PAGE 6

DOMED FRUIT CAGE ASSEMBLY INSTRUCTIONS

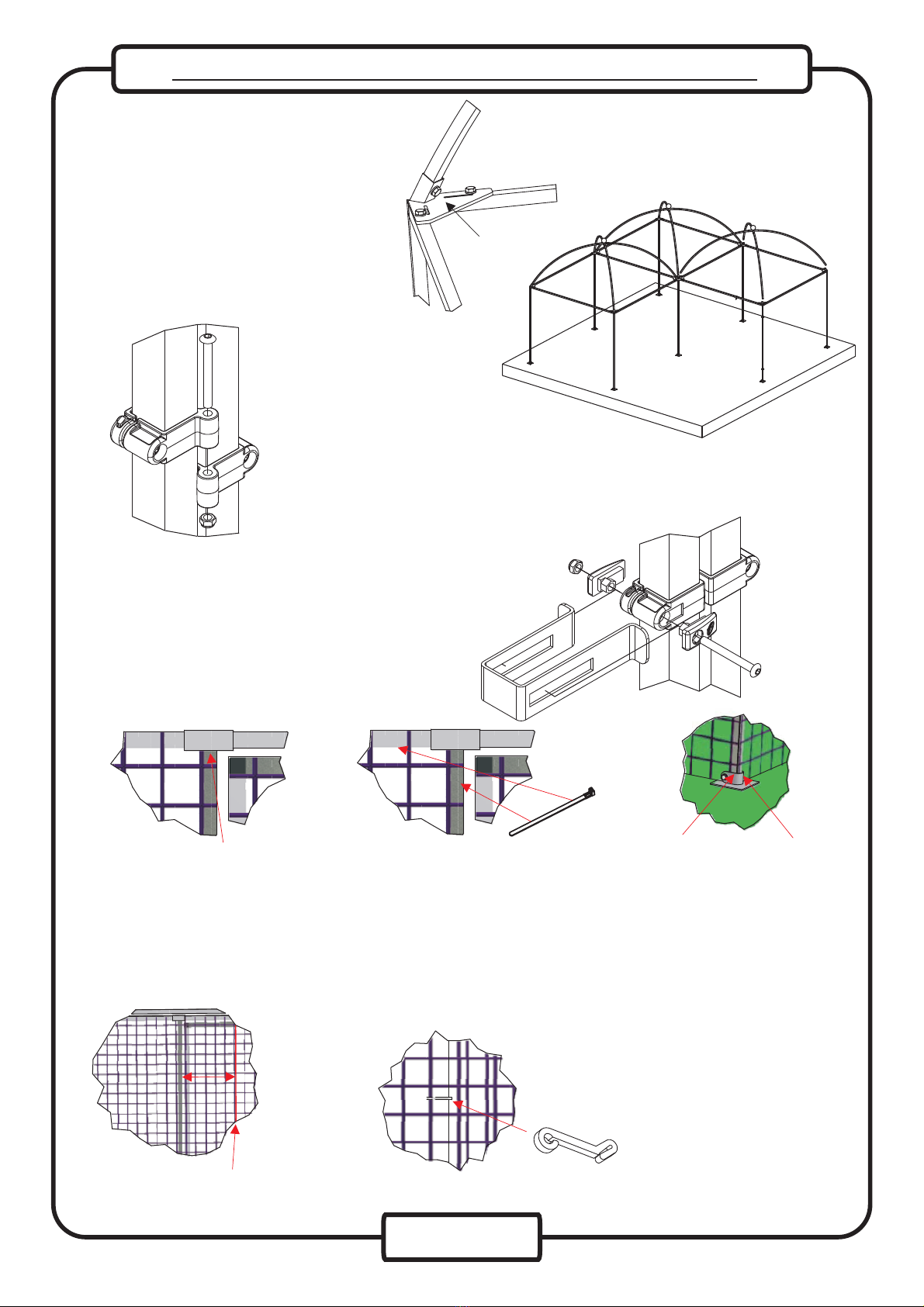

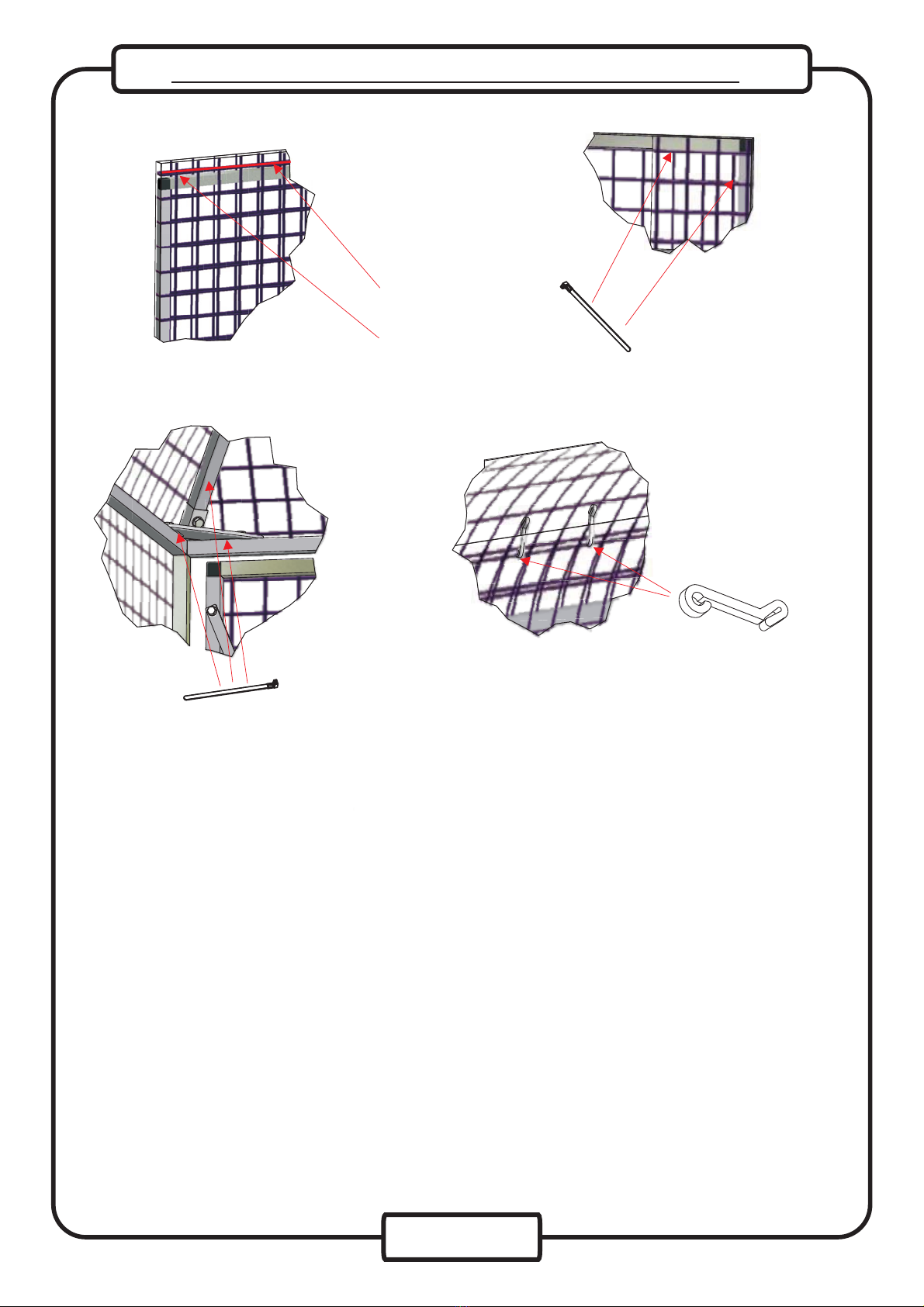

26: To fix the 2m wide side

netting, start by cutting to

allow the net to wrap around

the door support upright. This

will allow the top edge of the

net to run along the top edge

of the horizontal support bars.

27: Wrap the cut section of the side

net around the door support upright

as described in step 24. Tie in place

using net ties ( ref :26) at the top and

the bottom of the upright and a couple

equally spaced in between. Secure

the top of the net along the horizontal

bars using net ties (approx four for

every 2.5m length).

28: Continue to unroll the side

netting all the way round the

perimeter of your cage, keeping it

as taught as possible, securing as

step 25. When corners are

encountered snip the bottom few

cms flush with the ground to allow

the net to neatly fold.

29: To finish the side net and to cover the

door, unroll about 30cm past the door and

cut vertically.

30: Fold the side net around

the catch side of the door and

hold securely with several

equally spaced net clips

(ref:25). A small cut can be

made in the net to allow the

catch to protrude cleanly.

