N.KO UZ 18 Hardworker Manual

1

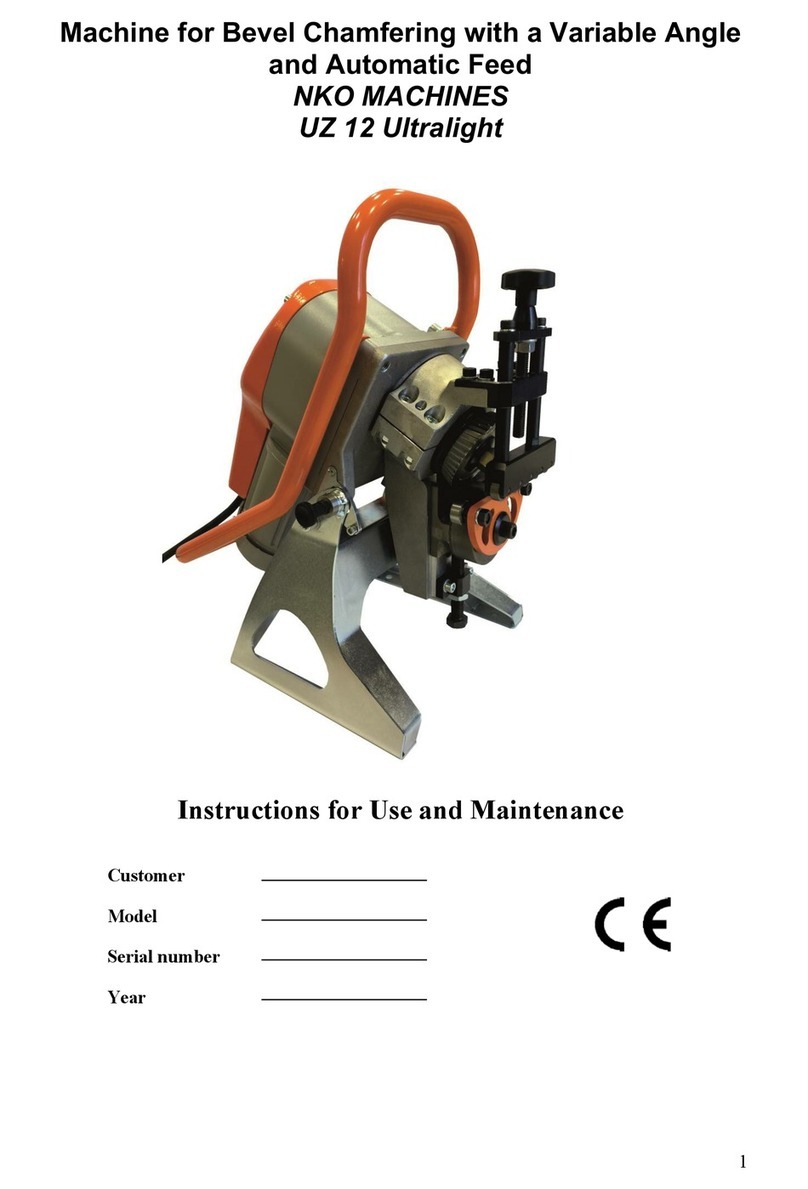

Bevelling Machine with Variable Angle and

Automatic Feed

NKO MACHINES

UZ 18 Hardworker

Operating and Maintenance Instructions

2

Contents

1 General information

Introduction 3

Testing 3

Guarantee 3

Identification data 4

Reference standards 5

2 Safety

Safety recommendations 6

Safety labels 7

Qualification and protection of operators 7

Safety devices 8

Residual risks 9

3 Technical specifications

Machine description 9

Technical data 10

Noise level 10

Working conditions 11

4 Installation

Transport and lifting 11

Setting and connection 12

Checking before use 13

Dismantling and disposal 14

5 Usage

Correct usage 14

Description of control devices 15

Preliminary settings 15

Bevelling 21

6 Maintenance and adjustment

Recommendations 24

Lubrication 24

Exchange of tools 25

7 Technical diagrams

Wiring diagram 28

8 Spare parts

How to order spare parts 29

Wear parts 29

Schematic drawings of spare parts and spare parts list 30 - 36

3

General information

1.1 Introduction

Thank you for purchasing one of our machines. We hope you will be fully satisfied with it.

