06/14 Model 7501/7501T/7501T240 Page 4 of 7

B. If water is discharged for any reason – follow Procedure 1 or Procedure 2 of

Step 2 above to ensure that water quality is maintained.

© 2016 Haws®Corporation – All Rights Reserved

HAWS® and other trademarks usedin these materials are the exclusive property of Haws Corporation

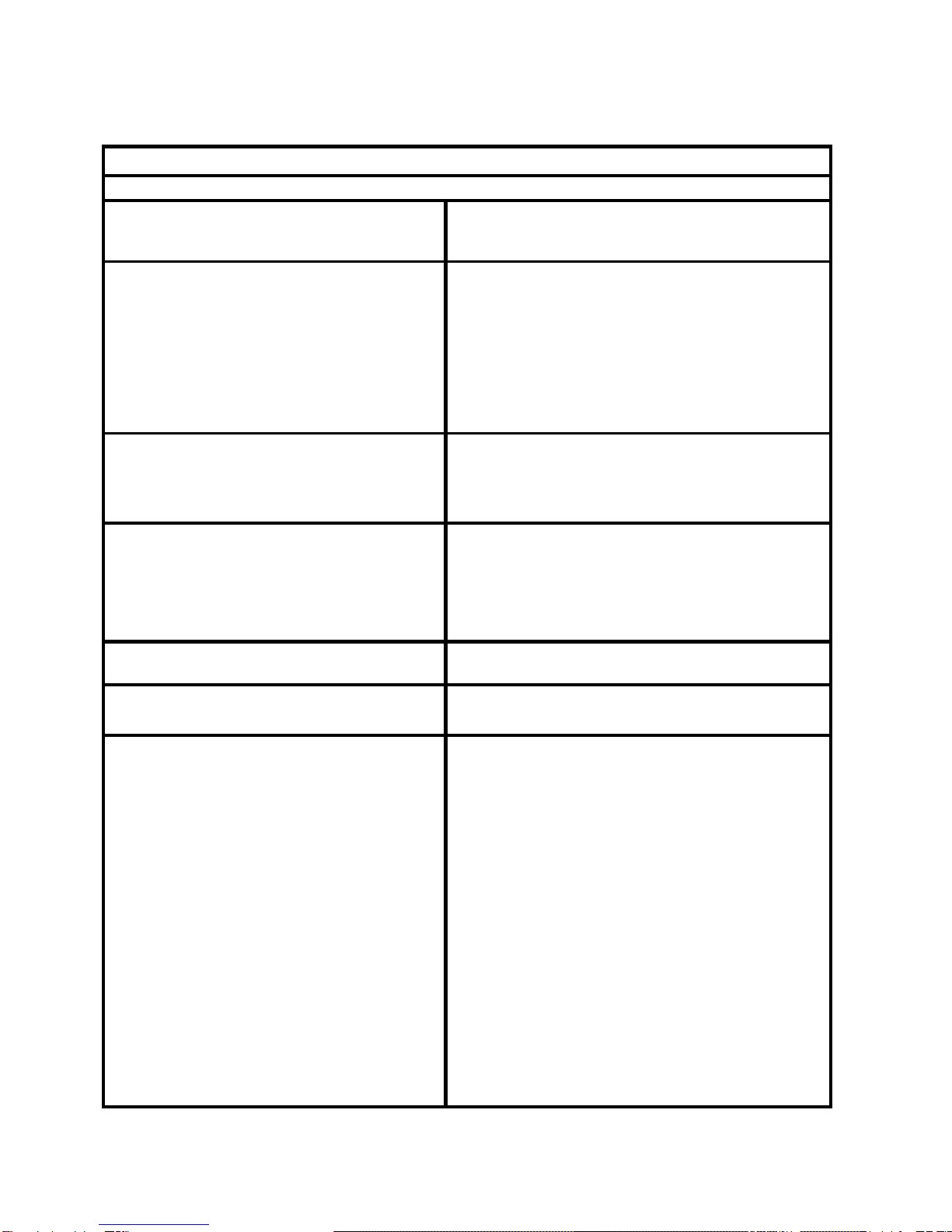

TROUBLESHOOTING

PROBLEM REPAIR CHECKLIST

1. No flow. 1. a. Tank empty. Refill tank (8.75 gallons).

b. Obstruction in line or fitting. Clear

obstruction.

2. Poor flow from eyewash head(s). 2. a. Tighten head assembly.

b. Check for obstructions. If necessary,

remove eyewash head(s), clean and

reassemble. To reassemble head, place

cap screw through head and thread into

head anchor two or three turns. Tilt head

assembly and work anchor legs into

eyewash armholes. Tighten assembly.

Check for leaks.

3. Water leak between joints or fittings. 3. a. Pull hose off fitting. Smooth raised plastic

edge on center of fitting. Return hose and

hose clamp to original position.

b. Tighten hose clamp(s) with pliers.

4. Water leaking from eyewash heads. 4. a. Check to see if water level has exceeded

water fill line (indicated on side of unit). If

so, remove excess water till fill line is

reached.

b. Make sure unit is level from front to back

and left to right.

5. Eyewash flows for less than 15

minutes. 5. a. Fill water level in eyewash tank even with

water fill line (indicated on side of unit.

6. Excessive water loss 6. a. Check unit for leaks. Some loss due to

evaporation is normal.

7. Heater doesn’t turn on. (Model

7501T/7501T240) 7. a. Not plugged in or no power to plug.

Check GFCI and circuit breaker (7501T

only).

b. If ambient temperature is high and

doesn’t allow the water temperature to

drop below 68°F (20°C) the heater may

not switch on. Heater settings are: Non-

adjustable thermostat preset to switch at

73°F ± 5°F (23° ± 3°C). Test the

thermostat and heater function by

applying ice in a circular motion to

thermostat location. Apply ice to this

location for approximately 3-5 minutes.

The heat trace cable should become

warm to the touch when operating

properly. Thermostat locations are

indicated on Installation Drawing page 7

of 7.