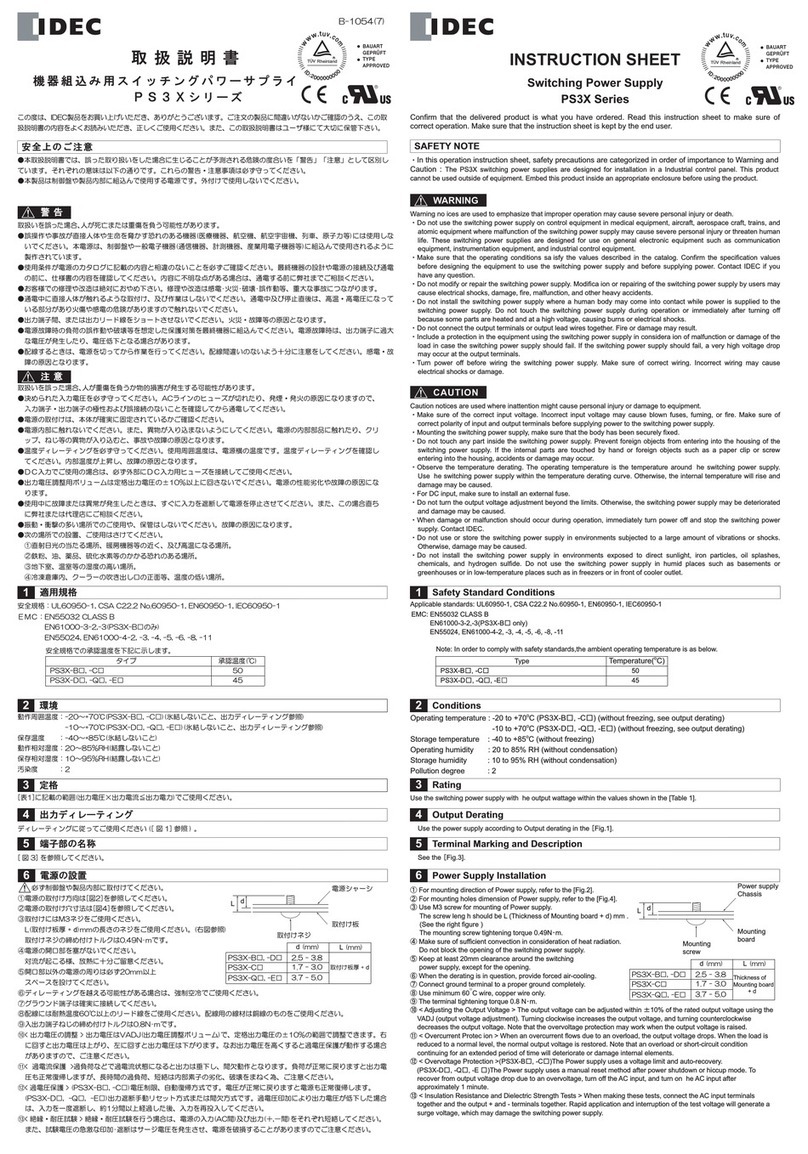

IDEC PS3V User manual

Switching Power Supplies

PS3V

Compact & Reliable

Power Supplies

Flexible installation allows mounting in four directions

Suitable for downsizing of equipment

Compact & efcient switching power supplies

Suitable for downsizing of equipment

(Image: 15W type)

Applications

Wide temperature range

Compact size

IDEC’s reliable technology enable stable power supply and its

compact size allows installation in small equipment.

Operates in a wide temperature range from

–25 to +70°C. Suitable for use in a wide

temperature range from cold to hot environment.

Suitable for global use and various industries.

Warranty period 5 years

Conditons apply to:

Operating temperature 40°C, load rate 60%, standard mount

For details on warranty, see page 11.

Safety equipment at station platforms Other examplesControl panels at plant factories

Complies with safety standards for various facilities

other than factories.

Control panels in facilities such as buildings

Operates in temperatures ranging from –25 to +70°C.

Ideal for use in various storage facilities such as

freezers and refridgerators.

Warehouse storage

Machine tools

Semiconductor manufacturing equipment

Mold injection machines

Food and packaging machines

Multilevel parking garage

Car facilities

Logistics and transport facilities

Agricultural facilities

Energy-related facilities, others

QR codes are printed on the product enabling

easy access to the latest instruction manuals.

Safety Standards

Compact

Operating

Temperature

Push-in

connection

Mounting examples

When PS3V-030AF is mounted (standard mount)

with PS9Z-3E3C mounting bracket

Direct mount DIN rail mount

As a manufacturer

of factory automation

products,

we provide total solutions and

related PLCs & HMI products

One step wiring.

Safe and effiecient push-in connection.

*Push-in models available in summer 2021.

When PS3V-050AF is mounted (standard mount)

with PS9Z-3E3B mounting bracket

Image

Vibration-resistant and maintenance-free (no retightening of

screws). Push-in improves efciency in limited spaces.