This manual contains all the instructions for installation, adjustment, operation and

maintenance of the UZ18 Hardworker machine in conformity with valid safety standards.

The information and data in this manual are subject to change as a result of further

development of the machines. If in any doubt, please contact N.KO if you find any

deviations.

Never carry out any operations on the machine until you have read and understood the

instructions in this manual. Most accidents occurring in the workplace result from not

observing instructions and recommendations in manuals.

Graphic symbols are used in the manual to highlight important information regarding machine

safety and operation.

Attention:

Important information for the operating personnel’s safety

Important:

Instruction which must be observed to ensure correct operation of the machine

1.2 Testing

The bevelling machine is tested in our technical test room.

During the test, correct functioning of the electric system, and correct functioning of the

bevelling plates and profiles of different types and sizes are checked.

1.3 Guarantee

The Seller provides a guarantee for fault free material and workmanship of the

UZ 18 Hardworker bevelling system for a period of 5 years from the delivery date of the

goods.

A guarantee for correct functioning of the goods and materials used is provided for a period of

5 years from the delivery date of the goods.

The Seller undertakes to remove all possible defects covered by the guarantee, free of charge

and without undue delay, so that the Purchaser can use the goods appropriately. Should the

Purchaser make a claim based on a liability for defects not covered by the guarantee, s/he

shall cover the expenses incurred by the Seller.

4

The guarantee period is suspended on the day when the Purchaser notifies the Seller of a

defect covered by this guarantee, due to which the Purchaser is unable to use the goods and

makes a claim based on the liability for defects covered by the guarantee granted, until the

date when the defect is removed by the Seller.

The guarantee does not cover natural and normal wear of the goods and defects caused by

incorrect use of the goods contrary to the training and documentation provided. Further, the

guarantee does not cover defects due to overloading of the goods or those resulting from

incompetent interference in the goods or incompetent repair or modification. Incompetent

interference, repair or modification means any interference, repair or modification executed

contrary to the training or documentation provided, or executed by any person other than the

Seller or a person authorized or approved by the Seller.

Claims based on liability for defects under the guarantee granted must be made at the Seller

without undue delay after the Purchaser has found the defect; at the latest, by the end of the

guarantee period, however, otherwise these claims expire.

To make a claim based on liability for defects under the guarantee granted, the guarantee

certificate must be submitted; otherwise, the Purchaser’s claims cannot be allowed.

The Seller’s liability for defects covered by the guarantee does not arise if the defects have

been caused by passage of the risk of damage to the goods by external events. Particularly,

external events include natural disasters, force majeure, or third persons’ acts.

N.KO. considers the guarantee invalid in the event of:

- improper use of the machine;

- use contrary to national or international standards;

- incorrect installation;

- defective electrical power supply;

- serious maintenance shortcomings;

- incompetent modifications and/or interferences;

- usage of unoriginal or incorrect spare parts and equipment for the given model;

- full or partial infringement of instructions;

- exceptional events, natural or other disasters.

1.4 Identification data

The identification data of the bevelling machine are indicated on the aluminium CE label

attached to the top of the bearing housing.

5

1.5 Reference standards (CE Declaration of Conformity)

6

SAFETY

2.1 Safety recommendations

Attention:

Read the following instructions carefully to prevent personal injuries and/or property

damage.

- Never try to operate the machine unless you have carefully acquainted yourself with its

functions. If after having read this manual carefully and fully you are still in doubt, contact

the N.KO company.

- Make sure that all technical workers entrusted with operation and maintenance of the

machine are fully acquainted with all the relevant safety recommendations.

- Transport and installation of the machine can only be done by specialized workers in

conformity with the instructions in this manual.

- Before starting the machine, the operator must check that all safety devices are functional

and all safety guards are in place.

- Never use the machine for any purposes not indicated in this manual. Never process

products other than what is indicated here.

