Harrington WA100H User manual

Ravenstor Road

Wirksworth

Derbyshire

DE4 4FY

ENGLAND

Sales Tel:

+44 (0) 1629 824 284

Sales Fax: +44 (0) 1629 824 613

Email: [email protected]

Website: www.hgigenerators.com

Installation Guide

Welf-Air Cube

10.0kVA Water Cooled Diesel Generator

Build No: WA100H

Publication: 498-1075

© Harrington Generators International Limited

All rights reserved. No part of this publication may be reproduced in any material form (including photography or storing in

any medium by electronic means or other) without the written permission of the copyright holder except in accordance with

the provisions of the Copyright, Designs and Patents Act 1988.

Applications for the copyright holder’s written permission to reproduce any part of this publication should be addressed to

Harrington Generators International Limited at the address above.

Any reference to trademarked product names used within this publication is owned by their respective companies.

Harrington Generators International Limited reserves the right to change the contents of this document without prior notice.

Change Control

Date Version Author Reason for change

May 17 Provisional MC Draft for Review by NC

May 17 A MC Updated and released following review

Harrington Generators International

498-1075Welf-Air 10kVA Cube

Contents

Contents

1.0 INSTALLATION............................................................................................1

1.1 General......................................................................................................1

1.2 Ventilation .................................................................................................1

1.3 Hot Air Outlet ............................................................................................1

1.5 Fixing Skids ..............................................................................................2

1.6 Connecting Hot Air Outlet .......................................................................2

1.7 Fixing Down..............................................................................................2

1.8 Cabin’s Exhaust Outlet ............................................................................2

1.9 Connecting the Exhaust ..........................................................................2

1.10 Electrical Connection..............................................................................2

1.11 Clearance Space......................................................................................2

2.0 CONTACT....................................................................................................2

3.0 DRAWINGS..................................................................................................3

3.1 General Arrangement................................................................................3

3.2 Installation Drawing ..................................................................................5

4.0 MANUFACTURER’S SERVICE AND USER GUIDE LINKS.......................6

4.1 Kubota Engine Operator’s Manuals........................................................6

4.2 Deep Sea Electonics 3110 User Guide ...................................................6

4.3 Sincro SK160 User Manual .....................................................................6

Harrington Generators International

498-1075 Welf-Air 10kVA Cube

Harrington Generators International

498-1075Welf-Air 10kVA Cube

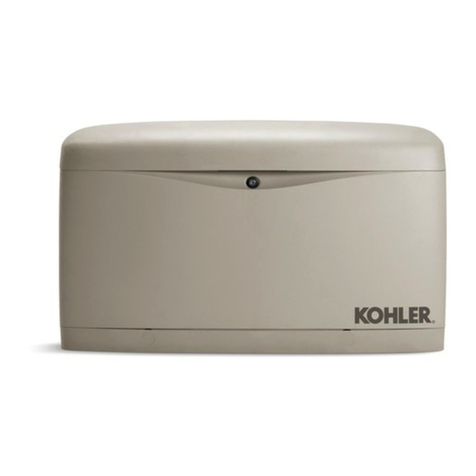

Welf-Air

WA100H

1500 RPM

Diesel Generator

Harrington Generators International

1 498-1075Welf-Air 10kVA Cube

Installation Guide

1.0 Installation

Installation of the generator is to be made by qualified

personnel in accordance with the appropriate

regulations e.g., Electricity Safety, Quality and

Continuity Regulations 2002 (S.I. 2002/2665), and the

following Electrical Safety regulations:

• I.E.E Regulations 17th Edition (BS 7671:2008)

• Health and Safety Executive Publications GS27

• Protection Against Electric Shock

• Health and Safety Executive Publications GS24

• Electricity On Construction Sites

• Health and Safety Executive Publications PM53

• Emergency Private Generation

1.1 General

The Welf-Air Compact range of generators has

been designed by HGI to perform exceptionally

well in the confines of a small cabin. New type

mounts are used in the set, so that vibration is

kept to a minimum, when placed on a cabin floor.

Two silencers, special sound insulation, water

cooled engines and careful canopy design keep

noise level to an absolute minimum.

The integral base mounted tank gives many

hours of continuous operation, is easy to refill and

has a low fuel shutdown to stop air entering the

fuel system. The access door is a lift-off type to

save space. The keyless stop/ start means no

lost keys.

The Welf-Air Compact has long service intervals

and its service items are on the outward facing

side, thus making servicing easy and economic.

Hot air exits the top quarter of the end panel

opposite the air inlet panel. The set is designed to

be pushed up to the right and against a cabin

wall, which should have a louvre panel cut into it.

Other louvres need to be made in the cabin to

allow cool air to enter the generator compartment.

The generators exhaust exits vertically. An

extension tube, brackets and heat wrap are

supplied. It is important that the heat wrap is

fitted so that operatives do not burn themselves.

These instructions explain the installation of Welf-

Air Compact generators. Read completely before

installing.

The following notes are for the guidance of cabin

manufacturers and customers. Do not hesitate

to contact HGI Ltd for further advise and help.

The generators are supplied complete with:-

1. Approx 1 metre of flexible exhaust pipe, two

exhaust pipe clamps and thermal insulation wrap.

2. A 63 Amp plug and lead to electrically connect to

the set.

3. Two floor brackets that secure one side of the

generator.

4. Quick Start Guides with Manuals available for

download.

5. Laminated care sheets.

In essence, to install the generator:

1. Prepare the cabin, including air exits, louvres,

brackets and exhaust exit.

2. Fork truck the generator into position.

3. Push the set against the skid brackets and push

against the hot air outlet cut into the

4. cabin.

5. Bolt front skids down.

6. Clamp flexible to exhaust and cabin exhaust

outlet.

7. Connect cabin to the 63 Amp socket.

1.2 Ventilation

Adequate sized louvre panels should be built into the

cabin doors and cabin walls for generator ventilation

purposes.

NOTICE

Care must be taken to ensure that the machine

does not circulate its own exhaust fumes, the

machine must be able to take in cold air in order to

perform correctly.

1.3 Hot Air Outlet

A rectangular hole should be cut into the cabin wall

to allow the generator hot air to escape. The size

is 690mm wide by 973.5mm high and is positioned

112mm up from the top of the inside cabin floor (see

drawing PD901-908).

If at all possible, finish the interior of the cabins hot air

outlet with flat flush metal so that the generators foam

seal has a suitable surface to seal against.

The outside finish is the responsibility of the cabin

manufacturer but should take into account:

• Weather ingress

• Animals, pests and vermin

• Health & Safety considerations

Harrington Generators International

498-1075 2 Welf-Air 10kVA Cube

Installation Guide

• Security and vandalism

Allow a 210mm clearance to access the electrical

output socket at the front of the generator.

1.4 Positioning Generator

When you look into the cabins generator compart-

ment, the generator is positioned up against

the right hand cabin wall. The hot air escape

should be cut into the right hand wall.

1.5 Fixing Skids

The skids are fitted flush front and back to the

generator and at 170mm from the sides of the

generator.

The skids are 200mm wide by 70mm high (see

drawing WG-WA100H).

1.6 Connecting Hot Air Outlet

The hot air outlet is on the right hand side of the set

which should be pushed up to the right hand cabin

wall, to within 25mm of the cabin wall. The foam seal

(supplied fitted to the generator) around the hot air

exit will squash and act as an air seal. It does not

need to be perfectly air tight (see drawing PD901-

908)

Alternative arrangements for hot air outlet using

plenum connection to exit louvres can be provided by

HGI for installation into buildings.

1.7 Fixing Down

Fixing down is via the bolt holes in the skid pods on

the base of the generator. The fixing down holes

are located 57.5mm from front and back and are are

675mm apart on the same skid and 560mm distant

from the corresponding hole on the second skid. The

See drawings WG-WA100H.

The generator, when being fixed down using the

standard foam seal arrangement, will have the right

hand side fixing down hole approx 300mm from the

wall (see PD901-908).

The type of fixing will depend on the floor type,

thickness of floor material etc.

1.8 Cabin’s Exhaust Outlet

The exhaust pipe comes out of the top of the Welf-

Air generator’s canopy and is then turned through 90

degrees so that it comes out of the side wall of the

cabin. This is done so there are no problems with

water entry through the roof or stacking the cabins on

top of each other. The welded exit pipe can be cut

at an angle outside to stop rain getting in.

1.9 Connecting the Exhaust

Using the flexible pipe and clamps supplied,

connect the flexible pipe to the generator exhaust

stack and to the cabins exhaust outlet (see drawing

PD901-908).

Finally use the thermal insulating bandage supplied

to wrap around the flexible exhaust pipe to insulate

it and protect people from touching the hot pipe. Use

steel wire ties or similar at each end to prevent the

bandage from becoming unwrapped.

NOTICE

Care must be taken to make a gas tight seal

when connecting the exhaust.

1.10 Electrical Connection

A 63 amp BS4343 socket is fitted on the generator

adjacent to the fuel fill and below the socket panel.

This single socket supplies all the generators power

for the cabin. The additional sockets are for auxiliary

use for lights, tools or other cabins.

1.11 Clearance Space

The generators need to occupy a clear space within

the cabin compartment for ventilation and to allow

access for refuelling and service.

Cables, water pipes, pumps, tanks, waste and other

items should be located away from the generator.

2.0 Contact

If you are in any doubt or have any concerns about

the safe installation of the generator then please

consult with your service depot or contact HGI:

Technical Helpline: 01629 821 614

General Enquiries: 01629 824 284

Harrington Generators International

3 498-1075Welf-Air 10kVA Cube

Drawings

3.0 Drawings

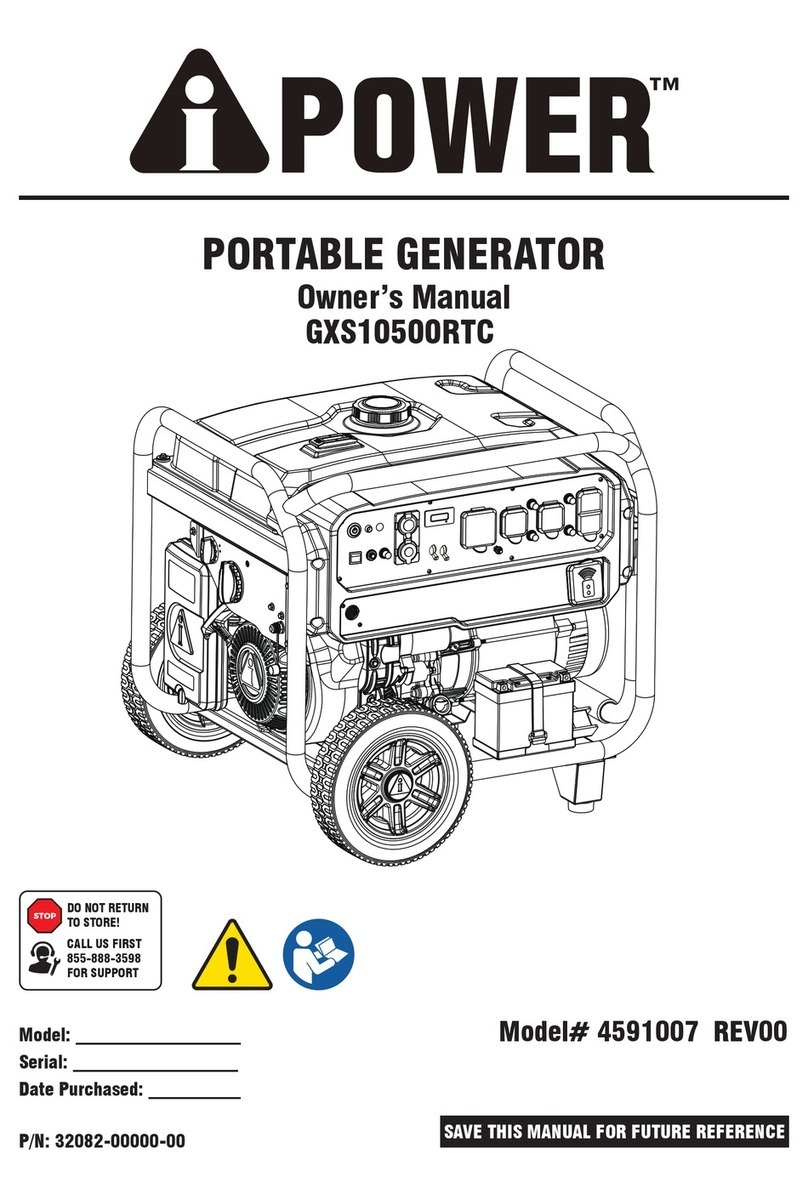

3.1 General Arrangement

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

C

Checked

Material Finish

Title Drg No.

For insert & fabrication specifications refer to PD999-001

02.12.14

10kVA Welfair Cube

General Arrangement

WG-WA100H

A

M.A

02.12.14

B

N.N

28.07.15

C

R.W

19.05.16

D

R.W

27.04.17

E

R.W

19.05.17

WG-WA100H

Item

Description

Item

Pt No.

Item

Material

Sht

no.

Weight (kg)

1 /2

3D views are for illustration only.

495 kg max.

Cool Air

Inlet

Cool Air

Inlet

Fuel Filler

Neck

Hot Air

Outlet

Hot Air

Outlet

Hot Air

Outlet

2.5 Tonne

Lifting Eye Exhaust Outlet

Radiator

Access Cover

Forklift

Pods

Lift-off

Service Door

Hinged Control

Panel Door

Terminal

Cover

Hinged Access

Panel for Alternator

& Battery

Harrington Generators International

498-1075 4 Welf-Air 10kVA Cube

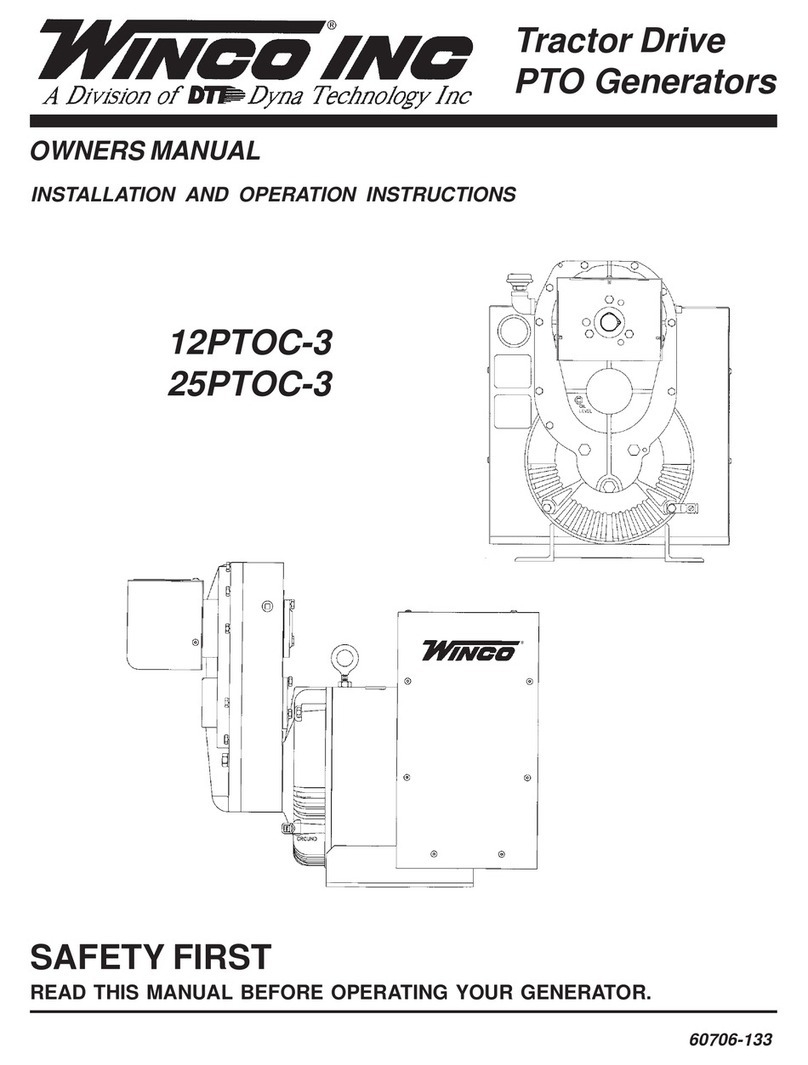

Drawings

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

C

Checked

Material Finish

Title Drg No.

For insert & fabrication specifications refer to PD999-001

02.12.14

10kVA Welfair Cube

General Arrangement

WG-WA100H

A

M.A

02.12.14

B

N.N

28.07.15

C

R.W

19.05.16

D

R.W

27.04.17

E

R.W

19.05.17

WG-WA100H

Item

Description

Item

Pt No.

Item

Material

Sht

no.

Weight (kg)

2 /2

3D views are for illustration only.

270.0 560.0

57.5

675.0

Cover Plate

over 32A 230V

socket

4 off -

Ø12.0 Bolt-down Holes

Lift-off Access

Door

790.0

844.4 max.

1283.0max.

1151.0

70.0

170.0

200.0 200.0

560.0

360.0

1100.0

1104.6

89.0

84.0

1243.5

Harrington Generators International

5 498-1075Welf-Air 10kVA Cube

Drawings

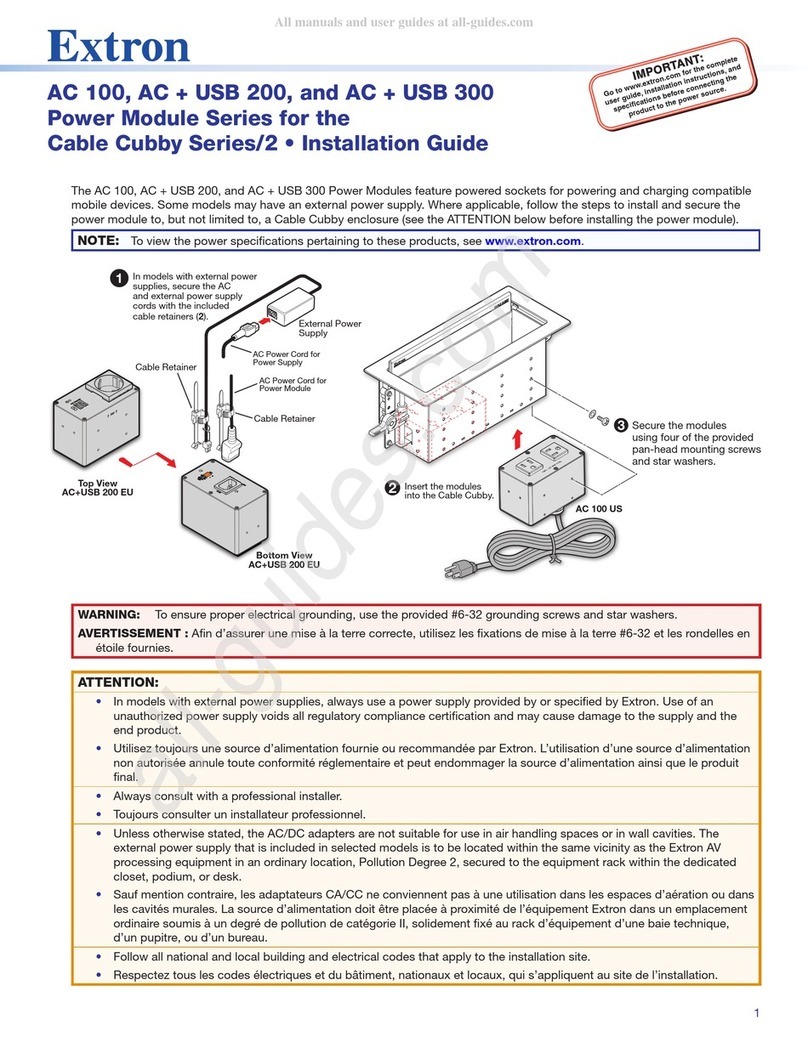

3.2 Installation Drawing

A-A

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

A A

B B

C C

D D

E E

F F

C

Checked

Material Finish

Title Drg No.

For insert & fabrication specifications refer to PD999-001

11.05.17

WA100H 10kVA Welfair

Installation Drawing

PD901-908

A

R.W

11.05.17

B

R.W

19.05.17

PD901-908

Item

Description

Item

Pt No.

Item

Material

Sht

no.

Weight (kg)

1 /1

A

A

3D views are for illustration only.

Front

Face

Rear

Face

Cabin Floor

Foam seal

112.0

973.5

450.0 approx.

690.0

300.0560.0457.5 675.0

Hot Air

Outlet

Internal Dimensions

of Foam Seal

690.0 450.0 approx.

CabinInternalWall

112.0973.5

Air inlet open area

required in cabin

is 0.087m²

Air outlet open area

required in cabin

is 0.132m²

Note:

Louvres to be kept clear from obstruction

inside & outside

Foam seal

for access

for access

489 approx.

114.0

1243.5

Harrington Generators International

498-1075 6 Welf-Air 10kVA Cube

Manufacturer’s Service and User Guides

4.0 Manufacturer’s Service and User Guide Links

Every effort is made to ensure that the manufacturer’s user and service guides contained in this manual are the

latest available at the time of publication. If in doubt about the recency of the documents then please contact the

manufacturer or visit their website for the latest information.

4.1 Kubota Engine Operator’s Manuals

- http://www.kubota.co.uk/after-sales-support/publication/

4.2 Deep Sea Electonics 3110 User Guide

- http://www.deepseaplc.com

4.3 Sincro SK160 User Manual

- http://www.sogagroup.com/

If you are still unsure then please contact HGI Technical Helpline: +44 (0) 1629 821 614 or 821 652

This manual suits for next models

1

Table of contents