SteelMax D2X User manual

D2X 8/2014 Operator's Manual For Drilling Machine - 1 -

SAFETY INSTRUCTIONS

AND OPERATOR’S MANUAL

FOR

DRILLING MACHINE

D2X

D2X

- 2 -

TABLE OF CONTENTS

I. SAFETY INSTRUCTIONS.............................................................................................................. 3

1.General information..................................................................................................................... 3

2.General safety advice.................................................................................................................. 3

II.START UP AND OPERATION...................................................................................................... .5

1.Cutters and optional equipment features.................................................................................... .5

2.Machine start up .......................................................................................................................... 6

3.Operating instructions.................................................................................................................. 9

III.ADJUSTMENT, MAINTENANCE AND SERVICE ....................................................................... 10

IV.TECHNICAL DATA....................................................................................................................... 11

V. PARTS LIST/EXPLODED DRAWINGS........................................................................................ 13

VI. ELECTRICAL DIAGRAM.............................................................................................................. 24

VII. EC DECLARATION OF CONFORMITY....................................................................................... 25

VIII. MACHINE TEST CERTIFICATE .................................................................................................. 26

IX. WARRANTY CARD...................................................................................................................... 27

X. ANNULAR CUTTERS................................................................................................................... 28

D2X

- 3 -

BEFORE YOU START WORK WITH THE MACHINE,

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND USE ALL RECOMMENDATIONS.

I. SAFETY INSTRUCTION

The magnetic drilling machine should be used only for the purpose described in this

manual. Using the machine incorrectly or not for its intended use may result in serious injury

and/or death.

1. GENERAL INFORMATION

Portable magnetic drilling machines are fast becoming universal power tools not only

at steel fabricating workshops or steel building sites but also at every factory maintenance

workshop, truck manufacturer & repair company, military equipment service, onboard ship

maintenance shop, etc.

Full advantages of electromagnetic drilling machines can only be achieved with

optimal tooling. Annular cutters are designed and manufactured specifically to offer a wide

range of advantages in one precise pass not otherwise attainable with heavy stationary

equipment. The drill is equipped with a powerful motor and automatically adjustable slides.

2. GENERAL SAFETY ADVICE

Drilling machine should not be used when:

1. The operator has not read the Operator’s Manual.

2. The work to be done is not in agreement with the recommendations in this Manual.

3. Drilling machine is not complete or has been repaired with non-standard parts.

4. Power supply parameters do not conform to those stated on the motor’s plate.

5. Machine operator has not checked the condition of the drilling machine, the condition of

the power cable, control panel, cutter and other components.

6. Power supply socket is not equipped with a protection circuit.

7. Machine is not secured with a safety chain to protect it from falling down,

especially when used at heights or in vertical or upside-down positions.

8. Bystanders are present in the immediate vicinity of machine.

D2X

- 4 -

Important rules of safe use of drilling machine

1. Before attempting to work with the machine, check condition of the electrical supply,

including power cord and plug.

2. The drilling machine should be connected to an installation equipped with protection

circuit (neutral or ground) and protected with a 15 Ampere fuse/circuit breaker for 220V

and 20 Ampere fuse/circuit breaker for 120V.

3. Machine can be used outdoors, but it is not weatherproof. Do not expose to rain, snow

or frost.

4. Machine should not be used on: rusty surfaces, steel plates covered in thick paint,

uneven surfaces, next to a welding machine. When the machine is attached to any

metal surface, that surface should not be welded. Remove the drill from the steel before

beginning welding. This can cause damage to the machine and will void the

warranty.

5. In all cases, always use a safety chain/strap (see drawing below). The safety chain

must not be loose! To avoid this situation, the safety chain should be securely attached.

Do not use the machine in explosive hazard areas. Do not start work if the machine has

excessive play on guide slides. Always wear safety goggles and ear protection. Do not

remove metal chips and strands with bare hands

Safety chain can also secure the drill through

the handle.

1. Do not touch the spindle and cutter during work.

D2X

- 5 -

2. Tools must be fastened firmly. When an annular cutter is used, check before start of

work to ensure the screws holding the cutter are tight.

