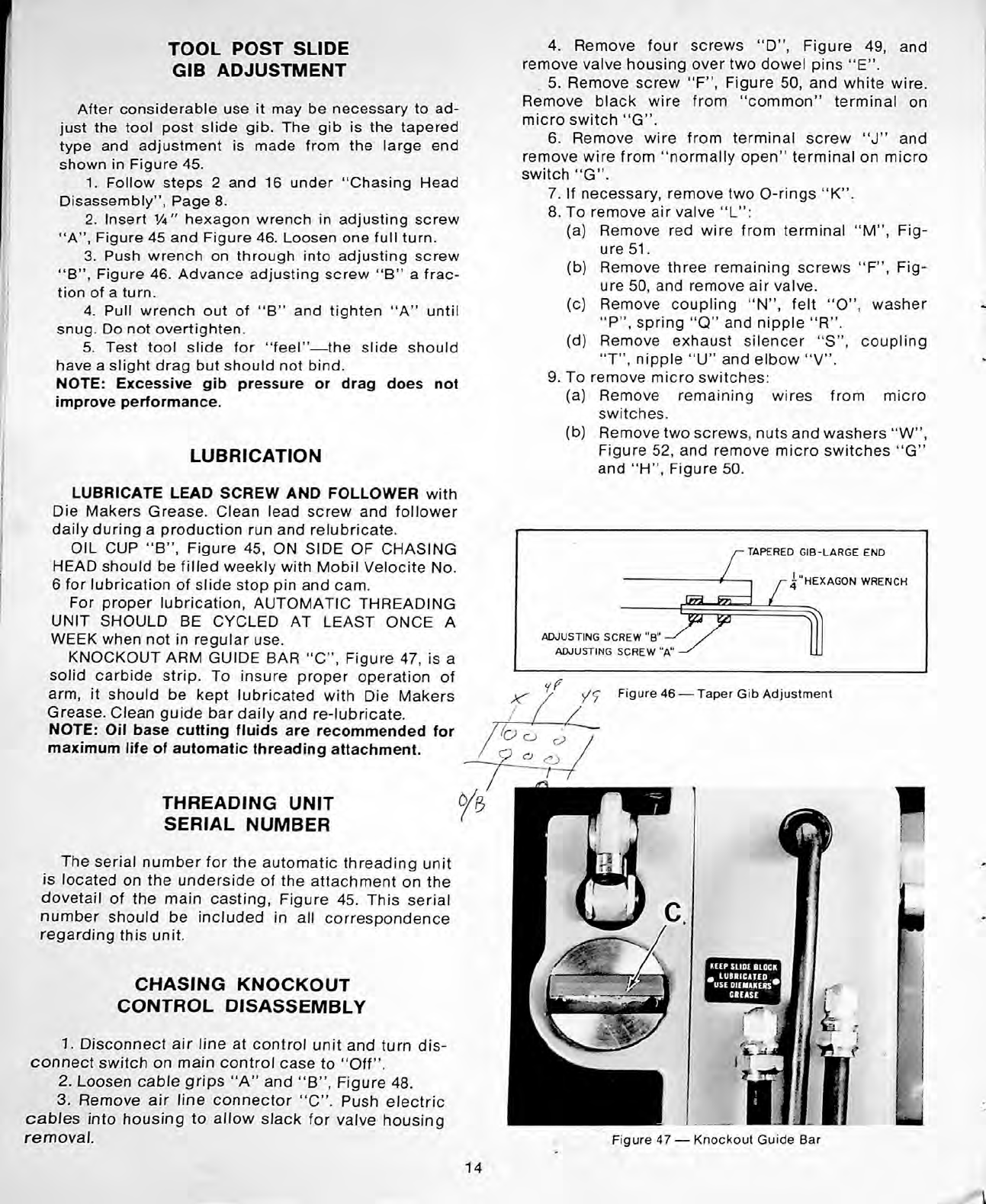

14.

Remove

ratchet

“

O

”

,

Figure

36.

CAUTION:

Remove

ratchet

slowly

while

pushing

in

hole

as

shown,

Figure

36,

with

a

small

rod

to

keep

ratchet

spring

in

place.

15.

Remove

ratchet

spring

“

P

”

,

Figure

37.

Use

needle

nose

pliers,

Figure

38,

to

remove

spring

over

pin

“

Q

”

,

Figure

37,

and

out

of

casting.

CAUTION:

Release

spring

slowly.

Figure

28

—

Stop

Screw

for

Lock

Plunger

L

K

J

SSSS!

k

:

ffi3ffiaaBaEas;

^

^

Figure

29

—

Lock

Plunger

and

Components

10

16.

Remove

lock

screw

“

R

”

,

Figure

39.

Remove

slide

stop

pin

“

S

”

.

Use

one

screw

“

N

”

,

Figure

25,

to

pull

slide

stop

pin

as

shown,

Figure

40.

17.

