haupa AH-12 User manual

... convincing solutions

El ctro-hydraulic crimping tool

„AH-12“

Art. 216503

INSTRUCTION MANUALHydraulic crimping tools

Vid o 216503

1. T chnical data

Area of application: For the creation of an electrical connection by means of compression

Scope of delivery: 1 crimping tool, 1 charger, 1 battery, 1 carry strap, in a plastic case,

without dies.

Pressing force: 120 kN

Oil type: ISO class viscosity 15

Feed rate: 2 speeds: Closing (fast) feed to bring the pressing dies to the conductor

and working feed for compression. Switching between the two speeds is

carried out automatically.

Safety: The tool is fitted with a safety value that has been set at the factory.

Structure: The working head can be rotated by 180° to make it easier to adapt to

the operation to be carried out. The hydraulic crimping tool does not

protect the operator when working on cables that carry power.

Guarantee: 2 year guarantee if used for the purpose it is intended.

2. Ar a of work

2.1. Sensortechnology

• Pressing force in kN: 120 kN

• Working pressure in bar: 700

• Opening/ Hub: 20 mm

• Pressing width: width

• Motorstop

• H-h ad „D p Ind nt Pr ssing“: Cu/Al Tube Cable lugs and connectors

• Crimping range cable lugs: Cu 10-400 / DIN Cu 10-300 / DIN Al 16-240

• Crimping range connectors: Cu 10-400 / DIN Cu 10-300 / DIN Al 16-240

• Pressing time, battery-operated in seconds: 6-12

• Battery charging time in minutes: 120

• Battery type: Li-Ion, 18 V, 4 Ah

• Dual-piston pump

• Weight in kg: 7

• Weight of set in kg: 12

With the different colours of the sensor LED, it shows whether the pressing has

been completed successfully or which errors have occurred:

Light is green: Pressing completed as standard, motor stopped

Light is orange: Battery voltage not sufficient

Light is red: Pressing interrupted before completed

The device also has 2 white LED designed to illuminate the working area.

Germany: HAUPA GmbH & Co. G, önigstraße 165-169, D-42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected] • Errors and technical changes reserved.

nglish

... convincing solutions

3. Op rating instructions

CAUTION! TOOLS MAY NEVER BE USED WITHOUT FIRST INSERTING THE PRESSING DIES.

Ensure that the pressing dies fit precisely to the appropriate area and are seated perfectly in

the holders.

OTHERWISE THIS MAY CAUSE SERIOUS DAMAGES OR BREA AGES AND THE GUARANTEE

WILL BE VOIDED.

Pr paration:

Before starting up the tool, read the operating instructions first.

All current-carrying elements in the area you are working in should be disconnected.

Otherwise the protective procedures for working in the vicinity of

components under current must be implemented. (DIN EN 50110)

Do not use the tool if you are tired or under the influence of medication, drugs or alcohol.

Take into account the valid accident prevention and safety regulations and use the tool exclu-

sively for the purpose for which it is intended.

Only electro-technically trained persons over 16 years of age may process connecting materi-

als using the tool.

The operating instructions must always be carried with the tool.

The instructions must have been read and understood by the user.

The operator must ensure that this is the case.

Op rating:

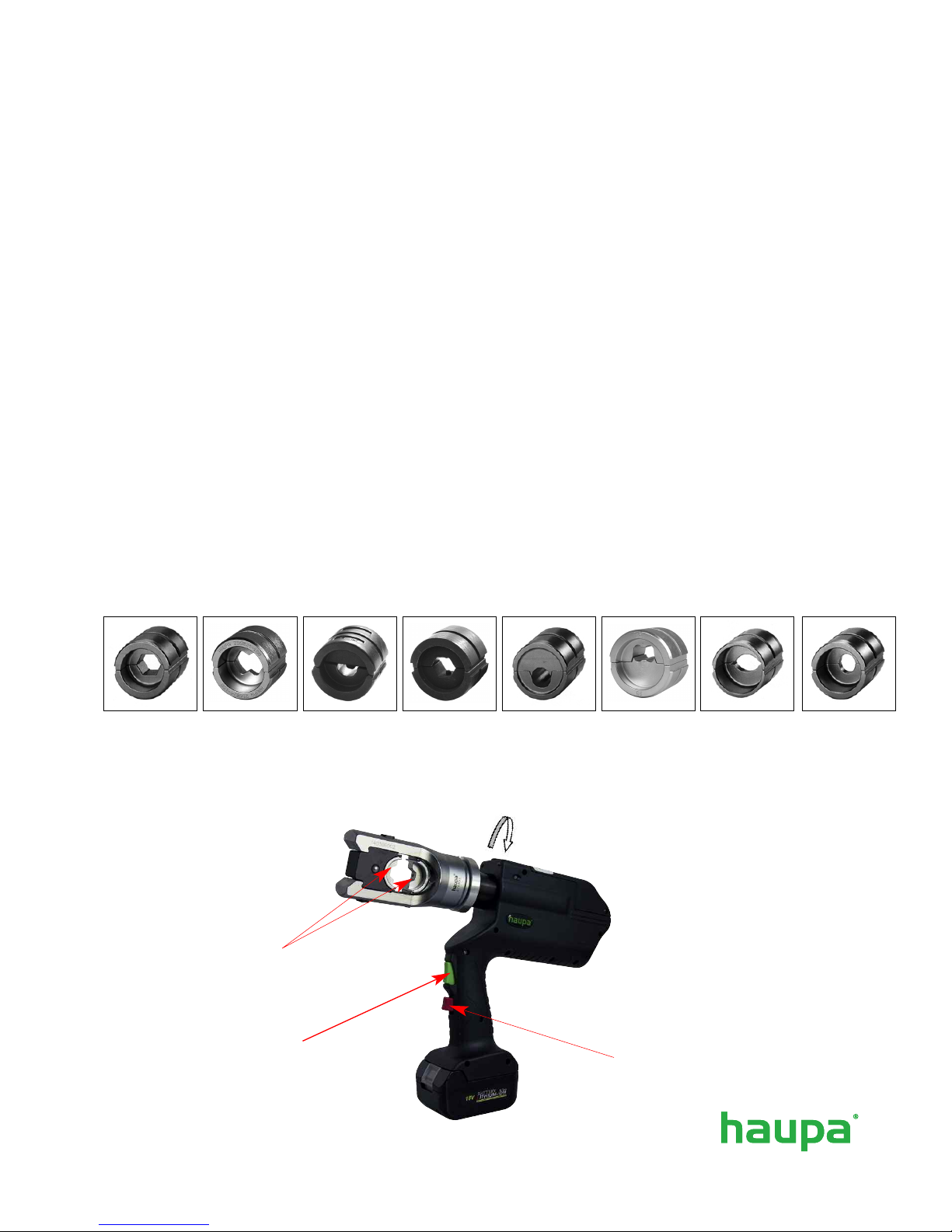

• Select the appropriate pressing dies for the connection to be pressed.

• Insert the pressing dies in the tool head. All of the pressing dies that can be used in

Pushbutton

to advance

Die holder

Pushbutton for

return movement

these models are half-circles, regardless of the type of crimping or pressing being carried

out. They are made up of two parts with identical external measurements, so that they both

can be inserted at will into the piston or the head.

• The procedure for inserting pressing dies is identical for mounting to both piston and head.

• The dies are inserted via the guides until they come to a stop at the blocking pin.

Op rating:

• When inserting into the piston, you must only ensure that this is pushed far enough forward

for the release button to be visible and accessible.

• To remove the dies, in both instances, the relevant release button must be activated.

Then allow the dies to slide out. Please note that in order to remove the inserts at the

piston, the steps listed above must be carried out in reverse order.

Start:

- Bring the tool to the working position.

- Select the appropriate pressing dies for the connection to be pressed.

- Insert the pressing dies in the tool head.

- Feed the conductor into the connector.

- Place the connector between the two pressing dies.

- Approach of the pressing dies (closing feed rate)

- Hold the tool securely and press the operating button to move the piston quickly

forwards until the pressing dies meet the connector to be compressed.

