Contents

1Introduction ................................................................................................... 4

2Safety Information and Notes ........................................................................... 5

2.1 Storage of this Manual ............................................................................... 5

2.2 Special Conditions for Safe Use ................................................................... 5

2.2.1 ATEX/IECEx .............................................................................................. 5

2.3 List of Notes ............................................................................................. 5

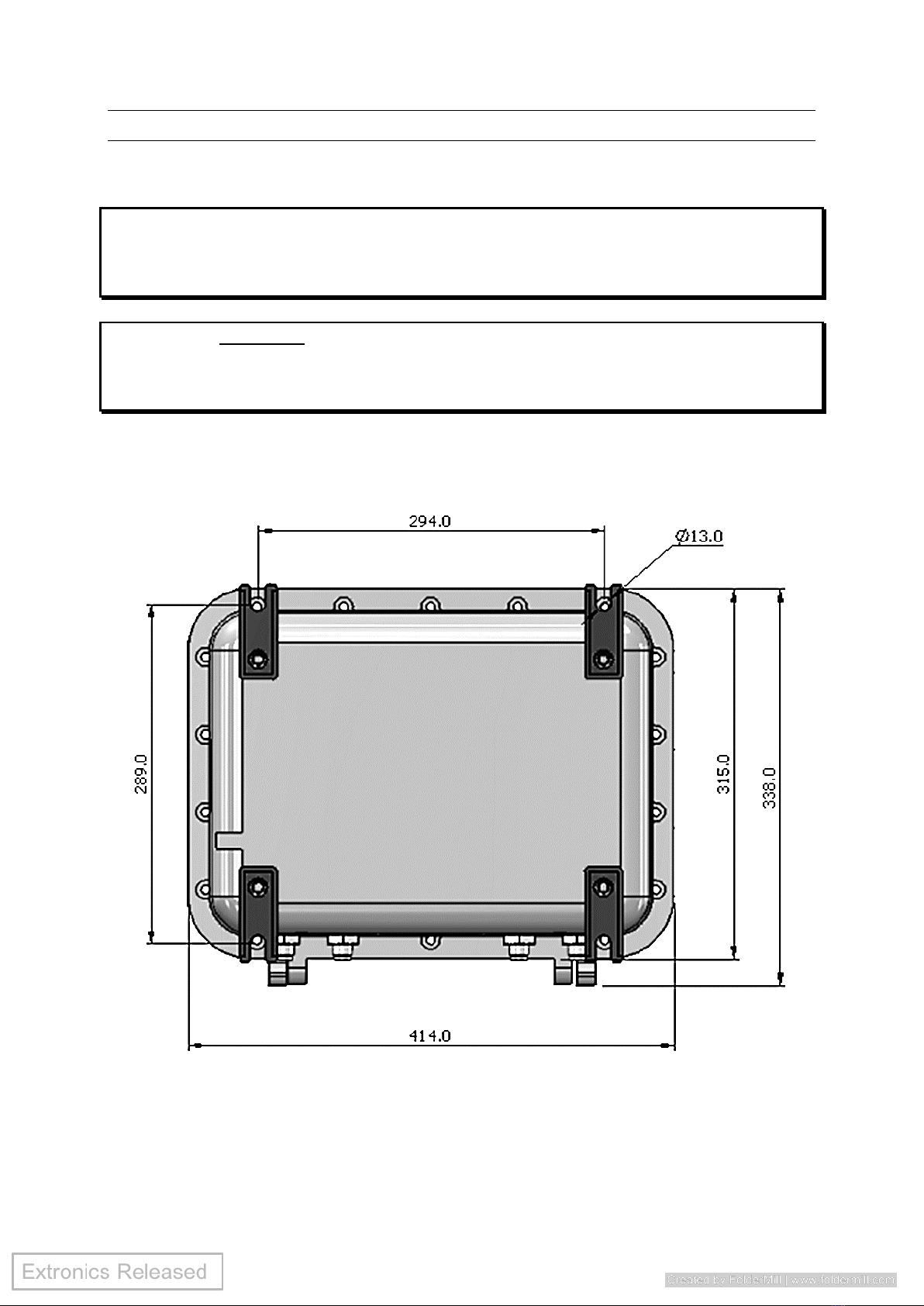

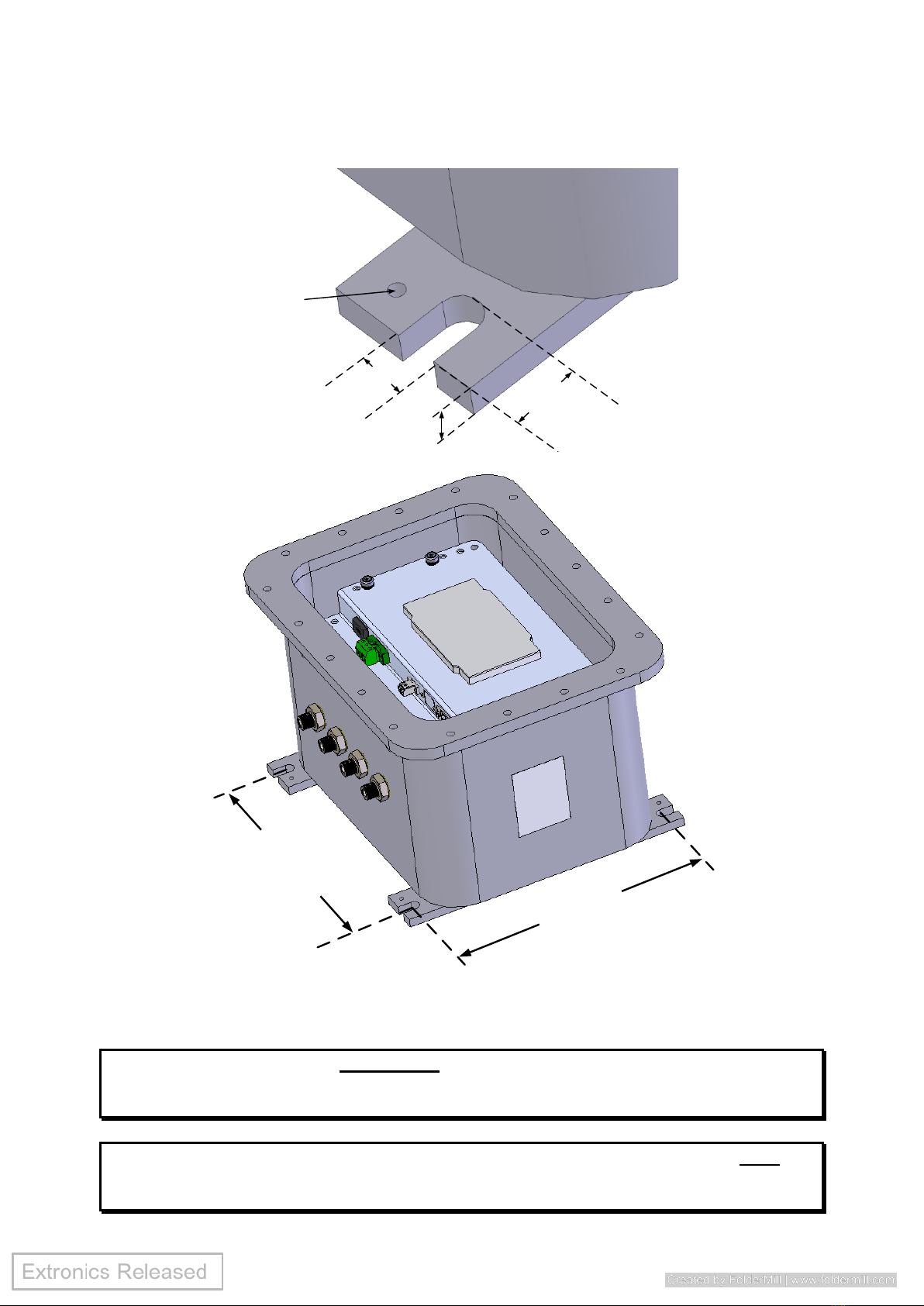

3Installation..................................................................................................... 8

3.1 Mounting.................................................................................................. 8

3.2 Opening and Closing the Enclosure .............................................................. 9

3.2.1 Opening the Enclosure (Aluminium and Stainless Steel enclosures) ................10

3.2.2 Closing the Enclosure................................................................................11

3.3 Cable Entries ...........................................................................................11

3.3.1 Typical Cable Entries and Connections ........................................................11

3.4 Earthing ..................................................................................................12

3.4.1 iWAP107/iRFID107 earth bond point (stainless steel enclosure) .....................12

3.4.2 iWAP107/iRFID107 earth bond point (aluminium enclosure) ..........................13

3.5 Electrical Installation ................................................................................13

3.6 Power supply ...........................................................................................14

3.7 Fusing.....................................................................................................15

3.7.1 Fuse Ratings ............................................................................................15

3.7.2 Changing Fuse .........................................................................................15

3.8 External Overcurrent Protection .................................................................15

3.9 Data Connections .....................................................................................16

3.9.1 Copper Ethernet .......................................................................................16

3.9.2 Power-Over-Ethernet (POE) .......................................................................16

3.9.3 Optical Fibre ............................................................................................16

3.10 Intrinsically Safe RF Outputs......................................................................17

3.10.1 Example of RF threshold power calculation ..................................................18

3.11 Antenna Requirements..............................................................................18

3.12 Antenna Installation .................................................................................18

3.13 Prevention of Electrostatic Charging............................................................20

3.14 Additional Labels & Non-Metallic Materials ...................................................20

4Intended Purpose Usage .................................................................................21

4.1 Transportation and Storage .......................................................................21

4.2 Authorized Persons ...................................................................................21

4.3 Cleaning and Maintenance .........................................................................21

4.4 Cleaning and Maintenance Intervals............................................................21

4.5 Aggressive substances and environments ....................................................21

4.6 Exposure to external stresses ....................................................................21

5Technical Data...............................................................................................22

6Coin Cell Information......................................................................................23

7Label Drawing ...............................................................................................24

8Type Codes ...................................................................................................25

9EU Declaration of Conformity...........................................................................27