Hayward DuraNiche User manual

1. All DuraNiche™ underwater lighting fixture housings are Underwriters Laboratories (UL) Listed under File E 39338- Category

WBDT. These niches are New York City (NYC) Bureau of Electrical Control approved for use with low voltage (12 volt) lighting fix-

tures. U.L. Listed for fresh water and complies with 1999 National Electrical Code [NEC].

2. DuraNiche™ model SP0600U and SP0607 underwater fixture housings are UL Listed only for use with Hayward Submersible

Light Fixture Series SP 0540, SP 0570, SP 0580 and SP 0580S. Model SP 0601 Underwater Light Fixture Housing (Niche) is UL

Listed for use with Hayward Submersible Light Fixture Series SP 0590.

3. All DuraNiche™ underwater lighting fixture housings must be installed in compliance with Article 680 of the National Electrical

Code (NEC) or other applicable electrical codes and with any applicable building codes. Article 680 requires that light fixtures be

installed with the top of the fixture lens at least 18 inches below the normal water level of the pool or spa.

4. All DuraNiche™ underwater lighting fixture housings are provided with three (3) UL Listed

Conduit Fittings. A 1" trade size -45° sweep elbow is provided for the purpose of directing

the conduit pipe towards the SP 0680/ SP 0681 Listed Junction Box location. A 1" conduit

pipe coupling is provided for the purpose of connecting the conduit pipe to the 45° sweep

elbow. A 1" - 3/4" reducer bushing is provided to permit the use (in conjunction with the 1"

coupling) of 3/4" conduit pipe. These conduit fittings must be cemented to the fixture hous-

ing (niche), field supplied conduit pipe and to other conduit fittings using approved PVC

primer and cement.

5. All DuraNiche™ underwater lighting fixture housings are provided with a combination bonding/grounding connector. The outside

connection is the bonding connector as required by Article 680-22 of the NEC. The NEC requires that the bonding wire be AWG 8

or larger. Local codes may require a continuous loop and may require that the bonding point on the fixture housing (niche) be

encapsulated. The inside connection is the grounding connector as required by Article 680-20 (b) of the NEC. The NEC requires

that where a nonmetallic conduit is used, an AWG 8 insulated copper conductor be installed in this conduit. This conductor is to be

connected to the niche grounding connector. The connector and wire termination must be encapsulated in 3M Inc. Scotch Cast

Wet Niche Potting Compound No. 2135 (UL File E130394) or equivalent to protect such connection from the possible deteriorat-

ing effect of pool water.

6. All DuraNiche™ niches are equipped with Internally-threaded connection for pressure testing of conduit line before installing light.