Temperature DeratingTemperature Derating

0

20

40

60

80

100 Standard

mount

-30 -20 -10 0 10 20 30 40 50 60 70 80

Ambient temperature (°C)

Output Current (%)

Easy access

(mm)

34

65

Actual

size

50.8

15W 30W50W100W15 0W

Flexible mounting

Mounts in 4-directions Upward

B mount

C mount D mount

A mount

(standard mount)

(Pending)

*Push-in terminal types also available.

(except 15W)

2

Suitable for downsizing of equipment

Compact & efcient switching power supplies

Suitable for downsizing of equipment

(Image: 15W type)

Applications

Wide temperature range

Compact size

IDEC’s reliable technology enable stable power supply and its

compact size allows installation in small equipment.

Operates in a wide temperature range from

–25 to +70°C. Suitable for use in a wide

temperature range from cold to hot environment.

Suitable for global use and various industries.

Warranty period 5 years

Conditons apply to:

Operating temperature 40°C, load rate 60%, standard mount

For details on warranty, see page 11.

Safety equipment at station platforms Other examplesControl panels at plant factories

Complies with safety standards for various facilities

other than factories.

Control panels in facilities such as buildings

Operates in temperatures ranging from –25 to +70°C.

Ideal for use in various storage facilities such as

freezers and refridgerators.

Warehouse storage

Machine tools

Semiconductor manufacturing equipment

Mold injection machines

Food and packaging machines

Multilevel parking garage

Car facilities

Logistics and transport facilities

Agricultural facilities

Energy-related facilities, others

QR codes are printed on the product enabling

easy access to the latest instruction manuals.

Safety Standards

Compact

Operating

Temperature

Push-in

connection

Mounting examples

When PS3V-030AF is mounted (standard mount)

with PS9Z-3E3C mounting bracket

Direct mount DIN rail mount

As a manufacturer

of factory automation

products,

we provide total solutions and

related PLCs & HMI products

One step wiring.

Safe and effiecient push-in connection.

*Push-in models available in summer 2021.

When PS3V-050AF is mounted (standard mount)

with PS9Z-3E3B mounting bracket

Image

Vibration-resistant and maintenance-free (no retightening of

screws). Push-in improves efciency in limited spaces.

Temperature DeratingTemperature Derating

0

20

40

60

80

100 Standard

mount

-30 -20 -10 0 10 20 30 40 50 60 70 80

Ambient temperature (°C)

Output Current (%)

Easy access

(mm)

34

65

Actual

size

50.8

15W 30W50W100W15 0W

Flexible mounting

Mounts in 4-directions Upward

B mount

C mount D mount

A mount

(standard mount)

(Pending)

*Push-in terminal types also available.

(except 15W)