Remove

tool

slide

“

T

”

,

Figure

41.

18.

Remove

three

screws

“

U

”

,

Figure

42.

Remove

cam

“

V

”

,

Figure

43,

and

camshaft

“

W

”

.

Figure

34

—

Dial

Sleeve

and

Components

Figure

33

—

Nut

for

Dial

Sleeve

Figure

35

—

Ratchet

and

Stop

Screw

CHASING

HEAD

ASSEMBL

1.

Replace

cam

shaft

“

W

”

,

Figure

43.

Line

up

keyway

with

key

and

replace

cam

“

V

”

.

Replace

three

screws

“

U

”

,

Figure

42.

2.

Lubricate

matching

dovetails

on

slides

with

M-

88

Molylube

and

replace

tool

slide

“

T

”

,

Figure

41.

If

necessary

for

assembly

loosen

gib

screws

and

read

just

tool

slide

gib

per

instructions

under

“

Tool

Post

Slide

Gib

Adjustment

”

,

on

Page

14.

3.

Replace

slide

stop

pin

“

S

”

,

Figure

39,

and

replace

lock

screw

“

R

”

.

NOTE:

Position

tool

slide

by

viewing

through

hole

to

properly

locate

slide

stop

pin

with

cam.

4.

CAREFULLY

coil

ratchet

spring

“

P

”

,

Figure

37,

by

hand,

and

replace

spring

with

needle

nose

pliers,

placing

outside

end

over

pin

“

Q

”

.

5.

Replace

ratchet

“

O

”

,

Figure

36.

Use

small

rod

in

hole,

Figure

36,

to

line

up

inside

end

of

ratchet

spring

with

hole

in

backside

of

ratchet.

6.

Replace

retaining

ring

“

N

”

,

Figure

35,

and

replace

key

“

M

”

.

7.

Replace

dial

sleeve

“

K

”

,

Figure

34.

Turn

dial

sleeve

and

ratchet

“

O

”

,

Figure

35,

three

full

turns

to

the

right.

Hold

ratchet

and

turn

stop

screw

in

hole

“

L

”

in

until

it

prevents

ratchet

spring

from

un

winding.

8.

Replace

spring

“

J

”

,

Figure

34,

spring

retainer

“

H

”

and

nut

“

G

”

.

Tighten

nut

“

G

”

by

turning

until

contact

is

made

with

stop

screw

in

hole

“

L

”

,

Figure

Figure

36

—

Ratchet

Removal

9.

Replace

spacer

“

E

”

,

Figure

32,

and

replace

spring

“

D

”

.

Coat

with

M-88

Molylube

and

replace

pawl

post

“

A

”

.

35.

11

V

Figure

40

—

Slide

Stop

Pin

Removal

Figure

37

—

Ratchet

Spring

Figure

38

—

Ratchet

Spring

Removal

Figure

41

—

Tool

Post

Slide

Removal

Figure

39

—

Lock

Screw

and

Slide

Stop

Pin

for

Tool

Post

Slide

Figure

42

—

Mounting

Screws

for

Cam

12

10.

Coat

pawl

“

B

”

,

Figure

31,

with

M-88

Molylube

and

replace.

11.

To

reassemble

cover

"O

”

,

Figure

25:

(a)

If

removed,

press

needle

bearing

“

Q

”

,

Fig

ure

30,

and

seal

“

R

”

in

cover.

(b)

If

removed,

replace

pawl

block

“

N

”

,

Figure

27,

dowel

pin

“

P

”

,

and

two

screws

“

O

”

,

Figure

30.

(c)

Coat

with

M-88

Molylube

and

replace

lock

plunger

“

H

”

,

Figure

27.

Turn

stop

screw

in

hole

“

G

”

,

Figure

28,

into

elongated

slot

in

plunger

“

H

”

,

Figure

29.

Bottom

stop

screw

and

back

off

approximately

one

turn.

Replace

lock

screw

“

G

”

,

Figure

28.

(d)

Replace

pin

“

M

”

,

Figure

29,

spring

“

L

”

and

screw

“

K

”

.

(e)

Coat

plunger

release

bar

“

F

”

,

Figure

27,

with

M-88

Molylube

and

replace.

Replace

spring

“

E

”

,

block

“

D

”

,

and

screw

“

C

”

.

(f)

Replace

O-ring

“

B

”

.

Coat

with

M-88

and

replace

pawl

“

A

”

.

12.

Replace

plunger

spring

“

Q

”

,

Figure

26,

and

plunger

“

P

”

.