HAYWARD®

DuraNiche™SERIES

UNDERWATER LIGHTING FIXTURE HOUSINGS

MODEL NO. SP0600U-FOR CONCRETE POOLS

MODEL NO. SP0601U-FOR CONCRETE POOL/SPA

MODEL NO. SP0607U- FOR VINYL/FIBERGLASS POOLS

Approved for use by NYC

Department of Buildings

INSTALLATION INSTRUCTIONS

SAVE THESE INSTRUCTIONS

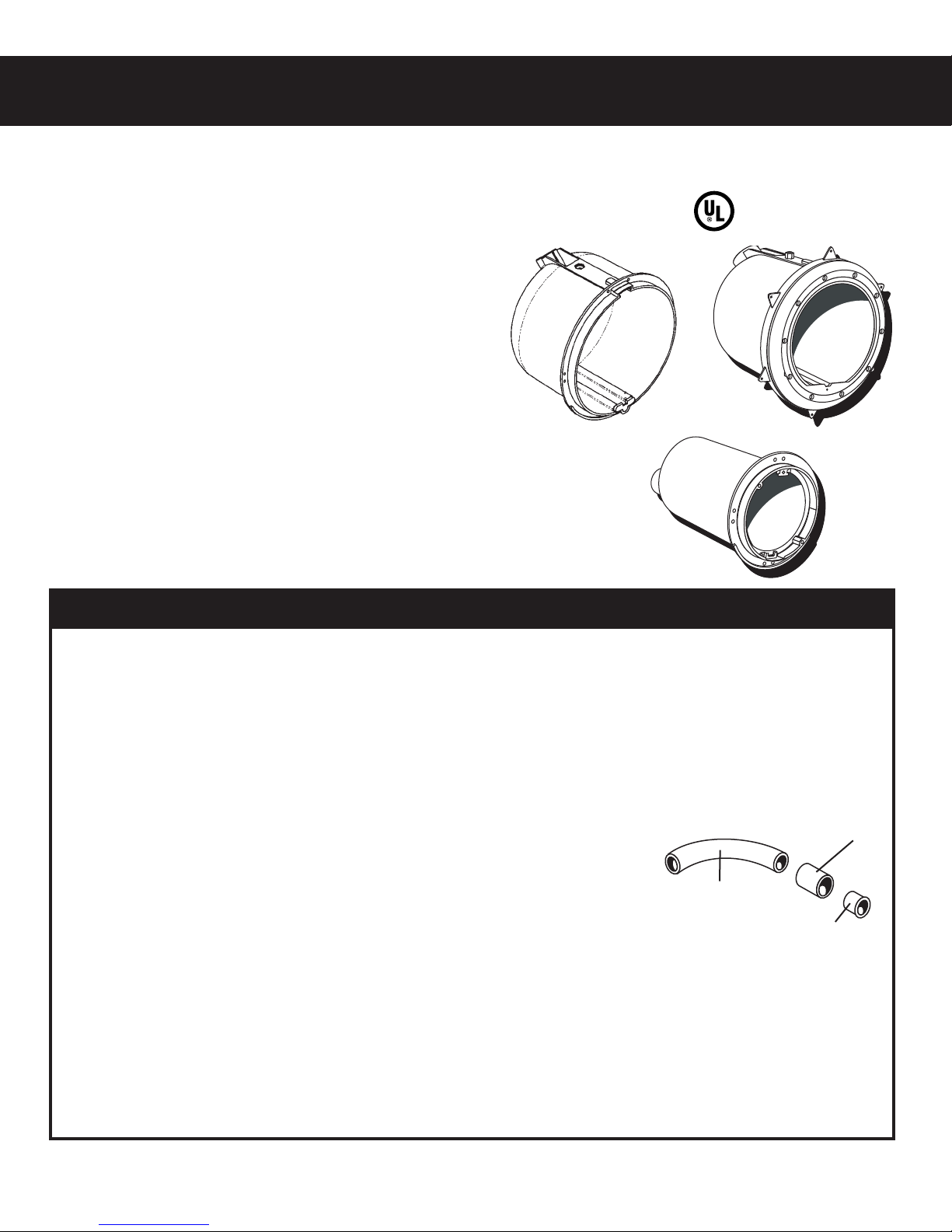

Unlike metallic niches, DuraNiche™ niches are

injection-molded of PVC for superior performance,

non-corrosive durability and plumbing versatility -

plus the lowest installed cost.

The ability to accept PVC over expensive metal

conduit enables DuraNiche™ to offer true bottom

line savings in materials, as well as time to install.

DuraNiche™ comes in three models for concrete/gunite pools,

vinyl/ fiberglass pools, or for concrete/gunite spas. When paired

with a Hayward AstroLite™ or AstroLite II™ light fixture, you have

the best quality and value in a lighting system available anywhere.

To facilitate installation, all DuraNiche™ fixture housings are

packed with U.L. listed conduit fittings (reducer, elbow, and cou-

pling.)

IS0600UA-03 Rev A

SP0600U

SP0601U

SP0607U

IMPORTANT INFORMATION REGARDING ALL MODELS

45° ELBOW

(SP0600M)

UL LISTED CONDUIT

FITTINGS

1” COUPLING

(SP0600N)

1” TO 3/4”

REDUCER

(SP0600P)

FEATURES COMMON TO SP0600U AND SP0601U- FOR CONCRETE POOLS

1. 3/4" set-back plaster flange with tie-off holes to secure to rebar and assure positive positioning during guniting.

2. Unique 90° ledge at the flange bottom prevents "slumping" during plastering.

3. Niche cover (see back page) included with each niche, protects the niche and mounting threads during guniting.

4. The SP0601U small diameter niche has extra space for easy coiling and storage of the relamping cord.

Models SP0600U (Pool) and SP0601U (Spa) Underwater Lighting Fixture Housings are intended for installation in

pools or spas with floors and walls formed of gunite or concrete (shotcrete) with a concrete reinforcing bar (rebar)

frame. Gunite is a mixture of Portland Cement and sand while shotcrete is a high strength (4000 psi) concrete utiliz-

ing Portland Cement and small size aggregate.