3

PS3V Switching Power Supplies

4

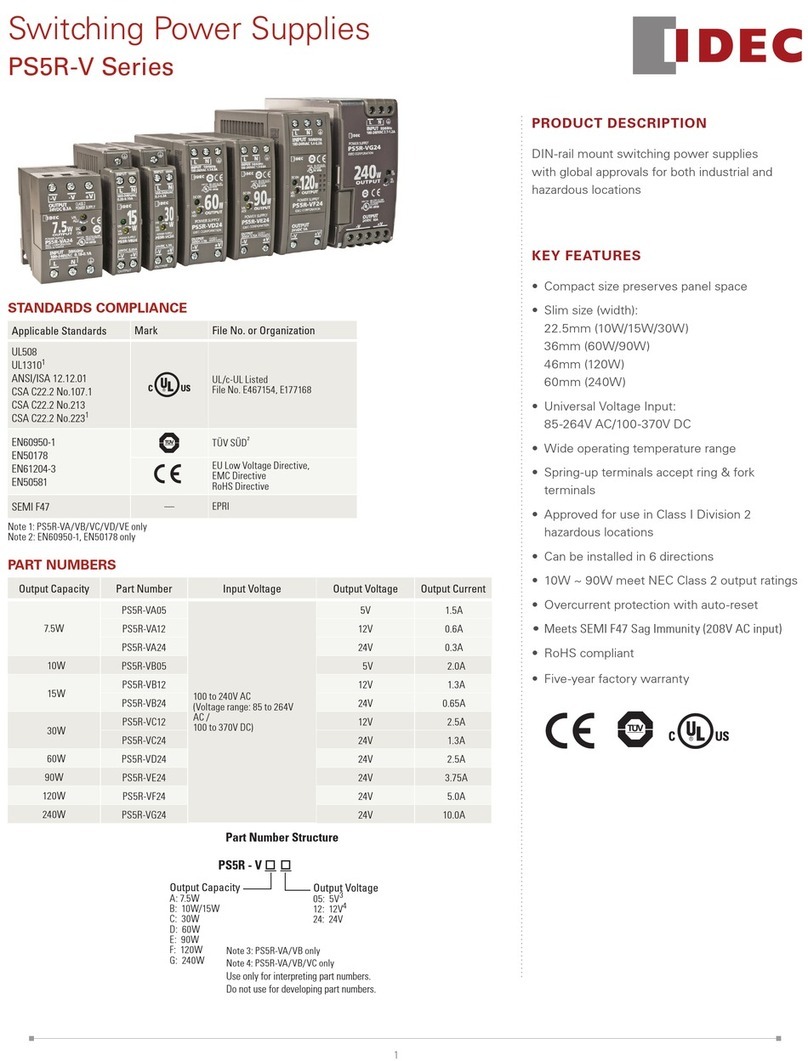

PS3V Package quantity: 1

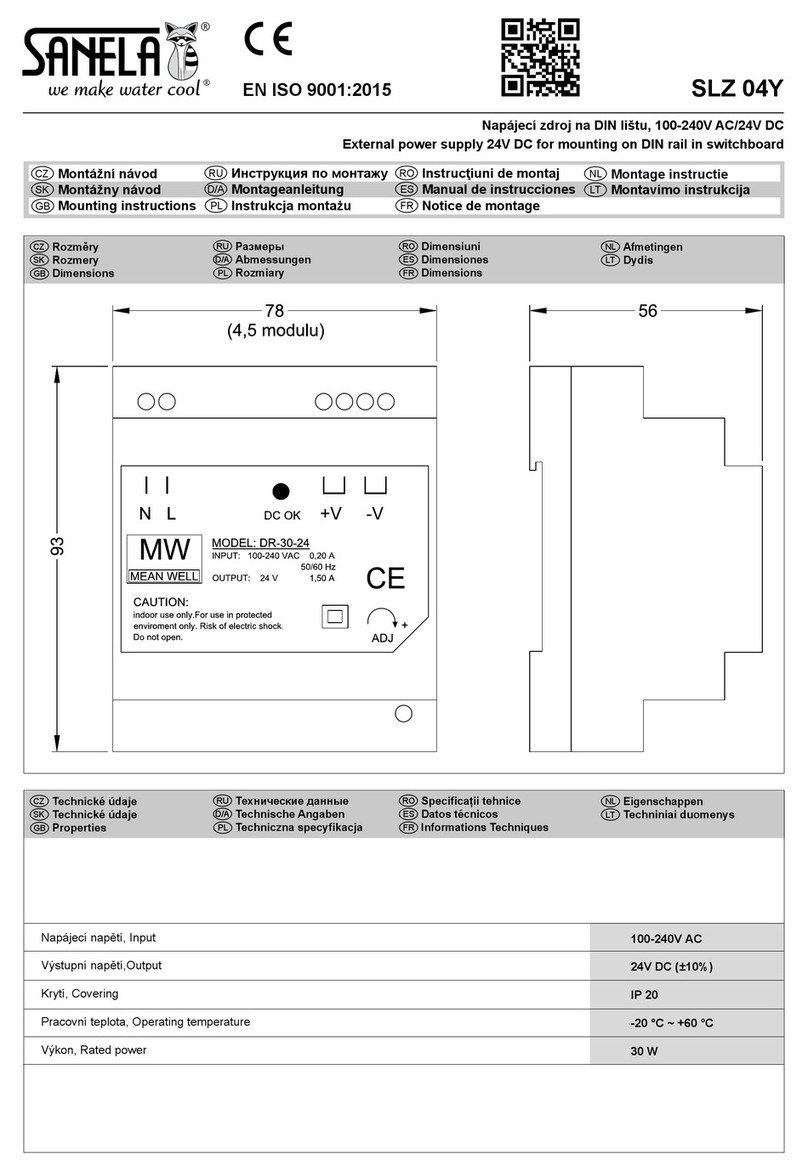

Output capacity Horizontal terminal type Push-in terminal type (*1) Input voltage Output voltage Output current

Part no. Part no.

15W

PS3V-015AF05C —

100 to 240V AC

5V 3.0A

PS3V-015AF12C —12V 1.3A

PS3V-015AF24C —24V 0.63A

30W

PS3V-030AF05C PS3V-030AF05P 5V 6.0A

PS3V-030AF12C PS3V-030AF12P 12V 2.5A

PS3V-030AF24C PS3V-030AF24P 24V 1.3A

50W PS3V-050AF12C PS3V-050AF12P 12V 4.5A

PS3V-050AF24C PS3V-050AF24P 24V 2.3A

100W PS3V-100AF24C PS3V-100AF24P 24V 4.5A

150W PS3V-150AF24C PS3V-150AF24P 24V 6.5A

*1) Push-in models available in June 2021

Accessories

Name Applicable model Part no.

(Ordering no.) Package quantity Remarks

L-shaped mounting bracket (*2)

PS3V-015AF PS9Z-3N3A

1L-shaped mounting brackets for PS3X switching power

supplies can be used.

