01/2018 Subject to change

Page 1 of 3

Operating and maintenance instructions for

Universal Hawlinger for later drilling with vertical and horizontal

ZAK® outlet 90° to pipe direction

Order No. 245-02

1. Intended use/Product description

Medium: Potable Water

Max. operating pressure: 16 bar

Material:

Body: GJS-400, Hawle epoxy powder coating

Spindle, shut-off device, shut-off blade: stainless steel

Gaskets: EPDM acc. to DVGW-worksheet 270

Universal-Hawlinger for later drilling are to be used for installation on cast iron, steel and AC pipes from DN65 - DN

500. Adjusting to the main pipe is achieved by means of retaining strap and saddle gasket (Order No. 310 or Order

No. 311) in the corresponding nominal width.

Type „NA“ Hawlinger®are used for the later drilling of previously installed service connections. The stringent de-

mands on hygiene, in particular the requirements of DIN 1988 (avoidance of dead water zones), are thus consistently

implemented. Subsequent excavation for drilling the main pipeline when commissioning the service connection is not

necessary with this system.

The horizontal ZAK® outlet is used, in combination with ttings, for the connection of house service pipes.

We recommend the use of our surface box Order No. 212 for later drilling via the drilling conduit and for actuating the

extension spindle.

During installation and maintenance operations, the applicable standards and guidelines, accident prevention regu-

lations and the regulations of professional associations are to be observed and complied with.

Installation and maintenance operations should only be carried out by qualified personnel.

2. Installation

2.1 Installing the pipe drilling saddle

1. Procedure for metallic pipes with sheathing in the area of the pipe drilling saddle

The DVGW leaet W333, Pipe Drilling Saddles and Drilling Procedure in Water Supply/9.2.2. Pipe Sheathing for

Metal Pipes must be observed.

PE sheathing: The PE sheathing on pipes according to DIN 30674-1 remains on the pipe providing there is sufcient

adhesion.

Cement mortar (CM) sheathing: The additional cement mortar sheathing on a PE-coated pipeline should be removed

in the area of the pipe drilling saddle, unless the borehole wall is sealed by suitable means.

The CM sheathing on cast iron pipes according to DIN 30672-2 also remains on the pipe, if it complies with Plastics

and Drinking Water (KTW) quality standards and provided that there is sufcient adhesion and surface smoothness

as well as low mortar porosity in the area of the pipe drilling saddle.

When removing protective sleeves, the unprotected pipe area between clamping bracket, service valve and PE/CM

sheathing must be protected after installing the pipe drilling saddle by means of secondary sheathing measures in

accordance with the raw material manufacturer‘s recommendations (e.g. suitable winding tape or shrink hose solu-

tions).

These instructions apply unless the pipe manufacturers expressly recommend otherwise for their sheathed pipes.

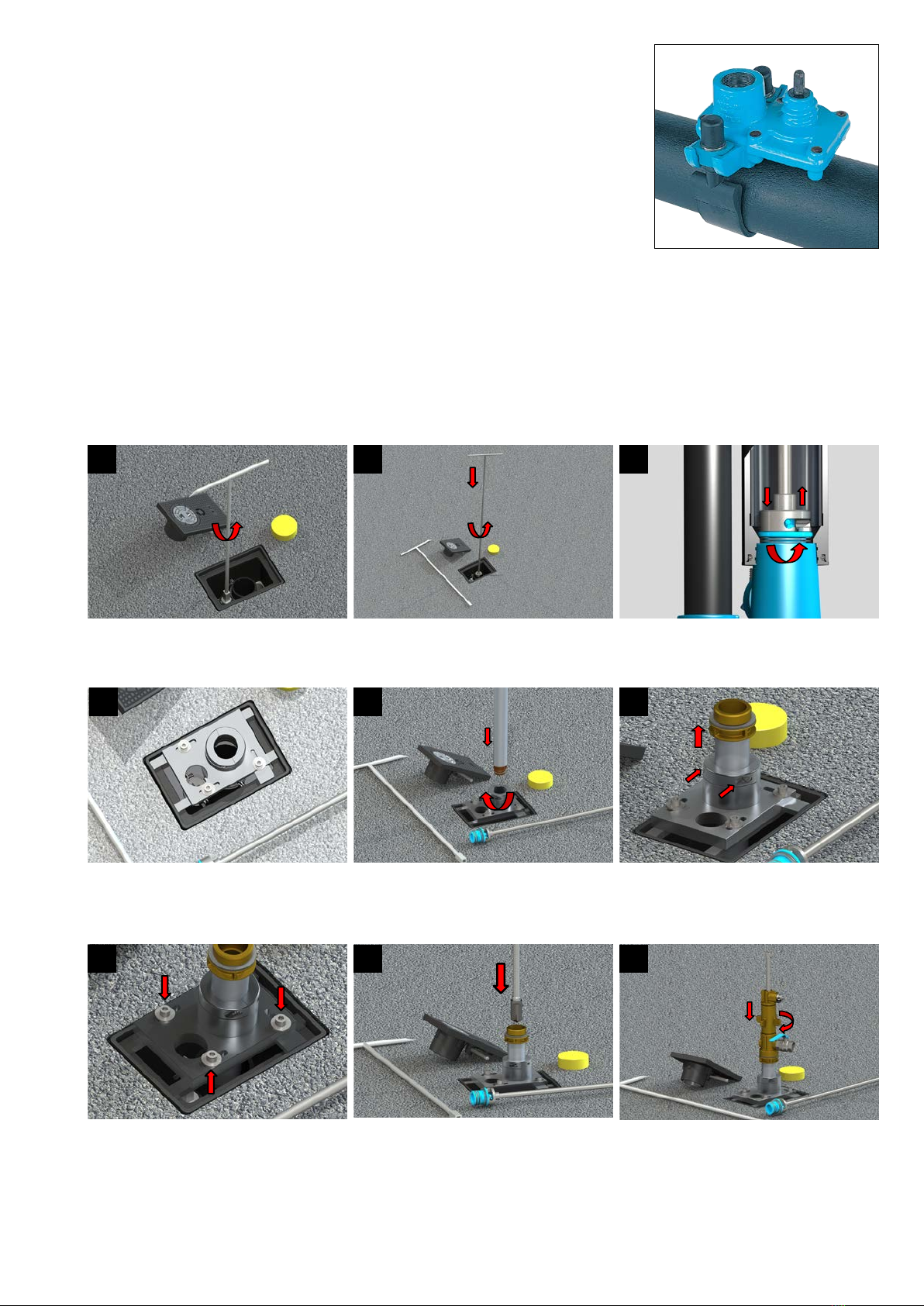

1: Universal-Hawlinger ZAK

2: ZAK-plug

3: Strap

4: PE-guide pipe

5: Aluminium pipe support

6: Pipe protection cap

7: Telescopic extension spindle (pipe cover

depth 1,30 - 2,00 m)

8: Base plate

9: Surface box

10: Pipe retaining clips

Important: Items 3, 8 and 9 are not included in

the scope of delivery!