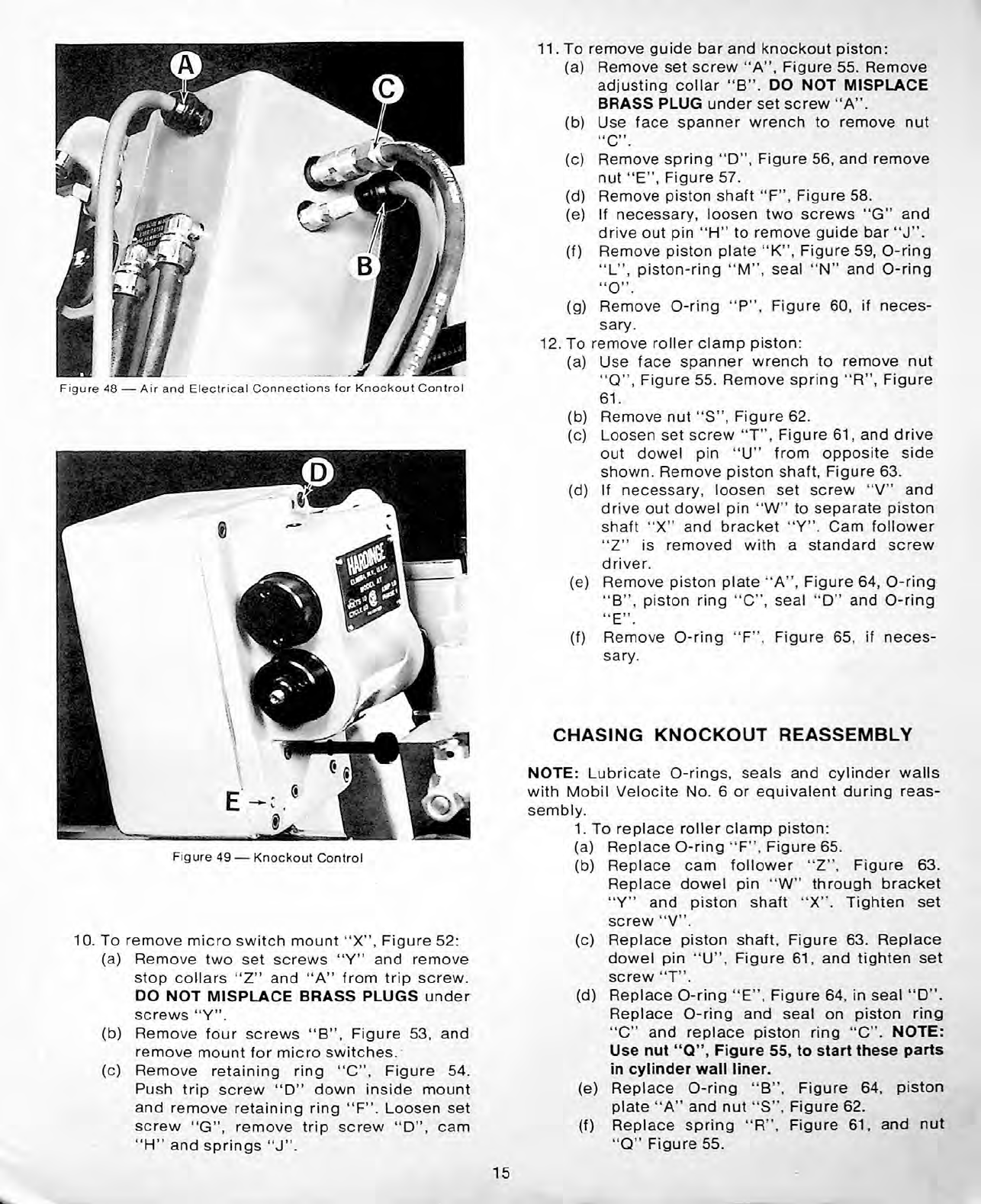

13.

With

plunger

release

bar

“

F

”

,

Figure

27,

in

unlocked

position

as

shown

in

Figure

27,

start

re

placement

of

cover

“

O

”

,

Figure

44.

As

cover

“

O

”

is

advanced

push

pawl

“

A

”

in

to

clear

casting,

pull

cycle

start

knob

“

B

”

and

push

pawl

post

“

C

”

,

in

that

order.

Replace

four

screws

“

N

”

,

Figure

25.

Adjust

set

screw

“

K

”

,

Figure

29,

for

six

pounds

pull

to

cock

plunger

“

H

”

.

Replace

lock

screw

“

J

”

.

14.

Replace

key

“

M

”

,

Figure

25.

15.

Replace

dial

assembly

“

L

”

,

Figure

24,

replace

dial

nut

“

K

”

and

tighten

two

screws

“

J

”

.

16.

Pull

and

set

white

dial

as

close

to

70

as

it

will

engage.

Turn

stop

screw

in

hole

“

L

”

,

Figure

35,

to

bring

the

70

graduation

line

to

the

center

of

zero

plug

in

cover.

Replace

lock

screw

in

hole

“

L

”

.

Figure

44

—

Cover

Replacement

17.

Replace

chasing

head

on

chasing

bar

and

tighten

two

bolts

“

H

”

,

Figure

23.

18.

Replace

micro

switch

cable

and

cable

grip

“

E

”

,

Figure

22.