PS3V-030AF

PS9Z-3E3B

PS3V-050AF

PS3V-100AF

DIN rail mounting bracket

PS3V-015AF PS9Z-3N4B

1DIN rail mounting brackets for PS3X power supplies can be

used.

PS3V-030AF PS9Z-3E4C

PS3V-050AF

PS3V-100AF PS9Z-3E4D

PS3V-150AF

*2) PS3X L-shaped mounting brackets (PS9Z-3N3B) cannot be used.

L-shaped mounting bracket is not available for PS3V-150AF. PS9Z-3N3B L-shaped mounting brackets cannot be used for PS3V-150AF.

Part no. configuration

DIN rail/End clip/Tools Specify the Ordering no. when ordering.

Name Part No. Ordering No. Package quantity Remarks

35mm DIN rail BAA1000 BAA1000PN10

10

Material: Aluminum Weight: 200g Length: 1,000mm

End clip

BNL5 BNL5PN10

10

Weight: 15g Material: Steel Plating: Trivalent zinc chromate

M4 screw used

BNL6 BNL6PN10 Weight: 15.2g Material: Steel Plating: Trivalent zinc chromate

M4 screw used

Crimping tool (for ferrules)

S3TL-CR06D S3TL-CR06D 1

Applicable ferrule: With/without insulated cover

Crimping shape

Auto-adjust stripping tool

S3TL-ST06 S3TL-ST06 1PVC-insulated thin stranded and solid wires

0.08 to 6mm² (28AWG to 10AWG)

Insulated driver

S3TL-D04-25-75 S3TL-D04-25-75 1 Blade size (dimensions: mm)

0.4 2.5 75

PS3V - 015 AF 05 C

Output capacity

015: 15W

030: 30W

050: 50W

100: 100W

150: 150W

Input voltage

100 to 240V AC

Output voltage

05: 5V DC (15W/30W only)

12: 12V DC (15W/30W/50W only)

24: 24V DC

Cover / terminal style

C: with cover/Horizontal terminal type

P: with cover/Push-in type (30W/50W/100W/150W only)

(*available summer 2021)

PS3V Switching Power Supplies

Specifications

Part no.

Item

[15W]

PS3V-015AF

05C / 12C / 24C

[30W]

PS3V-030AF

05/ 12/ 24

[50W]

PS3V-050AF

12/ 24

[100W]

PS3V-100AF24

[150W]

PS3V-150AF24

Input conditions

Rated input voltage 100 to 240V AC

(Voltage range) (*1) 85 to 264V AC (Single phase 2 wire)

Frequency 47 to 63Hz

Input current

(at rated output)

100V: 0.32A (typ)

230V: 0.2A (typ)

100V: 0.66A (typ)

230V: 0.35A (typ)

100V: 1.1A (typ)

230V: 0.6A (typ)

100V: 1.3A (typ)

230V: 0.6A (typ)

100V: 1.9A (typ)

230V: 0.9A (typ)

Inrush current

(Ta = 25°,

cold start)

at 100V AC 40A typ. 18A typ. 18A typ. 18A typ. 18A typ.

at 230V AC 60A typ. 45A typ. 45A typ. 45A typ. 45A typ.

Leakage current 120V: 0.5mA max., 240V: 1mA max.

Efficiency

(TYP.)

(at rated output)

5V

77% (100VAC)

76% (230VAC)

77% (100VAC)

77% (230VAC) – – –

12V 82% (100VAC)

81% (230VAC)

83% (100VAC)

83% (230VAC)

84% (100VAC)

84% (230VAC) – –

24V 84% (100VAC)

83% (230VAC)

85% (100VAC)

84% (230VAC)

87% (100VAC)

87% (230VAC)

85% (100VAC)

88% (230VAC)

85% (100VAC)

88% (230VAC)

Power factor (TYP.)

(at rated output) –––0.98 (100V AC)

0.9 (230V AC)

0.98 (100V AC)

0.95 (230V AC)

Output conditions

Output voltage/Current

5V / 3A 5V / 6A – – –

12V / 1.3A 12V / 2.5A 12V / 4.5A _ –

24V / 0.63A 24V / 1.3A 24V / 2.3A 24V / 4.5A 24V / 6.5A

Adjustable voltage range ±10% (Front, adjustable using V.ADJ volume)

Output holding time

(at rated output)

5V 15ms typ. (100V AC)

120ms typ. (230V AC) 18ms typ. (100V AC)

110ms typ. (230V AC)

– – –

12V 17ms typ. (100V AC)

125ms typ. (230V AC)

– –

24V 20ms typ. (100V AC)

130ms typ. (230V AC)

35ms typ. (100V AC)

35ms typ. (230V AC)

24ms typ. (100V AC)

24ms typ. (230V AC)

Start time 650ms max. (at rated input/output)

Rise Time 300ms max.

(at rated input/output) 200ms max. (at rated input/output)

Constant voltage accuracy

Input uctuation 0.4% max.

