Hardinge SERIES I Owner's manual

INSTALLATION, OPERATION,

MAINTENANCE, AND PARTS LIST

SERIES I

MILLING MACHINES

Revised: August 29, 2005

Manual No. M-450 Litho in U.S.A.

Part No. M -0009500-0450 June, 2003

TP5260

CHAPTER 2 - OPERATION

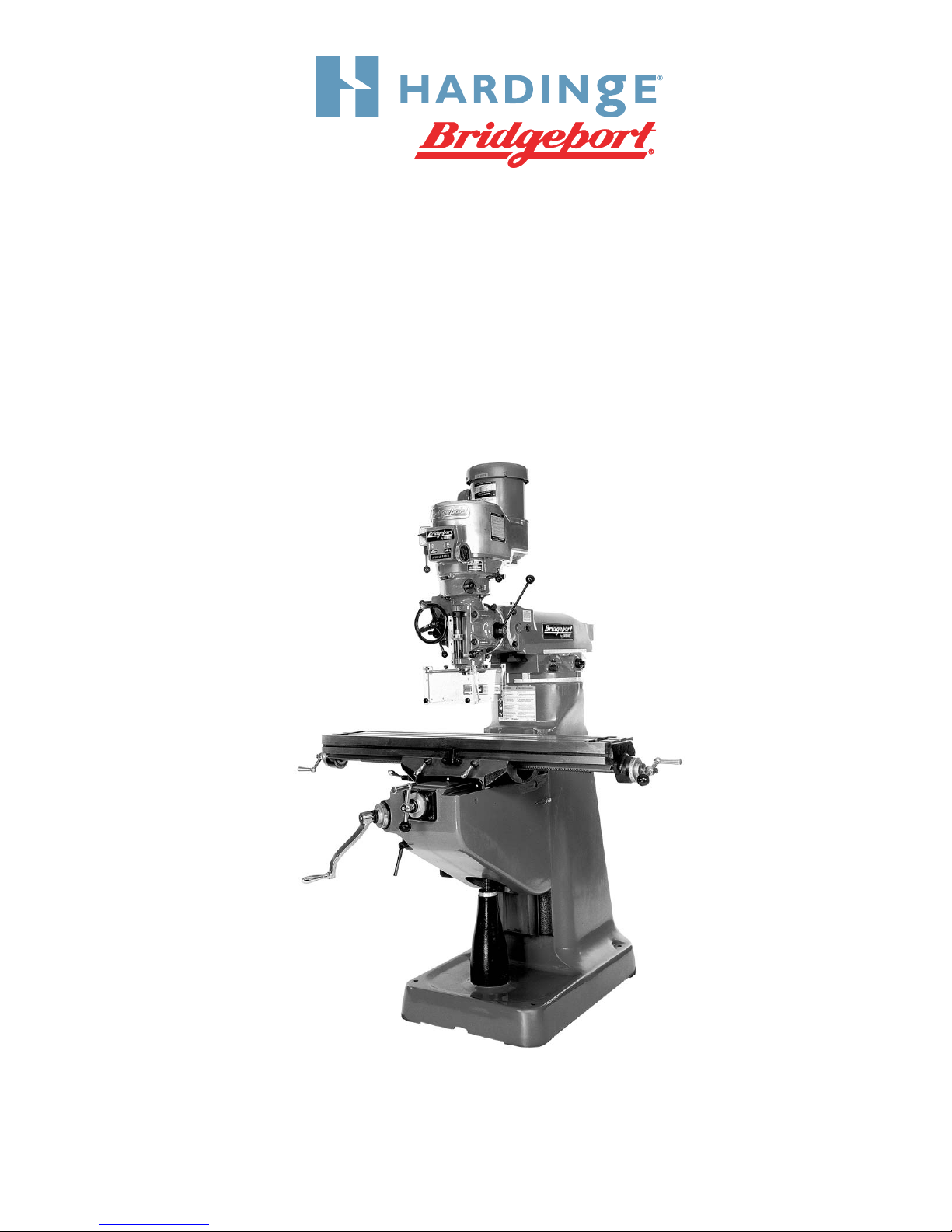

HEAD CONTROLS

M-450 2-1

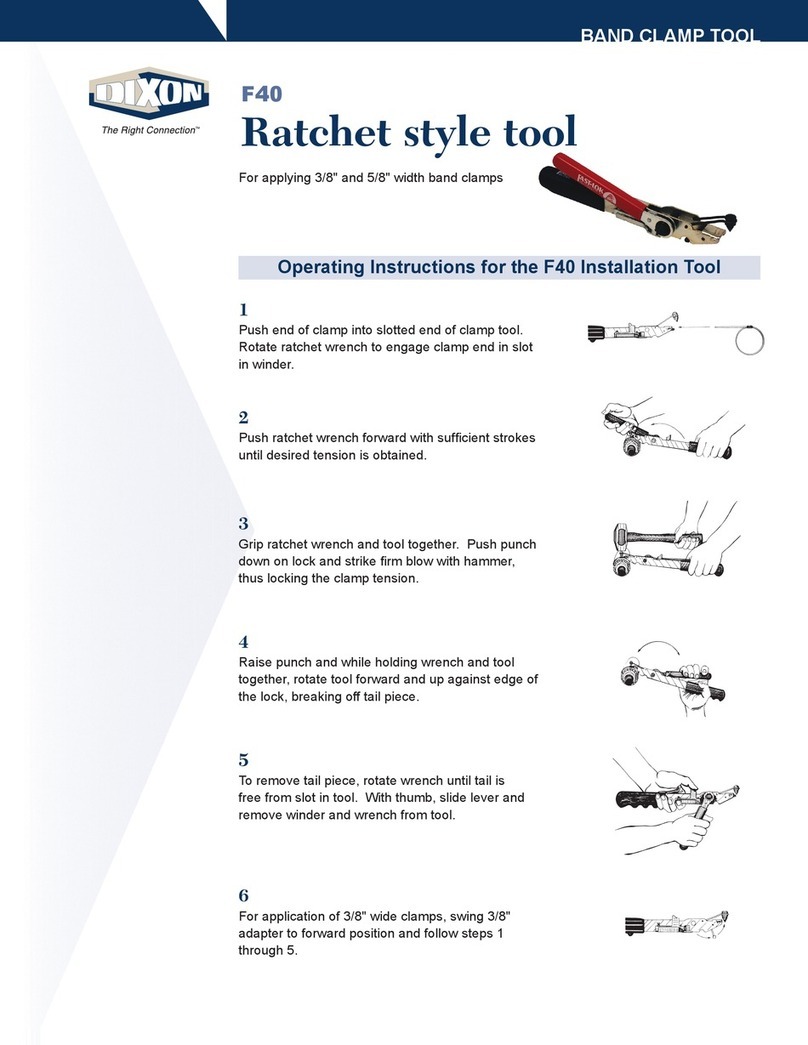

Figure 2.1 - Head Controls Parts Assembly

A

N

O

P

Q

R

C

B

M

G

E

D

F

H

I

J

K

L

TP5285

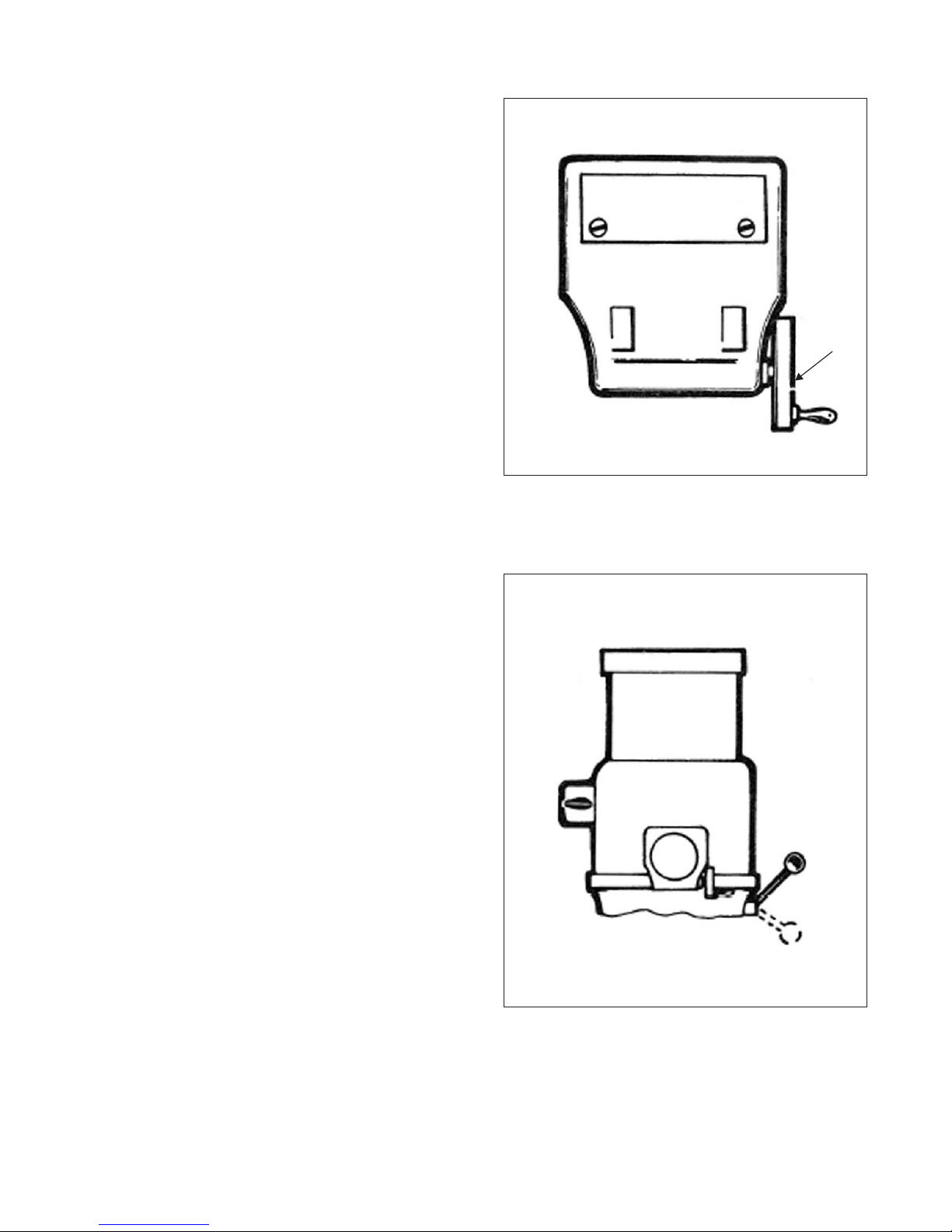

HIGH-LOW RANGE SWITCH

High-Low Range Switch “A”, Figure 2.2, is a

motor reversing switch. When the attachment is in

direct drive (HIGH SPEED), the motor and spindle

are turning in a clockwise direction as viewed from

the top of machine. When the attachment is in “Back

Gear”(LOWSPEED),thespindlewillrunbackwards

(counter-clockwise) unless the motor direction is

reversed by moving switch to “Low”.

The back gear lever is marked Hi-Lo. This will

indicate the proper switch position. They should be

positioned alike or the spindle will run backwards.

- NOTE -

Spindle should run in clockwise position.

VARIABLE SPEED DIAL

Variable Speed Dial “B”, Figure 2.3, visibly indicates, in windows, the speed range that the

machine is operating in, 60 to 500 low range, 500 to 4200 high range.

2-2 M-450

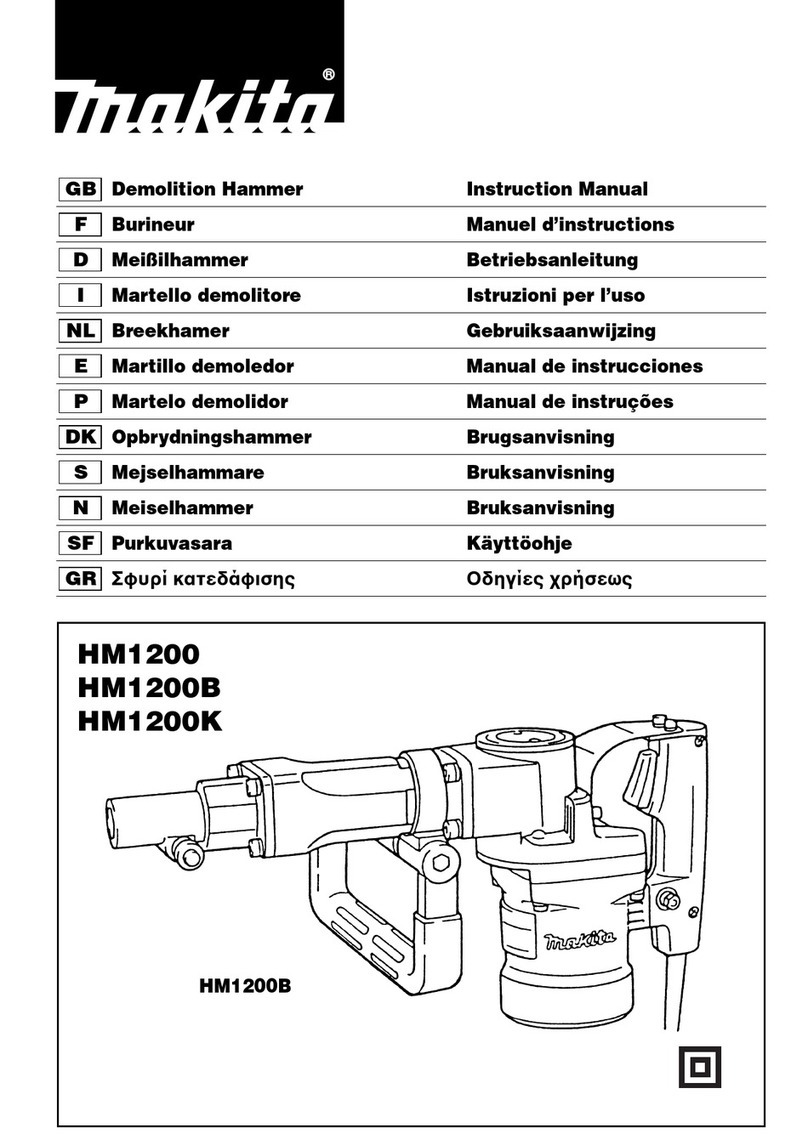

Figure 2.2 - High-Low Range Switch

A

TP5286

Figure 2.3 - Variable Speed Dial

TP5287

B

SPINDLE BRAKE

Spindle Brake “C”, Figure 2.4, can be moved in

either direction to stop spindle; however, when

locking spindle, brake lever should be moved either

