2

HM 500/630/800 HM3digitATCE26

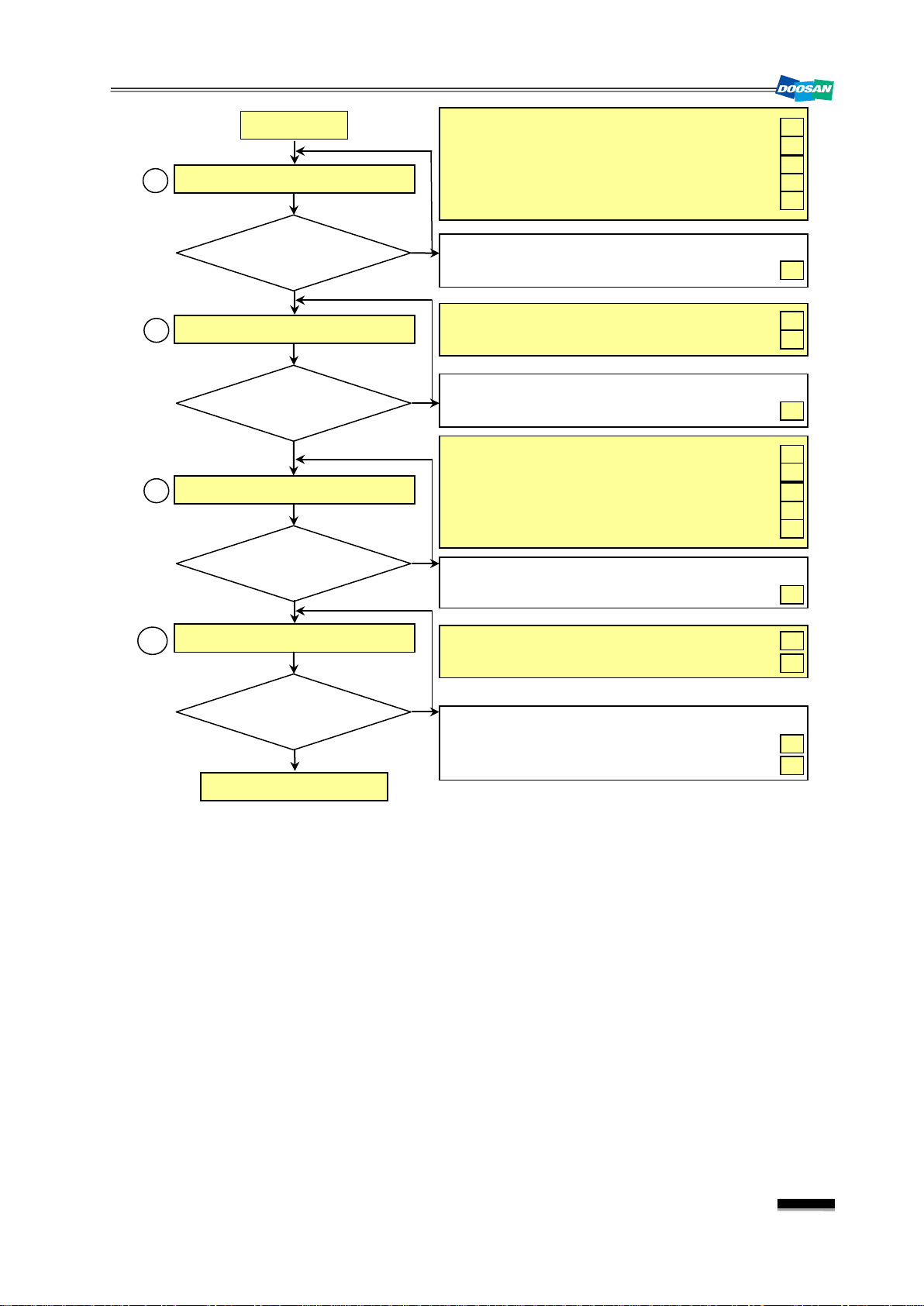

4) Depending on a specific situation, turn the mode

selection switch in the ATC manual OP to

“TOOL

CHANGE STEP REVERSE” (4-1), (4-3)

or

“TOOL CHANGE STEP FORWARD” (4-2)

.

4-1)

If the changer arm is stuck while trying to pull out a tool from the spindle

Turn the mode selection switch on the ATC manual OP to “

TOOL CHANGE STEP

REVERSE”

.

☞

If the machine is in the state of tool unclamping, manually perform the tool clamping

before proceeding.

▪How to confirm the state of tool unclamping: Check if the spindle emits the collet air

(in MDI or Auto mode), or check if the button indicator of Tool Unclamp on the

manual OP turns on.

4-2)

If the changer arm is stuck in the spindle after changing a tool

Turn the mode selection switch on the ATC manual OP to

“TOOL CHANGE STEP

FORWARD”

.

4-3)

If the changer arm has stopped operation irrelevantly to the spindle

Turn the mode selection switch on the ATC manual OP to “

TOOL CHANGE STEP

.