Load uctuation 1% max.

Temperature uctuation 0.05%/°C max. (−10 to +50°C)

Ripple

(including

noise)

−25 to −10°C

5V: 8%p-p max.

12V: 6%p-p max.

24V: 4%p-p max.

5V: 8%p-p max.

12V: 6%p-p max.

24V: 4%p-p max.

12V: 6%p-p max.

24V: 4%p-p max. 24V: 4%p-p max.

-10 to 0°C

5V: 5%p-p max.

12V: 2.5%p-p max.

24V: 1.5%p-p max.

5V: 5%p-p max.

12V: 2.5%p-p max.

24V: 1.5%p-p max.

12V: 2.5%p-p max.

24V: 1.5%p-p max. 24V: 1.5%p-p max.

0 to 50°C

5V: 2.5%p-p max.

12V: 1.5%p-p max.

24V: 1%p-p max.

5V: 2.5%p-p max.

12V: 1.5%p-p max.

24V: 1%p-p max.

12V: 1.5%p-p max.

24V: 1%p-p max. 24V: 1%p-p max.

Supplementary

functions

Overcurrent protection 105% min. (auto reset) (*2)

Overvoltage protection

120% min.

(intermittent, auto reset)

Output off at 120% min, reset when re-input

Operation indicator LED (green)

Dielectric

strength

Between input and output terminals 3000V AC, 1 minute

Between input and ground terminals 2000V AC, 1 minute

Between output and ground terminals 500V AC, 1 minute

Insulation resistance 100MΩ min. 500V DC megger (at 25°C, 70% RH) (between input and output terminals, between input and ground terminals)

Operating temperature −25 to +70°C, (no freezing, output derating available)

Operating humidity 20 to 90% RH (no condensation)

Storage temperature −25 to +75°C (no freezing)

Storage humidity 20 to 90% RH (no condensation)

Vibration resistance 10 to 55 Hz, 2G constant, 2 hours each in 3 axes

Shock resistance 200M/s2, 11ms, 1 shock each in 6 axes

Expected life (reference value) (*3)

8 years min. (rated input, load factor 50%, operating temperature +40ºC, standard mounting)

EMC EMI EN61204-3 Class B

EMS EN61204-3 (Industrial)

Safety standards

EN62368-1 (TÜV), IEC 62368-1

UL61010-1, UL61010-2-201, CSA C22.2 No.61010-1, CSA C22.2 No.61010-2-201 (Listing, SELV *all models pending)

UL62368-1, CSA C22.2 No.62368-1-14 (Recognition)

Dimensions (mm) (terminal part except

protrusion)

50.8H×34W×65D 68.5H×34.5W×95.5D 80H×36W×99D 93H×39W×108D 95H×39W×159D

Weight (approx.) 135g 190g 230g 380g 510g

Terminal screw (horizontal type) M3 M3.5

*1) Not subjected to safety standards. Output delay also available.

*2) If overload continues for over 30 seconds, the internal elements may be damaged.

PS3V-015AF is equipped with a thermal shutdown function. When thermal shutdown operates, auto reset does not function until the temperature inside the power

supply drops.

*3)Calculation of the expected life is based on the actual life of the aluminum electrolytic capacitor.

The expected life depends on operating conditions.

5

PS3V Switching Power Supplies

Characteristics

Output current - Operating temperature characteristics (Output derating)

*Conditions: Natural air cooling (operating temperature is the temperature around the

power supply)

Operating temperature by safety standards

UL / c-UL / TÜV

A mount 50ºC

B mount 40ºC

Overcurrent protection characteristics

Output current - Input voltage characteristics (Output derating) (Ta=25ºC)

Output Current (%)

0 100 Over 105

0

100

Output Volta

g

e

(

%

)

Intermittent Operation

0

20

40

60

80

100

-30 -20 -10 0 10 20 30 40 50 60 70 80

Operating Temperature (°C)

B, C, D mount

A mount

(standard mount)

Output Current (%)

85 100 264

0

10

20

30

40

50

60

70

80

90

100

85 90 264

0

20

40

60

80

100

Input Voltage (VAC) 85 100 264

0

20

40

60

80

100

Output Current (%)

Input Voltage (VAC)

Output Current (%)

Input Voltage (VAC)

Output Current (%)

PS3V-015AF / -030AF PS3V-050AF

• Areas indicated with may take time for the output voltage to stabilize.

Overcurrent

detection

Detection

L

N

INPUT

Control

Line lter

Switching

Fuse

Rectier

Rectier

V.ADJ

+

–

Overvoltage

detection

Detection

L

N

INPUT

Fuse

Control

V.ADJ

Line lter

Rectier

Overcurrent

detection

Switching

Rectier

+V

–V

Overvoltage

detection

Block diagram

PS3V-015AF PS3V-030AF, PS3V-050AF

PS3V-100AF, PS3V-150AF

Control

L

N

INPUT

V.ADJ

Smoothing

Active lter

Overcurrent

detection

Rectier

Line lter

Rectier

Fuse +V

–

Detection

Control

Switching

Overvoltage

detection

PS3V-100AF / -150AF

6

PS3V Switching Power Supplies

Mounting direction

upward

D mount

C mount

B mount

A mount

(standard mount)

Marking Name Description Marking Name Description

AC(L),

AC(N) AC input terminal Accepts a wide range of voltage and

frequency. V.ADJ Output voltage

adjustment volume

Allows adjustment within ±10%. Turning

clockwise increases the output voltage.

Ground terminal Be sure to connect the terminal to a proper

ground. LED Operation indicator Lights on when the output voltage is on.

+V, −V DC output terminals Output terminal

PS3V-050AF

Parts Description

PS3V-015AF PS3V-030AF PS3V-100AF PS3V-100AF

Note) Note the terminal arrangement when wiring.

AC (L)

AC (N)

-V

+V

V.ADJ

LED

AC (L)

AC (N)

-V

+V

V.ADJ

LED

AC (L)

AC (N)

-V

+V

V.ADJ

LED

AC (L)

AC (N)

-V

+V

V.ADJ

LED

AC (L)

AC(N)

-V

+V

V.ADJ

LED

+V

-V

AC

(

L

)

AC

(

N

)

-V

+V

V.ADJ

LED

-V

AC

(

L

)

AC

(

N

)

-V

-V

+V

V.ADJ

LED

AC

(

L

)

AC

(

N

)

-V

-V

+V

V.ADJ

LED

AC

(

L

)

AC

(

N

)

-V

+V

+V

+V

-V

-V

V.ADJ

LED

PS3V-050AFPS3V-030AF PS3V-100AF PS3V-100AF

Horizontal terminal type

Push-in terminal type

Note) 15W is not available

for Push-in type.

General tolerance: ±1 mm

Dimensions All dimensions in mm.

65

(78.5)

50.8

15.1

39.1

34

14.4

7.62

(Terminal Centers)

5-M3

(Terminal Screw)

2-M3

2-M3

6.0

25.3

39.1

11.3

(Depth 3.5mm max)

(Depth 3.5mm max)

Horizontal terminal type

PS3V-015AFC

17

10.5

80

34.5

9.5

(Terminal Centers)

5-M3.5

(Terminal Screw)

2-M3

(Depth

6mm max)

95.5

(111)

68.5

8.2

2-M3

(Depth

6mm max)

36.5

1570

PS3V-030AFC

7

PS3V Switching Power Supplies

PS3V-030AFP

PS3V-100AF24C

General tolerance: ±1 mm

Dimensions All dimensions in mm.

PS3V-050AFC

80

45.5

23.555

99

(114.5)

17.5

774

36

2-M3

2-M3

8.2

9.5

(Terminal Centers)

5-M3.5

(Terminal Screw)

(Depth

6mm max)

(Depth

6mm max)

108

(123.5)

49 93

12.5

76

10

18

1477

19 39

3-M3

2-M3

8.2

9.5

(Terminal Centers)

(Depth

6mm max)

5-M3.5

(Terminal Screw)

(Depth

6mm max)

PS3V-150AF24C

159

(174.5)

10

100

95

32

45

78

10

18

14.5

12.5

19

118

35100

19

27

39

57

7-M3.5

(Terminal Screw)

3-M4

(Depth

6mm max)

3-M3

(Depth

6mm max)

2-M4

(Depth

6mm max)

2-M3

(Depth

6mm max)

8.2

9.5

(Terminal Centers)

17

10.5

80

34.5

2-M3

95.5

68.5

(101)

2-M3

36.5

1570

7.5

(Input terminal centers)

(Depth 6mm max)

5.0

(Output terminal centers)

(Depth 6mm max)

80

45.5

23.5

55

99

17.5

774

36

2-M3

2-M3

(104.5)

7.5

(Input terminal centers)

5.0

(Output terminal centers)

(Depth 6mm max)

(Depth 6mm max)

108

49 93

12.5

76

10

18

14

77

1939

3-M3

(113.5)

2-M3

7.5

(Input terminal centers)

5.0

(Output terminal centers)

(Depth 6mm max)

(Depth 6mm max)

159

10

100

95

32

45

78

10

18

14.5

12.5

19

118

35

100

19

27

39

57

3-M4 (Depth 6mm max)

(164.5)

7.5

(Input terminal centers)

(Depth

6mm max)

2-M3

(Depth 6mm max)

2-M3

5.0 (Output terminal centers)

3-M3 (Depth 6mm max)

Push-in terminal type

PS3V-050AFP

PS3V-100AF24P PS3V-150AF24P

8

PS3V Switching Power Supplies

20

203.5

10 6.5

27

2

2-ø3.5

mounting hole

27

72

14

16.539.1

4126

4-ø3.5 hole

A part

3.5×4.5

mounting hole

5-ø3.5 hole

ø3.5

mouting hole

6.5

22.54.5

28

17.5

31

13.5

103

18

80±0.3

74±0.3

18

2.3

77±0.3

L1 L3

L2

H3

H1

35H2

L2

Part no. Applicable model L1 L2 L3 H1 H2 H3

PS9Z-3N4B PS3V-015AFC 93 107 35 5.2 21 50.8

PS9Z-3E4C

PS3V-030AFC 134 136 35 5.2 21 68.5

PS3V-030AFP 134 125 35 5.2 21 68.5

PS3V-050AFC 134 134 35 5.2 21 80

PS3V-050AFP 134 124 35 5.2 21 80

PS9Z-3E4D

PS3V-100AFC 186 186 39.5 5.2 20 93

PS3V-100AFP 186 176 39.5 5.2 20 93

PS3V-150AFC 186 192 39.5 5.2 20 95

PS3V-150AFP 186 182 39.5 5.2 20 95

Part no. Applicable model L2

PS9Z-3N3A PS3V-015AFC 83.5

PS9Z-3E3B

PS3V-030AFC 118.5

PS3V-030AFP 108.5

PS3V-050AFC 125.5

PS3V-050AFP 115.5

PS3V-100AFC 130.5

PS3V-100AFP 120.5

Mounting bracket (L-shaped bracket) Dimensions All dimensions in mm.

Dimensions when mounting bracket is used All dimensions in mm.

DIN-rail mount bracket

L-mount bracket

PS9Z-3N3A (applicable model: 15W) PS9Z-3E3B (applicable model: 30W/50W/100W)

This product is for use in control panels and inside products and

cannot be externally connected.

Do not use the product alone as an Electric Facilities for General Use.

•When using the product, follow the following precautions.

[Precautions on switching power supplies]

•This product is for industrial or general electronic equipment (such as

communication, measurement, and industrial electronic equipment).

Do not use for devices that may cause malfunction or may harm the

body or threaten human life.

•Make sure that the input voltage and output current do not exceed

the ratings. Otherwise, electric shock, re, or malfunction may occur.

•Do not touch the terminals of the switching power supply while input

voltage is applied, otherwise electric shock may occur.

•Take protective measures with the nal product to prevent

malfunctions caused by the switching power supply.

•Operating temperatures should not exceed the ratings. Be sure to

note the derating characteristics. Otherwise, electric shock, re, or

malfunction may occur.

•Blown fuses indicate that the internal circuits are damaged. Contact

IDEC for repair. If only the fuse is replaced, electric shock, re, or

malfunction may occur.

•Do not use the switching power supplies to charge rechargeable

batteries.

•Do not overload or short-circuit the switching power supply for a long

period of time, otherwise the internal elements may be damaged.

•Do not disassemble, repair, or modify the power supplies, otherwise

the high voltage internal part may cause electric shock, re, or

malfunction.

Safety Precautions

9

PS3V Switching Power Supplies

For details on mounting, wiring, and circuit examples, see the instruction manual from the below URL.

URL: https://product.idec.com/?product=PS3V

Instructions

Notes for installation

1. When mounting the PS3V, see page 7.

2. See page 7and 8for mounting hole layout.

3. Use M3 or M4 screw as mounting screws. The tightening torque of

the mounting screw is 0.49N·m.

Power supply chassis

Mounting panel

Mounting screw

6mm max.

(PS3V-015:

3.5mm max.)

4. Do not close the openings of the switching power supply. Ensure

proper heat dissipation by convection.

5. Maintain a minimum of 20 mm clearance around the switching

power supply.

6. When derating of the output does not work, provide forced air-

cooling.

7. Make sure to wire the ground terminal correctly.

8. Use copper wire only. In addition, refer to the below table to select

wire types and number of wires.

Terminal Wire size (Allowable current) Wire type

Input AWG18 to 14

Copper, solid/stranded

Output

AWG18 to 14

(AWG18-7A, AWG16-10A,

AWG14-15A

• Cross section - AWG18: 0.82mm2, AWG16: 1.31mm2, AWG14: 2.08mm2

• See page 11 for Push-in type

9. Recommended tightening torque of terminal screws: 0.8 N·m

(PS3V-015: 0.5N·m)

Adjustment of output voltage

The output voltage can be adjusted within ±10% of the rated output

voltage by using the V.ADJ control. Turning the V.ADJ clockwise

increases the output voltage. Turning counterclockwise decreases the

output voltage. Note that overvoltage protection may function when

output voltage is increased.

Overcurrent protection

The output voltage drops automatically when an overcurrent flows,

resulting in intermittent operation. Normal voltage is automatically

restored when the load returns to normal condition. However,

overcurrent for a prolonged period of time or short-circuit causes the

internal elements to deteriorate or break down.

Overvoltage protection

• PS3V-015:

Voltage limit and auto-recovery method. The switching power supplies

operate normally when voltage returns to normal.