Replace

O-ring

for

micro

switch.

19.

Follow

steps

5

through

8

under

“

Cycle

Stop

Micro

Switch

Replacement

”

Page

8.

20.

With

threading

head

engaged

pull

cycle

start

knob

and

while

holding

threading

head,

loosen

two

bolts

“

H

”

,

Figure

23.

Set

threading

head

at

20°

off

vertical

Figure

45.

Tighten

bolts

“

H

”

.

21.

Replace

bracket

“

F

”

.

Figure

23

per

instructions

under

“

Guide

Bar

Support

Bracket

”

in

operator

’

s

manual.

Figure

45

—

Setting

Threading

Head

Angle

Figure

43

—

Cam

and

Camshaft

Removal

13

4.

Remove

four

screws

“

D

”

,

Figure

49,

and

remove

valve

housing

over

two

dowel

pins

“

E

”

.

5.

Remove

screw

“

F

”

,

Figure

50,

and

white

wire.

Remove

black

wire

from

“

common

”

terminal

on

micro

switch

“

G

”

.

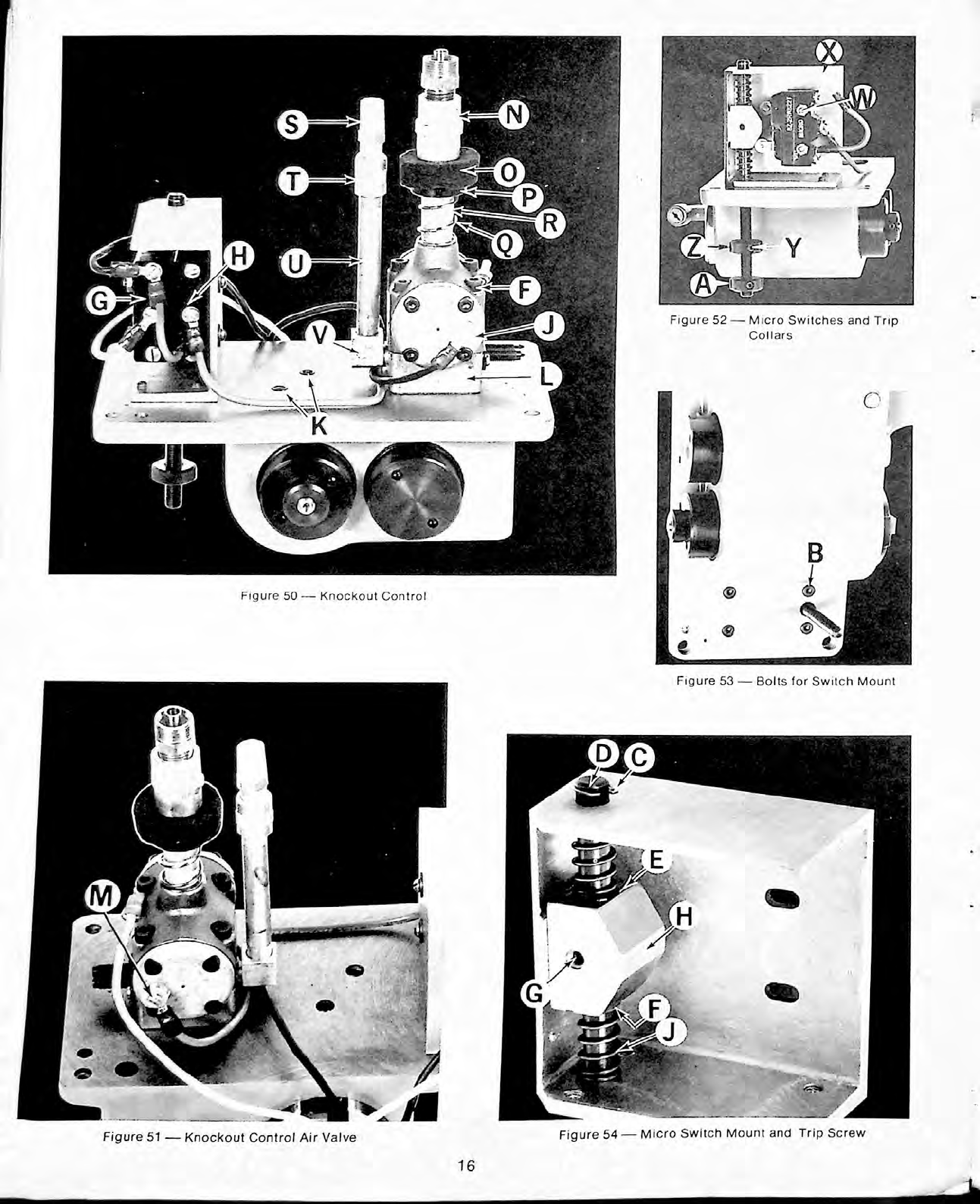

6.