- If you want to use the machine for purposes other than those defined, ask the N.KO

company for approval.

- The machine supply voltage values are dangerous; check whether all connections are

executed correctly. Never perform any maintenance of the machine or replacement of its parts

if the machine is connected to the electrical power supply. Never install any branches on the

electrical connections.

- Replace defective parts with those recommended by the manufacturer. Never use non-

original spare parts.

- Never wear clothing or jewellery which may get caught in the moving parts. It is

recommended to use protective clothing, non-slip shoes, and protective goggles.

Important:

If during the machine lifetime any defects occur which cannot be removed with the help

of this manual, it is advisable to ask the N.KO company to resolve the problem as soon

as possible.

7

2.2 Safety labels

Safety labels are placed on the bevelling machine to protect the operators.

Meaning of the labels:

This label is placed on the electrical panel of the bevelling machine, and indicates the

presence of high voltage.

Do not remove the label from the machine.

2.3 Qualification and protection of operators

The employer is obliged to inform the operators about safety standards; moreover, he must

ensure their observance and make sure that the working area is large enough and well lit.

The term “operator” means any person who carries out installation, operation, adjustment,

maintenance, cleaning or repairs of the machine.

Attention:

Before starting work with the machine, make sure that the operator understood the

content of the operator manual.

Attention:

The operator must always:

1. Check that all safety guards are in place and safety devices are functioning before

starting the machine.

2. Avoid wearing clothes or jewellery which may get caught in moving parts.

3. Wear approved protective clothing, such as non-slip shoes, ear protectors and

protective goggles.

4. Apply safety standards; see that they are observed at all times; and, if in doubt, consult

this manual again before taking any measures.

5. Contact the machine supplier if unable to remove defects causing its malfunction, if

there are defective parts or the running is abnormal.