5) Repeat pressing briefly the

“START”

button on the

ATC manual OP until the main changer arm moves

to the home position where it doesn't move further.

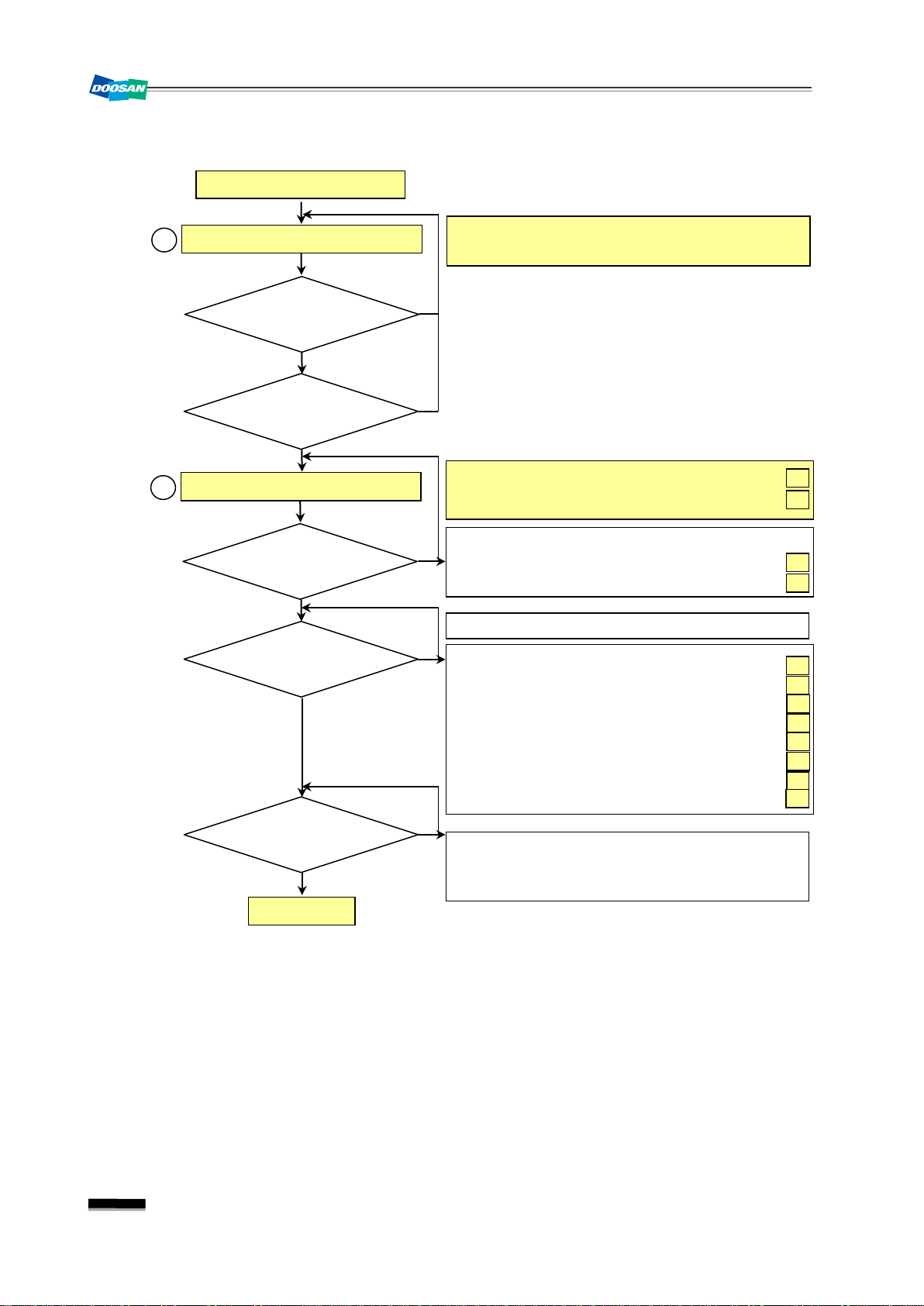

▪In case 4-1) above, the changer arm is stuck in

the spindle for a reason while changing a tool.

Return the changer arm to the home position and

find the cause by performing the tool unclamping

manually.

If the manual tool unclamping does not work at all, gently impact on the tool to remove it

with the hammer. Then, check the tool kick distance, the state of the unclamp cylinder,

collet, and the tapering side of the spindle or tool to find out the cause of trouble and take

a necessary measure.

▪In case 4-2) above, this happens when the gripper of the changer arm is stuck in the tool.

▪In case 4-3) above, this kind of trouble shooting will be made manually while the tools are

inserted in the changer arm. Just in case of a fall of the tool, prepare a shock absorber such

as wood palette under the machine, so that it can protect the machine from a possible fall.

If

the problem persists after following the steps below, use a rubber hammer to impact on the

end of the changer arm so that the gripper can be removed. Then, pull out the changer arm

and return it to the home position. Find out the cause of trouble and take a necessary action.

(check the tool and check also if ATC is aligned properly)