Remove

wire

from

terminal

screw

“

J

”

and

remove

wire

from

“

normally

open

”

terminal

on

micro

switch

“

G

”

.

7.

If

necessary,

remove

two

O-rings

“

K

”

.

8.

To

remove

air

valve

“

L

”

:

(a)

Remove

red

wire

from

terminal

“

M

”

,

Fig

ure

51.

(b)

Remove

three

remaining

screws

“

F

”

,

Fig

ure

50,

and

remove

air

valve.

(c)

Remove

coupling

“

N

”

,

felt

“

O

”

,

washer

“

P

”

,

spring

“

Q

”

and

nipple

“

R

”

.

(d)

Remove

exhaust

silencer

“

S

”

,

coupling

“

T

”

,

nipple

“

U

”

and

elbow

“

V

”

.

9.

To

remove

micro

switches:

(a)

Remove

remaining

wires

from

micro

switches.

(b)

Remove

two

screws,

nuts

and

washers

“

W

”

,

Figure

52,

and

remove

micro

switches

“

G

”

and

“

H

”

,

Figure

50.

TOOL

POST

SLIDE

GIB

ADJUSTMENT

After

considerable

use

it

may

be

necessary

to

ad

just

the

tool

post

slide

gib.

The

gib

is

the

tapered

type

and

adjustment

is

made

from

the

large

end

shown

in

Figure

45.

1.

Follow

steps

2

and

16

under

“

Chasing

Head

Disassembly

”

,

Page

8.

2.

Insert

V

a

"

hexagon

wrench

in

adjusting

screw

“

A

”

,

Figure

45

and

Figure

46.

Loosen

one

full

turn.

3.

Push

wrench

on

through

into

adjusting

screw

“

B

”

,

Figure

46.

Advance

adjusting

screw

“

B

”

a

frac

tion

of

a

turn.

4.

Pull

wrench

out

of

“

B

”

and

tighten

“

A

”

until

snug.

Do

not

overtighten.

5.

Test

tool

slide

for

“

feel

”

—

the

slide

should

have

a

slight

drag

but

should

not

bind.

NOTE:

Excessive

gib

pressure

or

drag

does

not

improve

performance.

LUBRICATION

LUBRICATE

LEAD

SCREW

AND

FOLLOWER

with

Die

Makers

Grease.

Clean

lead

screw

and

follower

daily

during

a

production

run

and

relubricate.

OIL

CUP

“

B

”

,

Figure

45,

ON

SIDE

OF

CHASING

HEAD

should

be

filled

weekly

with

Mobil

Velocite

No.

6

for

lubrication

of

slide

stop

pin

and

cam.

For

proper

lubrication,

AUTOMATIC

THREADING

UNIT

SHOULD

BE

C CLED

AT

LEAST

ONCE

A

WEEK

when

not

in

regular

use.

KNOCKOUT

ARM

GUIDE

BAR

“

C

”

,

Figure

47,

is

a

solid

carbide

strip.

To

insure

proper

operation

of

arm,

it

should

be

kept

lubricated

with

Die

Makers

Grease.

Clean

guide

bar

daily

and

re-lubricate.

NOTE:

Oil

base

cutting

fluids

are

recommended

for

maximum

life

of

automatic

threading

attachment.

TAPERED

GIB-LARGE

END

HEXAGON

WRENCH

\rri

RrT

ADJUSTING

SCREW

"B"

ADJUSTING

SCREW

"A"

if

Figure

46

—

Taper

Gib

Adjustment

/

THREADING

UNIT

SERIAL

NUMBER

The

serial

number

for

the

automatic

threading

unit

is

located

on

the

underside

of

the

attachment

on

the

dovetail

of

the

main

casting,

Figure

45.

This

serial

number

should

be

included

in

all

correspondence

regarding

this

unit.

CHASING

KNOCKOUT

CONTROL

DISASSEMBL

1.

Disconnect

air

line

at

control

unit

and

turn

dis

connect

switch

on

main

control

case

to

“

Off

”

.

2.

Loosen

cable

grips

“

A

”

and

“

B

”

,

Figure

48.

3.

Remove

air

line

connector

“

C

”

.

Push

electric

cables

into

housing

to

allow

slack

for

valve

housing

remo al.

14

i

11.

To

remove

guide

bar

and

knockout

piston:

(a)

Remove

set

screw

“

A

”

,

Figure

55.

Remove

adjusting

collar

“

B

”

.

DO

NOT

ISPLACE

BRASS

PLUG

under

set

screw

“

A

”

.

(b) Use

face

spanner

wrench

to

remove

nut

“

C

”

.

(c)

Remove

spring

“

D

”

,

Figure

56,

and

remove

nut

“

E'\

Figure

57.

(d)

Remove

piston

shaft

“

F

”

,

Figure

58.

(e)

If

necessary,

loosen

two

screws

“

G

”

and

drive

out

pin

"H"

to

remove

guide

bar

“

J

”

.

