Hawker FLEX ELITE User manual

OWNER’S MANUAL

www.hawkerpowersource.com

HAWKER FLEX®ELITE

TPPL BATTERY

CONTENTS

Introduction ...........................................3

Intended Use..........................................4

Battery Architecture..............................4

Operator Interfaces ...............................5

Safety......................................................7

Operational Data and Limits ................8

Handling .................................................9

Installation into Industrial Truck ..........9

Operation ...............................................10

Activation/Deactivation of Battery......10

Charging Battery ...................................11

Service and Maintenance .....................12

Troubleshooting ....................................12

Storage...................................................13

Description of Battery Labels...............14

Shipping HAWKER FLEX®Elite batteries

..14

Disposal and Recycling .........................15

Terms and Abbreviations......................15

2

The information contained in this document is critical

for safe handling and proper use of the HAWKER FLEX®

Elite battery for powering electrical industrial trucks. It

contains a global system specification as well as related safety

measures, codes of behavior, a guideline for commissioning and

recommended maintenance. This document must be retained and

available for users working with and responsible for the battery. All

users are responsible for ensuring that all applications of the system are

appropriate and safe, based on conditions anticipated or encountered during

operation.

This owner’s manual contains important safety instructions. Read and understand

the sections on safety and operation of the battery before operating the battery and

the equipment into which it is installed.

It is the owner’s responsibility to ensure the use of the documentation and any activities

related thereto, and to follow all legal requirements applicable to themselves and the

applications in the respective countries.

This owner’s manual is not intended to substitute for any training on handling

and operating the industrial truck or HAWKER FLEX®Elite battery that may

be required by local laws and/or industry standards. Proper instruction and

training of all users must be ensured prior to any contact with the battery

system.

Refer to the abbreviations and terms at the end of this document.

For service, contact your sales representative or call:

1-877-7HAWKER (USA and Canada)

www.hawkerpowersource.com

Your Safety and the Safety of others is Very Important

wWARNING You can be killed or seriously injured if

you don’t follow instructions.

INTRODUCTION

3

INTENDED USE

Intended Use

HAWKER FLEX®Elite batteries are designed for

industrial truck applications only. Only

HAWKER®-approved chargers are to be used with

HAWKER FLEX®Elite batteries.

The truck harness used between HAWKER FLEX®

Elite batteries and the industrial truck is dictated by

the truck original equipment manufacturer (OEM).

The truck harness shall comply with UL 583

requirements for electrical current carrying

capability and truck interface requirements.

Compliance shall be confirmed by the truck OEM.

wWARNING Installing the battery in a

non-UL 583 compliant truck is a fire risk due to a

potential for improperly sized cable harnesses, and

will void your warranty.

Battery Architecture

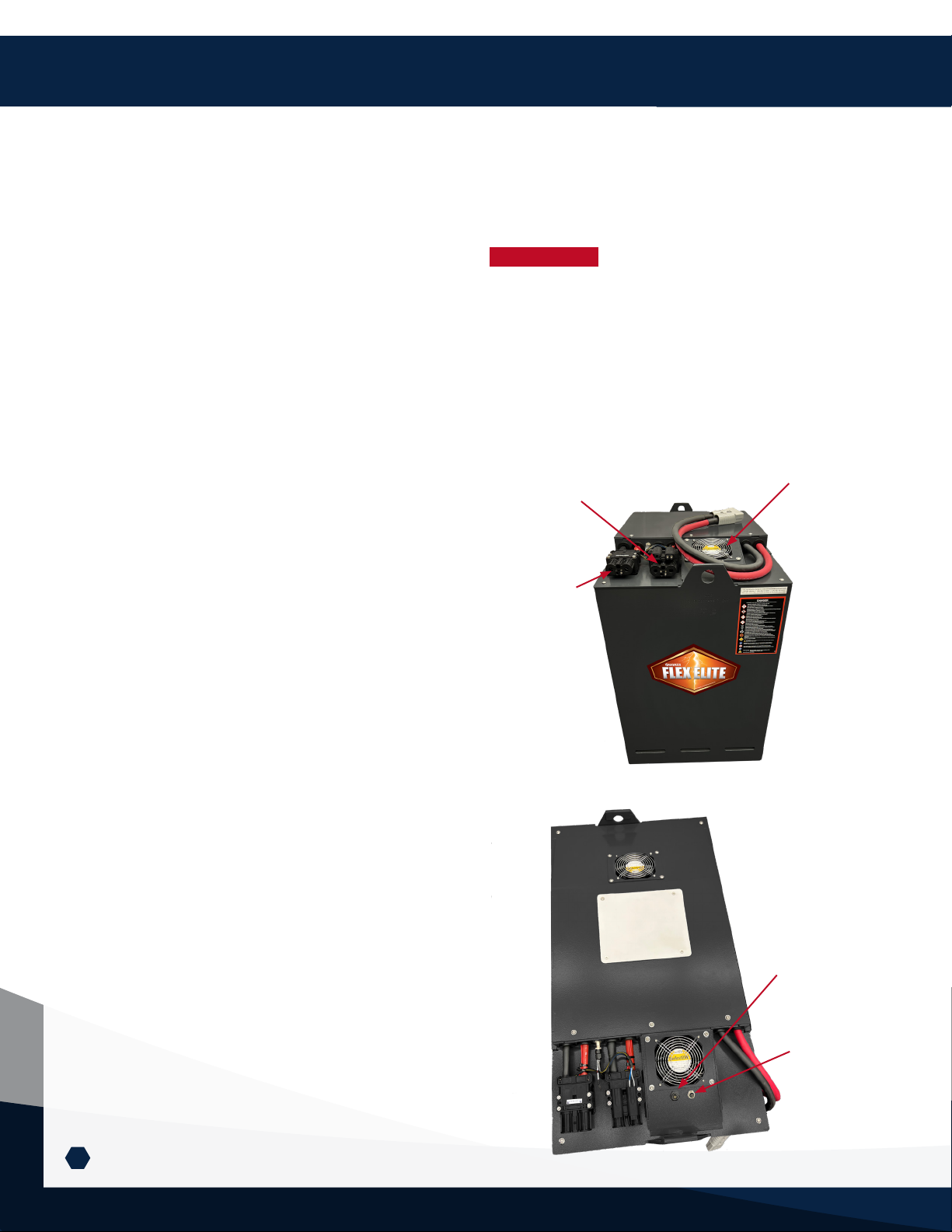

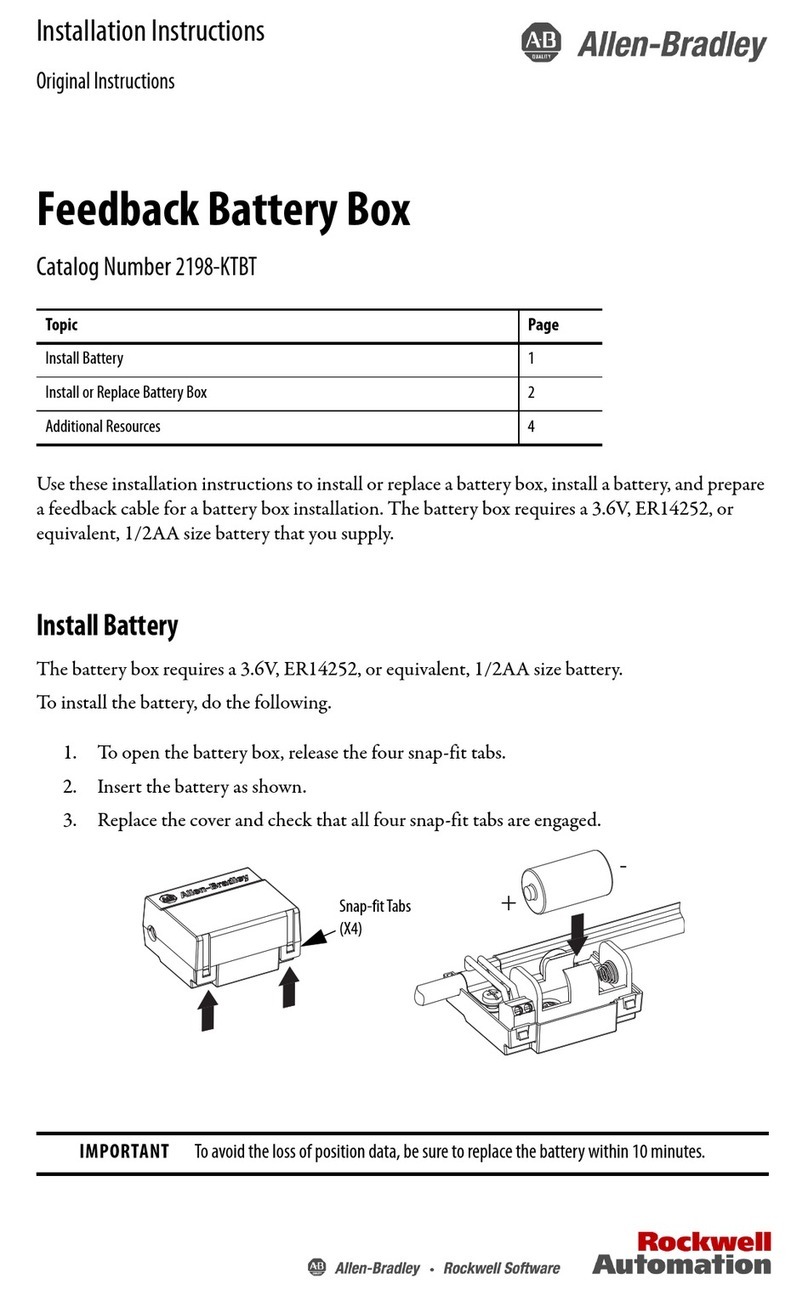

The parts of the battery are shown in Figures 1 & 2.

Figure 1: External Battery Features

Figure 2: Battery Management System (BMS)

Connections

Harness connection (35 pins) provides connectivity

to:

• Power

• Voltage sense leads (X2)

• Current measurement sensor

• CAN bus (charger communication)

• T°C (temperature leads [X3])

• Charger plug detection leads (X2)

• Contactor control

• Fan control leads (X2)

• HMI port allows connectivity with all the Human

Machine Interface devices as the BBWC and

HAWKER®battery discharge indicator (BDI)

• Controller area network (CAN) open port to

interface with the truck CAN bus

The battery is a modular design made of 12-Volt

Thin Plate Pure Lead (TPPL) blocs, combined

in serial and parallel to provide the energy

content required for the application. Different

configurations are available or can be designed.

Please contact your local HAWKER®representative

for more information.

The battery is protected by the BMS packaged

inside the unit. This control module contains

safety components and logic to control the main

contactor, preventing the operation of the battery

in unsafe or abusive conditions.

Figure 1

Cooling Fan

Primary

Charge Cable

Secondary

Charge Cable

(Connector type and appearance may vary.)

Figure 2

Truck Interface

Terminal

Operator

Interface Terminal

4

BATTERY ARCHITECTURE

Battery Architecture (cont.)

Safety Features:

• Functional safety qualified electronic monitoring

and control system to ensure safe electrical

operation within voltage, current and temperature

limits.

• A safe shut-off strategy to respond if operating

limits are violated (voltage, current, and

temperature).

• Charge circuit to prevent arcing if improper

disconnection is attempted.

• Dedicated handling/lifting points.

• Dedicated bloc ventilation to enhance

performance and energy throughput even in

high-temperature applications.

Interface Terminals: There are multiple low-voltage

interfaces on the battery exterior which must be

connected during commissioning, depending on

the end-user requirements:

Charge Interface Terminal: This is a required

connection for all HAWKER FLEX®Elite batteries.

This interface connects the charging adapter to

the battery system, allowing CAN communication

between the battery and charger.

Interface Terminals (cont.):

Truck Interface Terminal: This interface provides

specific communications for integration with the

truck’s state of charge (SoC) related features and

controls. This truck interface is not a requirement

from HAWKER®but may be required by the truck

manufacturer.

• Interlock: Allows the truck to send a signal to

tell the battery to shut down.

• Early Warning Signal: Battery will provide a

signal to the truck 10 seconds before battery

shutdown.

• CAN Open: Operating communications for

protocol sharing between truck and battery.

NOTE: If the use of this signal as the interface

with the truck is necessary, but not previously

discussed with HAWKER®, please contact your

HAWKER®service representative for support prior

to installation. Application prequalification and a

specialized cable could be required.

Operator Interface Terminal: 12-pin amphenol

connector to HAWKER® ABI device or battery

discharge indicator (BDI).

The low-voltage interfaces are protected by a 0.5A

fuse.

NOTE: Any unused connector must be protected

by a threaded cover to prevent the ingress of

contaminants or foreign material.

Operator Interfaces

An operator interface is required to be installed

in the truck cabin for ease of use and to ensure

the operator is alerted to any visual or audible

warnings such as low SoC. This in-cabin interface

can be either the BDI or the HAWKER® ABI smart

battery dashboard.

This requirement for an in-truck interface can only

be eliminated if full industrial truck OEM integration

options are deployed that allow the truck’s

preexisting operator interfaces to be utilized. Truck

integrations require prequalification and approval

from both HAWKER®and the truck OEM.

During operation as the SoC decreases, the

operator interfaces will provide an audible alarm

and visual warnings when the battery drops to the

Warning SoC level. After the battery continues to

fall below the alert level, the alarm will increase

in speed. Continuing to run the battery without

charging will ultimately result in the battery

deactivating due to low SoC.

The buzzer and LED behavior for the devices are as

follows:

• Warning SOC ON 1 sec./OFF 1 sec.

• Alert SOC ON 0.5 sec./OFF 0.5 sec.

• BMS error ON 0.1 sec./OFF 0.1 sec.

5

OPERATOR INTERFACES

Operator Interfaces (cont.)

With truck integration, the CAN cable must be

connected from the CAN port on the battery

(Figure 2 [see page 4]) to the truck. With truck

integration, warnings and alerts will follow the truck

OEM’s structure.

External BDI:

This device can be installed outside of the battery

compartment to allow operators to view the SoC

and the presence of a battery error as well as to

provide easy access to an activation/deactivation

button. The series of lights will indicate the SoC,

whilst audible alarms will notify the operator

that the battery requires recharging or that there

are battery errors. Continued operation after the

BDI indicated low SoC will ultimately result in

deactivation of the battery due to low SoC. The

BDI must be permanently and securely fixed in

a position for the operator to view the BDI for

information and access the button.

Figure 3: External BDI

Figure 4: SoC indicator screen

Truck iQ™ Smart Battery Dashboard:

Figures 5 & 6: HAWKER®ABI smart battery

dashboard

HAWKER®Advanced Battery Interface™ Dashboard:

The HAWKER®ABI smart battery dashboard is an

operator interface that provides operators with

more detailed battery information compared to

the BDI. The HAWKER®ABI device includes the

activation/deactivation button, as well as audible

and visual alarms. The HAWKER®ABI device

must be installed per the installation instructions

provided with the HAWKER®ABI device unit. The

HAWKER®ABI device must be permanently and

securely fixed in a position where the operator can

view the information and access the button.

Low SOC Audible Warnings

SOC Buzzer Stop Condition

Warning ON/OFF 1 sec. Normal SOC/On Charge

Alert ON/OFF 0.5 secs. Normal SOC/On Charge

Refer to the HAWKER®ABI smart battery device

manual for further information.

CAN bus Connectivity

The HAWKER FLEX®Elite battery can be integrated

into an OEM industrial truck CAN bus system which

allows full integration of the battery.

Figure 3

Figure 6

USoC 100% <75% <50% <25% Low Soc

or Error

Figure 4

Figure 5

6

SAFETY

Operator Interfaces (cont.)

Please contact your local HAWKER®Representative

for this option. This requires engineering

consultation between HAWKER®and the industrial

truck OEM.

HAWKER®MOD-ifi™ Smart Device App:

All data relating to the battery cycle life are stored

in the BMS (Figure 7).

The BMS data can be read wirelessly

through the HAWKER®MOD-ifi™

Smart Device App available

on both iOS®and Android™

platforms. Contact your HAWKER®

Representative for more information.

Safety

Important Safety Instructions

• Read all safety and operation instructions before

operating this battery.

• Anybody involved in handling, operating,

or maintenance of this battery must receive

appropriate training and use appropriately rated

tools and personal protective equipment.

• Follow all regulatory requirements for handling

electrical systems. The voltage of an electrical

system may impact what regulations are

applicable.

• Do not over-discharge or overcharge HAWKER

FLEX®Elite batteries as this poses a substantial risk

of damaging the battery.

• Only store and operate the battery within the

limitations given in the sections on operational

data and environmental limits.

• Keep the battery away from heat and ignition

sources.

• Do not charge or operate the battery in hazardous

environments.

• Only handle and store the battery in a dry

environment.

• Store only in monitored areas with suitable fire

control and protection per local requirements,

including local fire regulations.

• Recharge or operate only in monitored areas

with suitable fire control and protection per local

requirements, including local fire regulations.

• Recharge requires ventilation (refer to

local standards or contact your HAWKER®

Representative).

• Do not customize the battery hardware or software

as supplied by HAWKER®; or your warranty may

be voided.

• Only operate with HAWKER®-approved interface

devices.

• Service of the battery must only be performed by

HAWKER®-approved technicians.

• Dismantling of the battery is not authorized except

by qualified HAWKER®personnel due to potential

hazards involved; or your warranty may be voided.

• In the case of any error that cannot be reset,

do not attempt to continue the operation of the

battery until support and direction is provided by

HAWKER®; or your warranty may be voided.

• Do not leave the truck idle in temperatures below

the battery operating temperature as this may

result in the truck becoming nonoperational.

• Do not attempt to operate this battery in

temperatures above the operating range.

• Do not expose the battery to extended periods

of direct sunlight that allow the temperature of

the battery to rise above the storage or operating

temperatures of the battery.

• Do not operate the battery outdoors without

suitable weatherproof protection.

• Do not immerse the battery in water or clean the

battery using pressurized water.

• Do not operate the battery in condensing

environments.

• Do not install the battery on the underbody of an

electrical industrial truck.

Figure 7

7

SAFETY

Safety (cont.)

Interoperation with truck and battery charger

• The instructions in this owner’s manual do not

replace or supersede the instructions for the

truck and battery charger.

• The operation limits given in this owner’s manual

do not replace or supersede the permissible

operation parameters of the industrial truck or

charger.

• Only charge this battery with

HAWKER®-approved chargers for HAWKER

FLEX®Elite batteries.

• The battery must be installed in a truck with

appropriately sized cables.

Risks posed during normal operation

• This battery is designed to be stable and tolerant

to the applications within the scope laid out

in the operating conditions, however, battery

systems are inherently hazardous.

• Do not short the battery terminals. A shorting

event with a high current may occur, leading

to potential explosions and various hazards for

the operator. A resulting electric arc fault may

emit an intense hot flash of infrared, visible, and

ultraviolet light. Molten and vaporized metal

may be ejected. Toxic fumes may be released.

Components may become extremely hot.

• The weight and size of the battery make it

cumbersome to handle.

• Always properly restrain the battery. Failure to

restrain the battery may result in the battery

shifting or dropping. Additionally, this may result

in the battery crushing, pinching, or impacting

personnel or nearby equipment.

Damaged batteries

• Exposure of the battery to conditions outside of

its operational and environmental limits poses a

substantial risk of damage to the battery. Do not

assume damage to the battery will be apparent.

• If the battery experiences conditions outside of

the allowable limits as stated in this document,

immediately cease and do not resume operation,

and contact your HAWKER® Representative.

• If the mechanical integrity of the battery is

compromised (e.g., penetration of case, rupture

of the case, etc.) immediately cease and do not

resume operation of the battery. Contact your

HAWKER® Representative.

• Stop operation of the battery if there is a crush,

pinch, cut, or other damage to the power cables

or power connectors.

• If any material, such as liquid electrolyte, from

a damaged battery comes into contact with a

person’s skin or eyes, rinse the affected areas

with clean water for at least 15 minutes. Then

immediately obtain medical attention.

• If any material, such as liquid electrolyte, from

a damaged battery comes into contact with the

mouth or is swallowed, rinse out the mouth

as well as the area around the mouth. Then

immediately obtain medical attention.

• Contact with heated gases or components of

a damaged battery may cause serious thermal

burns. Treat any thermal burns, then immediately

obtain medical attention.

Additional information can be found in the safety

data sheet for the VRLA batteries, SDS 853027H.

Operational Data and Limits

• Nominal capacity: Nominal Capacity (C6) :

840 Ah

• Nominal voltage: 36V

• Configurations: 3 blocs series 3 blocs parallel

(3s3p)

• Max charging current: 588 Amps

• Discharge current (continuous): 1x C6, up to a

max of 320 A (limited by traction cable harness)

• Max energy throughput per day: up to 180% C6

8

HANDLING AND INSTALLATION

Handling

General Handling Considerations

• Handling of the battery is only allowed by trained

personnel that are familiar with the potential

risks of traction batteries for industrial trucks and

for lifting heavy loads.

• Avoid sudden acceleration, deceleration, drops,

and other mechanical abuse conditions while

handling the battery.

• Handling must only be performed after the

battery is disconnected from all electrical loads

and charge sources.

• Prior to lifting, secure all connectors and cables

so that they will not be crushed, pinched,

or otherwise damaged during the lift. User

interfaces may be removed prior to handling.

• Appropriate PPE must be worn during all lifts.

• Appropriate lifting methods and tools that can

safely lift and control the load must be checked

prior to all lifts. Tools must be properly rated for

weight.

• Attach lifting tools to the tray lifting points.

• The battery must only be lifted vertically. Do not

allow the battery to swing during lifting.

• The operational and safety instructions of the

lifting gear manual must be respected.

• If the battery is being handled while installed

on a truck, for instance during the battery

installation or removal operation, the truck must

be secured to prevent movement.

Installation into Industrial Truck

Mechanical Installation

• This battery is designed to be a direct

replacement of a standard lead-acid battery

intended to power an electric industrial truck.

• Upon receipt of the battery, it must be checked

for any visible signs of damage to the battery

and all cables, plugs, and accessories.

• Before installation, check that the battery is

supplied with the appropriate cable harness to

connect the battery to the industrial truck.

• Ensure that the battery weight and center of

gravity requirements per the truck manufacturer

are followed.

• The battery must be handled in a way that

mitigates the risk of drop events and crashes.

The correct tools, lifting points, and methods

should be used.

• After placement of the battery into the truck’s

battery compartment, the technician must ensure

the battery is mechanically secured in the truck

against movement as specified by the industrial

truck manufacturer. After the battery is secured

in the truck’s battery compartment, the battery

unit must be checked again to ensure no cables,

wires, or plugs were crushed, pinched, cut or

damaged during insertion.

Electrical Installation

• The battery must be connected with the

appropriate cables and connector to the

industrial truck per the truck manufacturer’s

recommendation.

• Only use HAWKER®-approved fasteners,

connectors, cabling, and plugs with this battery.

• The cable dimensioning and DC connecting plug

will vary depending on the truck and end-user

requirements. The truck harness shall comply

with relevant requirements for current carrying

capability and truck interface requirements.

Compliance shall be confirmed by the truck’s

OEM.

wWARNING Defective cables and connectors

can result in functional issues and/or severe safety

hazards such as short circuits and/or fire. Cables

and connectors must be regularly inspected for any

damage or issues. Cables and connectors should

only be repaired or replaced by an authorized

HAWKER® Representative using the correct factory

replacement parts. No substitution is allowed.

9

OPERATION

Operation

While HAWKER®has used reasonable efforts

towards the application of legal requirements, this

documentation should neither be considered nor

relied upon as legal advice.

Anybody using this battery must be trained on the

aspects of the battery they are responsible for as

required by local laws and regulations.

The battery must be handled, operated, stored,

maintained, and serviced in accordance with the

instructions in this owner’s manual.

wWARNING Failure to follow the instructions in

this owner’s manual can result in serious damage

to the battery and may result in serious injury.

Failure to follow the instructions in this owner’s

manual or using parts that are non-original will

void the battery warranty.

Opportunity charging is highly recommended

to maximize the daily operating capability of the

battery. It will also optimize the service life of the

battery by decreasing the discharge window of the

battery during discharge.

The capability of the battery to power the truck

decreases at low SOC. If the truck is operated at

a low SOC, this may result in the battery shutting

down with or without a 10-second warning. If this

occurs, reactivate the battery and slowly drive

the truck to a matching charger to connect and

recharge.

In contrast to traditional lead acid batteries, it is

beneficial to operate HAWKER FLEX®Elite batteries

at a partial state of charge with frequent and rapid

opportunity charges during periods of non-use

(operator breaks, shift changes, etc.).

This battery is designed to be charged indoors in

the truck.

The battery temperature influences the capacity of

the battery. For example, run time may be reduced

at lower temperatures. Battery temperatures at the

extreme ends of the temperature limits as stated in

this owner’s manual will influence performance.

Respect all visual and audible warnings from the

user interface devices.

Activation/Deactivation of Battery

The BMS will deactivate automatically when a

no-load condition is detected for a default setting

of 156 continuous hours to ensure that an unused

battery is not deeply discharged.

Activation:

During use: Provided the pack is not connected to a

charger and there are no battery errors, the battery

will automatically switch to the traction state

applying power to the truck. In all cases, a short

press of about half a second is required.

During charging: The battery is activated when it

is plugged into the charger. This allows battery

activation and charging even without previous

activation of the battery by other measures above.

Deactivation:

Extended non-use: The battery will deactivate after

a default of 156 hours when there is less than a

3 A current draw. If different values for these are

desired, contact your HAWKER® Representative to

make adjustments.

Manual deactivation: Ensure the equipment is shut

down prior to deactivating the battery. To manually

deactivate the battery, press the button on any user

interface for 3 to 5 seconds. Holding for longer

may result in turning the unit OFF and then back

ON.

wWARNING When deactivating the battery,

there is approximately a 20-second shutdown

sequence in which an audible alarm will be heard.

Pushing the button again during this time will stop

the shutdown procedure and return the pack to a

fully ON state.

10

CHARGING BATTERY

Charging Battery

Unlike standard lead acid batteries, HAWKER

FLEX®Elite batteries must remain connected to

the traction connector of the truck. To charge,

dedicated charging plug(s) must be used

connecting to a HAWKER®-approved charger. Upon

connecting the first charging plug, power to the

industrial truck is disabled, preventing inadvertent

operation.

This battery must only be charged by

HAWKER®-approved chargers for HAWKER FLEX®

Elite batteries, which are specially designed

to allow optimum energy transfer and CAN

communication with the battery to control the

battery recharge. This ensures a safe and optimal

operation of the system. All operating instructions

found in the owner’s manual of the charger must

be followed.

wWARNING Never attempt to charge using the

connector from the battery to the truck.

The battery system is equipped with drive-away

protection that will disconnect the traction power—

disabling the truck when any battery-charging plug

is connected to a charger. This mitigates the risk

of an operator accidentally driving away when the

charger is still connected.

Charge the battery only in an appropriate

environment. Additionally, follow all environmental

requirements from the charger.

The charge plug has embedded anti-arc contacts

to reduce arcing while performing inadvertent hot

disconnect operations.

NOTE: The CAN-enabled charge (piggy-back)

connector from the battery must be plugged into

the matching CAN-enabled charge connector from

the charger.

After installation is complete, the battery should

not be disconnected from the industrial truck to

charge, nor is it required to open the lids and

covers on the battery compartment.

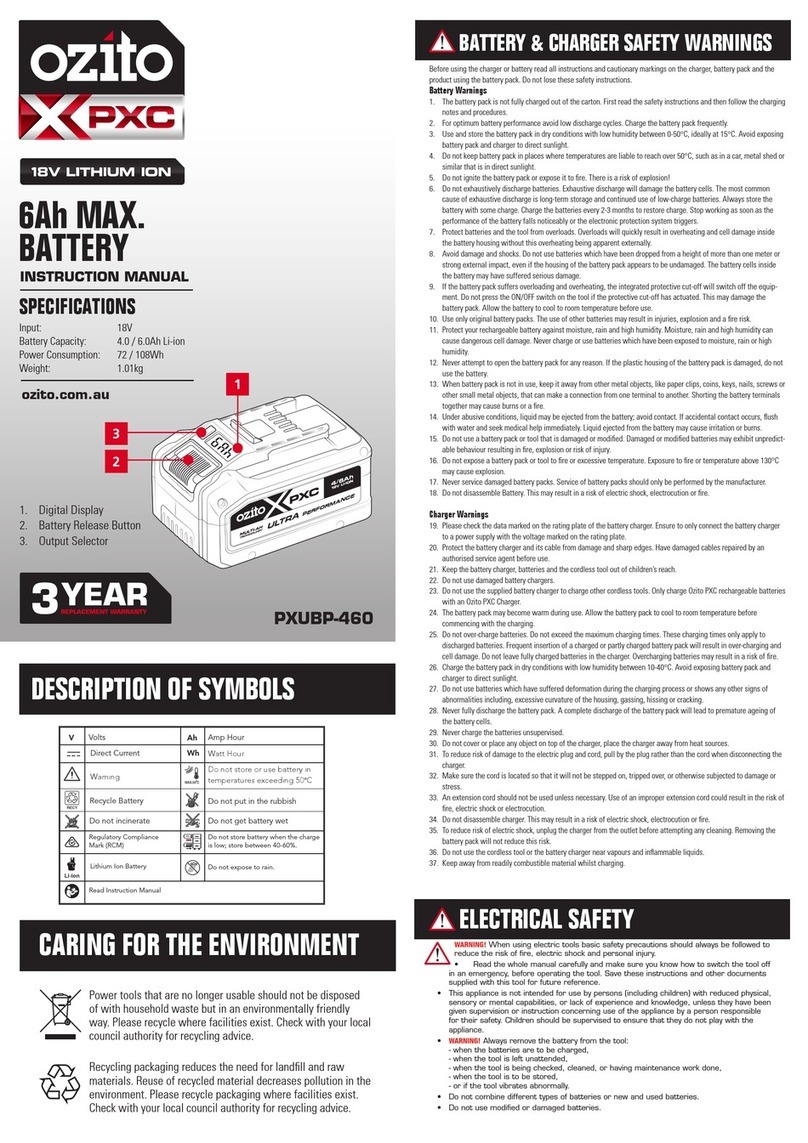

Charging Sequence

• Inspect the battery and charging cable(s) to

ensure they have no damage and are free of

contaminants prior to connecting.

• Connect the charger to the battery-charging

connectors (both primary and secondary DC

cables).

• Once a charging cable is connected, the traction

contactor will open, removing power from the

truck for drive-away protection.

• Charging will begin after communication (CAN

bus) has started between the battery and

the charger, which occurs when the primary

charging cable with the communication links is

connected (Figure 8). The optimal charge current

will automatically be determined based on the

battery conditions (SOC, temperature, etc.) and

charger conditions (temperature, charger size).

The charge level will dynamically change during

the charging process, ensuring fast charging

and optimal lifetime of the battery. If the battery

detects a fault condition, the charging will stop.

• To stop prior to completion of full recharge, such

as during opportunity charging, press the ON/

OFF button on the charger prior to disconnecting.

wWARNING Even if the battery is equipped

with anti-spark systems, the battery should not

be disconnected while still being charged by the

charger.

• After a full charge cycle is complete, the charger

screen will indicate that charging is complete.

At this point, the charger is no longer supplying

power to the battery and the charging cable(s)

can be disconnected from the battery. After

completely disconnecting the charging cable(s),

the battery will then automatically be ready for

operation. If the battery remains connected, the

charger will periodically provide a refresh charge

to maintain the battery’s full state of charge.

Primary Cable

Top connectors: Charger

communication

Bottom connectors: Power

Secondary

Cable

(Power only)

(Connector type and appearance may vary.)

Figure 8

11

SERVICE AND TROUBLESHOOTING

Service and Maintenance

HAWKER FLEX®Elite batteries are designed to

be virtually maintenance-free. However, external

cabling, connectors, etc. (including operator

interfaces) must be regularly examined to ensure

there is no damage to such parts and in compliance

with local regulations. If any of these parts are

damaged or show signs of serious wear, they need

to be replaced. Please contact your HAWKER®

Representative for all repairs and replacements. All

repairs must be done by an authorized HAWKER®

technician trained on HAWKER FLEX®Elite products.

All power cables must be checked any time

the battery has been exposed to any type of

stress, whether it be overvoltage, overcurrent, or

mechanical stresses such as crushing.

Cleaning instructions

• The exterior of the battery can be cleaned using

warm water and an antistatic cloth.

• Do not clean the battery with pressurized water.

Troubleshooting

Battery does not provide power to the truck.

• Ensure the battery is turned on using an operator

interface.

• Deactivate and reactivate the battery.

• Ensure the battery is not connected to the

charger. Power to the truck is turned off during

charging to prevent drive-away from the charger.

• Confirm there are no active errors listed on the

user interface. In case of errors, review the error

ID checklist below.

• Inspect power cables to the truck to ensure they

are not damaged.

• If the battery has OEM integration, check the

communication cables between the truck and the

battery.

• Contact your HAWKER® Representative for

further troubleshooting steps.

Battery will not charge.

• Ensure the charger is powered and the charger

does not have any errors. In case of an error on

the charger, follow the instructions in the charger

owner’s manual.

• Deactivate and reactivate the battery.

• Ensure the charging cables are properly

connected to a HAWKER®-approved charger.

• Ensure the charger communication cable is

properly connected to the charge communication

port.

• Confirm there are no active errors listed on the

battery user interface. In case of errors, review

the error ID checklist below.

• Check connectors, auxiliary pins, and CAN cables

for damage.

• Contact your HAWKER® Representative for

further troubleshooting steps.

12

STORAGE

Storage

During storage, it is recommended to turn the

battery on at least every two months to confirm it

has not dropped below 75% SOC.

Make a full recharge cycle if the battery is below 75%

SOC.

The battery must be stored in a dry environment

away from fire, sparks, and heat.

The allowable storage temperatures are -40°F to

140°F (-40°C to 60°C). To ensure battery health and

maximize service life, the maximum temperature of

the long-term storage location should be less than

95°F (35°C).

The storage area must be compliant with local

regulations (including fire, safety, and building

regulations) for lead acid batteries and in accordance

with the building’s insurance.

The battery must only be stored in an upright

position (as installed in the vehicle) with all service

lids properly attached.

During storage, it is highly recommended to

disconnect the truck and battery communication

connector as there may be a slight trickle discharge.

When storing for longer than one month, precautions

must be taken to ensure the battery is not deeply

discharged. The pack must be stored at full charge.

Troubleshooting (cont.)

ID Description Action

8Contactor stuck open Contact your HAWKER®service representative

9Contactor stuck closed Contact your HAWKER®service representative

74 Interlock 1 or 2 error Contact your HAWKER®service representative

154 NTC Ambient (TP1) Contact your HAWKER®service representative

155 NTC Bloc 1 (TP2) Contact your HAWKER®service representative

156 NTC Bloc 3 (TP3) Contact your HAWKER®service representative

444 Fan error Contact your HAWKER®service representative for replacement

449 No charger CAN communication with

plug connected Contact your HAWKER®service representative

In case of any other error ID please contact your HAWKER® Representative for further troubleshooting direction.

Error ID Checklist and Recommended Actions

13

LABELING AND SHIPPING

Shipping HAWKER FLEX®Elite TPPL Batteries

HAWKER FLEX®Elite batteries are classified as

“non-spillable wet electric storage batteries” and

may be shipped by air or ground transportation

without restriction.

HAWKER FLEX®Elite batteries comply with the

requirements of:

1.US Dept of Transportation - 49 CFR Section

173.159 para d

2.ICAO/IATA Packing Instruction 872, Special

Provision A67

3.IMDG Class 8, UN ID 2800 special provisions

238

4.ADR 2011 and RID 2011 Special Provisions 238,

295, and 598 are classified as non-spillable

and exempt from hazardous goods regulations

when securely packed and protected against

short circuits.

For further transport and regulatory information

(USA and EU; classifications and labeling) refer

to VRLA batteries - SDS 853027H instructions or

regulations by the International Civil Aviation

Organization (ICAO), International Air Transport

Association (IATA), International Maritime

Dangerous Goods (IMDG), Convention concerning

the Carriage of Goods by Rail (CIM), and Annex A:

International Regulations concerning the Carriage

of Dangerous Goods by Rail (RID) codes. Other

laws and regulatory requirements may apply.

Description of Battery Labels

Label Type:

Identification Labels Danger Label

The danger label, located on the side of the battery,

contains warnings critical for safe usage of the

battery.

DANGER

CONTAINS: Lead, sulfuric acid (electrolyte), lead compounds, arsenic.

Harmful if swallowed, inhaled, or in contact with skin.

Acid causes severe skin burns and eye damage.

May damage fertility or the unborn child if ingested or inhaled.

May cause harm to breast-fed children.

May cause cancer if ingested or inhaled.

Causes damage to central nervous system, blood and kidneys through prolonged

or repeated exposure if ingested or inhaled.

Causes skin irritation, serious eye damage.

Irritating to eyes, respiratory system, and skin.

Contact with internal components may cause irritation or severe burns.

May form explosive air/gas mixture during charging.

Extremely flammable gas (hydrogen).

Explosive, fire, blast or projection hazard.

Obtain special instructions before use.

Do not handle unless all safety precautions have been read and understood.

Wash thoroughly after handling.

Do not eat, drink, or smoke when using he product.

Avoid contact during pregnancy/while nursing.

Wear protective gloves/protective clothing, eye protection/face protection.

Use only outdoors or in a well ventilated area.

Avoid contact with internal acid.

Do not breathe dust/fume/gas/mist/vapors/spray.

Keep away from heat/sparks/open flames/hot surfaces. No smoking.

IF SWALLOWED OR CONSUMED: Rinse mouth. Do NOT induce vomiting. Call a

poison center/doctor if you feel unwell.

IF ON CLOTHING OR SKIN (or hair): Remove/take off immediately all contaminated

clothing and wash it before reuse. Rinse skin with water/shower.

IN INHALED: Remove person to fresh air and keep comfortable for breathing.

Immediately call a POISON CENTER or doctor/physician.

IF IN EYES: Rinse cautiously with water for several minutes. Remove contact

lenses, if present and easy to do. Continue rinsing.

If exposed/concerned, or if you feel unwell seek medical attention/advice.

Store locked up in a well ventilated area, in accordance with local and national

regulations.

Dispose of contents/container in accordance with local and national regulations.

Keep out of reach of children.

WARNING: Cancer and reproductive harm. Wash hands after handling. www.

P65Warnings.ca.gov

WARNING: Risk of fire, explosion, or burns. Do not disassemble, heat above

60°C or incinerate. Not recommended for inverted use. Follow product charging

instructions.

EACH AND EVERY COMPONENT OF THIS BATTERY IS RECYCLABLE. VISIT OUR

WEBSITE FOR MORE INFORMATION CONCERNING RECYCLING.

HIGH VOLTAGE: RISK OF SHOCK. DO NOT TOUCH UNINSULATED TERMINALS OR

CONNECTORS.

Do Not Remove Vent Valves.

14

Disposal and Recycling

RECYCLING AND TERMS

Terms and Abbreviations

Term/Abbreviation Explanation/Description

BDI Battery Discharge Indicator

BMS Battery Management System

CCapacity at six-hour rate of discharge

DC Direct Current

LV Low Voltage (may also refer to communication)

OEM Original Equipment Manufacturer

PPE Personal Protective Equipment

SDS Safety Data Sheet

SOC State of Charge

SOH State of Health

Activated In an ON state

Deactivated In an OFF state

Cable Harness DC cable and plug that connects to the industrial truck or battery charger

Operation Refers to charging or discharging the battery. Includes idling of the battery

while activated

Storage Refers to the battery being stored

Handling Refers to activities such as lifting, moving, positioning of the battery. Includes

connecting and disconnecting of charge and power cables

Maintenance Cleaning of the battery and inspection of the battery and connected

components (charging cables and user interfaces) for damage

Service Operations performed by HAWKER® Representatives to restore the battery to

full performance

HAWKER FLEX®Elite TPPL batteries are recyclable.

Scrap units must be packaged and transported in

accordance with prevailing transportation rules

and regulations. Scrap units must be disposed of

in compliance with local and national laws by a

licensed or certified lead acid bloc recycler with

these attributes.

HAWKER®, in line with local regulations, will accept

HAWKER FLEX®Elite batteries and related products

at specific facilities for disposal. Contact your local

HAWKER® Representative for specific recycling

instructions for your area.

15

www.hawkerpowersource.com

© 2023 Hawker Powersource, Inc. All rights reserved. Unauthorized

distribution prohibited. Trademarks and logos are the property of Hawker

Powersource, Inc. and its affiliates .except UL, Android and iOS, which are not

the property of Hawker Powersource, Inc. Subject to revisions without prior

notice. E.&O.E.

AM-HFLE-OM REV. AA 0423

Table of contents

Popular Batteries Pack manuals by other brands

Odyssey

Odyssey PC310 user guide

Swarovski Optik

Swarovski Optik RB AFL manual

EnerSys

EnerSys datasafe HX Installation, operation and maintenance instructions

Rockwell Automation

Rockwell Automation Allen-Bradley 2198-KTBT installation instructions

NightSearcher

NightSearcher GenZero 500W manual

Ozito

Ozito PXC PXUBP-460 instruction manual