3. It is not safe or productive to use blunt or damaged tools.

4. Do not use annular cutters without pilots, and arbors without ejection spring.

Do not touch or replace the annular cutter with power source on –

while electromagnetic base is being used.

5. Use tools recommended in Operator’s Manual only.

6. After use, always clean metal chips and coolant from drilling machine.

7. Always unplug the machine from the power supply during any maintenance work on the

machine.

It is not advisable to use the drill on steel less than 3/8” (10 mm) thick.

On thin steel (less than 3/8” (10 mm)) the magnet’s adhesive power would be

significantly reduced and can cause machine failure or operator injury. The

Safe Magnet technology may not allow the drill to start. Use of a thicker

backing plate under the surface to be drilled can solve this problem. The

entire surface of the electromagnetic base should be located on the work

piece! Before positioning the machine on the work surface, it is recommended

that the work surface under the electromagnetic base be sanded down with

abrasive paper to allow better adhesion!

Please follow all recommendations.

II. START UP AND OPERATION

1. Cutters and optional equipment features

The D2X uses a #2 Morse taper which makes it possible to use twist steel bits by

using our optional ½” adjustable chuck adapter. (Part # SM2MTJ)

The annular cutter (2) slides inside arbor body (1) and is fastened with screws

(3). While fastening the cutter in the socket, be aware that screws should be screwed tight

so that they do not come loose. It is important to position the cutter in relation to the socket

in such a way that the flats on the cutter shank are positioned in line with the fixing screws

(3). Both fastening screws (3) should be tightened on the cutter. The pilot (5) is located

inside the cutter. It makes it easier to position the annular cutter over the center of a

planned hole. During drilling, as the cutter goes deep into the steel, the pilot moves back

into the arbor body and tightens the discharge spring (4). This spring ejects the plug which

is a by-product of drilling a hole with an annular cutter. On occasions when there is a need

for an overlapping hole the pilot pin should not be used.

D2X

- 6 -

2. Machine start up

The machine is supplied in a metal box with complete standard equipment.

D2X comes in standard equipment set which consists of:

metal box for storage or transport

drilling machine

arbor AMT2-C-19/2-2

cooling system

chip guard

spoke handles

Allen wrenches:

- hex s=4

- hex s=5

wedge, MT2

safety chain

snap hook

operator’s manual

Drawing 3.

A few types of holes that can be done with an annular cutter

.

Drawing 2.

Principle of annular cutter’s work

D2X

- 7 -

2.1 Before first drill:

Steel elements of the drilling machine are protected for transit and storing with grease

film.

All grease should be removed before first start up of the machine

All handles should be screwed into pinion before each use.

2.2 Before you cut

Before positioning the machine on work piece always make sure that:

-Work piece is made of steel;

-Thickness of work piece is at least 3/8” (10 mm)

-Surface of the steel under the magnet is flat

-Wipe, brush or sand down clean surface where you intend to place the drilling

machine, so that you remove rust, paint, dirt etc which would reduce adhesive power of the

electromagnetic base.

Install drill bit, annular cutter or other tooling such as tap or reamer in the machine

before power is supplied to the unit. Then plug it in (see paragraph 3) and position where

you wish to use it. Place the machine so that the tool is over the center of the hole you

intend to make, and turn the magnetic base ON.

Prior to use always make sure that the machine is secured from falling with

original chain (as described in paragraph 1 no. 2 “Important rules of safe use

of drilling machine”).

2.3 Cutting

-Select the right speed for the tool you intend to use (see the speed chart in this

manual on page 12). Choose suitable cooling/lubricating fluid and fill cooling reservoir with

it. The cooling system is an integral part of the machine and should always be used.

Warning: The cooling system can only be used when drilling machine is in the

vertical position. In other positions, additional external source of cooling should be

used, for example: a pressurized coolant bottle or an alternative lubricant such as

Edge Cream which can be applied directly to edge of the cutter.

-Check proper operation of the cooling system. Open coolant reservoir’s tap and

apply pressure on the pilot by turning spokes counter clockwise. Cooling liquid should start

to run down the cutters inner wall as the pilot starts to sink into the cutter. If there is no liquid

flowing down the cutter, check if the tap is fully opened. It may take a few seconds for

cooling liquid to fill the whole system.

-Turn the motor on.

Making a hole with an annular cutter should ideally be done in one pass. Enter the

cut slowly until the cutter is ejecting a continuous thread of cuttings. Then apply steady and

continuous pressure letting the cutter do the work. Excessive pressure will cause excessive

D2X

- 8 -

heat and premature dulling of the cutter. Plug must be ejected after the hole is completed. If

you experience plugs getting stuck inside a cutter after hole is complete, try to reduce

pressure on the cutter or use a different coolant. Do not allow excessive shavings to build

up around the cutter and arbor. If a plug is stuck in the cutter after the drilling operation then

turn off the drill and the coolant flow, move the drill over a smooth metal surface and tap the

cutter lightly using the spoke handles to lower the cutter down to the flat surface. Tapping

the plug with a wooden object can also help dislodge the plug. In severe cases the plug

may need to be removed with pliers. Stuck plugs can be the result of using dull or dirty

cutters.

WARNING: When the annular cutter goes through the material the

plug can be pushed out often with considerable strength.

Pay attention to avoid injury.

-After a hole is made, the cutter should be withdrawn back and both the motor and

the electromagnet should be switched OFF.

-When work with the machine is finished, the power cord should be disconnected

from the power source, the machine should be cleaned, and the cutter should be removed

and cleaned.

2.4 How to use the special functions

There are some factors affecting the value of the clamping force. They are as follows:

thickness of the base, presence of the paint coats, rust and other contamination, non-flat

surface, excessive stock roughness, extended wear of the magnets lower surface and the

make up of the steel surface.

The Safe Magnet circuitry will not allow the motor to operate when there is

insufficient magnetic holding power which can occur under any of the conditions

cited in the previous paragraph.

To operate this machine properly you should push on the main switch in position “I”.

Then you should turn on the green button “I” to turn on the motor. To stop the motor you

should push on red button “O” (It turns the motor off, the magnet still holds). To move the

machine and drill in another place you should stop the motor and then push the main switch

in position “O”.

2.5 Working in difficult areas

While working in difficult access areas, as well as for left-handed operators, one may

change location of the pinion with the spoke handles to the other side of drilling machine.

D2X

- 9 -

2.6 Semiautomatic gib adjustment

Turn the spoke handles (1), so the screws (2) in the face plate are visible through the

openings in the slider (5).. After loosening all the screws, slide the slider up and down

several times so that the pressure strip aligns itself and automatically adjusts the gib to the

proper clearance. This is only necessary in case the drill drops to the bottom by itself (too

loose) or binds during operation (too tight or out of straight alignment).

After resetting the gib clearance, tighten screws (2) starting from the middle screw. The

slider should be located symmetrically relative to the middle screw. Next, tighten the

neighboring screws (2) moving the slider, as necessary, to make the screws accessible.

Then, tighten screws (3) until any noticeable resistance is felt. When the screw is in this

position and held with an allen key, tighten counter nut (4). The screws (3) counteract the

machining force and protect the pressure strip from shifting during operation.

D2X

- 10 -

2.7 Installing and uninstalling the cooling system

Hang the cooling system on the screws (1) and lower the chip guard (2). Insert the

cooling hose, with the spring positioned as in the figure below, between the pin and

arbor (3), and attach the tip of the cooling hose to the coupling. Then, slide the

spring to the end of the hose (4), until it touches the arbor (5). Dismount in reverse

order.

Before starting the machine:

unscrew the bottle cap,

fill the bottle with the cutting fluid,

tighten the cap.

Then, make sure the cooling system is mounted properly and the cooling hose properly

attached to the coupling. Next, unscrew the bottle cap by 1/3 rotation and open the valve,

after which the hose will be filled with the fluid. Then, start the machine (see II point 3).

Once the work is finished, tighten the cap and close the valve (to prevent fluid from

leaking during idle period) and dismount the cooling system before inserting the machine

into the tool box.

1

2

3

4

spring

valve

5

D2X

- 11 -

3. Operating instructions

The machine is supplied in a metal box. Steel elements of the drilling machine

are protected for transit and storing with grease film. Before first start up of the

machine all grease should be removed. Before each use all spoke handles should

be screwed into the pinion.

Control panel includes below elements:

(01) - Main switch MAGNET,

(02) - START-STOP button MOTOR.

a) In order to start the machine, press the main switch MAGNET (01) on “I“ button.

Now you can start the motor by pressing green button MOTOR (02) on “I”.

b) Stopping the motor is executed with red button “O” (then the motor is switched

OFF but the electromagnetic base is still ON) (02).

c) To move machine into next drilling spot, stop the motor as described above and

push the magnet switch (01) to the position “O”.

d) Use the gear box lever to change the speed. It may be necessary to slightly rotate

the arbor by hand in order to change speeds.

To move the machine into next drilling spot, stop the motor as described

above and push the main switch MAGNET to the position “O”. To change the speed,

use the gear box lever. The motor must be stopped before switching gears.

. READ THE WHOLE INSTRUCTION MANUAL BEFORE

ATTEMPTING TO START UP

Drawing 5. Control panel

D2X

- 12 -

III. ADJUSTMENT, MAINTENANCE AND SERVICE

Every 50 hours of work, or as need arises, elimination of excess play in slide

guides should be performed. The screws and the locking nuts are provided for

that reason. The slide guide should go up easily and not slide down under its

own weight.

When the drill is not in regular usage it should be stored on its side (laying

horizontally) in order to keep the gearbox grease spread adequately around the

gears. Simply return the drill to its case which prevents dust accumulation on the

drill and lay the case flat on a shelf.

The position of the gear lever (used for selection of gearbox speed) should be

changed occasionally to ensure proper gearbox lubrication. Regularly check

condition of carbon brushes. (see paragraph IV –Technical data).

Lubricate the brass slide guide inserts regularly with grease as well as the rack

and pinion.

To prevent the machine from rusting (especially when used outdoors) all steel

parts should be covered with thin layer of grease film.

All repair work should be done only by authorized service centers.

D2X

- 13 -

IV. TECHNICAL DATA

Power supply

□ 110÷120V AC / 50-60 Hz

□220÷240V AC / 50-60 Hz

Power required

1300 W

Motor power

1260 W

Tool holder

3/4" (19 mm) Weldon

Max. twist drill diameter

7/8” (23 mm)

Max. annular drilling diameter

2” (50 mm)

Max. annular drilling depth

2” (50 mm)

Insulation Class

I

Standard adhesive force of electromagnet

(for steel 7/8” (22 mm) thick and Ra< 1,25)

12 000 N

Slide stroke

6” (153 mm)

Machine speeds /under load/

Low speed –200 rpm

High speed –400 rpm

Electromagnetic base

90x180x48 mm

Length of the power cord

10’ (3 m)

Total weight

36.3lbs (16.5 kg)

Noise level

85 dB

Surrounding temperature

32°F to 104°F (0°C ÷ 40°C)

D2X

- 14 -

The D2X machine is capable of cutting 2” (50 mm) holes through 2” plate. That is

unique for an electromagnetic drill of this size and weight

Check the condition of the carbon brushes for every 100 hours of work. If the length

of the brush is less than 5 mm, they should be replaced. After replacement, new

brushes should be run without a load for about 20 minutes in order to seat properly

for efficient operation. Replacement of brushes is possible without removal of the

motor.

The transmission spine may also be replaced which can extend the life of the

D2X by a considerable amount.

.

1. Relationship between machine speed and cutter diameter –parameters

Position of gear lever (used for selection of gearbox speed) should be changed

occasionally in order to keep the gearbox fully lubricated.

Relationship between machine speed and cutter diameter

The cutter diameter

Rotary speed

[rpm]

[inch]

[mm]

1” to 1.5”

12mm to 35mm

400

1.5” to 2”

36mm to 50mm

200

Relationship between machine speed and twist drill diameter

The twist drill diameter

Rotary speed

[rpm]

[inch]

[mm]

0.04 to .5”

3.5mm to 13mm

400

9/16” to 7/8”

14mm to 22mm

200

D2X

- 15 -

V. Parts List and Exploded Drawings

ITEM

PART NUMBER

DESCRIPTION

Q-TY

1

KLN-0103-01-00-00-0

WEDGE MT2

1

2

DZW-0212-12-00-00-0

SPOKE HANDLE INCLUDING KNOB (ASSY)

3

3

UCW-0220-00-00-01-0

ARBOR SET - AMT2-C19/2-2

1

4

LNC-0223-00-01-00-0

SAFETY CHAIN

1

5

OSL-0399-17-00-00-0

SAFETY SPRING

1

6

UKL-0399-11-00-00-0

COOLING SYSTEM

1

7

SKR-0399-15-00-00-1

METAL BOX

1

8

KLC-000007

4 MM HEX WRENCH

1

9

KLC-000005

HEX. WRENCH S=2,5

1

10

KLC-000003

FLAT WRENCH S=8

1

11

KLC-000037

HEX WRENCH 5 MM

1

12

OPK-000001

PLASTIC BOX

1

14

PRT-0151-06-13-00-7

BAR L=25

1

15

SPR-000002

SPRING 2x2 MT2

1

16

WYP-0203-06-02-00-0

PLUNGER

1

17

USZ-0203-06-03-00-0

SEAL

1

18

PDK-0203-06-04-00-0

WASHER

1

19

KRP-0220-00-02-00-0

ARBOR BODY

1

20

PDK-0234-00-09-00-0

WASHER II

2

21

KNC-0257-05-03-04-1

CONNECTOR 4x11,5

1

22

TLJ-0284-00-07-00-3

COOLANT RING

1

23

PRS-000009

INTERNAL RETAINING RING 19w

1

25

3

19

18

22

15

4

23

6

17

7

16

2

5

12

26

20

21

14

24

11 10

8

1

9

D2X

- 16 -

ITEM

PART NUMBER

DESCRIPTION

Q-TY

24

PRS-000017

EXTERNAL RETAINING RING 25z

1

25

PRS-000105

SEAL O-RING 25.2x3

2

26

WKR-000032

HEX SOCKET SET SCREW WITH FLAT POINT M10x10

2

ITE

M

PART NUMBER

DESCRIPTION

Q-

TY

1

STJ-0399-01-00-00-1

FRAME ASSEMBLY

1

2

WLK-0212-00-07-00-1

PINION SHAFT

1

3

SZN-0212-10-02-00-2

POWER CORD 230V 3x1.5 WITH STRAIN RELIEF ASSY

1

3

SZN-0075-00-51-00-5

POWER CORD 120V 3x2,08 WITH STRAIN RELIEF ASSY

1

3

SZN-0212-10-02-00-5

POWER CORD 230V 3x1.5 WITH STRAIN RELIEF ASSY

(AU)

1

4

PNL-0300-04-00-06-1

CONTROL PANEL ASSY - 230V

1

4

PNL-0300-04-00-06-0

CONTROL PANEL ASSY - 120V

1

5

KRP-0399-01-01-00-1

MAIN BODY ASSY

1

6

NPD-0399-02-00-00-0

MOTOR ASSY - 230V

1

6

NPD-0399-02-00-00-1

MOTOR ASSY - 120V

1

7

OSL-0399-04-00-00-0

GUARD ASSY

1

9

TLJ-0399-06-00-00-0

BOTTOM SLEEVE

2

10

PDK-000151

NYLON WASHER

4

11

PDK-000161

EXTERNAL TOOTH LOCK WASHER 3,7

4

12

PDK-000060

EXTERNAL TOOTH LOCK WASHER 4,3

1

13

SPR-000030

PUSH SPRING

2

14

WKR-000415

CROSS RECESSED PAN HEAD SELF-TAPPING SCREW 3,5x13

4

15

WKR-000184

CROSS RECESSED PAN HEAD SCREW M4x12

1

16

WKR-000395

HEX SOCKET ROUND HEAD SCREW WITH FLANGE M5x20

2

17

PRS-000019

EXTERNAL RETAINING RING 28z

1

18

PDK-000043

SPRING WASHER 4,1

1

19

LST-0257-01-03-00-0

SLIDE INSERT - LEFT

1

20

DLW-000007

CABLE GLAND WITH STRAIN RELIEF PG11

1

26

2

1

18

5

4

11

10 13

9

16

20

3

28

12

17

29

19

30

34

31

23

26

21

33

24

27

35

10

6

7

36 32

22 25

15

14

D2X

- 17 -

ITE

M

PART NUMBER

DESCRIPTION

Q-

TY

21

LST-0399-01-01-02-1

PRESSURE PLATE

1

22

NKR-000016

NUT M5

3

23

PDK-000017

ROUND WASHER 5,3

5

24

SPR-000043

SPRING 1,6x8x14,5

4

25

WKR-000043

HEX SOCKET SET SCREW WITH FLAT POINT M5x10

3

26

TLJ-000010

SELF-LUBRICATING SLEEVE 28x32x16

2

27

SRB-000086

HEX SOCKET BOLT M5x20

5

28

PDS-0300-01-02-00-0

ELECTROMAGNETIC BASE

1

29

PAS-0212-00-23-00-0

D-RING STRAP

1

30

PDK-000046

SPRING WASHER 6,1

4

31

SRB-000115

HEX SOCKET BOLT M6x25

4

32

WLC-000007

SWITCH START-STOP - 230V

1

32

WLC-000005

SWITCH START-STOP - 115V

1

33

STR-0257-04-03-00-2

ELECTRONIC CONTROLLER SW-31M - 230V

1

33

STR-0257-04-03-00-3

ELECTRONIC CONTROLLER SW-31M - 120V

1

34

FLT-0257-04-12-00-0

INTERFERENCE ELIMINATOR

1

35

MSK-0300-04-01-00-1

PANEL PLATE ASSY

1

36

PNK-000013

MAGNET SWITCH

1

D2X

- 18 -

54

51

33

11

45

38

23

19

9

16

35

25 24

42

1

2

17

8

58

48

52

57

46

20

57

12

52

49

47

21 27

14

56

3

53

4

18

55

50

29

28

10

30

31

15

7

6

40

5

22

32

13

34

44

26

43

37

41

39

36

D2X

- 19 -

NPD-0399-02-00-00-0

MOTOR ASSY - 230V

NPD-0399-02-00-00-1

MOTOR ASSY - 120V

ITEM

PART NUMBER

DESCRIPTION

Q-TY

1

TLJ-0171-00-22-00-0

SWITCH SLEEVE

1

2

SPR-0171-00-23-00-0

SWITCH SPRING

1

3

DZW-0171-00-24-00-0

SHIFT LEVER

1

4

WLK-0202-00-16-00-1

SHIFT PIN SHORT

1

5

KOL-0211-00-10-00-0

GEAR z 52, m=1,25mm

1

6

WPS-0211-00-13-00-1

KEY 6x6x15

1

7

PDK-0211-00-15-00-0

WASHER, THRUST 10x1 (2x2)

1

8

PDK-0211-00-16-00-0

BEARING WASHER 8,1

1

9

WDL-0211-00-28-00-1

SHIFT FORK

1

10

WLK-0211-01-02-00-0

PINION SHAFT z=12 ASSY

1

11

SLN-0399-02-01-00-2

MOTOR ASSY- 230V

1

11

SLN-0399-02-01-00-3

MOTOR ASSY- 120V

1

12

KRP-0399-02-02-00-0

GEARCASE ASSY

1

13

OBD-0399-02-03-00-3

MOTOR HOUSING

1

14

PWD-0399-02-05-00-0

MOTOR WIRE ASSY

1

15

PWD-0399-02-07-00-0

GROUND CONDUCTOR

1

16

WLK-0399-02-08-00-0

PINION SHAFT z12, z20 ASSY

1

17

KLK-000005

SPRING DOWEL PIN 3x14

1

18

PDK-000060

EXTERNAL TOOTH LOCK WASHER 4,3

2

19

WKR-000184

CROSS RECESSED PAN HEAD SCREW M4x12

2

20

WKR-000450

CROSS RECESSED PAN HEAD SCREW M5x10

2

21

TBL-0202-00-30-00-0

GEAR LABEL

1

22

PRS-000017

EXTERNAL RETAINING RING 25z

1

23

PDK-000043

SPRING WASHER 4,1

2

24

PDK-000045

SPRING WASHER 5,1

1

25

WKR-000180

CROSS RECESSED PAN HEAD SCREW M3x5

2

26

SRB-000092

HEX SOCKET BOLT M5x40

4

27

SRB-000090

HEX SOCKET BOLT M5x35

1

28

WLK-0211-00-07-00-0

GEARSHAFT 2x2

1

29

WPS-0211-00-17-00-1

KEY 3x3,7

1

30

KOL-0399-02-08-01-0

HELICAL INPUT GEAR z46

1

31

LOZ-000055

BALL BEARING 8x22x7

1

32

PKR-0399-02-01-01-3

MOTOR COVER

1

33

WRN-0399-02-01-10-0

ARMATURE ASSY - 230V

1

33

WRN-0399-02-01-10-1

ARMATURE ASSY - 120V

1

34

KNC-0399-02-04-00-1

ARMATURE TOOTH END z12

1

35

KRW-0400-02-01-02-0

GUIDE FAN

1

36

OBD-000024

UPPER HOUSING

1

37

PDK-000157

SPRING WASHER

1

38

SPR-000042

BRUSH SPRING

2

39

SCZ-000022

BRUSH - 230V

2

39

SCZ-000021

BRUSH - 115V

2

40

WKR-000407

CROSS RECESSED PAN HEAD TAPPING SCREW M4x20

4

41

STN-000027

FIELD - 230V

1

41

STN-000026

FIELD - 120V

1

42

SRB-000295

HEXAGON BOLT M5x57

2

43

LOZ-000055

BALL BEARING 8x22x7

1

D2X

- 20 -

NPD-0399-02-00-00-0

MOTOR ASSY - 230V

NPD-0399-02-00-00-1

MOTOR ASSY - 120V

ITEM

PART NUMBER

DESCRIPTION

Q-TY

44

LOZ-000025

BALL BEARING 12x28x8

1

45

WRZ-0399-02-02-02-0

SPINDLE

1

46

LST-0399-02-02-03-0

GEAR RACK

1

47

KRP-0399-02-02-11-1

GEARCASE

1

48

PRS-000035

INTERNAL RETAINING RING 62w

1

49

KLK-000034

DOWEL PIN 4n6x14

1

50

PRS-000017

EXTERNAL RETAINING RING 25z

1

51

PRS-000021

EXTERNAL RETAINING RING 30z

1

52

PDK-000045

SPRING WASHER 5.1

2

53

LOZ-000028

BALL BEARING 25x47x12

1

54

LOZ-000075

BEARING 30x62x16

1

55

LOZ-000006

NEEDLE BEARING 8x12x10

1

56

LOZ-000009

NEEDLE BEARING 10x16x10

1

57

SRB-000086

HEX SOCKET BOLT M5x20

2

58

PLC-0399-05-00-00-0

STOP ROD

1

SMR-000001

GREASE LUBRIPLATE BP1

0,39 kg

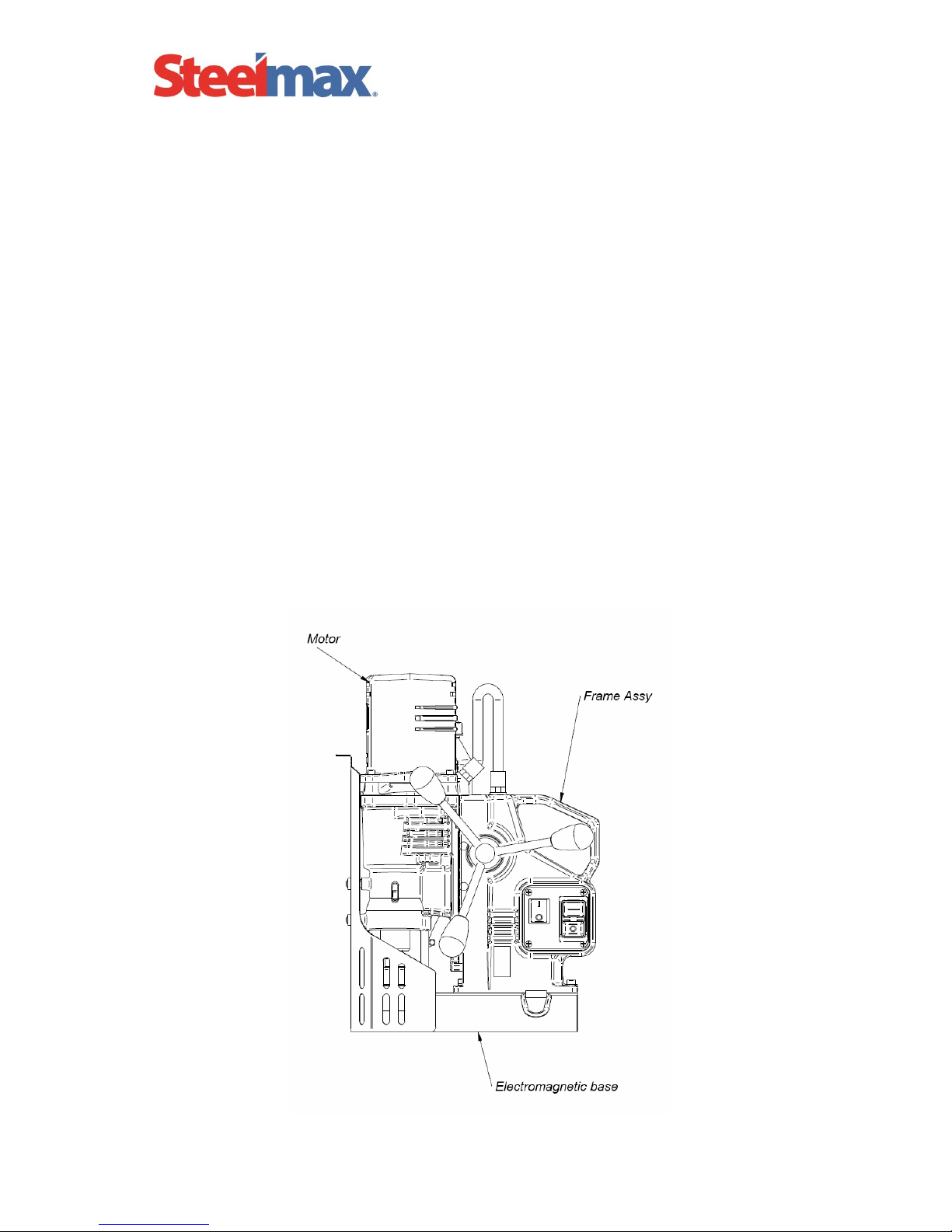

Other manuals for D2X

1

Table of contents

Other SteelMax Drill manuals

SteelMax

SteelMax D1PRO User manual

SteelMax

SteelMax D200XT User manual

SteelMax

SteelMax D3X R User manual

SteelMax

SteelMax SM-D2 User manual

SteelMax

SteelMax D4X User manual

SteelMax

SteelMax D1 AUTO User manual

SteelMax

SteelMax SM-D1 User manual

SteelMax

SteelMax SM-D1 User manual

SteelMax

SteelMax SM-D1 User manual

SteelMax

SteelMax D2X User manual

Popular Drill manuals by other brands

Hilti

Hilti TE 60-ATC-AVR operating instructions

Festool

Festool PDC 18/4 Li Original operating manual

Villager

Villager VLN 1609 Original instruction manual

Milwaukee

Milwaukee BF-312 Service parts list

HERKULES

HERKULES HBH 1000 operating instructions

Wolfcraft

Wolfcraft 5027000 Translation of the original operating instructions