(f)

Remove

piston

plate

“

K

”

,

Figure

59,

O-ring

“

L

”

,

piston-ring

“

M

”

,

seal

“

N

”

and

O-ring

“

O

”

.

(g)

Remove

O-ring

“

P",

Figure

60,

if

neces

sary.

12.

To

remove

roller

clamp

piston:

(a)

Use

face

spanner

wrench

to

remove

nut

“

Q

”

,

Figure

55.

Remove

spring

“

R

”

,

Figure

Figure

48

—

Air

and

Electrical

Connections

for

Knockout

Control

61.

(b)

Remove

nut

“

S

”

,

Figure

62.

(c)

Loosen

set

screw

“

T

”

,

Figure

61,

and

drive

out

dowel

pin

“

U

”

from

opposite

side

shown.

Remove

piston

shaft,

Figure

63.

(d)

If

necessary,

loosen

set

screw

“

V

”

and

drive

out

dowel

pin

“

W

”

to

separate

piston

shaft

“

X

”

and

bracket

“

”

.

Cam

follower

is

removed

with

a

standard

screw

“

Z

driver.

(e)

Remove

piston

plate

'

‘

A

”

,

Figure

64,

O-ring

“

B

”

,

piston

ring

“

C

”

,

seal

“

D

”

and

O-ring

“

E

”

.

(f)

Remove

O-ring

“

F

”

,

Figure

65,

if

neces

sary.

CHASING

KNOCKOUT

REASSEMBL

NOTE:

Lubricate

O-rings,

seals

and

cylinder

walls

with

Mobil

Velocite

No.

6

or

equivalent

during

reas

sembly.

1.

To

replace

roller

clamp

piston:

(a)

Replace

O-ring

“

F

”

,

Figure

65.

(b)

Replace

cam

follower

“

Z

”

,

Figure

63.

Replace

dowel

pin

“

W

”

through

bracket

“

”

and

piston

shaft

“

X

”

.

Tighten

set

screw

“

V

”

.

(c)

Replace

piston

shaft,

Figure

63.

Replace

dowel

pin

“

U

”

,

Figure

61,

and

tighten

set

screw

“

T

”

.

(d)

Replace

O-ring

“

E

”

,

Figure

64,

in

seal

“

D

M

.

Replace

O-ring

and

seal

on

piston

ring

“

C

”

and

replace

piston

ring

“

C

”

.

NOTE:

Use

nut

“

Q

”

,

Figure

55,

to

start

these

parts

in

cylinder

wall

liner.

(e)

Replace

O-ring

“

B

”

,

Figure

64,

piston

plate

“

A

”

and

nut

“

S

”

,

Figure

62.

(f)

Replace

spring

“

R

”

,

Figure

61,

and

nut

“

Q

”

Figure

55.