by pulling towards the operator or pushing away

from the operator, then raised. When brake is worn

out it has to be replaced. There are no adjustments

to be made.

- CAUTION -

BE certain that spindle brake is re-

leased before starting the motor.

This is important as the motor can

be damaged if switch is turned on

with brake in locked position.

QUILL FEED SELECTOR

The Quill Feed Selector “D”, Figure 2.5, is used

for selecting the three feeds: .0015”, .003” and .006”

per revolution. It is shifted by pulling knob out and

turning from one position to the other. Feeds are

stamped on cover below indentation hole. Feed is

more readily engaged when spindle is running.

M-450 2-3

Figure 2.4 - Spindle Brake

Lock On

Lock Off

TP5288

C

Figure 2.5 - Quill Feed Selector

D

TP5289

QUILL STOP KNOB

Quill Stop Knob “E”, Figure 2.6, is used to

disengage automatic feed in either direction as well

as the stop point setting working depths.

MICROMETER NUT

Micrometer Nut “F”, Figure 2.6, is used for setting

depths. Each graduation on nut indicates .001” of

depth, it reads directly to scale mounted along the

side of it. Depths may be obtained by setting

micrometer nut in conjunction with quill stop.

FEED REVERSE KNOB

The position of the Feed Reverse Knob “G”,

Figure 2.7, depends upon direction of spindle

rotation. If boring with right hand cutting tools, pull

feed handle towards operator until clutch becomes

engaged.

Neutral position is between forward and reverse

position. It is recommended that the handle be left in

neutral position when not in use.

