DECORATIVE FRUIT CAGE ASSEMBLY INSTRUCTIONS

PAGE 4

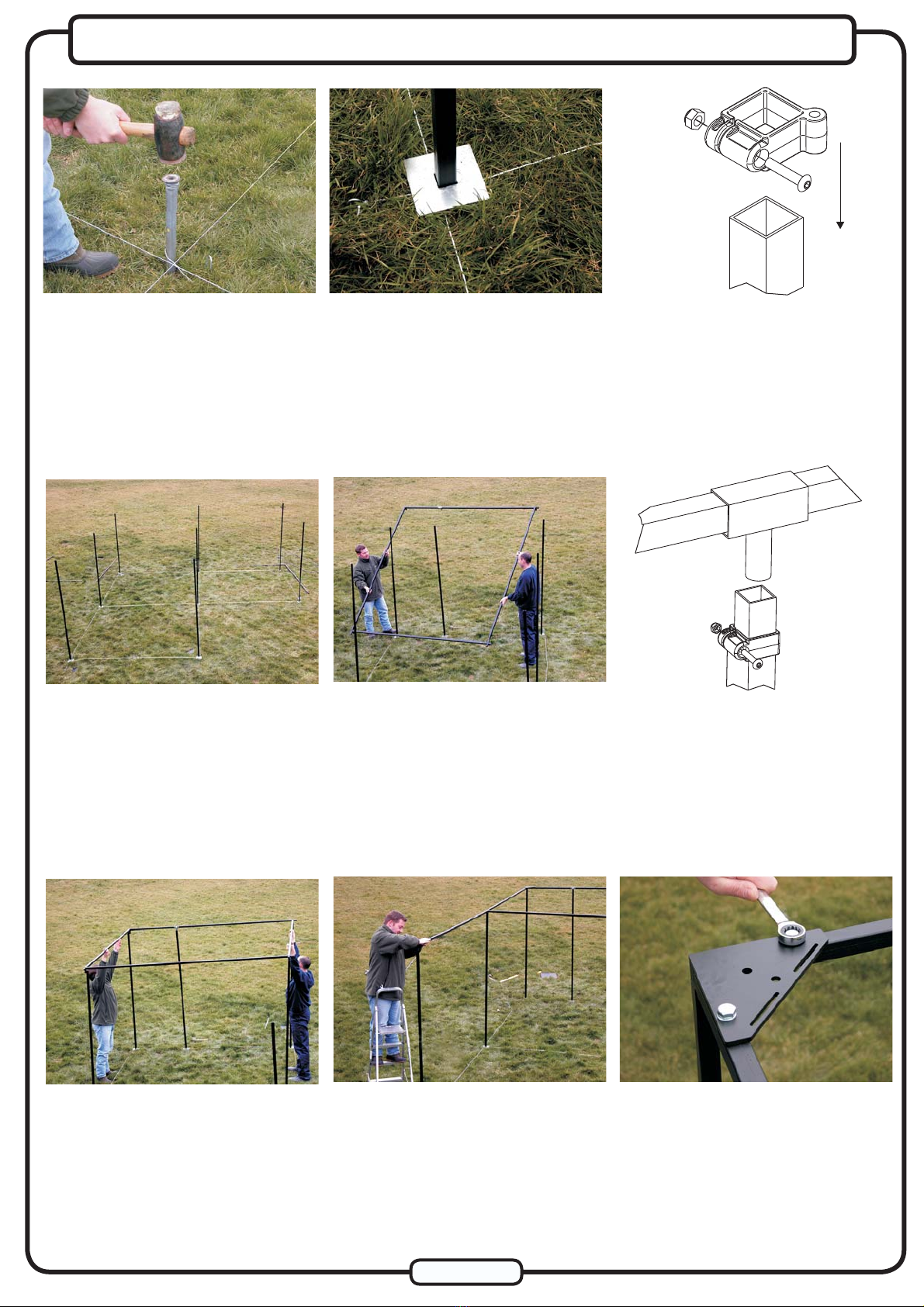

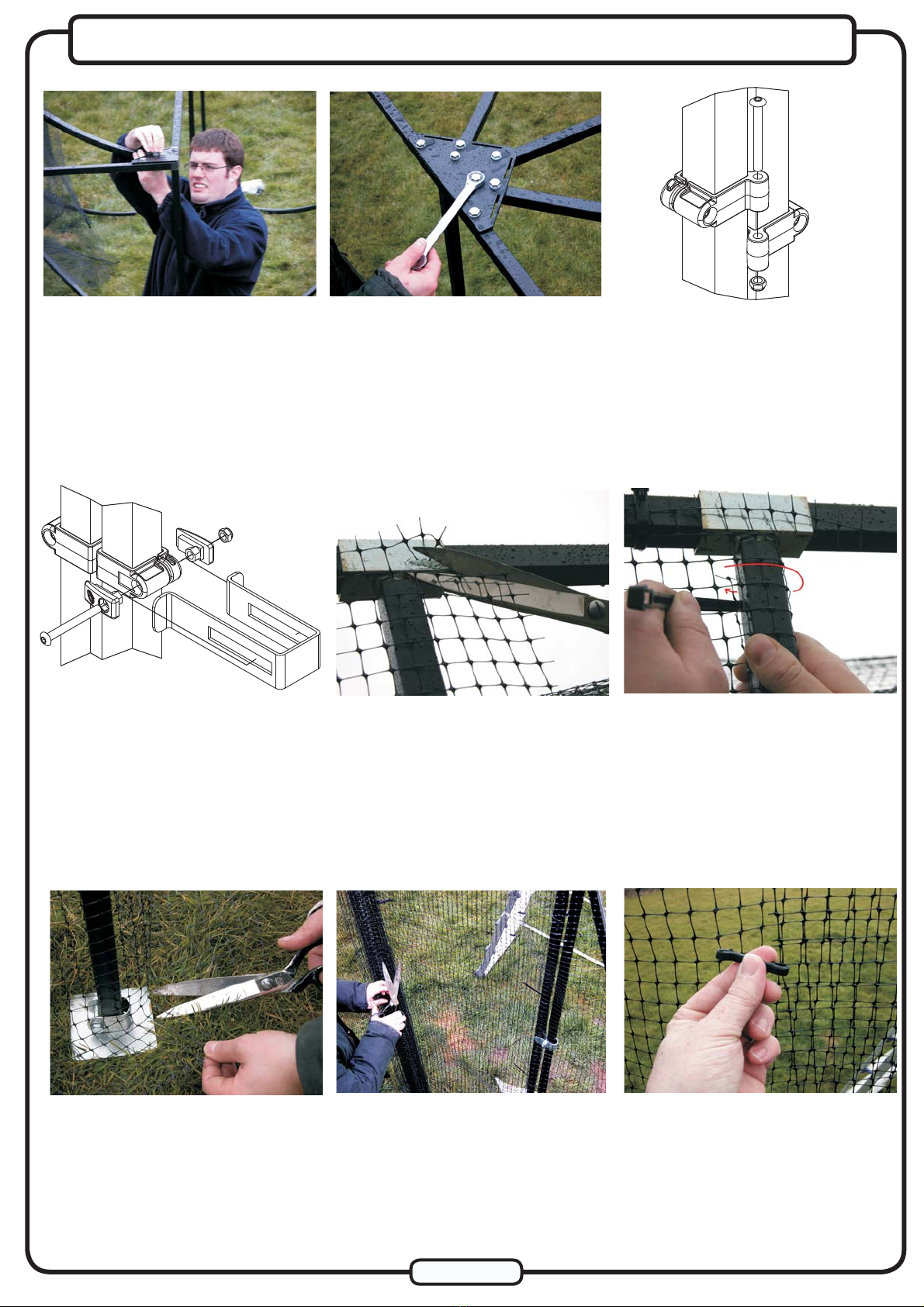

1. After reading the introduction,

lay out on the ground in the desired

arrangement of the final cage all 2.5m

horizontal support bars (ref. 14), all

connector plates (ref. 18,19, & 20) and

all three, four & fve way connectors

(ref. 15,16, & 17).

3. Using the correct connector (ref.

15,16 & 17) for the joint in question,

connect the 2.5m horizontal bars (ref.

14) together to form a framework of

bars which represents the roof of your

cage (in plan form) on the ground. The

soft mallet may be needed to help slide

the bars home.