The outside shape of the pool or spa is formed from SteelTek or other suitable material.

In some cases, the excavated dirt wall will serve as the outside form. The inside wall of

the pool or spa is formed from rebar that is bent to the desired shape (See Illustration A ).

The distance between the outer and inner wall is called the beam and is typically 8 to 12

inches. Rebar steel should be set at 10” for a 12” beam and 8” for a 10” beam. The dis-

tance between the niche flange and the outer wall should be the beam dimension. At all

points where the rebar crosses, tie wire is used to connect the rebar securely.

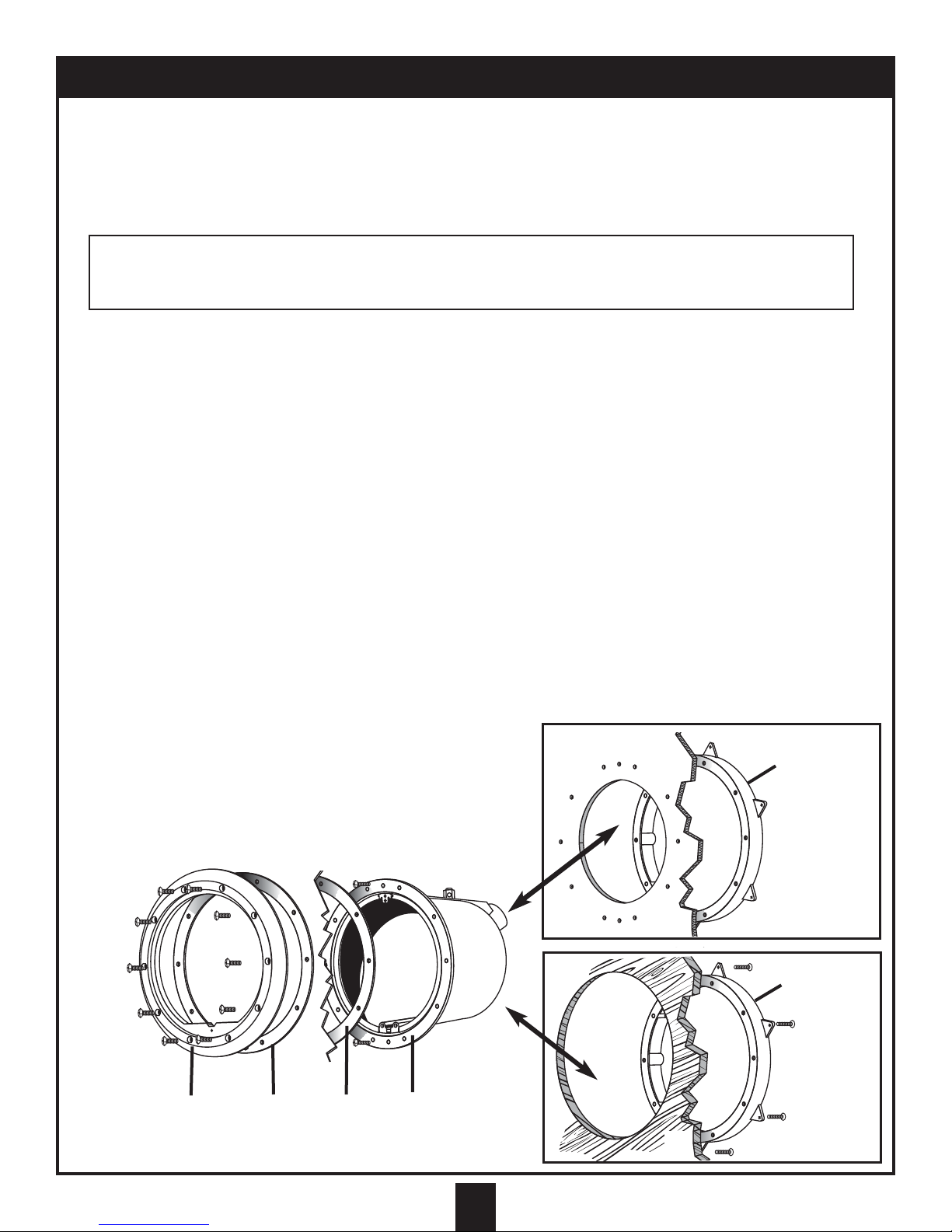

1. Position the Model SP 0600U (Pool) or SP 0601 U (Spa) between adjacent rebars

such that the niche is held on four sides by sections of rebar. At the time the niches

are installed it may be necessary to add sections of rebar or move existing sections to

one side or another in order to insure that the niche is held securely. See illustration