MANUAL FEED HANDWHEEL

Feed Reverse Knob “G” should be in neutral

position and Feed Control Lever “I”, Figure 2.8

engaged. Clockwise rotation of Manual Feed

Handwheel “H”, Figure 2.7, moves quill down. The

manual feed handwheel and the quill feed handle

may be disengaged by moving them outward about

.125”.

2-4 M-450

Figure 2.6 - Quill Stop Knob and

Micrometer Nut

E

F

TP5290

Figure 2.7 - Feed Reverse Knob and

Manual Feed Handwheel

Neutral

G

Down

TP5291

Up

H

FEED CONTROL LEVER

Feed Control Lever “I”, Figure 2.8, engages

overload clutch on pinion shaft when positioned left

and will stay engaged until either quill stop comes in

contact with micrometer adjusting nut, forcing feed

control lever to drop out automatically, or release

manually by engaging lever to right.

FEED CONTROL OVERLOAD CLUTCH

The Feed Control Overload Clutch is set at the

factory to hold up to 200 lbs of down pressure on

quill, which will accommodate drills up to .375”

diameter in mild tool steel.

- CAUTION -

This clutch should not be tampered

with in the field.

- NOTE -

The feed control lever must be en-

gaged in order to use manual feed

controls. the quill feed handle and

manual feed handwheel may be

removed when not in use.

QUILL

Quill “J”, Figure 2.9, contains the spindle

assembly and can be raised or lowered by using the

quill feed handle “M”, Figure 2.10.

SPINDLE

Spindle “K”, Figure 2.9, performs the actual

rotation and also retains the machine tooling.

QUILL LOCK

Quill Lock “L”, Figure 2.9, is a friction lock for use

when quill is in a stationary position such as a milling

operation. It is recommended that this lock be used

whenever quill movement is not desired.

M-450 2-5

Figure 2.8 - Feed Control Lever and

Feed Control Overload Clutch

I

Engage

Disengage

TP5292

Figure 2.9 - Quill, Spindle and

Quill Lock

J

L

TP5293

K

QUILL FEED HANDLE

Quill Feed Handle “M”, Figure 2.10, is used to

raise and lower the quill manually. It is generally

recommended that handle be engaged when using

the power feed. It may be removed by simply pulling

handle off.

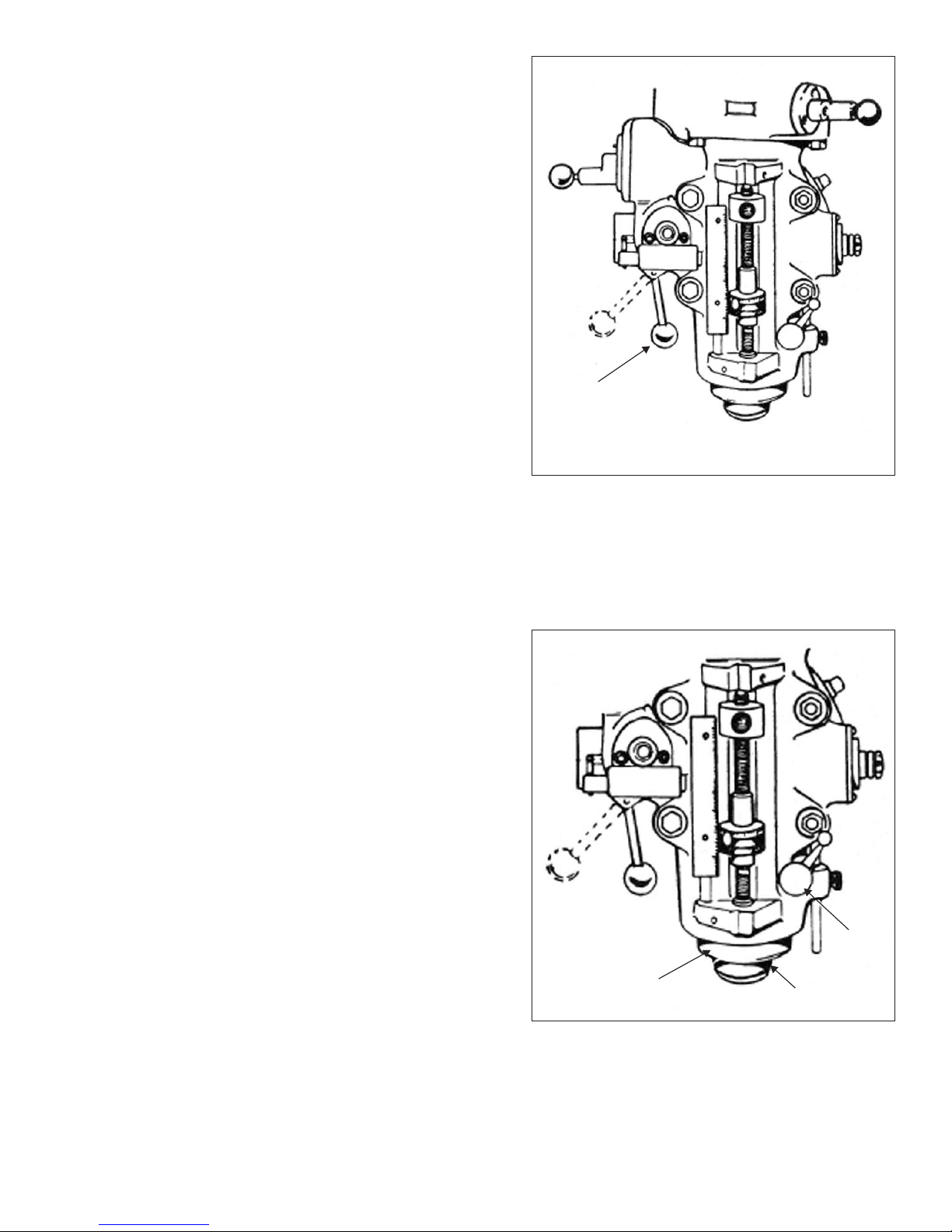

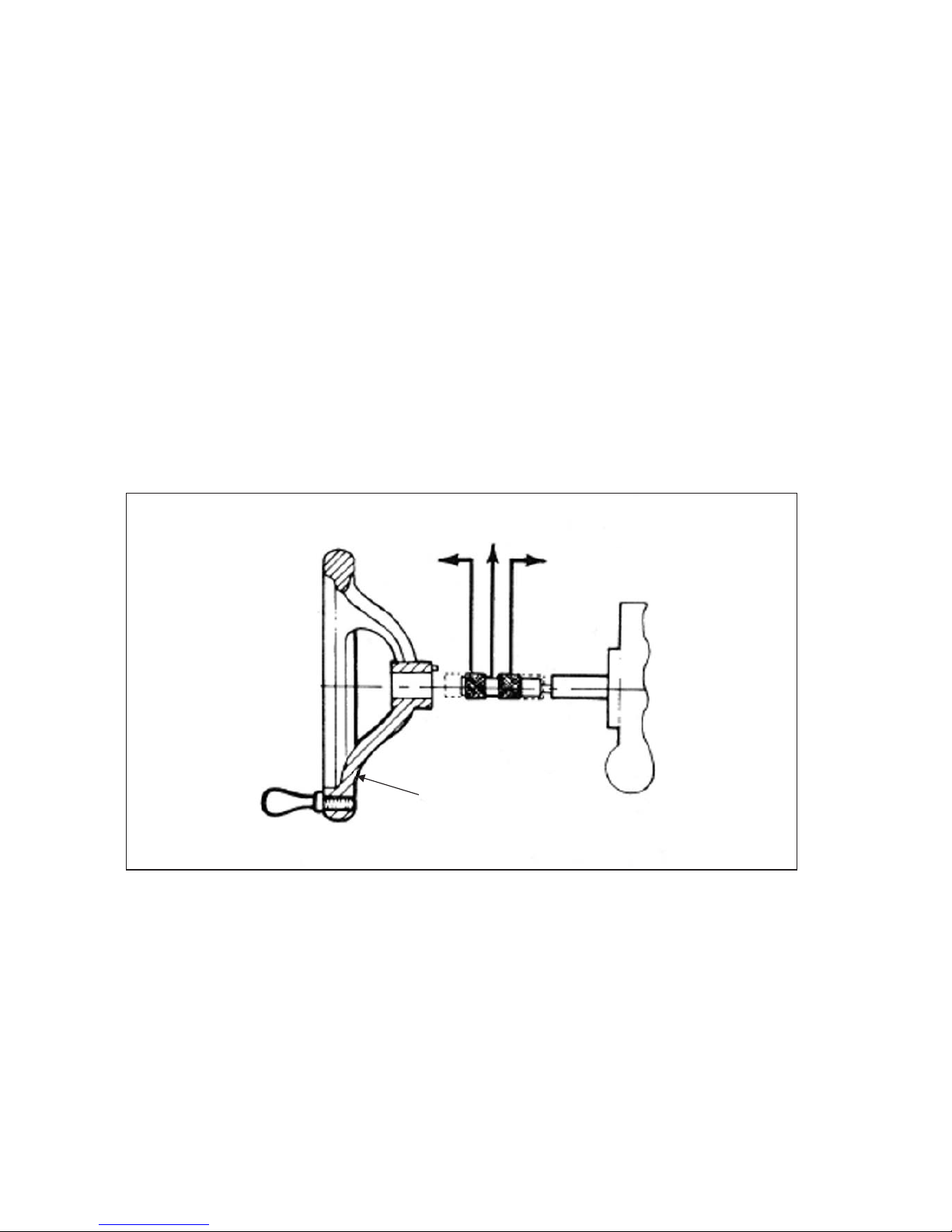

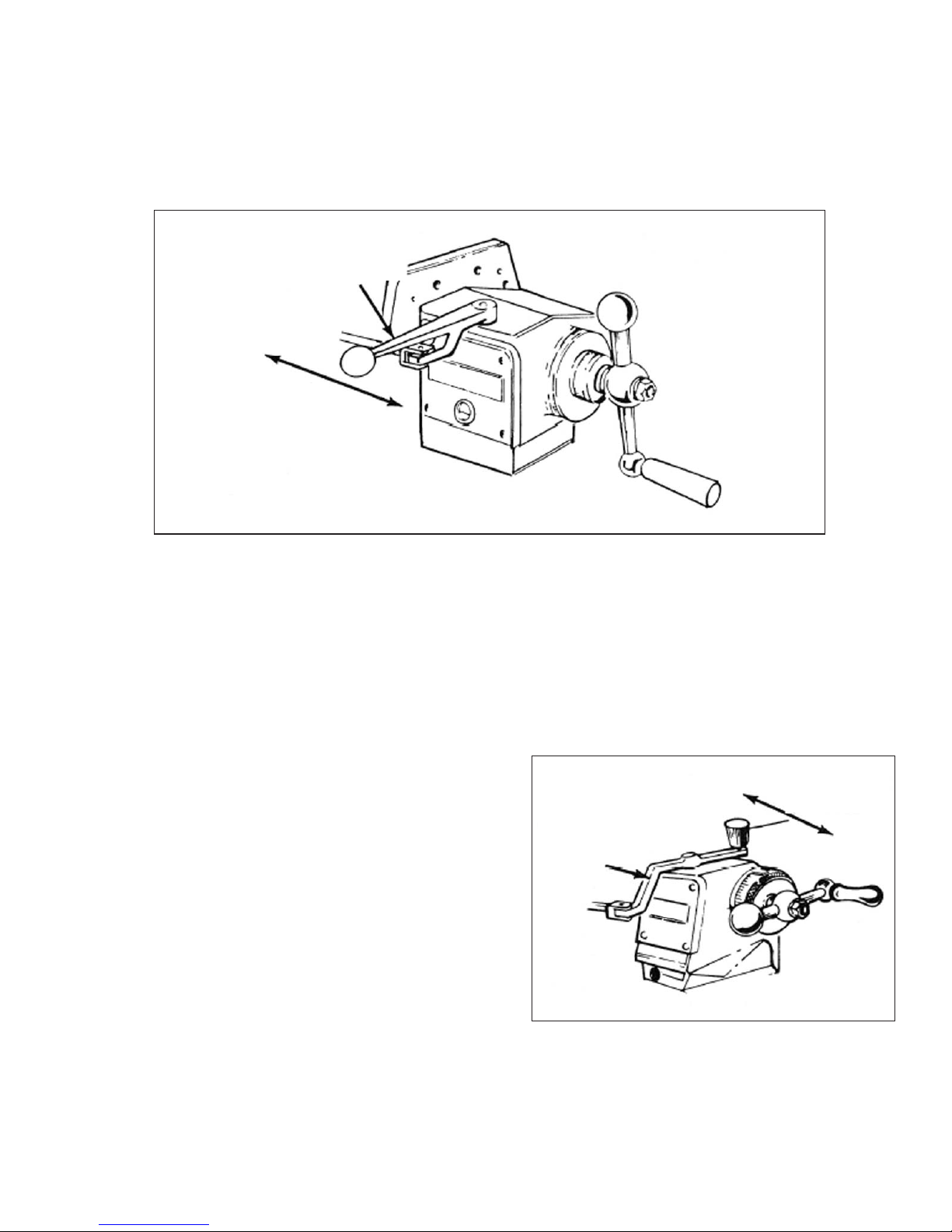

POWER FEED TRANSMISSION ENGAGEMENT

CRANK

Power Feed Transmission Engagement Crank

“N”, Figure 2.11, engages power feed worm gear.

When lever is in right hand hole, the power feed

worm gear is engaged.

To engage worm gear, pull knob out and crank

handle in clockwise or down direction and move to

opposite position (see Figure 2.12).

- NOTE -

Crank should be rotated counter-clock-

wise to engage power quill feed. Crank

should be rotated clockwise to disen-

gage.

- CAUTION -

Power feed worm gear may be en-

gaged when spindle is rotating,

however, it should be engaged

gently to avoid damage to worm

gear. The worm gear may be disen-

gaged at any time. do not use power

feed at speeds above 3000 RPM.

2-6 M-450

Figure 2.10 - Quill Feed Handle

M

TP5294

Figure 2.11 - Power Feed Transmission

Engagement Crank

N

TP5295

Figure 2.12 - Worm Gear Disengagement

Disengaged Engaged

Clockwise Counter-

Clockwise

TP5296

HI-NEUTRAL-LO LEVER

The Hi-Neutral-Lo Lever “O”, Figure 2.13, is used to put the attachment into either back gear or

direct drive. Rotate the spindle by hand to facilitate meshing of clutch or gears.

Neutral is provided to permit free spindle rotation for indicating and setup work.

In the high speed position (direct drive) the spindle is driven by tapered clutch teeth. If the clutch is

not meshed tightly, clutch rattle will be heard. This can be corrected by loosening the two securing

screws in lever while in high speed position. The clutch spring will automatically adjust the clutch.

Tighten the two securing crews in lever.

- CAUTION -

Do not shift hi-lo lever while motor is running.

M-450 2-7

Figure 2.13 - Hi-Neutral-Lo Lever

Neutral

High Low

Securing Screws

TP5297

O

SPEED CHANGE HANDWHEEL

- CAUTION -

DO NOT attempt to change spindle RPM unless the motor is running. Dial

speeds will only be approximate. Belt wear will cause a slight variation in

speeds from what is indicated on the dial.

Spindlespeedsareadjustedby turningSpeedChange Handwheel“P”,Figure 2.14,onthe frontof

the belt housing. There are two ranges: 60 to 500 and 500 to 4200.

To obtain 60 to 500 (low range):

1. Hold the Hi-Neutral-Lo lever (right rear

side of the attachment) so the gears are

clear of one another.

2. rotate the spindle nose by hand until the

gears line up, then move the Hi-Neu-

tral-Lo lever to the “Lo” position (back

gear).

3. Use the low range on the drum switch to

engage the back gears.

- CAUTION -

If the back gears do not mesh, do

not force the lever.

To obtain 500 to 4200 (high range):

1. Hold the Hi-Neutral-Lo lever (right rear

side of the attachment) so the gears are

clear of one another.

2. rotate the spindle nose by hand until the

gears line up, then move the Hi-Neu-

tral-Lo lever to the “Hi” position.

3. Set the drum switch to high range.

- CAUTION -

Try to avoid shifting the hi-lo lever when the feed worm is engaged.

2-8 M-450

Figure 2.14 - Speed Change Handwheel

- CAUTION -

Do Not Move

Unless Motor is

Running

Increase

Speed Decrease

Speed

P

TP5298

MOTOR

Motor “Q”, Figure 2.15, has the following specifications:

•2 HP variable speed (with 2J head)

•3 HP 30 minute duty rate

DRAWBAR

When tightening or loosening the Drawbar “R”, Figure 2.15, it is necessary to lock the spindle. To

accomplish this, use the spindle brake which is located on the left side of the belt housing, pulling

towardstheoperator orpushingawayfromtheoperatoruntil itbinds,thenraisethequillfeed handle.

Drawbar has 7/16”-20 right hand thread and should be tightened by hand with normal amount of

pressure using wrench furnished with machine. To loosen collet, back off drawbar and if collet does

not open immediately, give knob on top of drawbar a slight tap. Spindle has non-sticking taper and

collet should release readily.

M-450 2-9

Figure 2.15 - Motor and Drawbar

TP5299

Q

R

OPERATIONAL PROCEDURES

Spindle Speed

- CAUTION -

DO NOT change speed when spin-

dle is stationary. Change speed only

when spindle is running.

To change speed within range:

1. Start spindle.

2. Turn handwheel “A”, Figure 2.16, to select

required speed.

Back Gear (Low Speed)

- CAUTION -

DO NOT change range while spindle

is running. Change range only when

spindle is stationary.

To change range from direct to back gear drive:

1. Switch “B”, Figure 2.17, to OFF (Stop spindle

rotation).

2. Move lever “C” through neutral to LOW (This

reverses the spindle rotation).

3. Switch “B” to LOW.

2-10 M-450

Figure 2.16 - Spindle Speed Change

A

TP5300

Figure 2.17 - Back Gear Range Change

C

B

TP5301

Direct Drive (High Speed)

To change range from back gear to direct drive:

1. Switch “B” to OFF (Stop spindle rotation).

2. Move lever “C”, Figure 2.18, through neutral

to HIGH.

3. Rotate spindle by hand until the clutches are

felt to engage.

4. Switch “B” to HIGH.

Quill Feed

FINE HAND FEED

1. Disengage Auto Quill Feed “D”, Figure 2.19.

2. Locate “F” in mid (neutral) position.

3. The quill is now under handwheel control

M-450 2-11

Figure 2.18 - Direct Drive Lever

High

C

Neutral Low

TP5302

Figure 2.19 - Quill Feed

Fine Hand Feed Control

E

F

I

D

H

G

Off

On

Engage

TP5303

AUTOMATIC FEED

- NOTE -

Maximum loading .375” (9.5mm) diameter drill steel.

1. Ensure quill lock “G”, is off.

2. Set micrometer dial “H” to required depth.

3. Engage auto quill feed “D” when motor has stopped

4. Select feed rate “I”.

5. Select feed direction “F”, Figure 2.22.

6. Engage feed trip lever “E”. The feed will automatically trip out at a depth within .010”

(.25mm)

7. Hand feed to dead stop for repeating accuracy .001” (.025mm)

- CAUTION -

Do not engage quill feed “D” over 3000 RPM.

2-12 M-450

Figure 2.20 - Quill Feed

Automatic Feed Control

F

Up

Neutral

Down

Fine Feed

Handwheel Engage

TP5304

HEAD

OPERATIONAL PROCEDURES

Spindle Brake

Brake lever has capability to rotate in either

direction to brake and lock.

1. CAM upwards to lock and prevent movement

of spindle (see Figure 2.21).

Quill Sensitive Hand Feed

1. Place the handle on the quill feed shaft.

2. Select the most suitable position.

3. Push home until the locating pin engages.

M-450 2-13

Figure 2.21 - Spindle Brake

Brake

Brake

Off

Turn and

Lift to

Lock

TP5306

Figure 2.22 - Quill Sensitive Hand Feed

TP5307

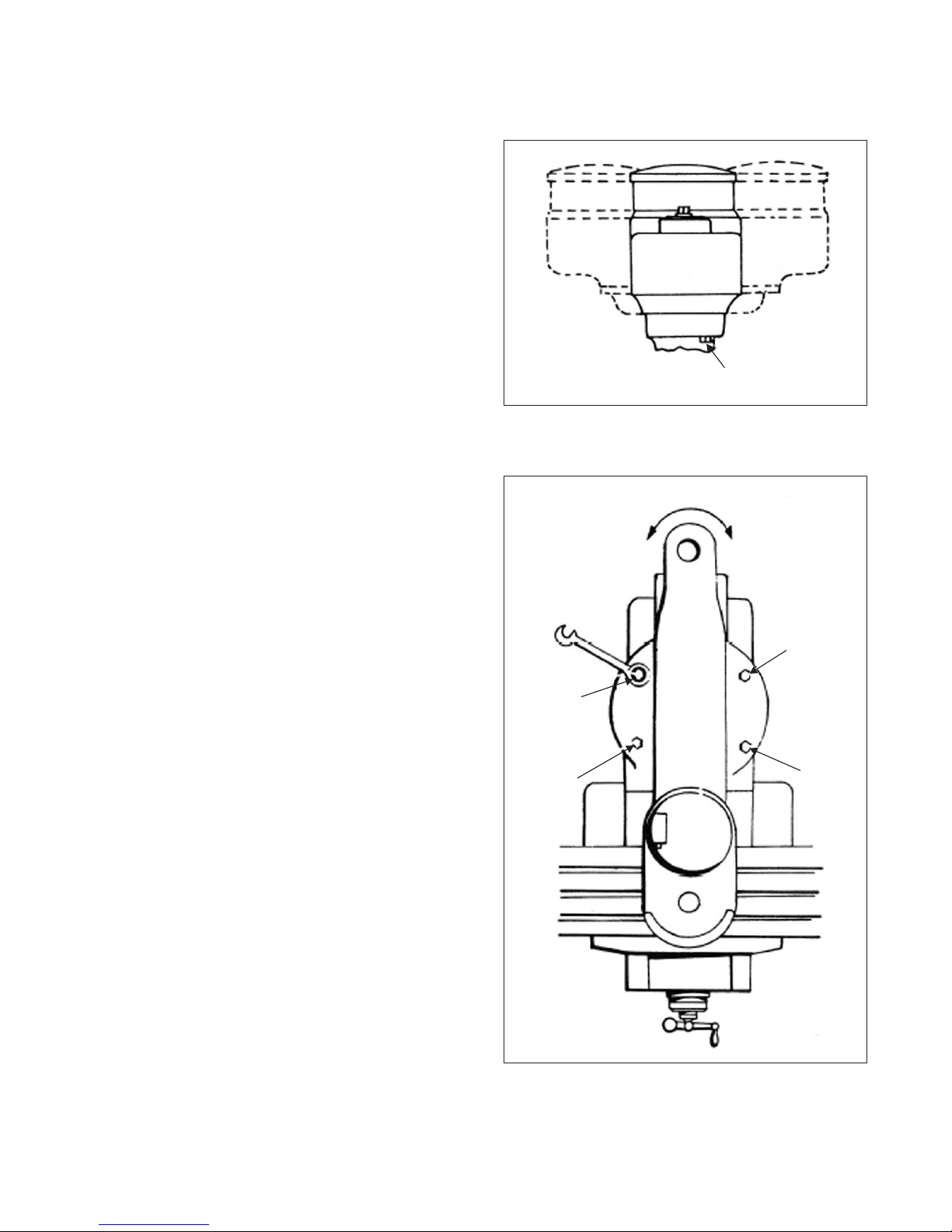

MACHINE

OPERATIONAL PROCEDURES

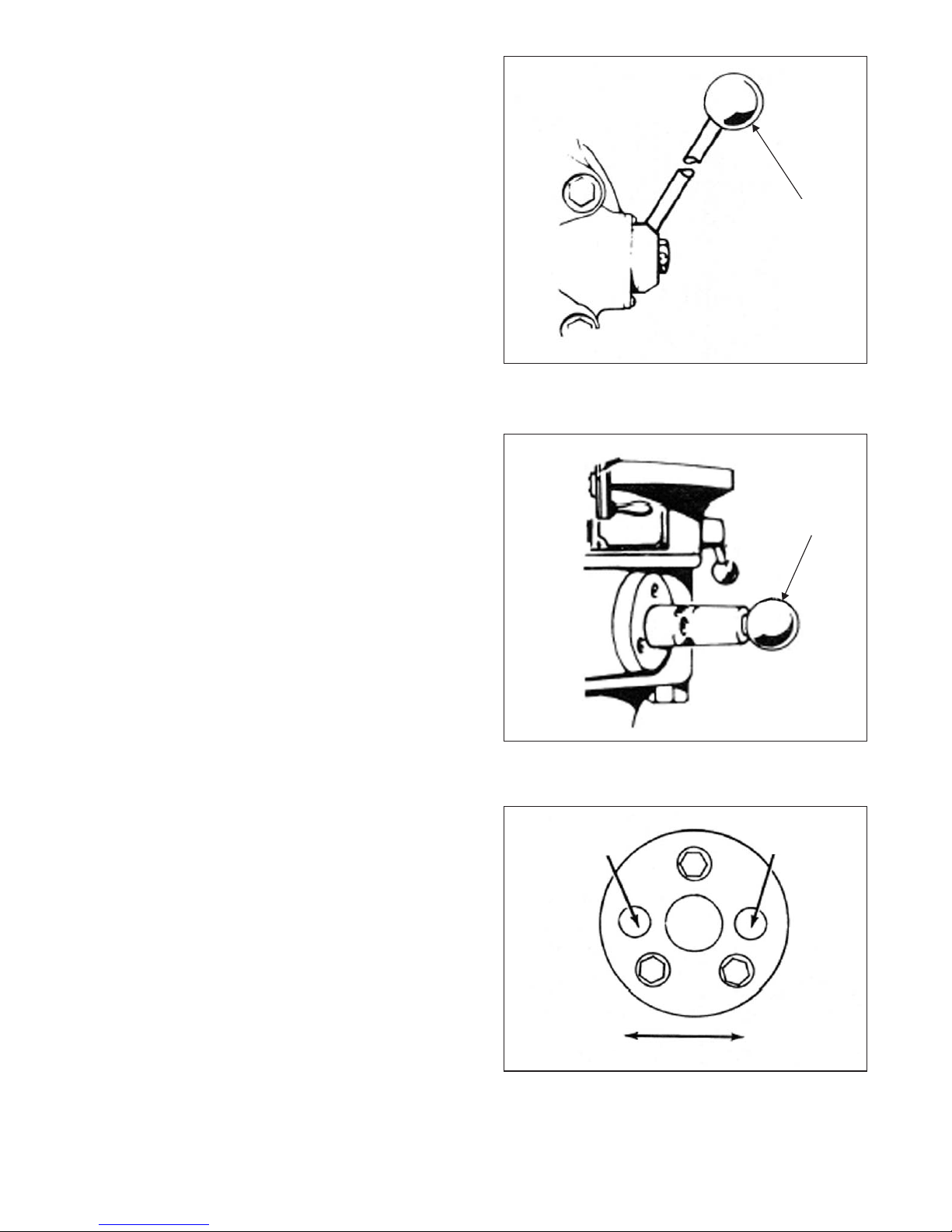

Swivel Belt Housing

- CAUTION -

Incorrect spline alignment can be

caused by unequal tightening of the

locknuts ’J’ causing fluctuation of

the quill feed which can be felt

through the sensitive feed handle. It

is advised to call Hardinge service

department before attempting this

procedure.

1. Loosen three locknuts “J”, Figure 2.23.

- WARNING -

DO NOT remove these locking nuts.

2. Swivel to required angular setting.

3. Tighten three locknuts “J” snugly before final

tightening of locknuts. Run spindle to give

correct spline alignment, then tighten lock-

nuts securely.

Swivel Turret

1. Use wrench supplied with machine to loosen

the four bolts “K”, Figure 2.24.

- WARNING -

DO NOT remove these four bolts.

2. Index to the required setting.

3. Lock the four bolts “K” to 47 lb-ft.

2-14 M-450

Figure 2.23 - Swivel Belt Housing

TP5305

J

Figure 2.24 - Swivel Turret

360°

K

KK

K

TP5308

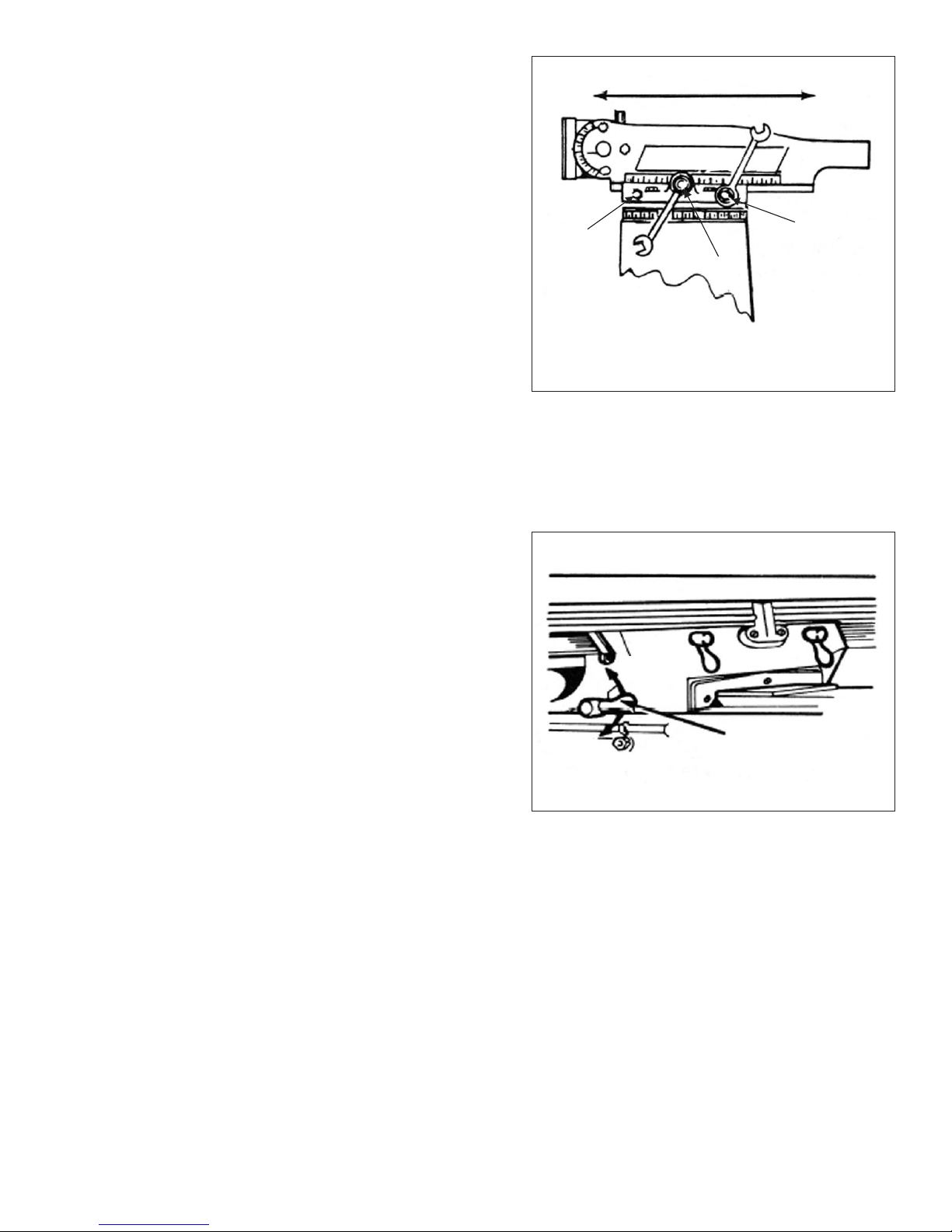

Move Ram Slide

1. Use wrench provided with machine to loosen

bolts “L” and “M”, Figure 2.25.

2. Use wrench to move the slide to the desired

position using bolt “N”.

3. Tighten bolts “L” and “M”, starting with the

rear bolt.

- NOTE -

It is recommended that on heavy mill-

ing work, head should be kept as close

to column as possible, where maxi-

mum rigidity is obtained.

Saddle Clamping

When milling with longitudinal table feed only, it is

advisable to clamp the knee to the column (see

Figure 2.27) and the saddle to the knee to add

rigidity to these members and provide for heavier

cuts with a minimum of vibration. The saddle locking

lever is located on the left hand side of the saddle.

Excessive moisture can cause slight table bind.

Use moderate clamping pressure, as this will hold

saddle sufficiently.

M-450 2-15

Figure 2.25 - Ram Slide

TP5309

L

N

M

Rear

Figure 2.26 - Saddle Clamping

TP5310

Unlock

Lock

Saddle

Locking Lever

Table Clamping

The table clamp levers are located on front of

saddle and should always be clamped when

longitudinal movement is not required (see Figure

2.28).

Knee Clamping

The knee clamping levers are at the left side of the knee and front of knee. Leave clamped at all

times unless using knee in operation (see Figure 2.27).

2-16 M-450

Figure 2.27 - Knee Clamping

Knee

Clamp

On Off

Clamp

Knee

Clamp

Off

On

TP5312

Figure 2.28 - Table Clamping

Unlock

Lock

Table Clamp

Levers TP5311

POWER FEED CONTROLS

OPERATIONAL PROCEDURES

Variable Table Feeds

Power Feed (X-Axis) Table

Quick-Release Safety Handle

Grip handle and turn to either left or right until spring loaded plunger engages in position.

- NOTE -

Ball crank handle is a safety device. Do not tamper with this assembly.

Variable Cross Slide Feed

Cross Feed Power Feed (Y-Axis)

M-450 2-17

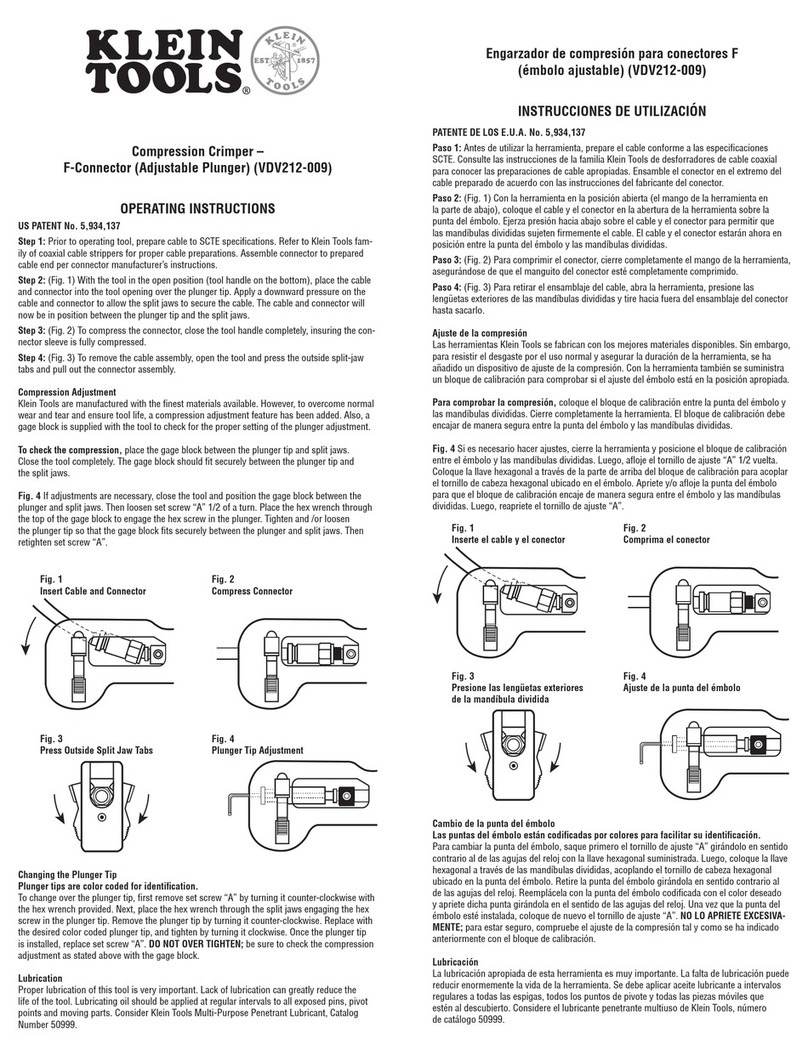

Figure 2.29 - Variable Table Feeds

Feed Engage

Lever

TP5313

Feed Left

Feed Right

Neutral

Figure 2.30 - Variable Cross Slide Feed

TP5314

Neutral

In

Out

Cross Feed

Engage Lever

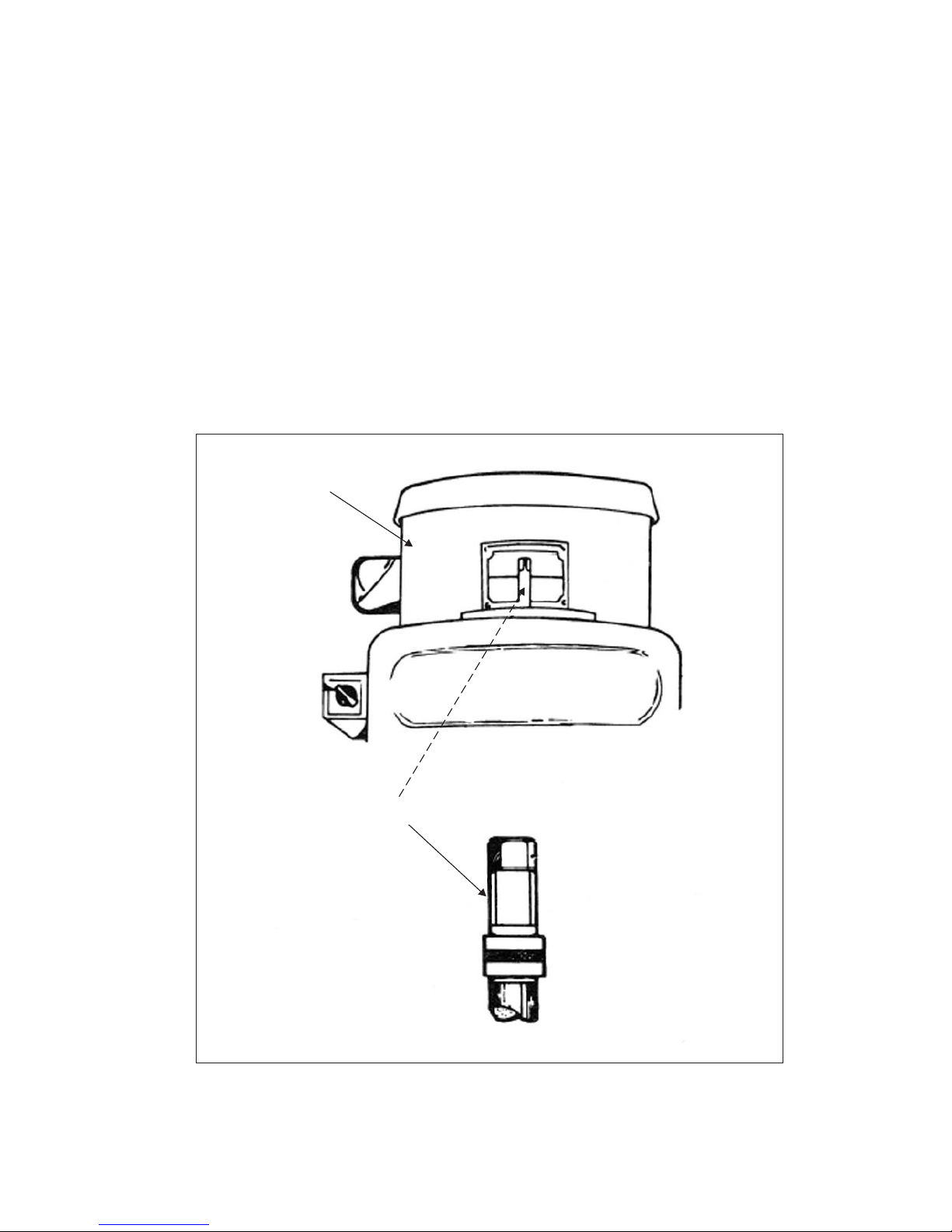

E-HEAD CONTROLS

OPERATIONAL PROCEDURES

Head Swivel

1. Loosen the four locknuts (see Figure 2.32). Support unit to prevent free fall.

2. Swivel to required angular setting.

3. Tighten the four locknuts first to 25 lb-ft. Then 50 lb-ft (ref. Page 1-4).

- NOTE -

Remove the screw sealing vent hole before operating machine (ref. Page 3-15).

2-18 M-450

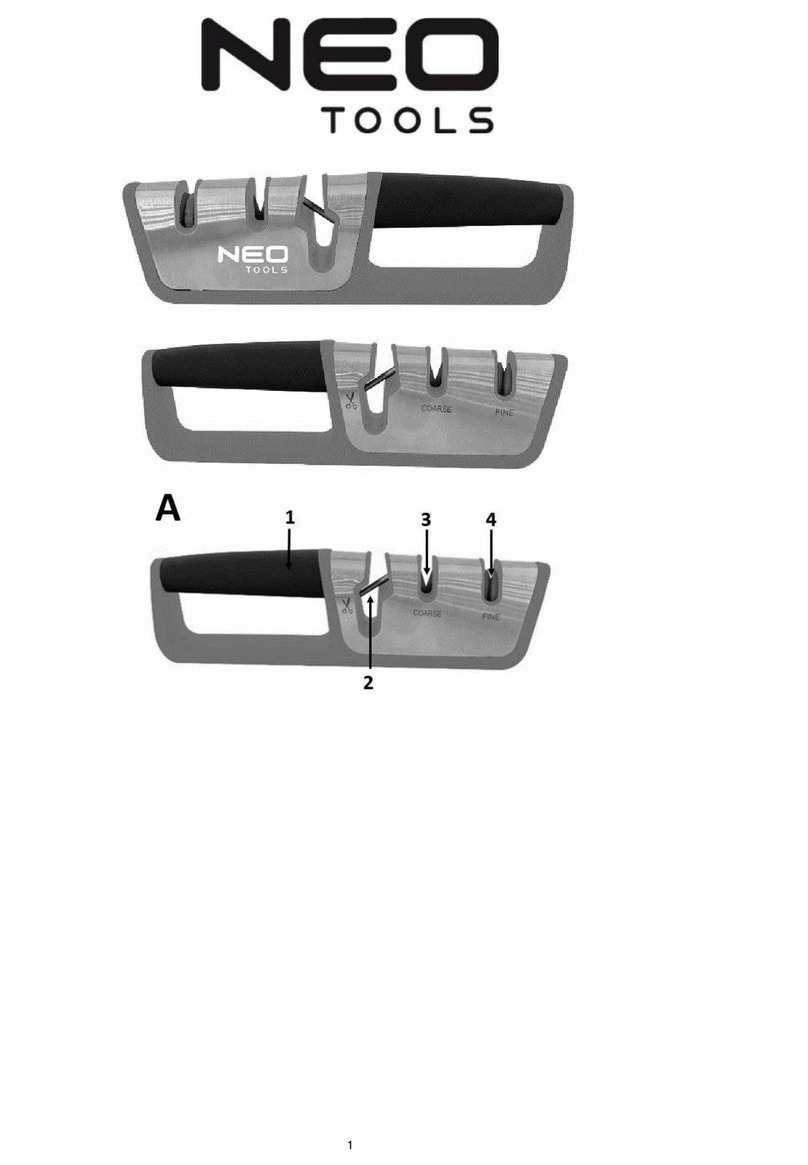

Figure 2.31 - Shaping Head

(Guard Removed for Clarity)

Motor

Locking

Nuts

Stroke

Adjustment

locknut

On/Off

Switch

Tool Holder

Clapper Box

TP5315

Figure 2.32 - Shaping Head

(Guard Installed)

TP5316

Locknuts

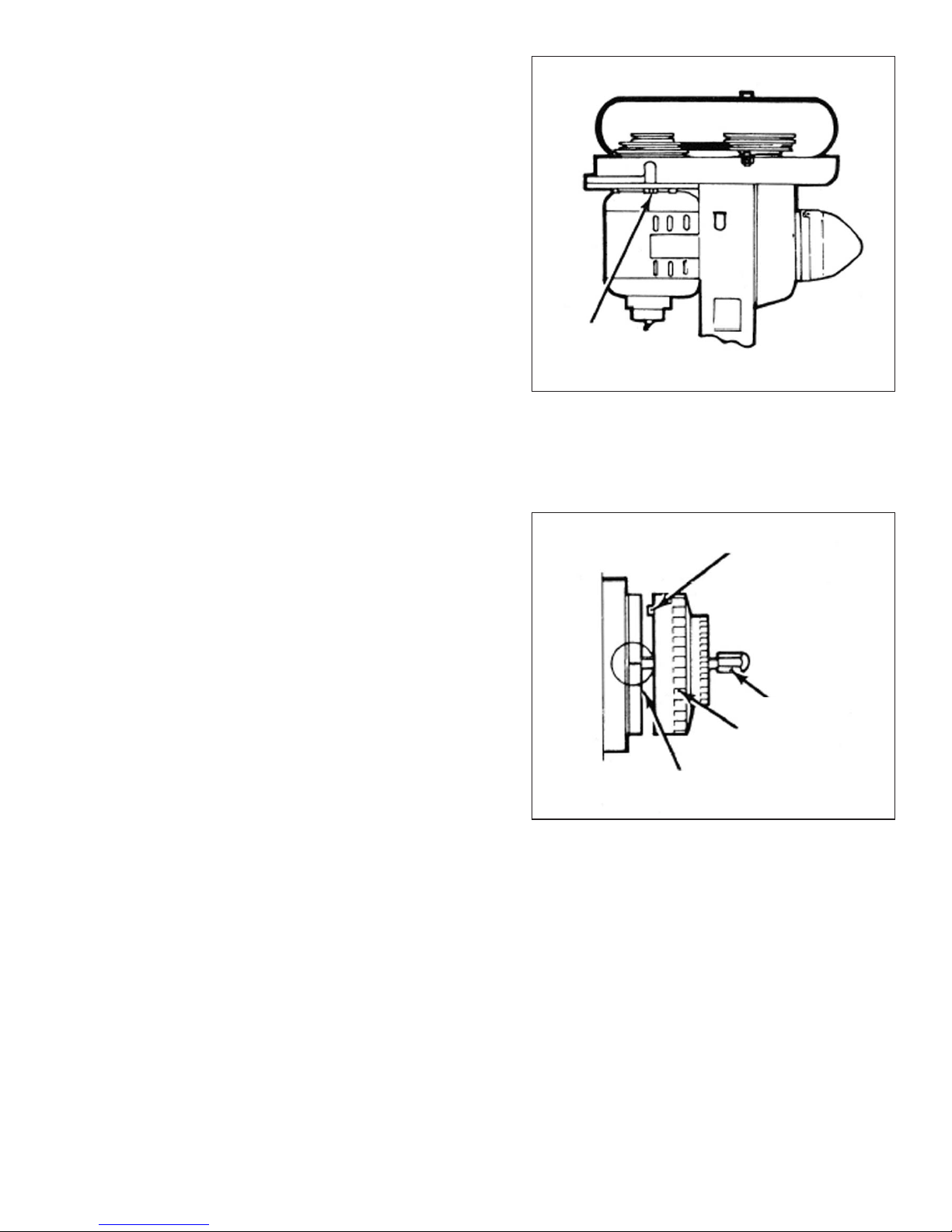

To Change Speed

1. Disconnect power from head.

2. Loosen the two motor locknuts (see Figure

2.33).

3. Slide motor forward.

4. Position vee belt on appropriate pulleys.

5. Slide motor to rear to tension vee belt.

6. Tighten the two motor locknuts.

With 50 cycle 1425 rpm 60, 85, 120, 170, 245 350

strokes per minute.

To Change Stroke

1. Loosen locknut (see Figure 2.34).

2. Turn stroke dial to required setting.

3. Press dial home to engage pin.

4. Tighten locknut.

- NOTE -

Before operating attachment, ensure

locknut is tight.

M-450 2-19

Figure 2.33 - Changing E-Head Speed

Locknuts

TP5317

Figure 2.34 - Changing E-Head Stroke

Engage Pin

Locknut

Stroke Dial

Setting Datum

TP5318

Table of contents

Other Hardinge Power Tools manuals