8

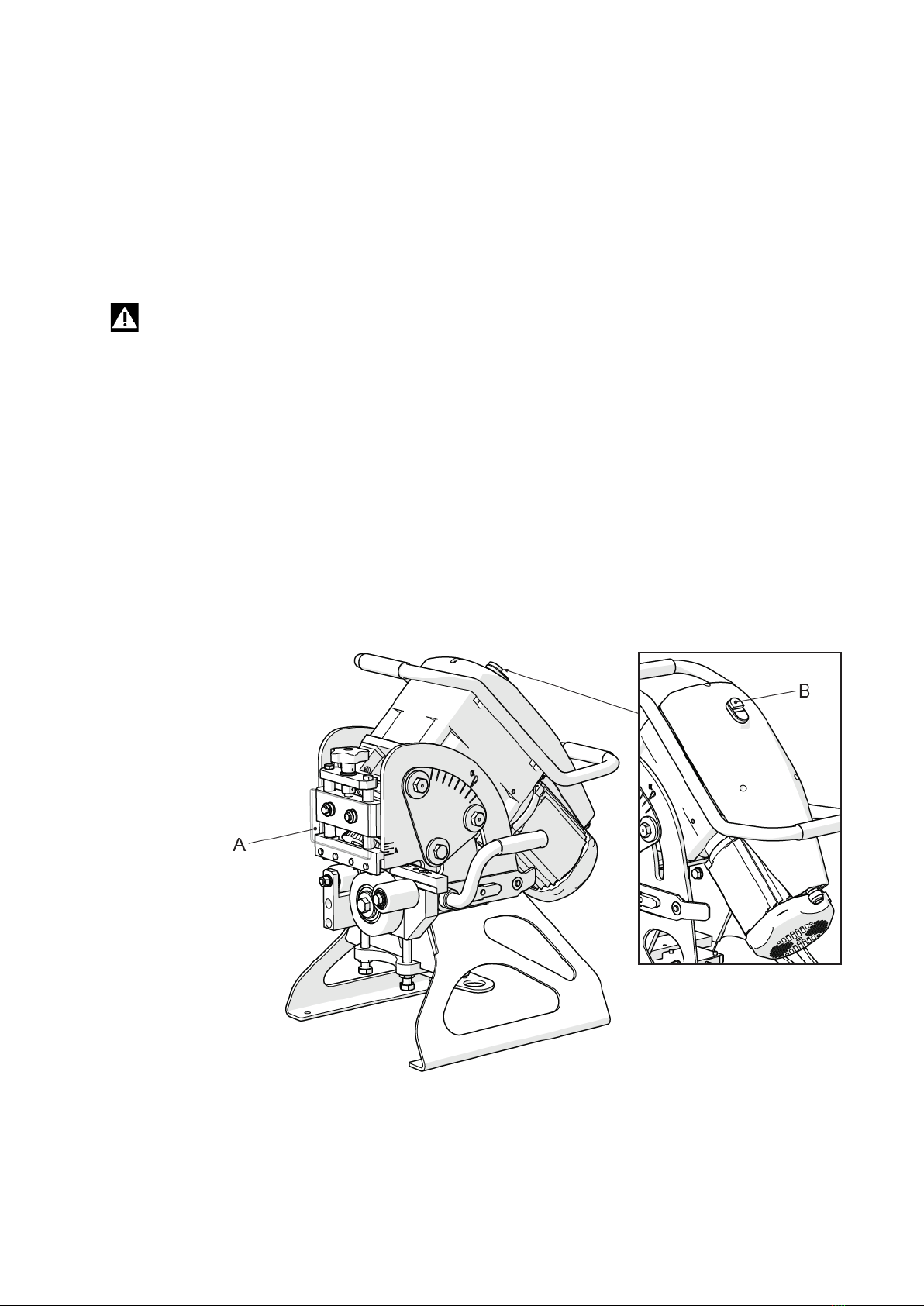

2.4 Safety devices

The machine is equipped with safety guards to isolate the zones potentially dangerous to the

operators. The guards are attached to the frame or screwed to with the machine housing. They

can be dismounted with suitable tools. This operation may be necessary during certain

maintenance activities. An acrylic glass guard is mounted in front of the cutting tool

(position A. Fig. 2.4.1) to protect the operator during bevelling.

Attention:

The guard can only be removed if the machine is at standstill, with the power supply

plug disconnected. Never use the machine without the safety guards in place.

The machine is equipped with a mushroom emergency button. This red button overrides all

other operations and stops the machine immediately (position B, Fig. 2.4.1).

Use the emergency button:

- in case of immediate danger or mechanical accident;

- for short interventions, if the machine is switched off, to perform maintenance in this state;

- the button is also equipped with a lock to prevent start of the machine by an unauthorized

person.

Fig. 2.4.1

9

2.5 Residual risks

The machine has been designed and manufactured with all devices and equipment for health

protection and the safety of operators.

The machine is fully covered to minimize the risk of contact with movable parts.

There is, however, one risk remaining:

As mentioned above, the working zone is protected as much as possible; however, it has to

remain open partly to enable feeding of the material to be bevelled.

Therefore, there is a risk of the operator putting his/her fingers into the zone in which both the

cutting tool and the work piece holder are.

Attention:

Always keep your hands as far from the cutting zone as possible.

Attention:

Always apply the safety regulations contained in this manual and ensure their

observation and the elimination of all residual risks.

TECHNICAL SPECIFICATIONS

3.1 Machine description

The bevelling machine model UZ 18 Hardworker has compact dimensions. One of its main

features is the adjustable bevel angle and automatic material feed.

The machine is equipped with a hardened cutting tool, sturdy work piece holder, direct-

reading scale used for setting values (bevel size and angle), and a special guide facilitating the

loading of material.

These characteristics enable easy setting of the working angle without exchange of the lower

cylinder, and precise regulation of the bevel angle.

The UZ 18 Hardworker bevelling machine is reliable and requires minimum maintenance.

10

3.2 Technical data

Voltage 400/480/220 V*

Frequency 50/60 Hz*

Motor power 750W,

Sheet thickness 6 ÷ 40 mm / 0.23 ÷ 1.57 in

Max. bevel width 18 mm/0.71 in (600 MPa/87 022 PSI)

Bevel angle range 15° ÷ 50°

Feed 1,9 m/min./6.23 ft/min

Dimensions 450 x 800 x 400 mm

Weight 110 kg / 242.5 lb

(*) Exact voltage and frequency values are indicated on the motor identification label.

3.3 Noise level

The machine has been designed and manufactured so that it emits the minimum noise

possible.

Measurements done at the operator’s workplace, when the machine is running in the

automatic cycle mode, ascertained these values:

- during cutting: LpA m. = 74.9 dB

LwA = 84.1 dB

11

- during unloaded operation: LpA m. = 64.5 dB

LwA = 76.4 dB

3.4 Working conditions

The work environment of the machine must satisfy these values:

Temperature: 0 °C - 50 °C

Humidity: 10 % - 90 % (without condensation)

The machine must be placed in a covered room protected from rain.

Working conditions different from the above-mentioned ones might result in serious damage

to the machine, particularly its electrical equipment.

If the machine is not used, you can store it in a place with temperatures ranging between:

-10o C and 70o C.

All the other values remain unaltered.

INSTALLATION

4.1 Transport and lifting

Important:

Activities described in this section must be performed by qualified personnel only.

Suitable unloading and setting means (cranes, forklift trucks, etc.) must be provided at the

destination.

When delivered to the destination, check (in the presence of the forwarding firm) whether the

machine conforms to the order specifications and has not been damaged during transport.

Should you find any damage or parts missing, immediately send a detailed message to N.KO

and the forwarding firm.

Attention:

Observe the following rules to ensure safe handling of the machine:

- Keep your distance from suspended loads and check that the lifting equipment and

pertinent tools are in perfect condition, and suitable for the loads stated in paragraph

3.2.

- During handling of the machine, wear protective clothing, such as work gloves, non-

slip shoes and helmet.

- If the machine is in the transport packaging, remove it and dispose in conformity with

valid regulations of the pertinent country.

12

- Lift the bevelling machine. To do that, use the band attached to the upper handle. See

Fig. 4.1.1.

Fig. 4.1.1

4.2 Setting and connection

Important:

Activities described in this section must be performed by qualified personnel only.

If you use the machine for processing small pieces, you must fix it to a level surface by means

of the holes at the bottom of the stand (Fig. 4.2.1, position A).

13

Fig. 4.2.1.

If you use the machine for processing large pieces, you must place it on the work piece, on

which it will move itself. When approaching the material and leaving the work piece at the

end, it is advisable to suspend the machine on the belt, as illustrated in Fig. 4.1.1.

During electrical installation, proceed as follows:

- Check the frequency and voltage values on the motor identification label;

- Fit the end of the cable to the power supply with the plug according to your local power

supply network.

4.3 Checking before use

Important:

Never start the UZ 18 Hardworker without carrying out the checks described in this

section.

Before starting the machine, check whether it is in working order by means of the following

checks and inspections in order to ensure the highest possible efficiency and to meet safety

regulations:

- Check whether there are no loose screws or other parts.

- Make sure that all electrical connections are correct and the electrical cable is fixed in place

with a cable gland.

- To start the machine, proceed as follows:

Green button (position B, Fig. 2.4.1). Press the button to turn on the engine. BE CAREFUL

of the direction of rotation of the tool. Working direction is only clockwise.

To shut down the machine, proceed as follows:

Red button (position B, Fig. 2.4.1). Press this button to disconnect the power supply. When

you press this button, the machine immediately stops prior to other commands.

14

4.4 Dismantling and disposal

When dismantling the UZ18 Hardworker machine, keep in mind it is made of safe materials.

They involve in particular:

- enamelled and plated ferritic steel;

- stainless steel, series 300/400;

- plastic materials of various characteristics;

- hydraulic oil;

- electric motor;

- electrical cables with corresponding sheaths;

- electrical monitoring and exciting equipment.

Follow this procedure:

- Observe the regulation concerning work environment safety valid in your country.

- Disconnect the machine from the power supply.

- Dismount the machine; classify the parts according to their chemical characteristics.

- Scrap the machine parts in conformity with the regulations valid in your country.

- During dismantling, strictly follow valid work safety regulations.

USAGE

5.1 Correct usage

The bevelling machine model UZ 18 Hardworker has been designed, manufactured and sold

for the purpose of bevelling the following kinds of metal parts and rolled metals: iron, steel

up to R=60kg/mm2, stainless steel, brass, copper and aluminium.

The maximum bevel dimensions and processed material thickness are indicated in detail in

chapter 3, paragraph 3.2, “Technical specifications”.

Usage other than that described above is forbidden. Strictly speaking, it is forbidden to:

- process products different to those for which the machine has been designed and sold;

- modify operation of the machine;

- replace parts with non-original ones;

- modify electrical connections and bypass internal safety devices in this way;

- remove or modify protective guards;

- operate the machine in places with aggressive environment.

Attention:

It is strictly forbidden to bevel materials other than those indicated, since their

processing may pose a risk to the operators and damage the machine.

Before making any modifications, you must ask the N.KO company for the corresponding

approval. If you fail to do so, the N.KO company will reject any responsibility.

15

5.2 Description of control elements

The bevelling machine is operated by means of control devices located on the distributing

box.

- Green button Press the button to turn on the engine. BE CAREFUL of the direction

of rotation of the tool. Working direction is only clockwise.

- Red button. Press this button to disconnect the power supply. When you press this

button, the machine immediately stops prior to other commands.

5.3 Preliminary settings

Attention:

During setting, use working gloves. The operations must be done on a stopped machine,

disconnected from the power supply.

Before starting work, you must execute some settings according to the material thickness and

bevel angle.

Setting the bevel angle

The bevel angle can be set from 15° to 50°.Perform the setting as follows:

- Loose sufficiently the 3 and 3 screws (position A, Fig. 5.3.1) located on both sides of

the machine.

- Grip the upper handle and lower handle and pull it to set the entire cutting unit to the

required angle.

- You can view the set angle value on the graduated scale located on the side of the

machine (position B, Fig. 5.3.1).

- To complete the operation, properly again tighten the 3 and 3 side screws (position A,

Fig. 5.3.1).

Important:

If you have problems setting the angle, the screws may not be loose enough (position A,

Fig. 5.3.1).

Important:

The machine offers a range of operating angles from 15-50 deg. In practice, it is very

difficult to achieve these limits. The condition for the attainment of these limit angles is

the perfectly prepared the edges of the material. However, the edges before bevelling

usually does not have 90 deg and there is no place to keep the machine on the material.

16

Fig. 5.3.1

Adjusting the lower cylinders (bottom support):

By adjusting the lower cylinders (bottom suport), you can set the size of the bevel.

Proceed as follows:

- Loosen the central cylinder screw sufficiently (position A, Fig. 5.3.2).

- Raise or lower the bottom support by means of the lower right adjustable screw

(position B, Fig. 5.3.2). If the left-hand support screw hampers lowering the bottom

support, loosen it.

17

- Meanwhile, check the graduated scale (position D, Fig. 5.3.2), making sure the desired

value has been reached.

(The scale indicator C is formed by the horizontal joint of the two parts of the assembly,

the bottom support.)

- After setting of value of size of bevel, you have to adjust also the left screw as follow.

Turn the left screw, until it touches body of bottom support and the rotate about one half

to whole rev so that left side of the lower support should be at same height as the right

side.

During this operation the right adjustable screw has to be constantly in contact with the

body of bottom support. It means that the right side of support must not be lifted up.

- After adjusting the bottom support, firmly tighten the central cylinder screw

(position A, Fig. 5.3.2). Secure both the left and right-hand support screw with the

locknuts included (position C, Fig. 5.3.2)

- Finally, check whether the main central cylinder is loose and can rotate freely.

Otherwise, it is necessary to clean the space behind the cylinder or to replace bearings

of the cylinder.

Important:

The scale value C (position D, Fig. 5.3.2) corresponds to the difference between

the bevel height (dimension A in Fig. 5.3.1.0) and the total material thickness.

So you set the so-called root face (feather, butt) on the scale (dimension C,

Fig. 5.3.1.0).

In other words, to adjust a bevel size of 8x8x45º on 10-mm-thick material, you must

set a scale value of 2 mm.

It is necessary to realize that when setting the facet height, you cannot set a value

at which the hypotenuse length of the bevel created (dimension P, Fig. 5.3.1.0)

exceeds 18 mm (maximum performance of the machine). You can check that in

the table (Fig.5.3.1.1).

18

Fig.5.3.1.0 Fig.5.3.1.1

Important:

Table of maximum material removal.

On the scale C (position D, Fig. 5.3.2.), it is FORBIDDEN to set a value lower than that

indicated in the right-hand column of the table. Otherwise, the machine may become

overloaded.

Note: The data is valid only for strength of steel to 45 kg/mm².

It is forbidden to set value C lower than indicated in the table – the machine may

become overloaded.

All of bevels where is the width of bevel (hypotenuse - position P Fig.5.3.1.0) bigger than

10mm, is necessary to bevel in two steps. For first step, set value C = C+1/2 A

It may be necessary to proceed the bevel in more than two steps for bevelling maximum

bevel.

19

Example No. 1:

Can you create a bevel of 15x15x45° on 20mm thick material?

For correct setting, you must set the difference between the desired bevel height and the

material thickness on the graduated scale C (position D, Fig. 5.3.2); that is, 20-15=5; so the

scale C should read 5 mm. The table indicates that the graduated scale minimum value can be

7,5 mm. This means the bevel cannot be made because 5 mm is less than 7,5 mm; at this

setting, the total bevel hypotenuse (dimension P, Fig. 5.3.1.0) exceeds the permissible 18 mm.

So the machine may be damaged.

Example No. 2:

Can you create a bevel of 10x10x45° on 15mm thick material?

For correct setting, you must set the difference between the desired bevel height and the

material thickness on the graduated scale C (position D, Fig. 5.3.2); that is, 15-10=5; so the

scale should read 5 mm.

The table indicates that the graded scale C minimum value can be 2.5 mm. That means the

bevel can be made because 5 mm is more than 2.5 mm; at this setting, the total bevel

hypotenuse (dimension P, Fig. 5.3.1.0) does not exceed the permissible 18 mm.

Example No. 3:

Can you create a bevel of 8x8x45° on 10-mm-thick material?

For correct setting, you must set the difference between the desired bevel height and the

material thickness on the graduated scale C (position D, Fig. 5.3.2); that is, 10-8=2 so the

scale should read 2 mm.

The table indicates that there are no setting limits for materials up to a thickness of 12 mm.

That means that the bevel can be made because even if you set 0 mm on the scale and create a

so-called sharp bevel on the plate, the total hypotenuse of the bevel (dimension P, Fig.

5.3.1.0) will not exceed the permissible 18 mm.

20

Adjusting work piece holder cylinders

To ensure correct functioning of the machine, the work piece holder cylinders must slightly

push on the work piece. Carry out their adjustment as follows:

- Turn the hand wheel in the upper part of the work piece holder (position F, Fig. 5.3.2)

to adjust the holder cylinder height. Adjust the setting of the machine, so cylinders can

press on the work piece lightly, check if their position is correct – adjust the bevel

height (dimension A, Fig. 5.3.1.0) on the relevant scale A (position E, Fig. 5.3.2.)

Indicator is the top of the cylinder bar.

- To ensure correct operation of the machine, it is important to check whether the

settings are correct. None of the illustrated situations (Fig.5.3.3.) can occur: the

position of the work piece machined in relation to the lower and holder cylinders must

be as illustrated in situations 1 and 4 in (Fig. 5.3.3.)

Fig. 5.3.2

Table of contents

Other N.KO Power Tools manuals

Popular Power Tools manuals by other brands

Huskie Tools

Huskie Tools REC-BCN658 Operation manual

Meister

Meister PS600M Translation of the original instructions

Tohnichi

Tohnichi WQL Series operating manual

Wacker Neuson

Wacker Neuson DPU 6055 Operator's manual

Chicago Electric

Chicago Electric 57226 Owner's manual & safety instructions

Avdel

Avdel Avbolt 07220 instruction manual