Assembly Instructions M8100-EN

12.Proceed as follows to calibrate the flow rate metre:

When setting parameters set DFM recognition to the

"integrated" value (in Settings / Miscellaneous), continue with

Step 13.

When setting parameters set DFM recognition to the "modular"

value (in Settings / Miscellaneous), continue with Step 14.

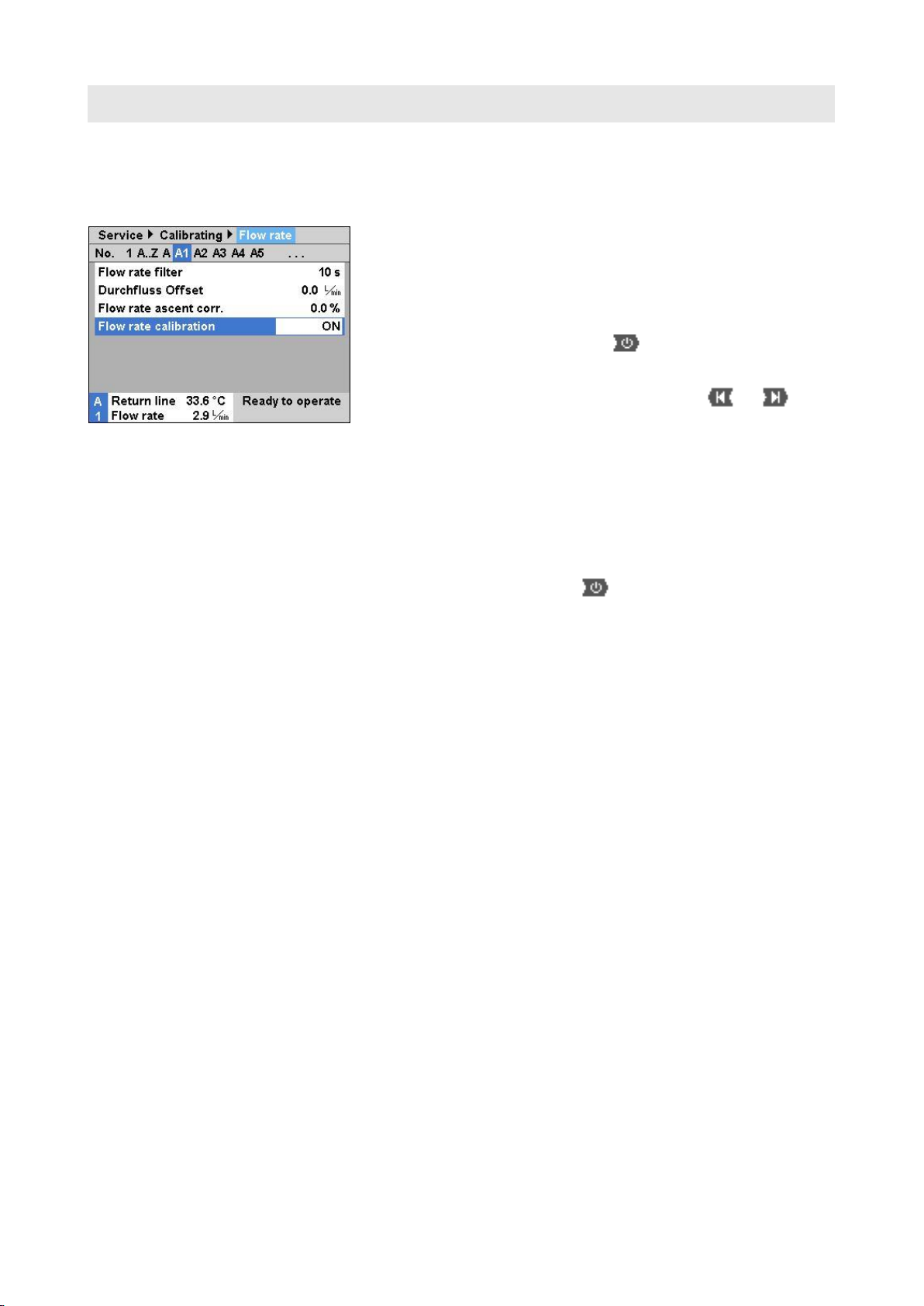

Fig. 8: Calibrate flow rate during integrated

operation

Integrated operation

13. Proceed as follows to calibrate the corresponding flow rate

metre:

(from software version SW51-1 0849B)

In normal operation operate the device at 40 °C for at least 10

minutes.

Only in the case of water units:

If present set the parameter Pressure relief with unit OFF at

Setting / Miscellaneous to "OFF".

Switch the unit off using button and wait at least 10

seconds.

Set corresponding parameter Flow rate ext. 1..8 Calibration at

Service / Calibration / Flow rate external 1 to 4 or Service /

Calibration / Flow rate external 5 to 8 to "ON".

The flow rate is calibrated automatically.

Only in the case of water devices:

If present set the parameter Pressure relief with unit OFF at

Setting / Miscellaneous to "ON".

Switch the unit on with the key.

Fig. 9: Calibrate flow rate during integrated

operation (<SW51-1 0849B)

(up to software version SW51-1 0849B)

In normal operation operate the device at 40 °C for at least 10

minutes.

Set corresponding parameter Flow rate ext. … offset at Service

/ Calibration / Flow rate external 1 to 4 or Service / Calibration /

Flow rate external 1 to 4 to "5 L/min".

Close the corresponding shut-off valve between the feed and

return line and wait for 1 minute.

Read current Flow rate.

Set the parameter Flow rate ext. … offset according to the

following calculation:

Flow rate ext. … offset new = 5 –flow rate as it currently stands

Opening the shut-off valve