(B)

THE NEC REQUIRES THAT THE TOP OF THE LIGHT LENS BE AT LEAST 18 INCH-

ES BELOW THE WATER LEVEL. BE SURE TO POSITION NICHE SO THAT YOU

COMPLY WITH THIS REQUIREMENT. SOME INSTALLERS POSITION NICHE 24

INCHES BELOW ANTICIPATED WATER LEVEL TO AVOID ANY INSPECTION

AUTHORITY ISSUES WITH THIS REQUIREMENT.

2. Once the niche(s) has been securely positioned (wedged) in the rebar it must be

securely tied to the rebar with tie wire. Before tying niche in place make certain that

niche is (vertical) plumb, and square to the form and that top of niche (where retaining

screw is located) is at highest point at the 12 O’Clock posiiton. The flanges of Niche

Models SP0600U and SP0601U are provided with .187" diameter holes through which

tie wire may be routed to facilitate securing the niche to the rebar. Tie wire should also

be wrapped tightly around the outer circumference of the niche and then tied to the

rebar. Once the niche is tied in place confirm that it is still plumb and that the distance

from the outer wall to the niche flange is the correct beam dimension

NOTE: The rebar will be approximately 2 inches from where the inside finished surface of

the pool will be. You must be sure to leave approximately 2” between the DuraNiche™

flange and the rebar (see illustration C)

3. After attaching the niche to the rebar of the pool wall and cementing conduit and conduit

fittings in place and connecting the #8 AWG bonding wire to the bonding connector as

described, install the provided DuraNiche™ Cover. The niche cover must be installed in order to prevent gunite or

concrete from entering the inside of the niche during the pouring/shooting process. Cover should be left in place until

the light is installed in the niche. (see illustration C)

4. The outside bonding connection must be inspected before the concrete/gunite, pouring/shooting operation. Follow

applicable codes. It is also necessary to keep concrete or gunite from hardening on the outer edge and flange of the

niche during pouring/shooting.

5. Once the concrete/gunite has completely dried, the niche is ready to be "plastered". Plaster is typically a mixture of

white Portland Cement and marble dust along with some pigment chosen to give the pool water the desired color.

The "plaster" is applied about 1" thick in the area surrounding the niche. The distance between the front edge and

the flange of the niche is filled with plaster.

18” TO

24” MINI-

MUM

2”

NICHE

COVER

8” TO 12”

A

B

C

2

INSTALLATION INSTRUCTIONS FOR SP0600U AND SP0601U

FEATURES EXCLUSIVE TO SP0607U- FOR VINYL/FIBERGLASS POOLS:

1.Attractive, injection-molded Duralon™ face rim assembly for corrosion-free performance.

2.Fits all standard punch designs, no tooling modifications are required.

3.Incorporates the dependability of Hayward's proven wall panel sealing method.

A. FOR VINYL LINED METAL WALL, FIBERGLASS PANEL OR FIBERGLASS POOLS

1. If not pre-punched by factory, drill and cut out wall panel sections as per dimensions below:

METAL OR FIBERGLASS PANEL CUT-OUT

CIRCULAR PANEL CUTOUT - 10 ¾" MAX. 10 5/8 MIN.

DRILL OR PUNCH - TEN (10) 5/16" HOLES ON 11 ½" B.C., SPACED 36°

DRILL OR PUNCH - TWO (2) ¼" HOLES ON 11 ½" B.C. SPACED 180°

2. Insert shell through panel section from interior of pool, securing Grounding Bracket at TOP (12 O'clock). For fiberglass

pools (without liner): Caulk rear side of shell flange with silicone or other suitable sealing compound prior to inserting shell

through pool wall.

3. Align the securing screw holes (at top and bottom) of the shell with those of the wall panel and insert the two pan head

securing screws through shell and panel. This step may be eliminated for fiberglass pools (without liner).

