Hawker DC1 User manual

Type DC1 & DC1/P

DC Powered Conductivity Level Controller

with ON/OFF Timer

OPERATING AND INSTALLATION INSTRUCTIONS

Hawker Electronics Limited

O&M 93

57 The Avenue Issue A

Rubery Industrial Estate FEB 2018

Birmingham B45 9AL

Telephone + 44(0)121 453 8911

Fax +44(0)121 453 3777

Email: info@hawker-electronics.co.uk

Web: www.hawker-electronics.co.uk

This product has been designed and complies with the relevant standards as listed in its certificate of conformity.

Due to continuing development, Hawker Electronics LTD reserves the right to change the specifications without notice.

Page 1 of 11

Contents Page

1.0 Product Overview 2

2.0 Operating Principle 2

3.0 Mounting, Electrical Installation and Connection 2

3.1 Connections 3

3.2 Cable installation general 4

4.0 Controls and Indicators 4

5.0 Adjusting the Controls 5

5.1 Sensitivity Control 5

5.2 Setting the Timer 6

5.3 Setting the Master / Slave switch 7

Application 1: Single controller for Alarm or Control 7

Application 2: Multiple controllers for Alarm and/or 7

Control with a single ‘G’ electrode

Application 3: Multiple controllers with separate ‘G’ 8

Electrodes in the same vessel

5.4 General Electrode Considerations 9

Technical Data Sheet 10

Declaration of Conformity 11

Page 2 of 11

HAWKER ELECTRONICS LTD.

The user should read this manual prior to installation or commissioning.

1. PRODUCT OVERVIEW

The DC1 controller is for use with Hawker sensing electrodes for detecting conducting

liquids. The DC1 can be used with two electrodes to provide high or low level alarm or

with three electrodes to provide control between two levels such as for pump control.

The internal control relay provides volt free changeover contacts and can be set to

either energise or de-energise on the presence of liquid thereby providing a ‘fail to safe’

feature to suit either ‘filling’ or ‘emptying’ of a vessel. Three selectable time delays are

available and can be used to prevent erratic operation due to wave motion, turbulence

or for general time delay applications.

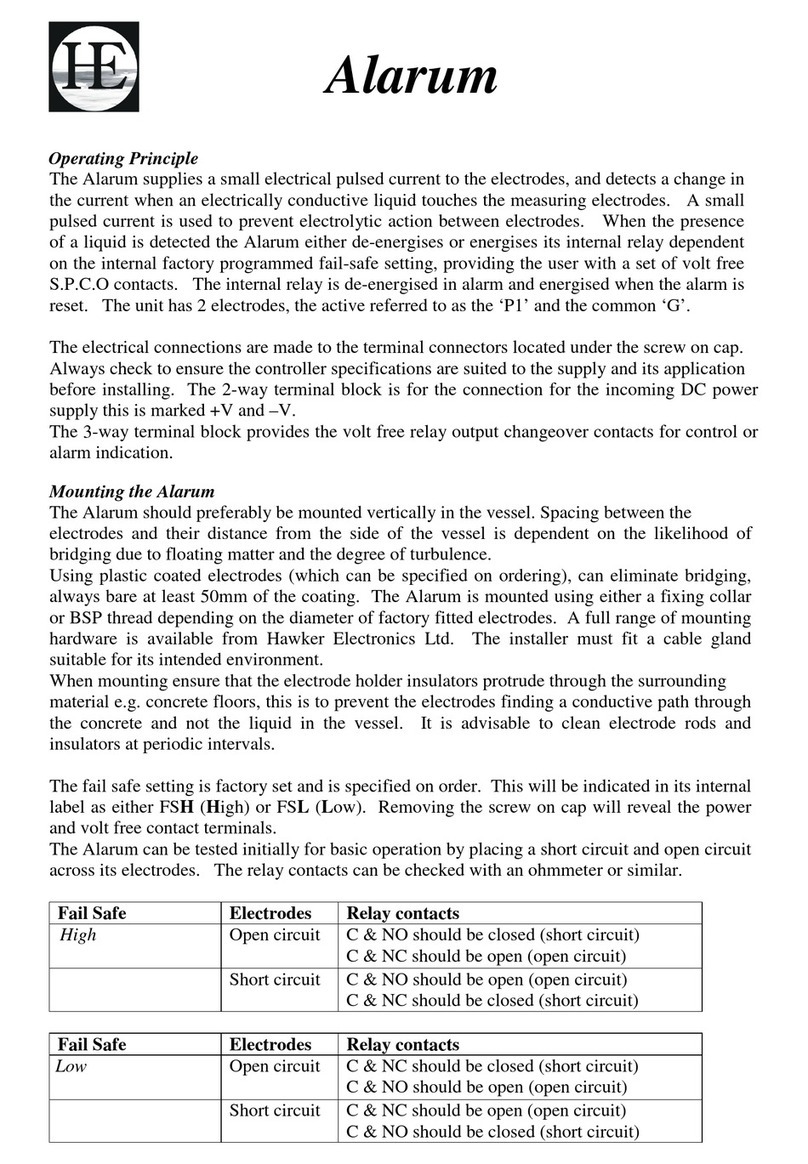

2. OPERATING PRINCIPLE

The controller employs sophisticated circuitry that converts DC to low voltage AC

signals for the electrode circuits. The level controller senses a change in the electrode

signals when the measuring electrodes are touched by an electrically conductive liquid.

Using low voltage AC prevents corrosion of the electrodes (electrolysis) and the low

voltage ensures electrical safety. The electrode circuits are isolated from the users

power supply.

3. MOUNTING, ELECTRICAL INSTALLATION AND CONNECTION

The product contains no user serviceable parts. The product should only be installed

and used by suitably qualified persons, or those who have relevant experience. The

product should be installed in line with national and or local regulations.

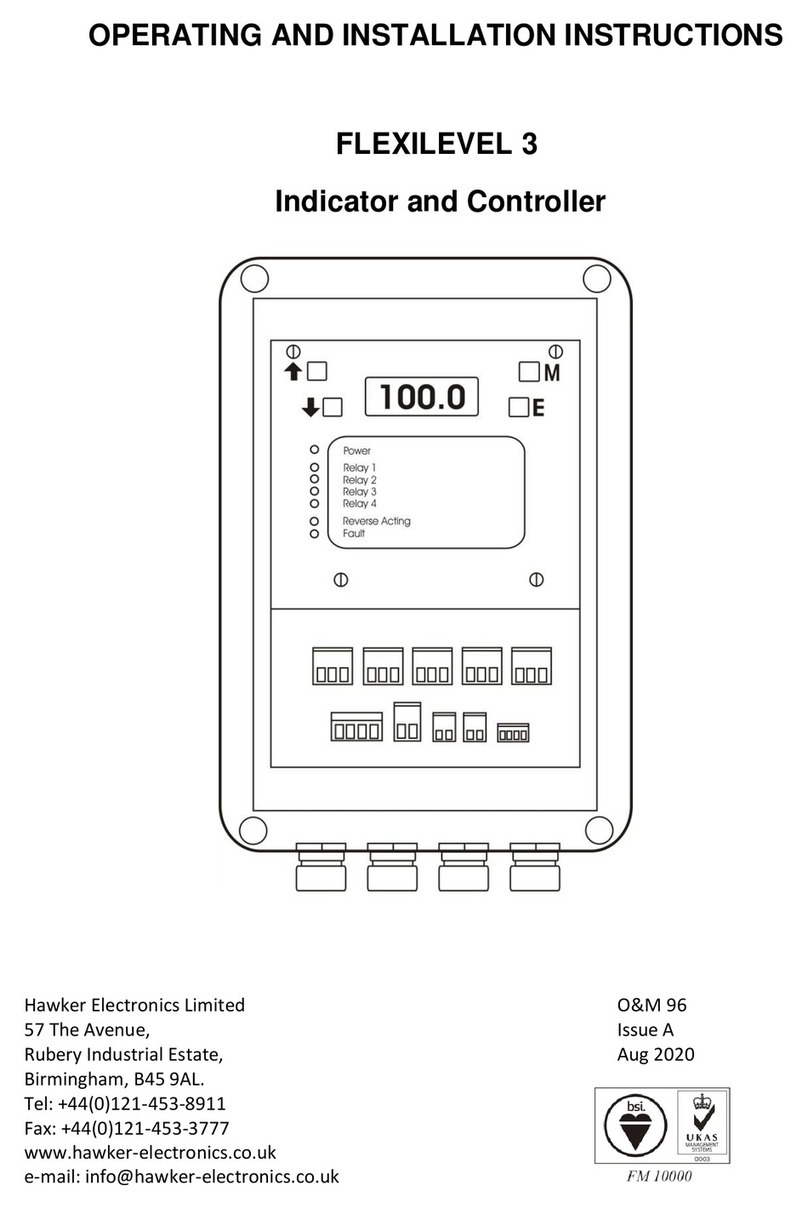

Two versions are available: The DC1/P which is DIN rail mounting and DC1 which is

supplied in a wall mounting enclosure. When using the DC1 the user must fit suitable

cable glands for the application. Care should be taken when drilling the cable gland

holes so as not to damage the electronic circuit or enclosure.

An air gap of 5mm minimum should be left around the enclosures outer perimeter for

proper air circulation to prevent overheating. It is recommended that the input supply is

sourced via a suitably fused isolator located near the product. If the user is switching

hazardous voltages through the product’s output relay contacts e.g. mains 240VAC this

should also be isolated and fused locally. Maintenance is not required for this product

other than periodic testing if demanded by the application. Cleaning can be performed

using a mild detergent and care should be taken not to clean the product with

aggressive substances that may damage the enclosure, terminals or labels. Cleaning

should be performed with the power disconnected; the unit should be completely dry

before power is reapplied.

The product should not be mounted close to heat sources; electrically noisy apparatus

e.g. welding machines and inverter drives; locations subject to strong vibrations or

shocks; dusty or corrosive gas environments; outdoors in direct sunlight or high

humidity areas.

Page 3 of 11

3.1 Connections

Each terminal block is labelled and care should be taken to ensure the correct

terminals are connected to the appropriate installation wiring. All wiring and

connections should be double checked before applying power to the product.

When commissioning it is advisable to check the

units basic operation is correct before connecting

the relay contact wiring.

DC1/P

The DC1/P has an upper and lower terminal block, the power input terminals at the

bottom, electrode terminals at the top.

DC1

During commissioning the enclosure lid may need to be removed on the DC1 to adjust

the sensitivity control and DIP switches. It is recommended that if the volt free contacts

are switching hazardous voltages the supply to these are turned off and disconnected

whilst adjusting the product controls.

The DC1 has terminals via plug and socket fittings in a row at the bottom of the

PCB.

Relay contacts may be

switching hazardous

voltages, depending on the

user application, take care.

Page 4 of 11

Terminal Connections

The terminals connected are as follows:

+V –V DC Power supply input to the product

C NC NO User volt-free relay contacts

P1 To the shortest electrode in the vessel

P2 To intermediate electrode in the vessel (if used)

G To longest electrode in the vessel or wall of metal vessel. See section

5.4.

SYNC Used only when more than one controller is installed in a sump or tank.

See section 5.3.

The DC1 has an additional earth terminal marked ‘E’; this is connected to the lower

PCB mounting holes but is isolated from the rest of the circuitry. If the user has an

incoming earth cable they can connect it to this terminal.

3.2 Cable installation general

The DC power supply and electrode cables may be run as single cores or multi-core

cable. The use of screened cables is not necessary unless run in an electrically noisy

environment, in this installation the screen may be earthed usually at the controller end

to provide a shield.

It is important to avoid running the low voltage electrode signal cables or the low

voltage DC supply cable alongside high voltage cables (i.e. 110V/250V/415VAC)

where possible.

The maximum electrode cable length is limited by the electrode cable capacitance, but

distances of several hundred metres are achievable using suitable cables. Screened

cables generally have a higher capacitance per metre than single core per metre, and

the higher the number of cores in a multi-core the higher the capacitance. Both of

which should be considered when selecting the installation cable, especially for lengths

over 100m.

4. CONTROLS AND INDICATORS

The DC1/P has a facia plate which shows the user settings and LEDs, this can be

found under its snap ON/OFF cover.

Page 5 of 11

The DC1 sensitivity control and switches are found on the PCB.

Green Led On when DC power is applied.

Red Led On when control relay is energised.

Sensitivity See section 5.1.

Control

DIL Switch

Switch 1 Upper position sets Fail Safe to High. Relay de-energises when

liquid is sensed.

Lower position sets Fail Safe Low, Relay de-energises when

liquid is absent.

Switches 2 & 3 Set the control relay time delay. See section 5.2.

Switch 4 Sets the Master/Slave operation. See section 5.3.

5.0 ADJUSTING THE CONTROLS

5.1 Sensitivity Control

For clean liquid applications setting of the sensitivity control is not critical and it can be

set to maximum. If foam is present on the surface a lower setting will enable this to be

ignored.

For dirty liquid applications the sensitivity can be decreased. This will reduce false

operation due to suspended matter clinging to the electrode such as a rag in sewage

installations.

The sensitivity control is adjusted using the following procedure;

Page 6 of 11

1. With the timer turned OFF (DIL switches 2 & 3 in the lower position) turn the

sensitivity control fully anticlockwise. Raise the liquid level to immerse the P1

electrode tip by at least 5mm. Slowly turn the sensitivity clockwise until the

relay changes state i.e. liquid is detected, continue turning clockwise one more

division.

2. Lower and raise the liquid level to ensure optimum setting.

Note: The sensitivity control setting is inversely proportional to the length of bare

electrode required for liquid detection, i.e. as the sensitivity control is increased less of

the electrode has to be covered by the liquid before the controller switches. It is

recommended that at least 50mm of electrode is bared. This will provide a better

electrically conductive path should part of the electrode be contaminated with an

insulating material e.g. fat or grease.

Where there are long cable lengths to the electrodes, the sensitivity can be set lower in

order to counteract cable capacitance if this is found to be a problem. See section 3.2

Cable Installation.

5.2 Setting the Timer

The timer delays both the energising and de-energising of the control relay. This can

be used to avoid false operation due to splashing, wave motion or turbulence. The

timer can also be used to allow a pump to run on so as to clear solids where ‘benching’

in sump does not allow the stop electrode to be low enough.

Four settings are available using the DIL switch:

Time

Switch 2

Switch 3

OFF

DOWN DOWN

2 Seconds

UP DOWN

6 Seconds

DOWN UP

10 Seconds

UP UP

Page 7 of 11

5.3 Setting the Master/Slave switch

The following application drawings show the DC1/P terminal blocks but also apply to

the appropriate connection on the DC1.

Application 1: Single controller for Alarm or Control application

When using a single controller with up to three electrodes in a vessel, switch 4 must be

set ‘down’ to the Master position and no connections are required to the ‘sync’

terminals.

Application 2: Multiple controllers for Alarm and/or Control in the same

vessel using a common ‘G’ electrode

When using multiple controllers with electrodes in close proximity in the same vessel

with a common ‘G’ electrode ensure the following is carried out to obtain best

performance.

1. Configure one controller as a Master and the others as Slaves using the facia

DIL switch. Link ‘sync’ terminals between controllers. Two internally linked

‘sync’ terminals are provided to facilitate wiring.

2. It is recommended that a maximum of six controllers share a common ‘G’

electrode, 1 master + 5 slaves. These can be for Alarm, Control or either.

3. When using a common ‘G’ electrode in a cluster of electrodes always position

the common ‘G’ electrode central to the other electrodes. The objective is to

ensure the active bare electrode tip has a clear conductive path to the ‘G’

electrode.

Page 8 of 11

4. Try to keep each controller P1 and P2 electrodes close together; do not mount

them in the conductive path of other controllers’ electrodes.

Application 3: Multiple controllers with separate ‘G’ electrodes in the same

vessel.

Configure the controllers as master devices switching DIL switch 4 to the lower

position. No connections to the ‘sync’ terminals.

Ensure a minimum spacing between each different controller’s electrodes of 300mm for

optimum performance.

Page 9 of 11

5.4 General Electrode Considerations

1. Try to keep each individual controller’s electrodes together as a set i.e. do not

locate an electrode of one controller in-between the electrodes of another.

2. Always place the G in the centre of the active electrodes to shorten the

conductive paths.

3. The ‘G’ electrode must always extend below the lowest electrode.

4. A metal vessel can be used for the ‘G’ electrode.

------------------------------------------------------------------------------------------------------------------

The crossed-out bin symbol, placed on the product, reminds you of the need to dispose

of the product correctly at the end of its life

Page 10 of 11

Technical Data

Specification given at 25

0

C over full input span

Supply

Voltage current: 10-27V DC

10V DC 110mA 1.1W

12V DC 90mA 1.08W

24V DC 49mA 1.2W

Reverse polarity protected. Maximum current under fault condition is limited to approx 150mA.

Electrodes

Configuration: P1, P2 and G.

Voltage: 10VAC RMS max.

Peak to peak: 18V A.C.

Current: 5mA RMS max.

Frequency: 40Hz ±10%.

Cable capacitance: Max cable capacitance is 180nF at maximum sensitivity, see cable manufacturers data sheet.

Typically 300m max using instrument type cable <150pF/m core/core.

Cable type: Typically, 0.75 – 2.5mm, single or multi-core, see general cable recommendations in user

operating manual.

Liquid sensing range: Approximately 200 to18,000 ohms, user adjustable via facia sensitivity potentiometer

Switching hysteresis: Better than 5%.

Fail-safe: Fail safe high or fail safe low user adjustable via facia DIL switch.

Timer: Auto resetting anti-splash on/off delay timer. User adjustable via facia DIL switch 0, 2s, 6s, 10s ±0.25s.

Response timer: <0.4s.

Output

Indication LED Green: Power on.

Indication led Red: Relay energised LED on, relay de-energised LED off.

Relay: SPCO, contact rating 5A 250V A.C./30V D.C., res. load

Max switching power 1250VA/150W.

Mechanical endurance 1x107ops

Electrical endurance min 1x105ops (full load)

Dielectric between open contacts 1000V A.C. 1 min

Operating temperature: -100C to +500C.

Enclosure DC1/P DC1

Material: Polycarbonate Polycarbonate base and transparent polycarbonate cover

Dimensions: 55W x 110D x 75H mm 162H x 122W x 90D mm

Terminals: Captive self-locking screws, accepts up to Internal Plug/Socket

4mm2conductor.

IP: IP20 IP66

Weight: 200g 550g

Due to continuing development Hawker Electronics Ltd reserve the right to alter the specifications without notice.

Page 11 of 11

This manual suits for next models

1

Table of contents

Other Hawker Controllers manuals