- As soon as the pressing dies start to compress the connectors, the system

automatically switches from closing feed to working feed.

- Press until the pressure limiter can be heard or the pressing dies meet.

- Pressing the front operating button takes the pressure off the system and piston travels

back (fully or partially, to directly carry out a second compression action).

Germany: HAUPA GmbH & Co. G, önigstraße 165-169, D-42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected] • Errors and technical changes reserved.

nglish

... convincing solutions

4. Removing and inserting the battery

Hold the tool firmly a d press the battery release butto to remove the battery.

ATTENTION:

Never short-circuit the battery.

Inserting the battery

I sert the battery u til it clicks i to place. Make sure the poles are faci g the right way

Charging

Before usi g the tool, charge the battery as follows: Co ect the cable of the charger to a

socket (AC).

Inserting the battery into the charger

I sert the battery firmly, as show i here until it touches the bottom of the charging

compartment.

ATTENTION:

If the battery is inserted incorrectly, it will not only not be charged, it may also damage the

charger (e.g. by bending the terminals/short-circuiting).

Charging

Whe you i sert a battery i to the charger, the battery is charged

a d the chargi g light.

Whe the battery is fully charged, the chargi g i dicator shows 100% a d a beep.

Remove the battery immediately a d disco ect the charger from the mai s.

Attention!

Please remove the battery during trans ort and after

usage – because of avoiding dee discharge!

Permitted only on stabilized ower sources!

Charging only for HAUPA batteries!

Li-ion Battery & Charger Instruction

Li-ion Batterie

Voltage 18 V

Weight 0,380 kg

Length 120 mm

Width 70 mm

Height 80 mm

Capacity(Ah) 3Ah

Charge time 0 min.

Charge(for Li-ion)

Voltage 110V / 220V

Weight 0,430 kg

Length 175 mm

Witdh 90 mm

Height 80 mm

Feature Digitaler Monitor

Auto-Inductions laden

4 Ah

120 min.

Germany: HAUPA GmbH & Co. G, önigstraße 165-169, D-42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected] • Errors and technical changes reserved.

nglish

... convincing solutions

Li-Ion Battery Manual Instruction

Panel Description:

1㸬Connect power shows , comes a beeping, and the fan rotates 2 seconds.

2㸬Fully charged, it shows and comes beeping every 3 seconds.

3㸬Unusual working == Too low voltage shows and comes a beeping every second.

4㸬Unusual working == Unusual temperature shows ᧨and comes a beeping every second.

5㸬The voltage is not rising after 10 minus charged. The battery is charged incompletely. The battery is faulty,

showing and coming beeping every 2 seconds by a second.

Specification:

1. The input power is external power DC24V 3Aᇭ

2. The charge voltage is 24V 2.5Aᇭ

3. When plug in the power, the panel shows and comes a beeping.

4. Uninstall the battery, the panel shows and twinkles every second.

5. Detect the battery voltage first and shows battery capacity rate when install battery.

6. When battery charged completed, the panel shows and comes beeping every 3 seconds.

7. When the voltage is too low, the panel shows and coms a beeping every second.

8. When the temperature is too high, the panel shows and comes a beeping every second.

9. The maximum charge time is 70 minutes. After 70 minutes, the charger will stop charging regardless the battery

is charged completed.

10. The full charged voltage for 18V Li-Ion battery is (5*4.3=21.5v); the voltage for 14.4V Li-Ion

is (4*4.3=v17.2v) (reference valve). The battery is coming with a protective plate which will stop charging automatically

when charged completely.

11. The lowest battery voltage for 18V Li-Ion battery is (2.9*5=14.5v); and the 14.4v is (2.9*4=11.6v).

12. It will stop charge when the battery temperature is higher than 65 degree centigrade.

13. The usual temperature for battery is between -20° to 65° centigrade when a fan is applied. The fan working voltage is 12V.

14. Under 90% battery capacity will carry in adding per 5%. Over 90% battery capacity will carry in adding per 1%.

5. Car and maint nanc

Cl aning

• Careful cleaning of the tool, in particular, the moving parts contributes towards a longer

useful life. Remember that dust, sand, environmental influences, in particular a high salt

index, and dirt in general are extremely damaging to hydraulic tools.

• Particular care should be taken when cleaning the pump drive piston and the piston.

The tiniest of contaminations may scratch the walls of the cylinder and damage the

leak-proof seals. For correct cleaning of the piston, we recommend extending the piston

and then cleaning it with a high-quality, non-corrosive solution.

Pow r switch

Check to see whether the switch on the machine automatically pops out again when you release

it.

Filling l v l of th oil tank

Ensure that the oil level is always sufficient. Do not fill the tank with unsuitable oil or brake fluid.

Oil type: VESTA HLP-15 from VER OL or an oil of a similar quality. Remove the tank lid and top up

the oil. The oil must be filtered first. If necessary, purchase the required oil from the HAUPA service

centre (Art. 216254).

Storag

To prevent damage to the tool as a result of bumps, dust etc. you should if possible store the

tools in the original packaging.

Oil l v l

The oil level in the tank should be checked at regular intervals, in particular, when it has been

used for a long time and topped up whenever necessary.

Oil filling

This process should only be carried out by an authorised technician.

Important: The hydraulic oil must be filtered, have an ISO viscosity class of 15 and a viscosity

index of 100 and correspond to the standards AFNOR NFE 48603-HM and

ISO 6743/4 L-HM.

WARNING NOTES!

A natural working position is required in order to operate the tool correctly, thus the handle must

point downwards.

Germany: HAUPA GmbH & Co. G, önigstraße 165-169, D-42853 Remscheid.

Phone: +49 (0)2191 8418-0, Fax: +49 (0)2191 8418-840, [email protected] • Errors and technical changes reserved.

nglish

... convincing solutions

6. Diagnosing faults

Before you carry out any work on the tool, ensure that it is no longer connected to the power

supply.

CAUTION! If you have a problem that is not listed in the table below, contact your local tech-

nical customer support service for assistance.

6.1. WARNING NOTES!

Caution:

Do not attempt to force the head to turn when the hydraulic circuit is pressurised.

Guarant :

2 year guarantee when used for the purpose it is intended when the annual maintenance

intervals are maintained by an authorised HAUPA service centre. We reserve the right to

rework the product.

Disposal:

Individual components must be disposed off separately.

The oil must be drained and disposed of at the designated points.

Caution:

Hydraulic oils represent a risk to the groundwater. Uncontrolled drainage or incorrect disposal

carries penalties. (Environmental Liability Law)

The remaining components of the aggregate must be disposed in accordance with the rele-

vant environmental standards.

The disposal should be carried out by authorised specialist companies. The free return to the

manufacturer cannot be guaranteed.

Always use original replacement parts. Other parts may seriously damage the tool

and will void the guarantee.

If the tool still does not work correctly, send it to the nearest repair service

for specialist maintenance and fine tuning, or

send and email to: [email protected]

WITH EVERY REPLACEMENT PART ORDER, INCLUDE THE FOLLOWING INFORMATION:

1) Article number.

2) Article description.

3) Reference to the operating instructions and/or date.

4) Tool type.

5) Serial number of the tool.

The guarantee is voided if you use parts that are not original replacement parts from HAUPA.

HAUPA GmbH & Co.KG, Königstr. 165-169, 42853 Remscheid, Germany

EC declaration of conformity

HAUPA factory certificate

Remscheid, 23.03.2016

Product: Battery hydraulic cutting tools

Product range: Around the cable

Art. no.: 216418; 216419; 216422; 216424; 216428; 216430

Note: These tools are used for cutting unarmoured CU / AL cables.

Art. no. 216418, 216424, 216430 can additionally also

separate armored cables.

The tools are not isolated and it is forbidden to work under

tension.

HAUPA GmbH & Co.KG

Königstr. 169, 42853 Remscheid

Germany

Tel. +49 2191 8418 – 0, Fax +49 2191 8418 – 840

Herewith we declare that the above mentioned tools are manufactured according the

following guidelines:

CE guidelines 98/37/EEC, 89/336/EEC

Jens-Ole Paas Jochen Husli

Qualitätsmanagement Produktmanagement

EC

atardeclEC

a

f

HAUPA

confofoniat

r

e

c

y

r

o

t

c

a

ytimorconf

e

t

a

c

i

f

i

t

G,K.oC&HbGmAPUHA

561.rtsginöK- Re42853169,

ynamreG,diehcsmRe

This manual suits for next models

1

Table of contents

Other haupa Power Tools manuals

Popular Power Tools manuals by other brands

Workzone

Workzone BT-CK 18 Li user guide

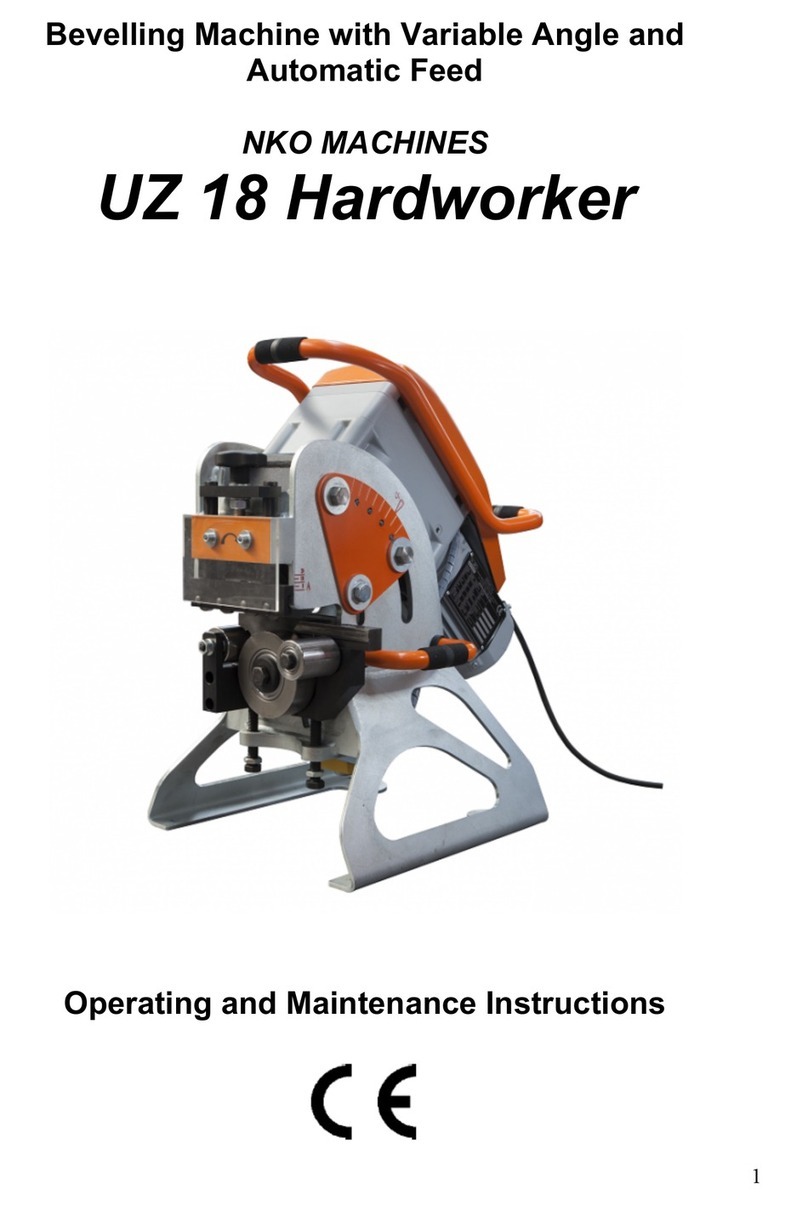

N.KO

N.KO UZ 18 Hardworker Operating and maintenance instructions

Milwaukee

Milwaukee 0566-1 Operator's manual

ABB

ABB Thomas&Betts BAT22-6NV2 operating instructions

Parkside

Parkside PDRD 13 A1 Operation and safety notes

Draper

Draper STORMFORCE CMG108SF/BMC user manual