4. Align the holes of the backup rim with those on the exterior side of the wall panel and fasten the shell and backup rim to the

wall panel with the two No. 13 x 5/8" self-tapping pan head securing screws. For fiberglass pools (without liner): Caulk

front surface of backup rim prior to installing.

5. Align holes in gasket with holes in shell and affix to shell with small quantity of adhesive. Cement to hold gasket in place.

(Two large holes in gasket will fit over the pan heads of the securing screws.)

6. If vinyl lined pool, install liner before proceeding with Step 7.

7. Align second gasket (not required for fiberglass pools without liner) and face plate and fasten tightly to shell assembly with

ten (10) No. 13 x 1 ¼" flat-head self-tapping screws provided. Use a properly sized Phillips screwdriver to tighten these

heavy-duty screws. (Note: Make sure that the two countersinks on the back of faceplate line up with the heads of the two

securing screws.) If vinyl liner pool, pierce liner through faceplate holes one at a time prior to inserting screws. Secure

DuraNiche™ to pool with screws following this sequence:

a. FACEPLATE b. GASKET c. VINYL LINER (OPTIONAL)

d. GASKET e. DuraNiche™ f. POOL PANEL g. BACKUP RING

8. Be sure to follow pool manufacturer's instructions. If vinyl lined pool, cut out liner along inside edges of faceplate.

B. FOR WOOD OR FIBER PANEL VINYL LINER POOLS

1. Cut out wall panel to 12 3/8" maximum, 12 1/8" minimum O.D. (Approximately 1/8 " larger than O.D. of backup ring).

2. Insert backup ring through circular hole, from rear of panel, and fasten to rear of panel with (6) brass wood screws of prop-

er length (not furnished).

3. Insert shell through panel from interior of pool, securing

Grounding Bracket at TOP (12 o'clock).

4. Align the two securing screw holes at top and bottom of the shell with

those of the backup ring with two (2) No. 13 x 5/8" self-tapping pan

head securing screws.

REFER TO STEPS 5 THROUGH 8 AS ABOVE.

INSTALLATION INSTRUCTIONS FOR SP0607U

(10) #13 1 1/4” SCREWS

3

abd

g

g

c

e

f

f

(6) BRASS SCREWS

(NOT FURNISHED)

(2) #13 5/8” SCREWS

FOR VINYL

LINED METAL

WALL, FIBER-

GLASS

PANEL OR

FIBERGLASS

POOLS

FOR WOOD

OR FIBER

PANEL

VINYL

LINER

POOLS

A

B

PRODUCT SPECIFICATIONS

Hayward Pool Products Worldwide Locations

Hayward Corporate

Headquarters

Hayward Pool Products, Inc.

900 Fairmount Avenue

Elizabeth, NJ 07207, USA

Tel: 908 351 5400

Fax: 908 351 5675

Hayward Pool Products, Inc.

2875 Pomona Boulevard

Pomona, CA 91768, USA

Tel: 909 594 1600

Fax: 909 598 6905

Hayward Pool Products

Canada, Inc.

2880 Plymouth Drive

Oakville, Ontario

CANADA, L6H 5R4

TEL: 905 829 2880

FAX: 905 829 3636

Hayward Pool Products Europe:

Parc Industriel de la Plaine de L‘Ain

Allee Des Chenses

01150 Saint Vulbas

FRANCE

TEL: 33 4 74 46 24 70

FAX: 33 4 74 46 24 87

Hayward Iberica S.A.

Carretera Nacional III, KM 333, 7

Nave 2

E-46930 Quart De Poblet,

Valencia, SPAIN

TEL: 34 6 152 3454

FAX: 34 6 152 3357

Hayward/IMG

International Marketing Group

801 Corporate Center Drive,

Suite 110

Pomona, CA 91768, USA

Tel: 909 620 4041

Fax: 909 620 1249

For further information or consumer technical support, please call (East Coast) 908-351-5400,

