haTmed Q50B User manual

SmallSteamSterilizer

UserManual

(InternalWaterTank)

Q50B/Q70B

2460

HӓTmed(Wuxi)Co.,Ltd

V01version

I

HӓTmedSmallsteamsterilizerforsterilizingmedicalandlaboratoryequipments,Theproductdesignconforms

totheYY/T0646‐2015standardandisaClassBsterilizer.ProcessevaluationsystemaccordingtoEN13060.

Do not sterilize any liquid,Violating the use of this product to

sterilizeliquidswilldamagetheproductandtheloads.

:

Symbols Indication Description

Warning

Identifies danger points or conditions and

the correct procedures that must be

followedtoavoidinjury.

HotSurfaces Hotitems,takecaretoavoidburns.

Caution

Identifies actions that could damage the

device/component.

PrecautionsDrawuser'sattentiontoimportantmatters.

Symbolsonproducts:

Symbols Description

takecaretoavoidburns

Manufacturerofmedicalequipment

Dateofmanufactureofthisdevice

Serialnumber

Symbolsdescription

Application

II

NameandaddressofauthorizedagentofthisproductintheEuropeanUnion.

Serviceshouldbeperformedbyqualifiedtechniciansonly.Observealllocal

andnationaldirectivesrelatedtoserviceandsafetystandards.

Thefunctionandlifespanofthisproductaredirectlyrelatedtowhetherthe

userfollowstheoperatingspecificationsandmaintenancerequirementsin

theinstallationandusemanual.

ManufacturerconfirmsthatthisproductcomplieswiththeEuropeanUnion

MedicalDeviceSpecification.

Drawuser'sattentiontoimportantmatters.

Identifies danger points or conditions and the correct proceduresthatmustbefollowedto

avoidinjury.

Liquidsterilization Donotsterilizeanyliquid

Professionals Theoperatorwhousesterilizersandfabricmustbegotatrainedprofessional.

Powercordandpowerplug

Donotreplacethepowercableorpowerplug.Donotuseadamagedpowercableor

powerplug.

Donotusethisproductifthepowercableorpowerplugisdamaged.Thepowercable

orpowerplugmustbereplacedbyaprofessionalauthorizedbythemanufacturerof

thisproduct.

Donotuseforceonthepowercable,besuretooperatetheplugitselfwhenplugging

andunplugging.

Makesurethepowercableisnotknotted。

Donotplacethepowercablenearaheatsource.

Donottouchthepowercablewithasharpobject.

Installation,setupand

commissioning

Installation, setup and commissioning should be performed by a professional

authorizedbythemanufacturerofthisproduct.

Safetyinstruction

III

Donotuseoroperatethisproductatsiteswherethereisariskofexplosion.

Theelectricalconnectionofthis productandtheconnectionoftheinletandoutlet

pipesshouldbecarriedoutbyprofessionals.

Thisproductshouldnotbeindirectcontactwiththepatient.Placethisproductoutside

therangeofatleast1.5meters(radius)inthetreatmentarea.

Ifanexternalprinterisconfiguredforthisproduct,theprintershouldnotbeplacedin

alocationwherethereisariskofcontactwithliquid.

Emergencydoor

openingdevice

Donotusethisdevicetoopenthedoorundernormalconditions.

Sewagepretreatment

andsterilization

Pretreatmentandsterilizationofinstrumentsandfabricsshouldfollowtheregulations

oftheinstrumentandfabricmanufacturers.

Strictly follow the relevant standards for disinfection and sterilization,e.g.WS506‐

2016,WS310‐2016.

Usepackagingmaterialsorcontainersthathavebeenconfirmedbytheirmanufacturer

forsterilization.

Sterilizationtermination

Thisproductterminatesabnormallyatcertainstagesoftheprogram,hightemperature

steamwillemergefromthechamberafteropeningthedoor.

Theloadeditemmaynotbesterilizedwhenthesterilizationisabnormallyterminated.

Please note the status of the program showed on the display when itterminates.If

necessary,theloadeditemsshouldberepackagedandsterilized.

Removetheloadeditem

Donotusestrongdooropening.

Usethetrayhandletotakeoutthetray.Donottouchthesterilizeditemswithbare

hand,includingchamberanddoorcover.

Checkiftheloadeditemsispackagedcompletelyaftersterilization.Ifthepackageis

damaged,pleasepackinstrumentorfabricagain.

Deliveryandtransportation

Atleast2peopleneedtomoveordeliverthisproduct.

Useproperbelts.

The shipping box provided by the manufacturer of this product must be used for

transportation.

Sterilizationload

Theloadmustbesterilizedwithallowedsteambythemanufacturerbeforeitcanbe

sterilized.

maintenance

Maintenanceofthisproductmustbeperformedbyaprofessionalauthorizedbythe

manufacturer.

Pleasemaintaintheproductatthetimeintervalsspecifiedinthismanual.

Mustusetheaccessoriessuppliedbythemanufacturerofthisproduct.

IV

malfunction

Ifthesamefaultmessageappearsrepeatedlyinthisproduct,pleaseturnoffthepower.

Repairmustbeperformedbyaprofessionalauthorizedbythemanufacturerofthis

product.

Nameofsterilization Standard

134

Standard

121 QuickB Quick

S 134+ Fabric

Classofsterilization B B B S B B

Dynamicpressuremonitoring√ √√√√√

Airleak √ √ √ √ √ √

Noload √ √ √ √ √ √

Solidload√√√√√

Smallamount,porous,permeable

mixedload √ √ √

Smallamount,porous,permeable√ √ √ √

Porous,permeablefullload√√√√

Bhollowload √ √ √ √ √

Ahollowload √ √ √ √

Simplepackaging√√√√√√

Compositepackaging √ √ √ √ √

Dry,solidload√√√√√

Dry,porouspermeableload√√√√

Sterilization Program Introduction

V

TABLEOFCONTENTS

1DeviceDescription........................................................................................................................................1

1.1Deliverylist...........................................................................................................................................1

1.1.1Standarddeliverylist.....................................................................................................................1

1.2Productview.........................................................................................................................................1

1.2.1Frontview.....................................................................................................................................2

1.2.2Frontview.....................................................................................................................................2

1.2.3Sideview.......................................................................................................................................3

1.2.4Rearview.......................................................................................................................................3

1.2.5Insideview.....................................................................................................................................4

1.2.6Topview........................................................................................................................................4

1.3TechnicalParameters............................................................................................................................4

1.4Loadingmethod....................................................................................................................................5

1.5Intelligentcontrollerandcontrolpanel..................................................................................................5

1.5.1Operationbuttons.........................................................................................................................6

1.6Emergencydooropeningdevice............................................................................................................6

1.7Equipmentworkflow.............................................................................................................................6

1.7.1Sterilizationprogram.....................................................................................................................6

1.7.2Vacuumtest...................................................................................................................................7

2Installationandhandlinginstructions...........................................................................................................7

2.1Unpackingprecautions..........................................................................................................................7

2.2Installationsiterequirements................................................................................................................8

2.3Deviceheightadjustment......................................................................................................................8

2.4Connectionrequirements......................................................................................................................9

2.4.1Electricalconnections.....................................................................................................................9

2.4.2Distilledwaterconnection.............................................................................................................9

2.4.3Wastewaterconnection...............................................................................................................10

2.5Installationservicelist.........................................................................................................................10

2.6Handlinginstructions...........................................................................................................................10

3Firsttimeoperation....................................................................................................................................11

3.1Startup................................................................................................................................................11

3.2Afterstartup.......................................................................................................................................11

3.3Openandclosethedoor......................................................................................................................11

3.4Distilledwaterinjection.......................................................................................................................12

3.5Drainage.............................................................................................................................................12

3.6Sterilizationeffectverification.............................................................................................................13

4Sterilizationprogram..................................................................................................................................13

4.1Loadingitemstobesterilized..............................................................................................................13

4.2Selectsterilizationprogram.................................................................................................................13

4.3Auxiliaryoption...................................................................................................................................14

4.3.1Warm‐upsetting..........................................................................................................................14

4.3.2Automaticprinting.......................................................................................................................15

4.3.3Extradrying.................................................................................................................................15

4.4Runningasterilizationprogram...........................................................................................................15

4.4.1Startsterilization.........................................................................................................................15

4.4.2Programrunningprocess.............................................................................................................15

4.5Manualstop........................................................................................................................................15

4.6Sterilizationprocesscompleted...........................................................................................................17

4.7Sterileitemstorage.............................................................................................................................18

5Functionaltestingandotherprocedures.....................................................................................................19

5.1Vacuumtest........................................................................................................................................19

5.2B&Dtest..............................................................................................................................................20

VI

5.3Helixtest.............................................................................................................................................20

5.4Drainageprogram................................................................................................................................21

6Systemsettings...........................................................................................................................................21

6.1Timesetting.........................................................................................................................................21

6.2Datesetting.........................................................................................................................................22

6.3Languagesettings................................................................................................................................22

6.4Warm‐upsetting..................................................................................................................................23

6.5Printingsettings...................................................................................................................................23

6.6Extradryingsettings.............................................................................................................................24

6.7Waterqualitytesting...........................................................................................................................24

6.8Systemreset........................................................................................................................................25

6.9Systeminformation..............................................................................................................................25

7Sterilizationlog...........................................................................................................................................25

7.1Logexport............................................................................................................................................26

7.2Logprinting..........................................................................................................................................26

7.3Loginterpretation................................................................................................................................26

8Smallsteamsterilizrmaintenance...............................................................................................................27

8.1Cleaningofitemsbeforesterilization...................................................................................................27

8.2Maintenance........................................................................................................................................27

8.2.1Cleaningandmaintenance............................................................................................................27

8.2.2Regularmaintenance....................................................................................................................29

9Failureandcommonproblem...........................................................................................错误!未定义书签。

9.1Noinformationonthedisplay..............................................................................................................29

9.2Largeconsumptionofdistilledwater....................................................................................................30

9.3Baddryingeffect..................................................................................................................................30

9.4Nodistilledwater.................................................................................................................................30

9.5Unabletoopenthedoor......................................................................................................................30

9.6Leakageatthedoorordrippingunderneath.........................................................................................31

Appendix1 Safetydevicedescription.............................................................................................................31

Appendix2 Schematicdiagramofpipingsystem............................................................................................31

Appendix3 Electricalschematicdiagram........................................................................................................32

- 1 -

1 Devicedecription

1.1 Deliverylist

1.1.1 Standarddeliverylist

Thestandardaccessoriessentwithsterilizerarelistedinthetablebelow.Pleasecheckthelistwhenunpacking.

1.2 ProductView

1.2.1 FrontView

1.1.1 Standarddeliverylist

AccessorynameAccessory

PictureQ’ty Description

Airlevel 1

Airlevelisplacedabovethesterilizerduring

installation.Twofootpadsatthefrontishigherthan

thebackend.Theanglebetweenthebottomof

sterilizerandcountertopisaround5‐10°.

Tray

3 Aluminumtraywithholesatthebottomforplacing

sterilizeditems.

Trayhandling

1 Tooltotakeoutthetray

Chamberrack 1 Racktoholdthetray

Fuse

2 220V/16Afuse

Airfilter

1

Airfiltertoensurethattheairenteringthe

sterilizationchamberishighlyfilteredtoreduce

bacteriaanddustentry.

Wastewater

pipe

2Transparentsiliconetubefordrainingwaste

water(Φ9*62M).

Drainconnector

(internaltank

only)2 Ajointconnectingthedrainpipetothesterilizer

wastewaterinterface

RandomDocument

Installationand

manual

1 Manualbook

ProductService

Manual1 Userguidance,installationserviceorder,

maintenancerecord

Operation

precautions1 commonproblemsandprecautions

- 2 -

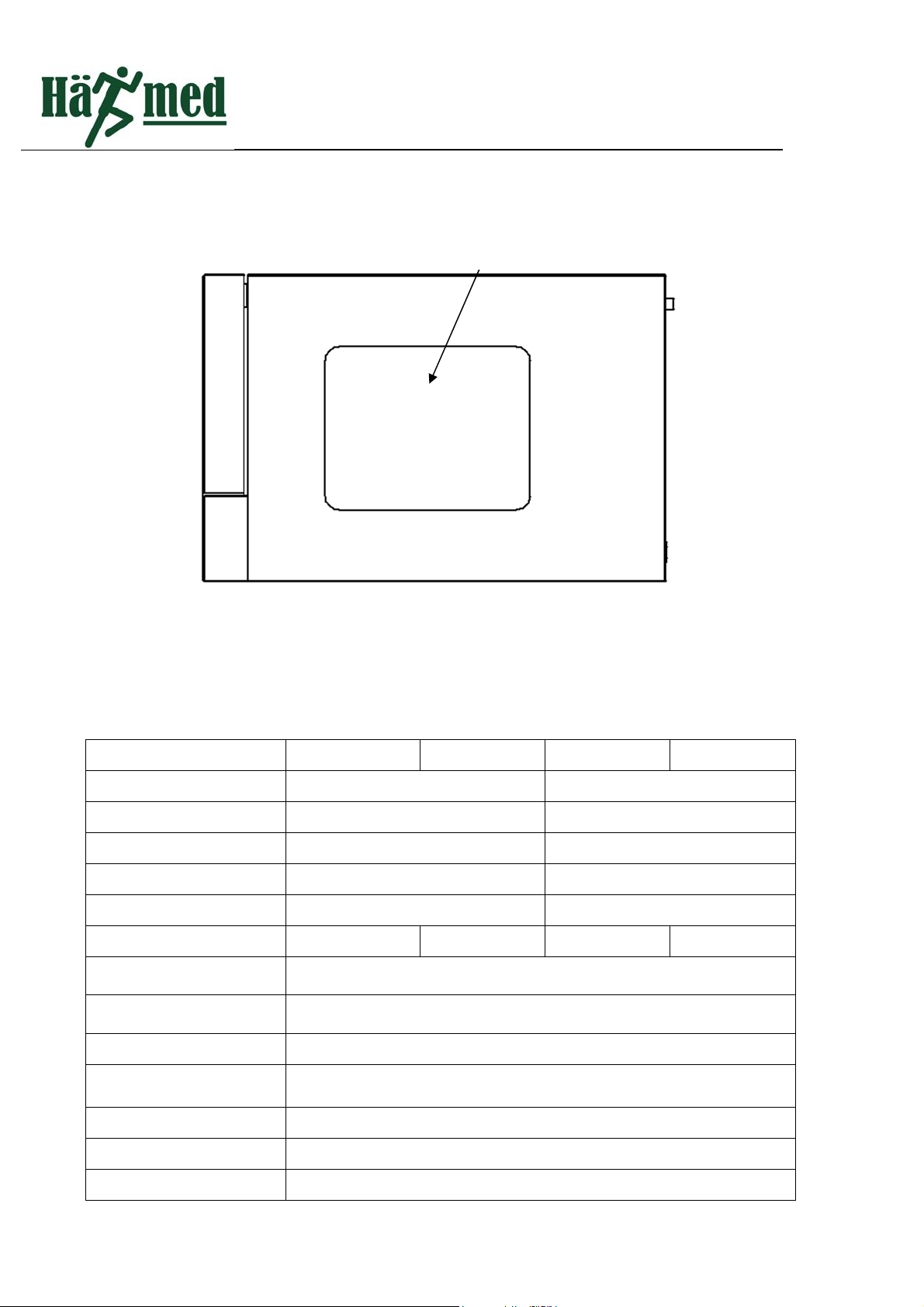

Fig1.1frontview

1.2.2 Sideview

Fig1.2sideview

Door

handle

Power

switch

Display

- 3 -

1.2.3 Rearview

Fig1.4RearView

1.2.4 InsideView

Fig1.5insideview

Wastewater

drainageinterfaceA(empty)

PowerSwitch

Printerinterface

Testinterface

USBinterface

Emergencydoor

openingdevice

Airfilter

Powercable

Safetyvalve

Wastewater

drainageinterfaceB(halfdrainage)

Coolingfan

- 4 -

1.2.5 TopView

Fig1.6Topview

1.3 Technicalparameters

parametername Q50B Q51B Q70B Q71B

Externalsize 570mm*450mm*470mm680mm*450mm*470mm

Packagingsize 688mm*576mm*688mm 806mm*576mm*688mm

Chambersize Φ253mm*355mmΦ253mm*475mm

CapacityofSterilizer 18L 23L

Pressurevesselweight 4.8kg 6.2kg

Equipmentweight 59.6kg 71.6kg 64.8kg 66.8kg

Built‐incleanwatertank

volume3.8L

Built‐inwastewatertank

volume4.5L

Softwareversion V00

Pressurevesseltechnical

indicators

Workingpressureislessthan0.25Mpa

Operatingtemperature

:

115℃‐138℃

Workingvoltage A.C220V±22V,50Hz±1Hz

Maximumpower 2000VA

Fuse 16A

Distilledwatertank

(Internal)

- 5 -

Workingenvironment

pressure70Kpa~106Kpa

Workingtemperature5

oC~40oC

Storageandtransportation

environmenttemperature‐20oC~55oC

environmenthumidity ≤85%

Maximumwastewater

temperature100oC

Maximumnoise 70dB(A)

Electromagnetic

compatibility

CompliancewithGB/T18268.1‐2010;Worksproperlyinitselectromagnetic

environment,butdoesnotconstituteanunacceptableelectromagnetic

harassmentofanythingintheenvironment。Atthesametime,ithasthe

abilitytoresistelectromagneticinterference.

AccordingtoGB4824‐2013,ElectromagneticradiationmeetsGroup1Class

Brequirements.

Standardscompliant YY/T0646‐2015;GB4793.1‐2007;GB4793.4‐2001;

Note1:Themaximumoperatingvoltagerange:198V~242V

Note2:Anti‐electromagneticinterferenceistheabilityofthesterilizerto

workproperlyinthepresenceofelectromagneticinterference

1.4 Loadingmethod

The tray rack is included in the delivery of sterilizer. The space inside the tray rack is a space that can be

effectivelysterilized,alwaysusethetrayrackwhenloadingitemstobesterilized.Thetrayrackcanhold5traysor

adapttothicknessofdifferentloadsorcontainersafterrotating90oC.

Fig1.6Loadingmethod

1.5 Intelligentcontrollerandcontrolpanel

Intelligentcontrolleristhecoreofsmallsteamsterilizer,Inadditiontocompletingoperationssuchasrapid

acquisition, processing, fault detection, and control of the system's real‐time parameters, the controller also

intuitivelyplotsthetemperatureandpressureversustimecurveinthechamber.

TheintelligentcontrolleriseasyandefficienttooperatewithLCDscreenwith4buttons.

- 6 -

1.5.1 OperationbuttonsandIdentification

Theuseof4buttonsindifferentsituationsisasfollows:

Buttonposition

(Faceupfromleft

toright)

1234

Whentheprogramis

selectedreturnPrevious

optionNextoptionSelect

standbymode Openthedoor Startup

Programruntime Stop

WhensettingConfirm

Thereisaniconintheinterfacetodisplaythedoorlockstatus.

StatusIdentificationDescription

DoorlockstatusThestatusofthedoorlock:onoroff

1.6 Emergencydooropeningdevice

Emergencyopeningisanunconventionalwaytoopenthedoorwhensterilizercannotbepoweredondueto

other reasons or the safety door failure.Please do not open thedoorinthiswayundernormalcircumstances.

Removethescrewontheemergencyprotectioncoveronthebackoftheproduct(Fig.1.4),thenusingyourright

hand to grasp the white plastic disc inside the protective cover,gently pull(distance is about 1CM).At the same

time,useyourlefthandtoliftthedoorhandleuptoopenthedoor

1.7 EquipmentWorkflow

1.7.1 Sterilizationprogram

Sterilizationprocessconsistsof3stages,pre‐vacuum,sterilization,drying.Aftertheprogramisstarted,the

usercanseethestageoftheprogramrunningontheinterface.

Processname Description

1.Pre‐vacuum

Duringthestageofpre‐vacuum,theprocessofevacuatingandinjecting

steamisproceededrepeatedly,Asthemixtureofairandsteamis

continuouslyextracted,theairinthechamberisminimized.Thenumberof

thisprocessvariesaccordingtotheselectedprogram,standardsterilization

procedurerepeated3times,Helixprogramand134+programrepeated4

times.

2.Heating

Afterthepre‐vacuumistheheatingstage,steamiscontinuouslyinjected

intothechamber,thetemperatureandpressureinthechamberrise

continuouslyuntilthespecifiedvalueoftheselectedprogramisreached.

- 7 -

3.Holding

Afterthetemperatureandpressurereachedthesetvalue,holdingphase

beginsandmaintainsstabletemperatureandpressureforaperiodoftime

toensurethatthesterilizationeffectmeetstherequirementsofthe

specification

4.Depressurizatio

n

Thepressureinthechamberisreleasedaftertheholdingtimeisover.Atthe

sametime,thesteaminthesteamgeneratorisdischarged.

5.Drying

Aftersterilization,thesterilizeditemsaredried.Dryingbeginsafterpressure

isreleased.Undertheeffectofahighefficiencyairfilter,theairinthe

chamberisalwayssterileduringthedryingprocess

6.Intake

Thedryingprocessisalsotheprocessofintake,makesurethatthepressure

inthechamberreturnstoenvironmentalpressureattheendofthe

program.

1.7.2 Vacuumtest

Thepurposeofthevacuumtestistotesttheleakrateofthesterilizer.Nosterilizationoftheitemsinthe

chamberduringtheprocess.Pleaserunthevacuumtestinacoldanddrychamberwithoutloads.

Processname Description

1.Vacuum Theairinthechamberisevacuatedtillthepressureinthechamberreaches

thesetvalueofthevacuumtest

2.Balancingtime Afterwaitingfor5minutes,thevacuumeverywhereinthechambertendsto

beuniform.

3.Testholding

time

Testholdingtimeis10minutes,Thedevicecontinuouslymonitorsthe

pressureinthechamberduringtheperiod

4.Endoftest Afterthetestisover,thescreendisplaysthetestresults:vacuumandleak

rate.

2 Installationandhandlinginstructions

2.1 Unpackingprecautions

Installation,setup,andcommissioningshouldbeperformedbya

professionalauthorizedbythemanufacturerofthisproduct.

Thisproductistakenoutoftheboxandtransportedmustbe

operatedby2people.

Totalweight:Q50B59.6kg;Q51B61.6kg;

Q70B64.8kg;Q71B66.8kg

- 8 -

Pleasecarefullychecktheboxandtakeoutthedevice.Ifthe

packageisdamagedortheequipmentisdamaged,pleasecontact

anauthorizeddealerorlogisticscompanyimmediately.

Pleasecheckthepackingboxandtherandomaccessoriesinside

thesterilizer.Alistofstandardaccessoriescanbefoundinsection

1.1ofthismanual.

2.2 Installationsiterequirements

Thisproductshouldbeplacedinadust‐freeanddryenvironment。Surroundinghumidityislessthan85%,

Temperaturebetween5oCand40oC.

Donotuseoroperatethisproductatasitewherethereisariskof

explosion.

Countertopmustbeabletosupporttheweightofthisproduct:

Q50B59.6kg;Q51B61.6kg;

Q70B64.8kg;Q71B66.8kg

Eachsurfaceofthedevice(exceptthebottom)musthaveagap

of10cmoutward.Toosmallagapwillresultinheatbuildup,

shortenthelifeoftheequipment,reducetheperformanceofthe

equipmentandextendtherunningtimeoftheprogram.

2.3 Deviceheightadjustment

Takeoutairlevelandputitinthehorizontalpositionatthetopoftheproductandadjustthetwofootpadsat

thefrontendtomakesurethefrontishigherthantherearside.Theanglebetweenthebottomofsterilizerand

countertopisaround5‐10°.Itisbeneficialtorealizethedryingoftheloadsandsavesdistilledwater.

Fig2.1Deviceheightadjustment

Rearend

Frontend

- 9 -

2.4 Connectionrequirements

2.4.1 Electricalconnections

220V/50Hzpowersupply.Themaximumpowersupply

fluctuationrangeis198V~242V.

Useaseparate16Apowercircuit.Provides30mAleakage

protection.

Makesurethepowercableisnotknottedorpressed.

Donotuseforcetopullthepowercable,

Donotplacethepowercablenearaheatsource.

Donottouchthepowercablewithasharpobject.

Donotreplacethepowercableorpowerplug.Donotusea

damagedpowercableorpowerplug

Do not use this device if the power cable or power plug is

damaged.Thepowercableorpowerplugmustbereplacedbya

professionalauthorizedbythemanufacturerofthisdevice.

2.4.2 Distilledwaterinjection

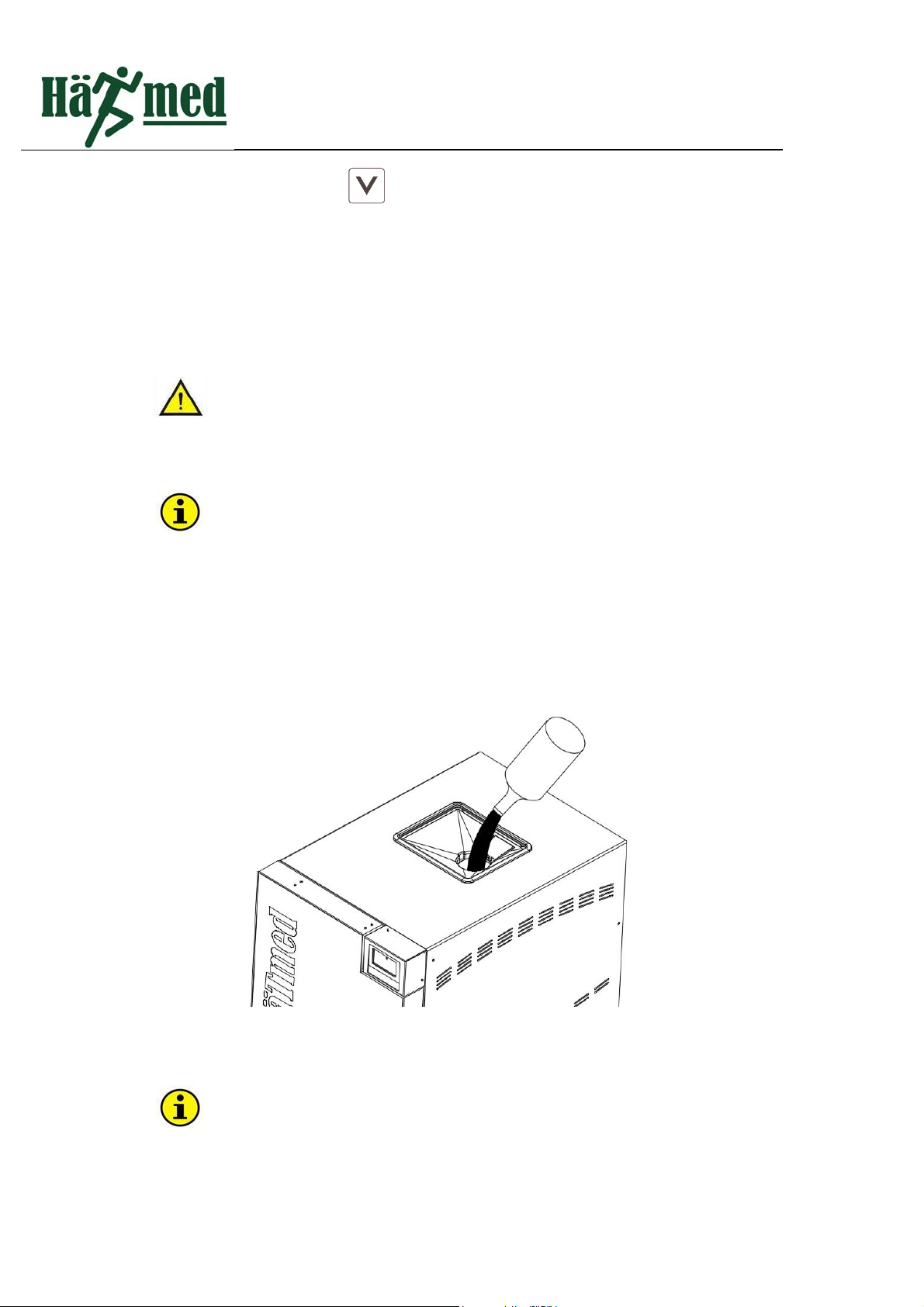

OpenupcoveroftheinternalwatertankandInjectthedistilledwaterintotheinternalwatertankthroughthe

watertank deflector,pleasebenotedthatthedistilledwateraddedshouldnotexceedtheheightof thewater

deflector,generallystoredinastandard12Ldistilledwatertank.Fulltankofdistilledwatercancompleteupto20

sterilizations.Please payattentiontotheamountofdistilledwaterremaininginthetanktoavoidaffectingthe

normaloperationofthisdevice.

Compliance with YY/T 0646‐2015 high quality distilled water as

specifiedinappendixBordemineralizedwaterbecausethedegree

offormationofruststainsdependsonwhetherthewaterqualityof

thedistilledwaterisuptostandard.

Conductivity≤20μs/cm;

Iftheinletpressureis>30Kpamaycauseexcessdistilledwaterto

enterthechamberandaffecttheoperationofthedevice.

Inordertopreventthedistilledwaterfrombeingcontaminated,the

lidofthedistilledwatertankmustbetightenedortightatalltimes.

Forsmallsteamsterilizerwithinternalwatertank,pleasedrainthe

wastewatertankbeforeinjectingdistilledwater.

Regularlycleanthedistilledwatertankatleastonceamonth.

- 10 -

This product has water quality monitoring device,it will not work

properlywhenunqualifiedwaterandwillgivewarningthatwater

quality cannot reach the standard.When you see this message,

pleasereplacehighqualitydistilledwaterintime.

If you need to use the water purifier, please consult the

manufacturerofthisdevicefirst.

Itisbesttotiltandsecureallthewaterpipesconnectedtotheback

ofthedevicearenotbentorknotted.

2.4.3 Wastewaterconnection

Forsmallsteamsterilizerswithoutinternalwatertank,takeoutthedrainpipefromtheaccessorybag

andinsertthewastewaterconnectiontothebackofthedevice(Figure1.4).

Itisbest totiltandsecureallthe water pipesconnectedto the

backofthedevicearenotbentorknotted.

2.5 Installationservicelist

After installation please carefully fill out the installation service

forminthemanualwhichisusefulinformationformaintenance.

2.6 Handlinginstructions

Thisdevicehastobestoredandtransportedathumiditylessthan85%andtemperature‐20oC~55oC.

Beforetransportation,pleasecarryout“drainageprogram”firstandtakeoffallpipes(includingdistilled

waterpipesandwastewaterpipes),ifprinterisconnected,removetheprintercable.

Ifthetrayrackandtrayareplacedinthechamberduringtransportation.Beforeclosingthedoor,placeafoam

pad between the door and the tray holder to prevent the tray frame from being damaged by shaking during

transportation

Forlong‐distancetransportation,theproductmustbereturnedtothepackageintheorderinwhichitwas

unpacked,andthepackagemustbesealed.

Pleasecarrydrainageprogrambeforehandlingthisdevice

- 11 -

3 Firsttimeoperation

3.1 Startup

Turnonthepowerswitch,thepowerswitchpositionisinthelowerrightcornerofthedeviceinsideview

(Figure1.4).

Makesuretoremovethelatexplugfromtheairfiltermounting

hole at the back of the device and install the air filter from the

accessoriesincluded.

3.2 AfterStartup

Afterstartupatthefirsttime,pleasesetuplanguageandcarryoutpressuretest.Afterthepressureverification

issuccessful,theinitialsettingiscompleted.Thedateandtimecanalsobesetasrequired.SeeChapter6system

settingsinthismanual.

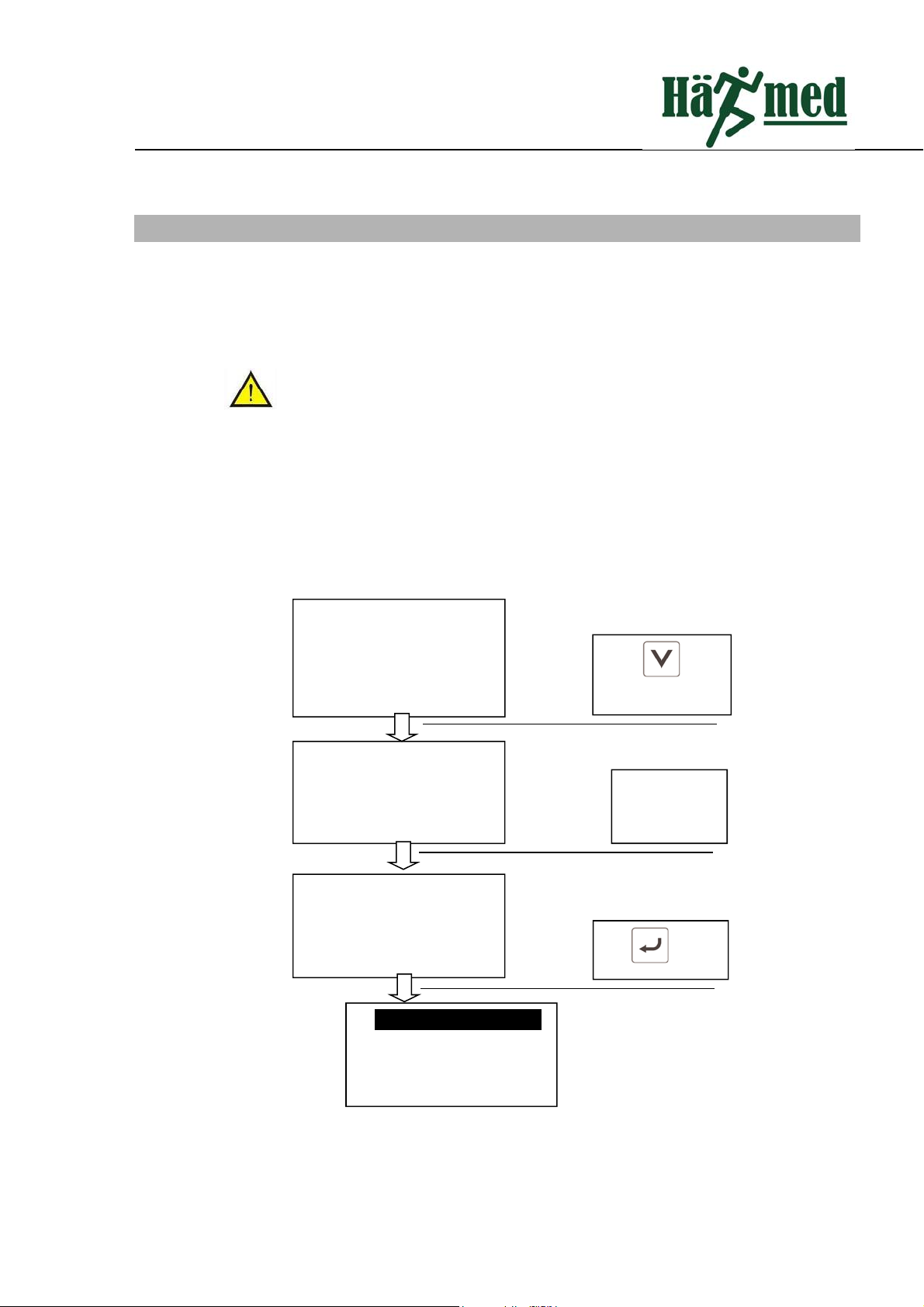

Stepsofpressureverificationisasfollows:

3.3 Open/closethedoor

Pressureverification

Verificationischecking…

P:0.00Bar

Pressureverification

Pressureverification

successful

Door open to complete

pressureverification

press button

andopenupthedoor

Wait for

calibration and

make sure the

doorisopen.

press toselect

1–Sterilizationprogram

2–Testprogram2‐

3–Sytemsetting

4–Filerecord

- 12 -

Dooropenupoperation:Pleasepress buttonatstandbymode,youwillseedoorlockiconwillchange

itsstatusonthedisplaytoindictedthedoorisopened.Atthistime,openthedoorhandleontherightsideofthe

deviceupwardsbyabout90oCandthenopenthedooroutward.

Closingoperation:Closethedoorofsterilizer,Thedoorhandleisturneddowntotheend。

Whenclosingthedoor,pleasepressthedoorhandledowntothe

end.Thestrengthrequiredafter using for a period of time may

increase

Don’tslamthedooratanytime.

Failure to comply with the above requirements may affect the

functionandreliabilityofthedoorlockdevice

Openthedooronlywhenloadingandunloading,Keepingthedoor

closedatothertimesisbeneficialtoenergysaving

3.4 Distilledwaterinjection

Injectqualifieddistilledwaterintothedistilledwatertankandmakesurethewaterlevelisbetweenthelowest

mark(MIN)andthehighestmark(MAX).Alwayscheckthewaterlevel inthewatertank andreplenishdistilled

waterintime.

Fig3.1Injectdistilledwater

Forthesterilizerwithinternalwatertank,pleasedischargewaste

watertankeverytimebeforeinjectingdistilledwater.

- 13 -

3.5 Drainage

Forsterilizerwithinternalwatertank.Afterusingitafewtimespleasetakeoutplasticdrainconnectorand

pipefromaccessorybagwhentodischargethewastewatertank.Pleaseinsertoneendofthedrainconnector

withoutablackrubbersealintothedrainpipeandinserttheotherintodrainageinterface(Figure1.4andFigure

1.5).

For sterilizer with internal water tank, please empty the waste

watertankbeforeinjectingthedistilledwater.

3.6 Sterilizationeffectverification

Smallsteamsterilizerinstalledorusedfor12monthsoraftermaintenanceshallcarryoutB&Dtestwithout

loadandcarryoutphysical,chemicalandbiologicalmonitoringwithfullload.Aftermonitoringisprovedsuccessful,

thesterilizercanbeusedagain.VerificationofsterilizationresultsshallcomplywiththerequirementsofAppendix

EofWS506‐2016

4 Sterilizationprogram

4.1 Loadstobesterilized

Properloadingisakeyfactorforeffectivesterilizationanddrying.You

mustalsopayattentiontothefollowingwhenloading

The load must be sterilized by the manufacturer if steam

sterilizationispermitted.

Packaging materials for packaged sterilization products shall

complywithGB/T19974standard.

Sterilizeditemspackedinpaperandplasticbags,Thepapermust

befacedupandlaidflatinthetray.

Formixedloadforsterilization,fabricisonthetopandthemetal

isonthelowerlayer.

Theremustbeagapbetweenthesterilizationbags.

Metalbagsanddressingbagscannotbeattachedtogether.

Theloadcapacitymustnotexceed90%ofthechambercapacity.

4.2 Selectsterilizationprogram

This product has 7 preset sterilization programs. Please select the appropriate sterilization program

accordingtotheloadtypeandpackagingmaterial.Theparametersettingofthesterilizationprogramandthetypical

loaddescriptionareasfollows.ThemaximumloadofQ50B/Q51Bis6kginstrumentsor2kgfabric.Themaximum

loadofQ70/Q71Bis7kginstrumentsor2.5kgfabric.

This manual suits for next models

3

Table of contents

Popular Laboratory Equipment manuals by other brands

BSi

BSi BT-71 Operation manual

Parker Laboratories

Parker Laboratories Thermasonic Gel Warmer operating instructions

GE

GE AKTApilot Site preparation guide

Oxford Instruments

Oxford Instruments ANDOR Sona 4.2B-6 Hardware guide

Curiox

Curiox Laminar Wash HT1000 user manual

Gamry Instruments

Gamry Instruments Reference 30k Booster Operator's manual