Figure

49

—

Knockout

Control

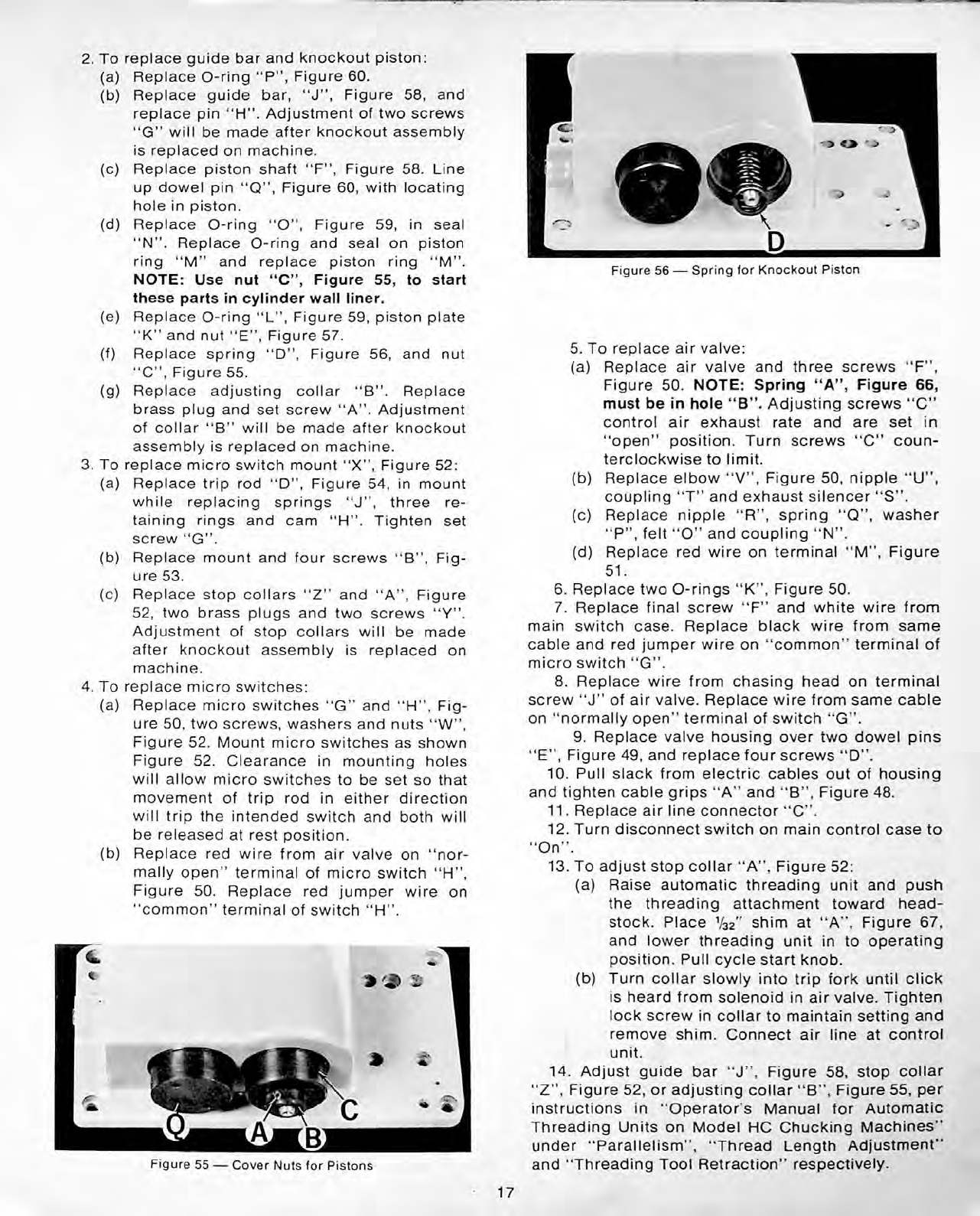

10.

To

remove

micro

switch

mount

“

X

”

,

Figure

52:

(a)

Remove

two

set

screws

“

”

and

remove

stop

collars

“

Z

”

and

“

A

”

from

trip

screw.

DO

NOT

ISPLACE

BRASS

PLUGS

under

screws

“

”

.

(b)

Remove

four

screws

“

B

”

,

Figure

53,

and

remove

mount

for

micro

switches.

(c)

Remove

retaining

ring

“

C

”

,

Figure

54.

Push

trip

screw

“

D

”

down

inside

mount

and

remove

retaining

ring

“

F

”

.

Loosen

set

screw

“

G

”

,

remove

trip

screw

“

D

”

,

cam

“

H

”

and

springs

“

J

”

.

15

Figure

52

—

Micro

Switches

and

Trip

Collars

Figure

50

—

Knockout

Control

Figure

53

—

Bolts

for

Switch

Mount

Figure

54

—

Micro

Switch

Mount

and

Trip

Screw

Figure

51

—

Knockout

Control

Air

Valve

16

2.

To

replace

guide

bar

and

knockout

piston:

(a)

Replace

O-ring

“

P

”

,

Figure

60.

(b)

Replace

guide

bar,

“

J

”

,

Figure

58,

and

replace

pin

“

H

”

.

Adjustment

of

two

screws

“

G

”

will

be

made

after

knockout

assembly

is

replaced

on

machine.

(c)

Replace

piston

shaft

“

F

”

,

Figure

58.

Line

up

dowel

pin

“

Q

”

,

Figure

60,

with

locating

hole

in

piston.

(d)

Replace

O-ring

“

O

”

,

Figure

59,

in

seal

“

N

”

.

Replace

O-ring

and

seal

on

piston

ring

“

M

”

and

replace

piston

ring

“

M

”

.

NOTE:

Use

nut

“

C

”

,

Figure

55,

to

start

these

parts

in

cylinder

wall

liner.

(e)

Replace

O-ring

“

L

”

,

Figure

59,

piston

plate

“

K

”

and

nut

“

E

”

,

Figure

57.

(f)

Replace

spring

“

D",

Figure

56,

and

nut

“

C

”

,

Figure

55.

(g)

Replace

adjusting

collar

“

B

”

.

Replace

brass

plug

and

set

screw

“

A

”

.

Adjustment

of

collar

"B

”

will

be

made

after

knockout

assembly

is

replaced

on

machine.

3.

To

replace

micro

switch

mount

“

X

”

,

Figure

52:

(a)

Replace

trip

rod

“

D

”

,

Figure

54,

in

mount

while

replacing

springs

“

J

”

,

three

re

taining

rings

and

cam

“

H

”

.

Tighten

set

screw

“

G

”

.

(b)

Replace

mount

and

four

screws

“

B

”

,

Fig

ure

53.

(c)

Replace

stop

collars

“

Z

”

and

“

A

”

,

Figure

52,

two

brass

plugs

and

two

screws

“

”

.

Adjustment

of

stop

collars

will

be

made

after

knockout

assembly

is

replaced

on

machine.

4.

To

replace

micro

switches:

(a)

Replace

micro

switches

“

G

”

and

“

H

”

,

Fig

ure

50,

two

screws,

washers

and

nuts

“

W

”

,

Figure

52.

Mount

micro

switches

as

shown

Figure

52.

Clearance

in

mounting

holes

will

allow

micro

switches

to

be

set

so

that

movement

of

trip

rod

in

either

direction

will

trip

the

intended

switch

and

both

will

be

released

at

rest

position.

(b)

Replace

red

wire

from

air

valve

on

“

nor

mally

open

”

terminal

of

micro

switch

“

H

”

,

Figure

50.

Replace

red

jumper

wire

on

“

common

”

terminal

of

switch

“

H

”

.

D

Figure

56

—

Spring

for

Knockout

Piston

5.

To

replace

air

valve:

(a)

Replace

air

valve

and

three

screws

“

F

”

,

Figure

50.

NOTE:

Spring

“

A

”

,

Figure

66,

must

be

in

hole

“

B

”

.

Adjusting

screws

“

C”

control

air

exhaust

rate

and

are

set

in

“

open

”

position.

Turn

screws

"C

”

coun

terclockwise

to

limit.

(b)

Replace

elbow

“

V

”

,

Figure

50,

nipple

“

U

”

,

coupling

“

T

”

and

exhaust

silencer

“

S

”

.

(c)

Replace

nipple

“

R

”

,

spring

“

Q

”

,

washer

“

P

”

,

felt

“

O

”

and

coupling

“

N

”

.

(d)

Replace

red

wire

on

terminal

“

M

”

,

Figure

51.

6.

Replace

two

O-rings

“

K

”

,

Figure

50.

7.

Replace

final

screw

“

F

”

and

white

wire

from

main

switch

case.

Replace

black

wire

from

same

cable

and

red

jumper

wire

on

“

common

”

terminal

of

micro

switch

“

G

”

.

8.

Replace

wire

from

chasing

head

on

terminal

screw

“

J

”

of

air

valve.

Replace

wire

from

same

cable

on

“

normally

open

”

terminal

of

switch

“

G

”

.

9.

Replace

valve

housing

over

two

dowel

pins

“

E

”

,

Figure

49,

and

replace

four

screws

“

D

”

.

10.

Pull

slack

from

electric

cables

out

of

housing

and

tighten

cable

grips

“

A

”

and

“

B

”

,

Figure

48.

11.

Replace

air

line

connector

“

C

”

.

12.

Turn

disconnect

switch

on

main

control

case

to

“

On

”

.

13.

To

adjust

stop

collar

“

A

”

,

Figure

52:

(a)

Raise

automatic

threading

unit

and

push

the

threading

attachment

toward

head-

stock.

Place

1

/

32

''

shim

at

“

A

”

,

Figure

67,

and

lower

threading

unit

in

to

operating

position.

Pull

cycle

start

knob.

(b)

Turn

collar

slowly

into

trip

fork

until

click

is

heard

from

solenoid

in

air

valve.

Tighten

lock

screw

in

collar

to

maintain

setting

and

remove

shim.

Connect

air

line

at

control

unit.

14.

Adjust

guide

bar

“

J

”

,

Figure

58,

stop

collar

“

Z

”

,

Figure

52,

or

adjusting

collar

“

B

”

,

Figure

55,

per

instructions

in

“

Operator's

Manual

for

Automatic

Threading

Units

on

Model

HC

Chucking

Machines"

under

“

Parallelism

”

,

“

Thread

Length

Adjustment

”

and

“

Threading

Tool

Retraction

”

respectively.

Figure

55

—

Cover

Nuts

for

Pistons

17

Figure

60

—

Seal

and

Locating

Pin

for

Knockout

Piston

Figure

61

—

Spring

for

Roller

Clamp

Piston

Figure

58

—

Knockout

Piston

Shaft

Removal

Figure

62

—

Spanner

Nut

for

Roller

Clamp

Piston

Figure

59

—

Piston

Rings

and

Seals

for

Knockout

Piston

All

adjustments,

including

spring

tension

are

fac

tory

set

in

this

proven

trouble

free

unit.

If

the

chasing

bar

appears

to

be

hanging

mounting

nuts

“

C

”

are

probably

unevenly

tightened

causing

distortation

in

the

mounting

bracket.

Should

this

assembly

ever

require

service,

return

threading

unit

to

factory.

Unit

should

be

properly

greased

to

prevent

rust.

MOUNTING

BRACKET

AND

CHASING

BAR

ASSEMBL

up,

or

over

The

mounting

bracket

and

chasing

bar

assembly

“

B

”

,

Figure

67,

is

housed

as

a

unit

and

is

properly

sealed

to

exclude

dirt

and

foreign

matter.

The

super-

honed

chasing

bar

rides

on

144

selected,

properly

greased,

balls

in

two

bearing

races.

18

Other Hardinge Industrial Equipment manuals