4. Check that you are happy with the

positioning of the framework within your

plot. Then using a corner connector

plate (ref. 20) make absolutely sure

that the joints are perfectly square as

the ultimate success of the assembly

relies upon this! Diagonals can also be

2. Decide where the door(s) should go

(see step 9) and slide a T-joint (ref. 6)

onto the appropriate horizontal bar(s)

(ref.14). Ensure that the orientation of

the parts is as shown, with the threaded

holes facing upwards and the locking

bolt on the T-joint facing into the cage.

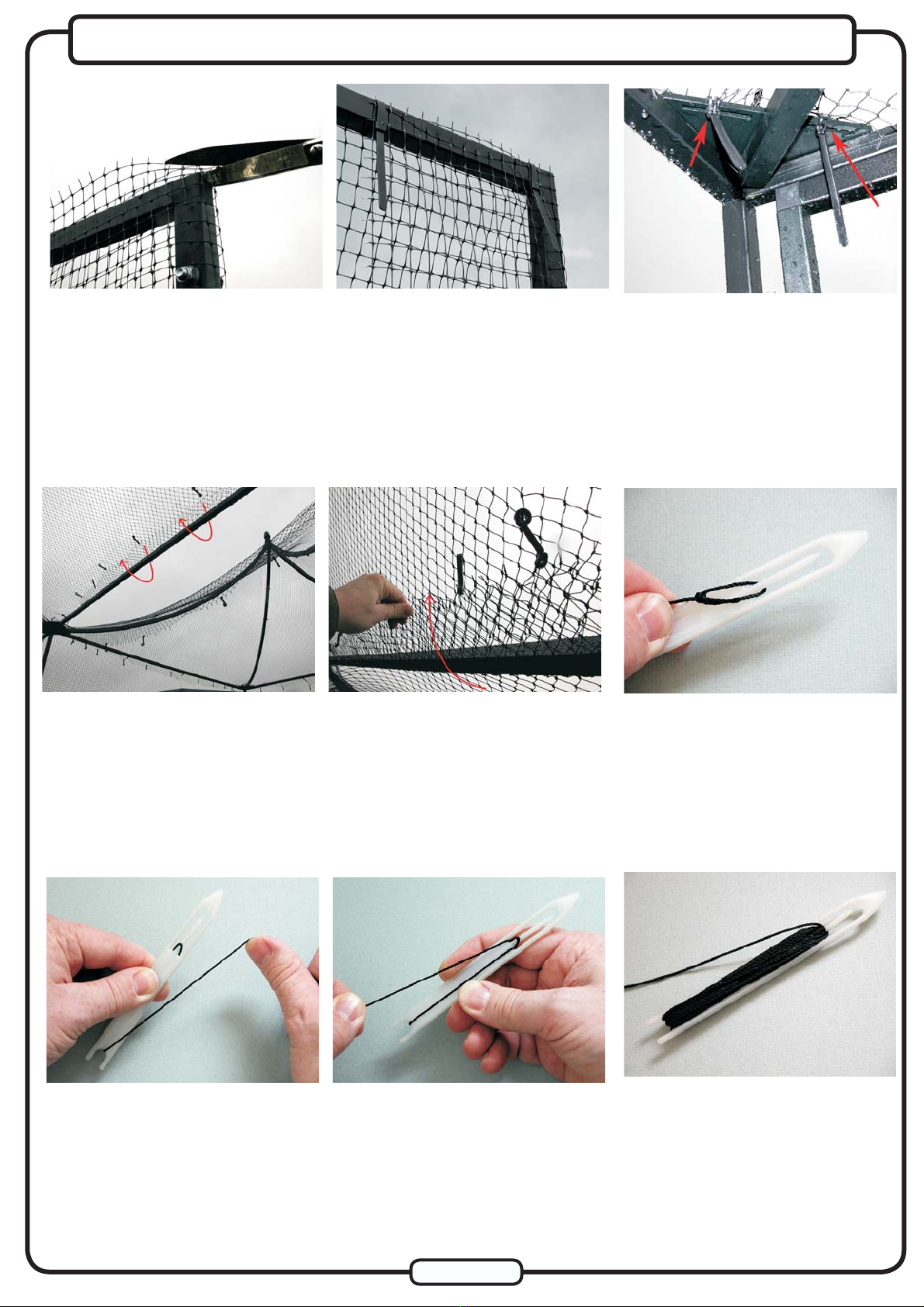

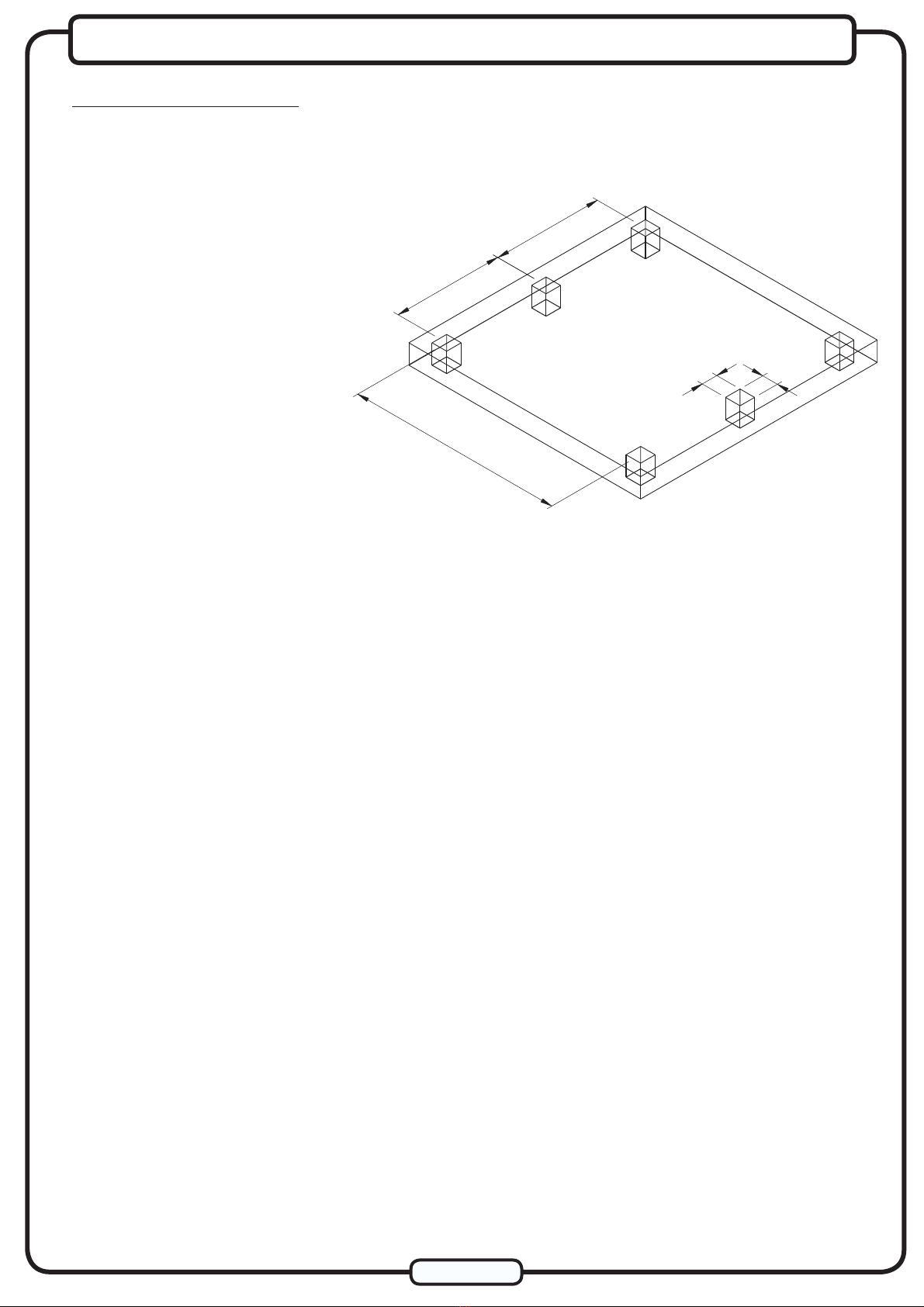

5. Using string tied to ground pegs (ref.

25), mark out the plan of the cage on

the ground as shown above. Where

ever the strings cross, this accurately

marks the intended position of an

upright (ref. 4).

6. Ensure that the marking string is

pulled tight and accurately follows the

framework of horizontal bars which act

as a template. Check once more that

all is square as described in step 4.

8. Once all of the marking out with

string is complete, carefully dismantle

the horizontal bar framework leaving

connected only bars that can exist as

a complete square unit (see step 13

for reference). Note that the threaded

holes in the horizontal bars always

face upwards.

7. When more than two horizontal bars

come together, it is essential to mark

which side of the string the uprights will

be located. Ground pegs (ref. 25) can

be used for this.

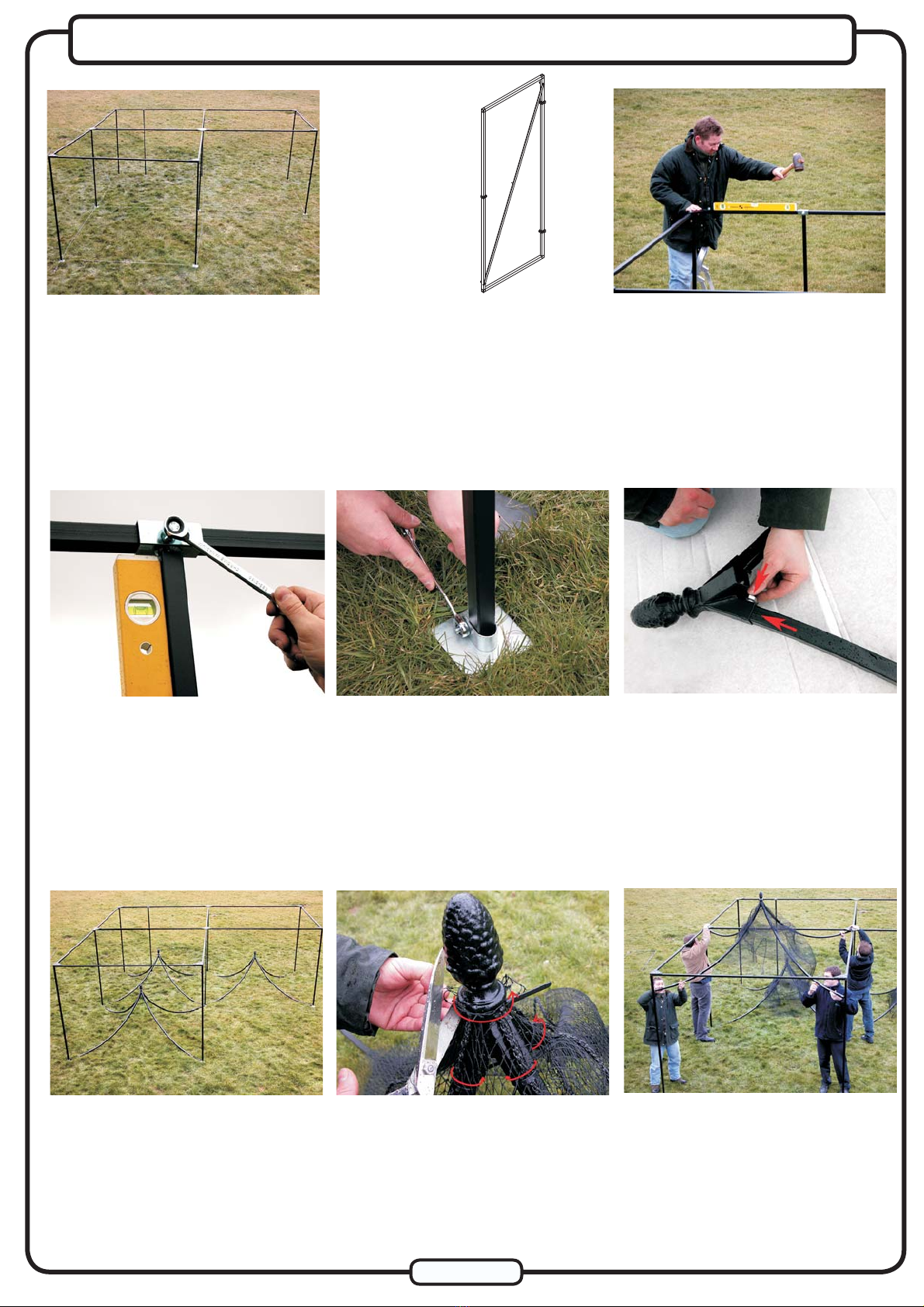

9. Your site should be marked out in

the manner shown above. If your site

slopes, level the strings with the aid

of a spirit level. Position the door on

the lowest side of the cage if possible

to ensure that all of the uprights (ref.

4) can enter the ground at least the

required distance of 32.5cm.

measured. When both are equal the

frame is square.