22: Slide the fitted roof net down over

the finial and align the seams with the

curved bars. Using net ties (ref :26)

secure the net around the base of the

finial and also around the curved bars.

Trim off the ends of the ties and also

any untidy stray netting.

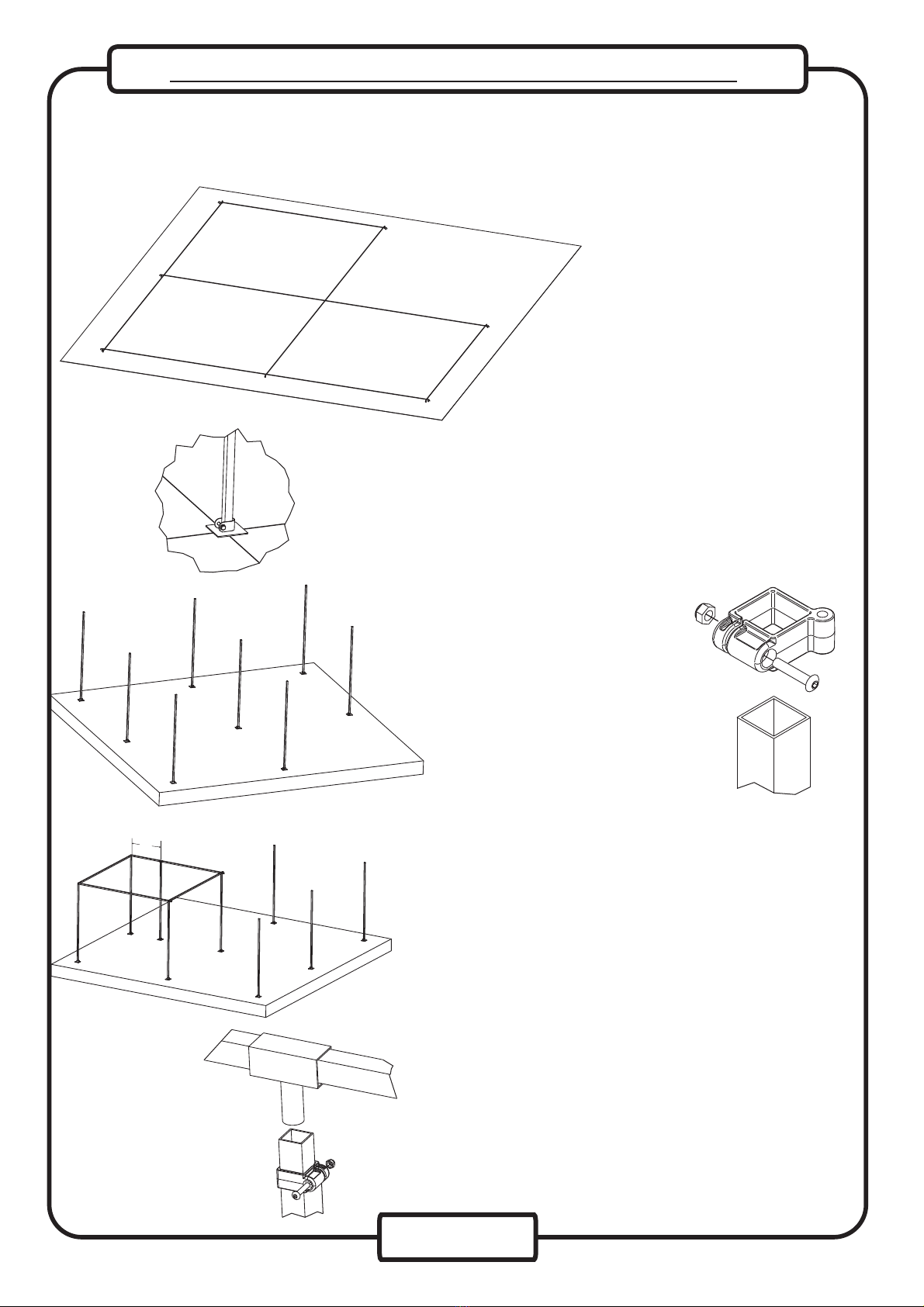

With the aid of at least three people lift

the unit(s) into place .

23: Bolt (ref 21,22) the curved roof

supports (ref 24) onto the connector

plate (ref:18,19,20). Tighten the bolts

using a 17mm spanner (fig 10).

fig 12fig 12

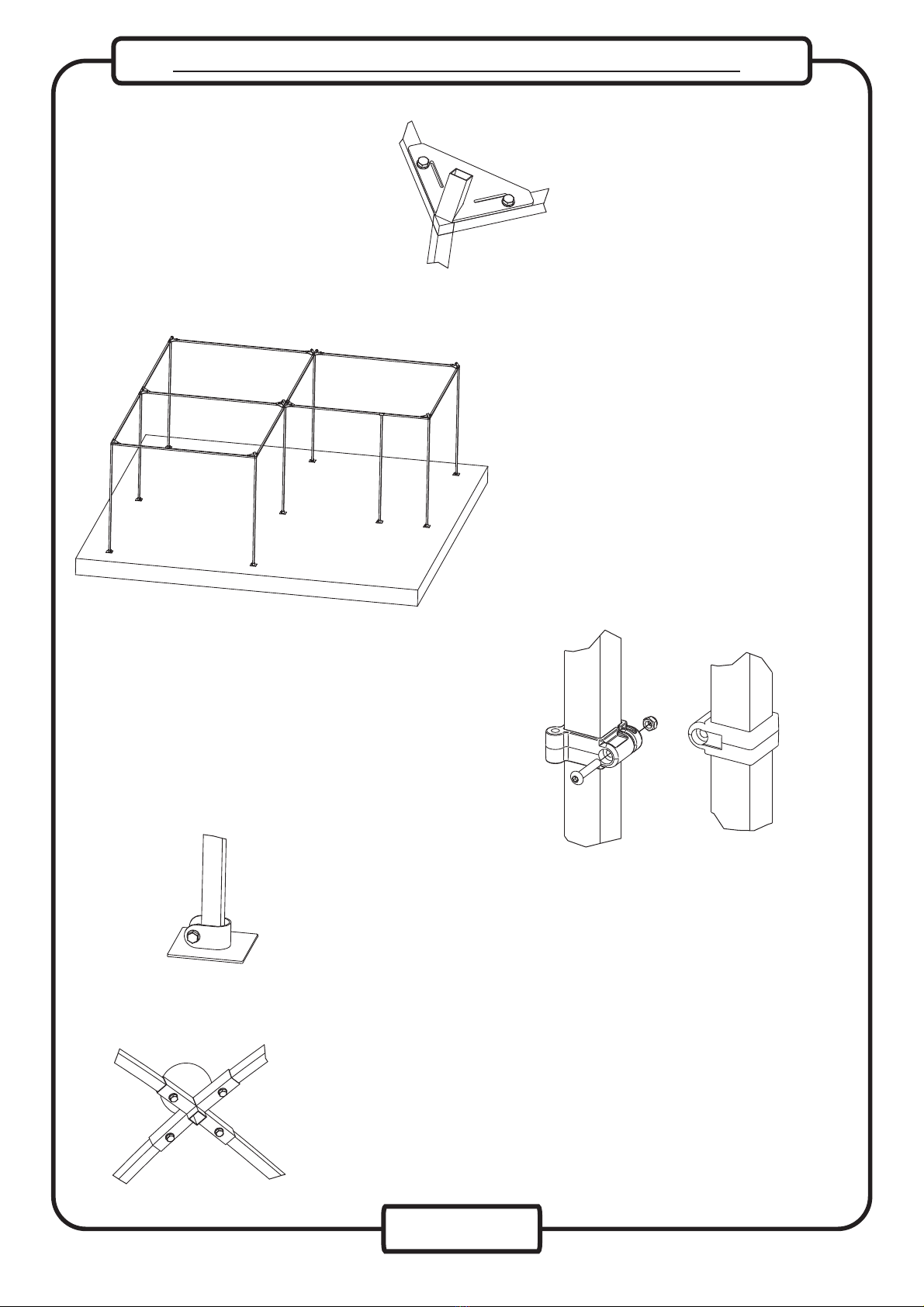

24. Place the assembled door frame in position and secure in by

joining the hinge blocks (Ref.8) as shown (fig 13) and tightening the

bolts with the 3mm allen key supplied and an 8mm spanner. Note as

the hinge blocks must spin on each other do not over tightening the

long bolt/nut through the bosses.

fig 13fig 13

25. Secure the latch in place by sliding it over

the latch block and inserting the latch inserts

as shown (fig 14). Tighten the bolts with the

3mm allen key supplied to hold in place. Note

the latch should not be over-tightened as it

must slide freely. Note the latch has one

longer side and this must be positioned on the

side you wish to open the door.

fig 14fig 14