(West Coast) 909-594-1600 or visit our web site at www.haywardnet.com

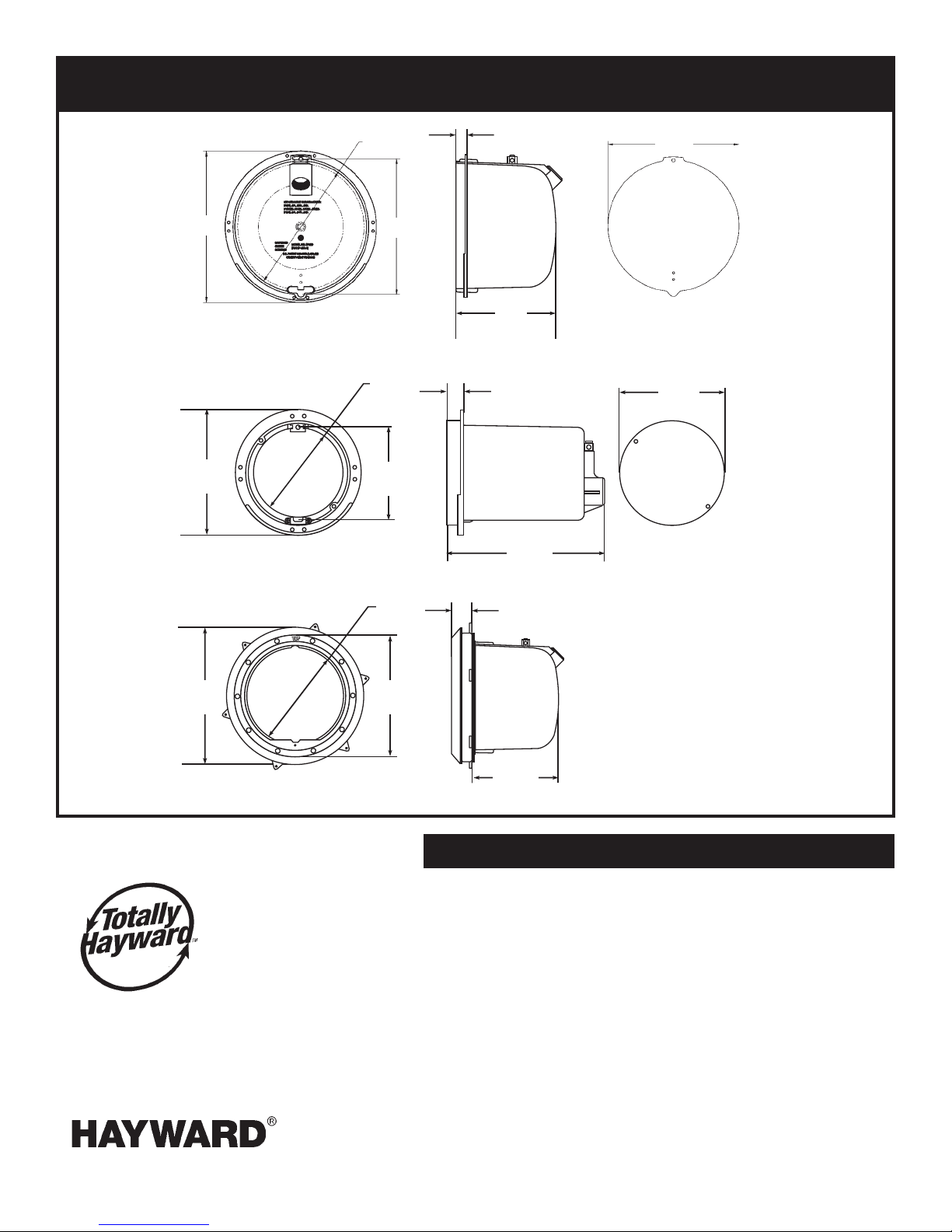

12.21”

6.50” 4.80”

4.63”

10.00”

12.19”

Dimensions varies

with wall thickness

8.156”

.850”

8.150”

6.50”

.850”

7.9”

DuraNiche™

SP0600U

DuraNiche™

SP0601U

Niche Cover-SP0600J

SPX0555Z2- Bolts (1)

Niche Cover-SP0601N

DuraNiche™

SP0607U

NOTE: These items are protected by the following patents:

#5.432.688. Other patents pending

SPX0507A1- Faceplate

SPX0507D- Backup Ring

SPX0506D- Gaskets (2)

SPX0555Z2- Bolts (1)

SPX0607Z1A- Screw Set 10 pcs. (1)

10.0”

10.0”

9.69”

11.13”

This manual suits for next models

4

Popular Camera Accessories manuals by other brands

Viltrox

Viltrox EF-NEX Mount instructions

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual