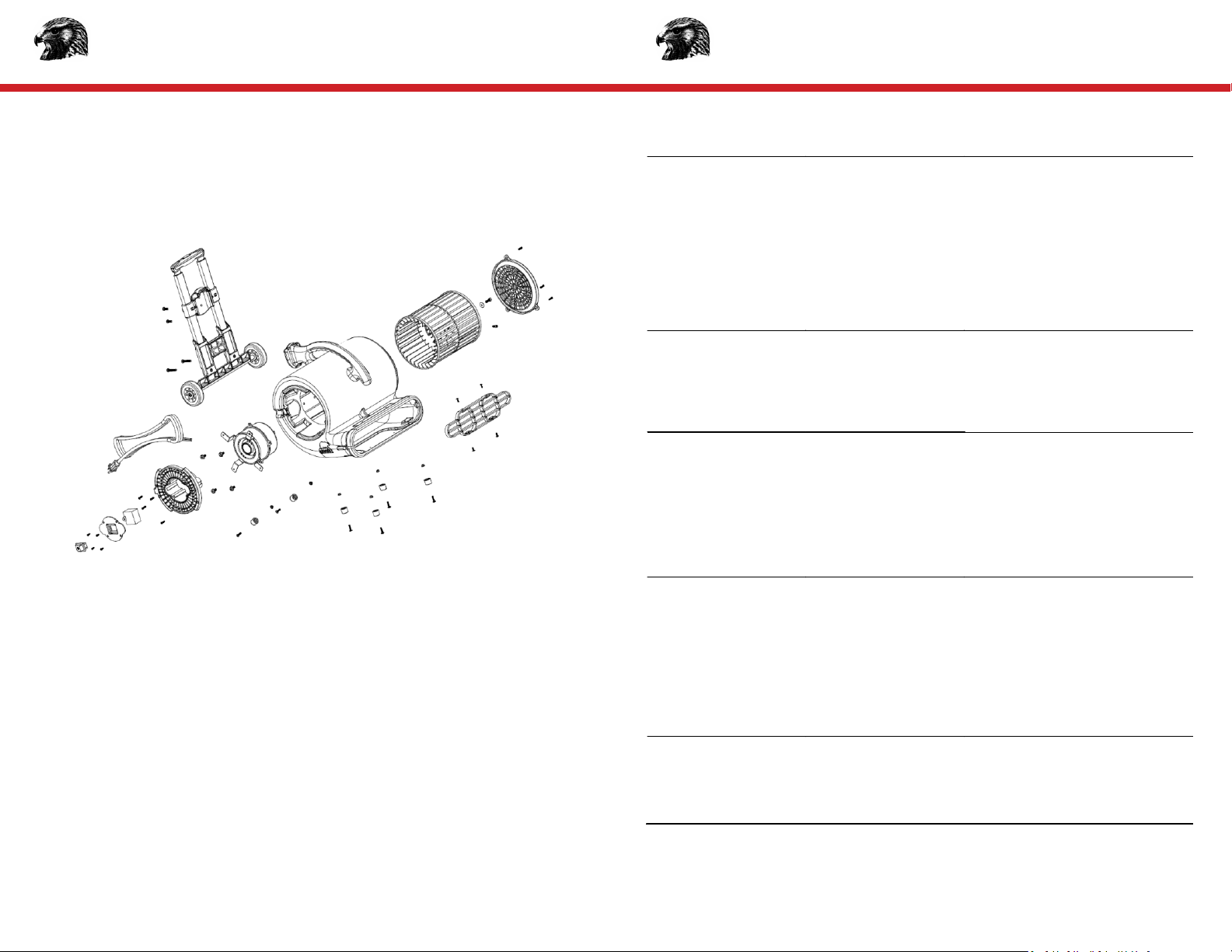

Unpacking & Checking Of Contents

Unpack your BVP50 carefully and inspect if all parts are intact. If any of the parts are

missing damaged, please contact Hawk Customer Service at (574) 294-1910 or customer-

service@hawkenterprises.com.

Operang Instrucons

This BVP50 requires NO ASSEMBLY. The BVP50 is packaged and ready to be put to work.

The BVP50H is intended to be used for drying carpet spills, drying surfaces such as

bathroom floors, venlang as well as circulang air.

1. Place the unit on the surface that needs to be dried.

2. Plug the unit into a grounded outlet .

3. Select the desired speed and posion

Floors and Carpet Maintenance

WARNING: As with all electrical equipment, the unit must be

disconnected from power before servicing or cleaning.

ŸBefore each use, inspect the unit for damage, blocked inlets and exhaust and for

foreign material buildup.

ŸWhen the BVP50 is turned on, inspect the unit for excessive vibraon. In the event of

excessive vibraon or if the fan wheel rubs against the rotomolded housing,

immediately turn off the unit and have a cerfied technician inspect the unit.

HAWK ENTERPRISES - 2902 Park Six Court, Elkhart, IN 46514

(574) 294-1910 - www.hawkenterprises.com

HAWK ENTERPRISES - 2902 Park Six Court, Elkhart, IN 46514

(574) 294-1910 - www.hawkenterprises.com

ATTENTION!

Read all safety rules carefully before aempng to operate the

BVP50H. Please retain this manual for future reference.

NEVER operate this unit when flammable materials or vapors

are present -- electrical devices produce arcs or sparks which

may cause a fire or an explosion.

NEVER operate this unit unaended.

WARNING!

To reduce the risk of fire, electric shock or injury, follow the

direcons below:

ŸDo not use an extension cord with this air

mover.

ŸDo not use with solid state speed control

device.

ŸDo not allow to be used as a toy. Close

aenon is necessary when used by or near

children.

ŸDo not unplug by pulling on cord. To unplug,

grasp the plug, not the cord.

ŸDo not use with damaged cord, plug or

other parts.

ŸCall customer service if your air mover is not

working as it should, has missing parts, has

been dropped, damaged, le outdoors or

dropped into water.

ŸDo not pull or carry by cord, use cord as

handle, close a door on cord, or pull cord

around sharp edges or corners. Keep cord

away from heated surfaces.

ŸDo not run cord under carpeng. Do not

cover cord with throw rugs, runners or

ŸUse product only as described in this

manual.

ŸTo reduce the risk of electric shock, do not

expose to rain, immerse in or use in standing

water. Store indoors only.

ŸUse only with GFCI-protected outlets.

ŸWhen storing or transporng, do not stack

air movers more than 5 units high.

ŸElectrical appliances can ignite flammable

vapors or dust. Do not use near combusble

liquids, gases or dusts.

ŸDo not leave plugged into outlet when not in

use or when servicing. Turn off before

unplugging.

ŸTo reduce the risk of srring up and inhaling

toxic vapors, do not use near toxic or

hazardous materials.

ŸNever operate with safety grills removed.

ŸThis unit has an automacally-operated

protecve device which may shut down the

unit during operaon. Unplug before

servicing or cleaning.

WARNING!

ŸTo reduce the risk of electric shock, connect only to a GFCI

protected outlet. Do not expose to water

CAUTION

ŸThis air mover has an automac motor shutoff device. It

may restart without noce.

ŸTo reduce the risk of injury, unplug before servicing.

WARNING!

ŸDo not use an extension cord with this fan. To reduce the

risk of p-over during storage or transport, stack up to 5

units high only.

32

BVP50

0 degrees

BVP50

45 degrees

BVP50

90 degrees

BVP50H

0 degrees

BVP50H

90 degrees

Hawk BVP50, BVP50H

User’s Manual

Hawk BVP50, BVP50H

User’s Manual

HAWK HAWK

ENTERPRISES ENTERPRISES