1

Instructions

301 Ziegler Drive, Grayslake, IL 60030

Phone: 847-548-8700

Fax: 847-548-8755

Website: www.harger.com

Revised 7.9.12

• Always follow the Welding and General Safety Instructions included with this mold.

• Always follow the Conductor Preparation Instructions included with this mold specific to the connection to be made.

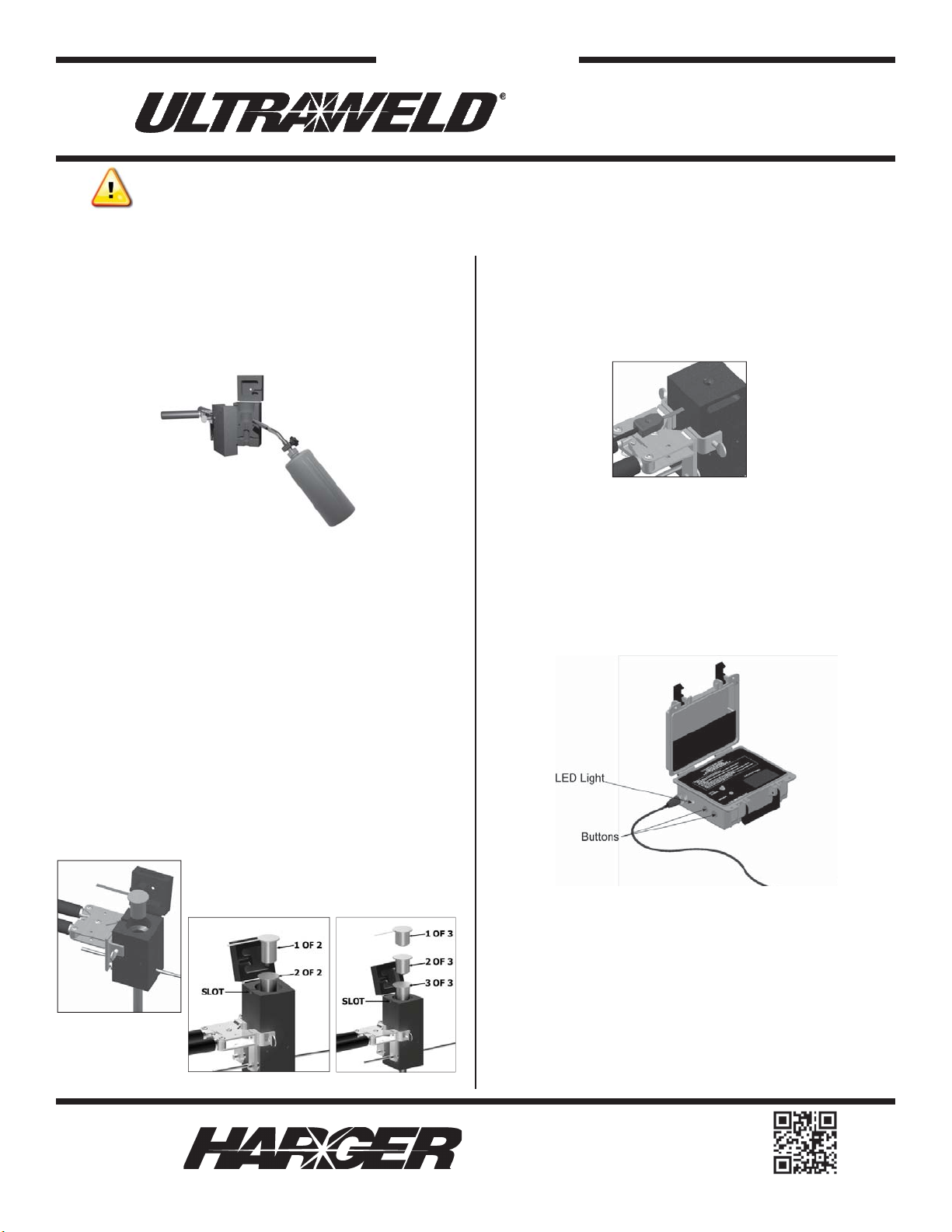

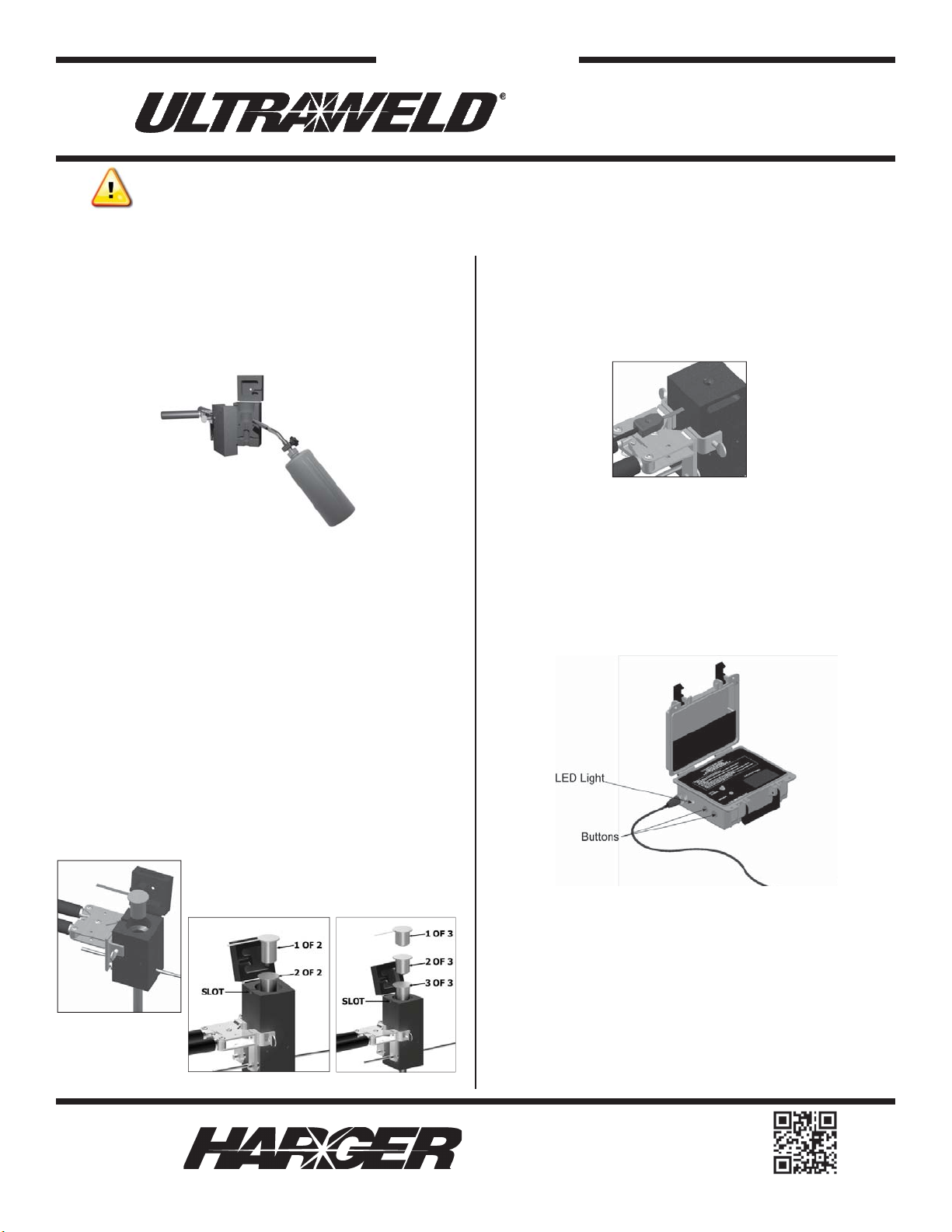

4. Position mold onto conductor(s). See front of the other

instruction sheet included with this mold for positioning

of conductors into mold. Lock mold with handle clamps

or frame, which ever is the case. Note that Handle Clamp

adjustments may be made by removing adjusting screw and

turning eye bolt 180° clockwise to tighten or 180° counter

clockwise to loosen.

5. If using UltraShot®, drop the weld metal cartridge into the

mold with the igniter exiting the mold through the slot in the

top of the mold. Ensure the lid is closed tightly.

Note: UltraShot®weld metal US500, US750, US1000 and

US1500 are made up of two or three cartridges. To use,

cartridge(s) without an igniter should be dropped into the

mold first. The cartridge with an igniter should be on top

and should be exiting the mold through the slot in the top of

the mold. Ensure the lid is closed tightly.

Ultraweld®UltraShot®Welding Procedures

Step 5 Notes

Step 5

UltraShot®

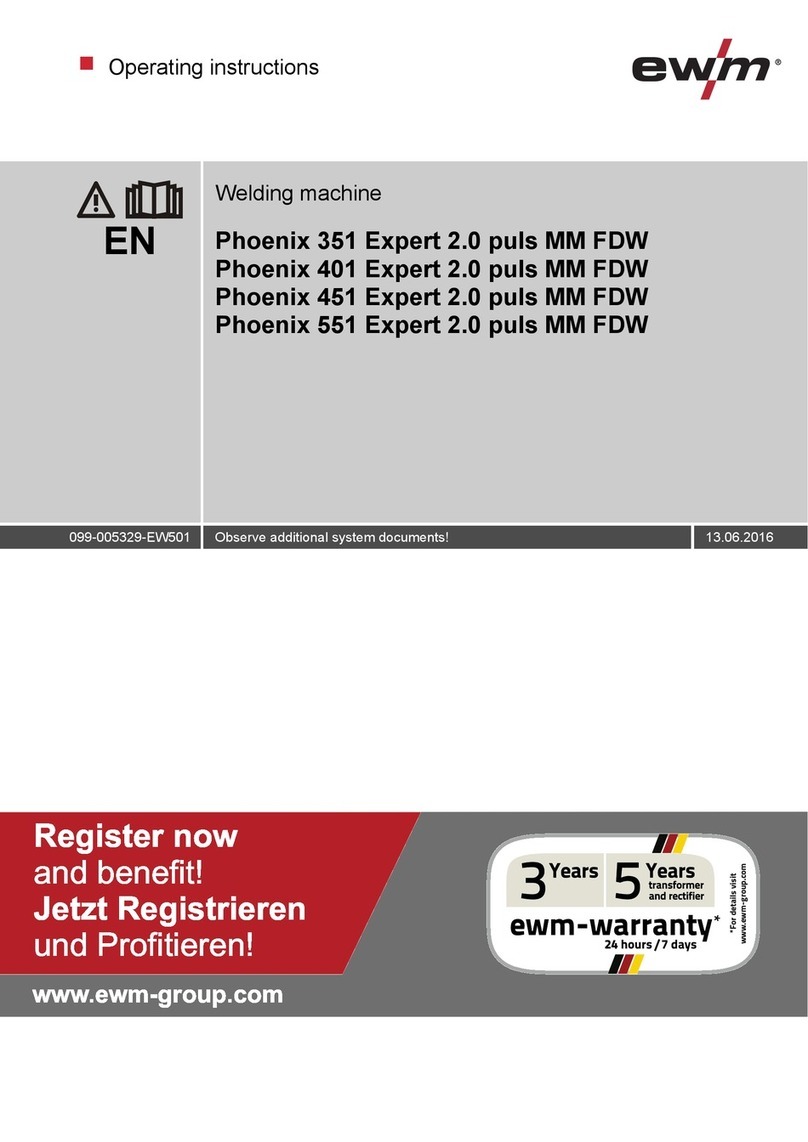

6c. Simultaneously push and hold both buttons on the side of

the USCONTROLLER until the reaction is initiated and then

release the buttons. Note that the LED light on the side

of the USCONTROLLER will illuminate while both buttons

are pressed. Do not hold buttons for more than 5 seconds.

Should the reaction not occur, wait 30 seconds and remove

the UltraShot®cartridge and insert another cartridge. If it

fails to ignite again, it is likely that the controller needs to be

recharged.

1. Check mold tag for conductors to be welded and proper

weld metal cartridge size to use.

2. Make sure all surfaces and conductors are clean, dry and are

the proper sizes for the mold’s application per mold tag.

3. For the initial connection, torch dry the mold with a hand

operated propane torch.

6a. Before igniting, verify conductor positioning and that mold is

closed completely.

6b. Slide the igniter lead connecter over the end of the igniter.

Push connector until the igniter bottoms out inside the

connector.

6d. After ignition, remove igniter lead immediately.