• PS3X-030, -050, -100, -150:

The output is turned off or intermittent operation when an overvoltage

is applied. When the output voltage has dropped due to an overvoltage,

turn the input off, and after one minute, turn the input on again.

Insulation/Dielectric test

When performing an insulation/dielectric test, short the input (between

AC) and output (between + and –). Do not apply or interrupt the voltage

suddenly, otherwise surge voltage may be generated and the power

supply may be damaged.

Noise

Small acoustic noise inside the PS3V may be heard depending on the

input voltage and load, but the performance of the PS3V is not affected.

Series operation

The following series operation is allowed. In (b) series operation,

connect Schottky barrier diodes. Choose (a) series operation when

using the PS3V as positive and negative output power supply. Insert

a Shottky barrier diode for loads such as operational amplifier where

outputs of two power supplies may be connected in series (Load 3).

Select a Schottky diode in consideration of the rated current.

L

N

L

N

+V

–V

L

N

+V

–V

Load

(a)

L

N

L

N

+V

–V

L

N

+V

–V

Load 3

(b)

Load 1

Load 2

Parallel operation

Parallel operation is not possible to increase the output capacity,

because the internal elements and load may be damaged.

Backup operation is a connection method of two switching power

supplies in parallel for emergency. Normally one switching power

supply has a sufficient output. If one switching power supply fails,

another one operates to continue the output. Make sure that the sum

of power consumption by load and diode is not greater than the rated

wattage (rated voltage × rated current) of one switching power supply.

The current of the diode that is used must be more than double the

output current of PS3V. Take heat dissipation into consideration.

+

–

IN

A

C OUT

+

–

IN OUT

Load

D

D

Rust and scratches on metal parts

Hot-dip galvanized steel and bonderized steel are used for the PS3V.

Rust on the edge and scratches on the surfaces may be developed

depending on the storage condition, but the performance of the PS3V

is not affected.

10

PS3V Switching Power Supplies

Warranty

IDEC warranties the PS3V switching power supplies for a period of five

years from the date of shipment.

Scope

In the event of a failure caused by our responsibility within the above

period, we will replace the product. However, if the product is used

under the following conditions, the warranty may not apply even within

the warranty period.

1. Average operating temperature (ambient temperature of switching

power supply) is 40°C maximum.

2. The load is 60% maximum.

3. Input voltage is the rated input voltage.

4. Standard mounting style

If we are responsible for a failure that occurs during the warranty

period described at left, we will repair the product or replace it with an

alternative product.

Please note that we will not be liable for any damage caused by

the failure of the delivered product. In addition, please note that the

warranty does not apply to the following cases.

1. Inappropriate handling, or operation beyond the specications.

2. Modication or repair by other than IDEC.

3. Failure caused by reasons other than the switching power supply.

4. Failure caused by natural disasters.

Warranty

Accessories and wiring for Push-in terminals

Wire size and recommended ferrules (Push-in terminal type only)

Ferrules with insulated covers

Applicable Wire

(Stranded Wire)

Wire Strip

Length

(mm)

Part No.

(Ordering No.)

AWG mm2

For 1

wire

18 0.75 12 S3TL-H075-16WW

17 1.0 12 S3TL-H10-16WY

16 1.5 12 S3TL-H15-16WR

For 2

wires 18 0.75 21 S3TL-J075-19WWS

Recommended tools (Optional. See page 4for details)

Name Part No. (Ordering No.)

Crimping tool S3TL-CR06D

Auto-adjust stripping tool S3TL-ST06

Insulated screwdriver S3TL-D04-25-75

Note) Use a at blade screwdriver with a blade size of 0.4×2 to 2.5 mm.

0.4mm

2.5mm

Wiring procedure

Wiring

(1) Insert the solid wire or stranded wire with

ferrule into the terminal entrance.

* If the shape of the ferrule becomes trapezoidal

after the clamping, insert the ferrule with the long

side of the clamped part parallel to the pusher.

* When inserting stranded wires directly, make sure

that the pusher in pressed down and there are no

loose wires.

Note) When inserting a ferrule terminal with two

wires, insert the insulated cover part vertically to

the pusher.

Insulated cover part

(2) After wiring, tug lightly to make sure that the wire is properly

connected.

Removing the wire

(1) Press the pusher using a insulated

screwdriver.

(2) Remove the wire by pressing the pusher.

Pusher

11

PS3V Switching Power Supplies

1. Notes on contents of Catalogs

(1) Rated values, performance values, and specification values of IDEC products

listed in this Catalog are values acquired under respective conditions in

independent testing, and do not guarantee values gained in combined

conditions.

Also, durability varies depending on the usage environment and usage

conditions.

(2) Reference data and reference values listed in Catalogs are for reference

purposes only, and do not guarantee that the product will always operate

appropriately in that range.

(3) The specifications / appearance and accessories of IDEC products listed in

Catalogs are subject to change or termination of sales without notice, for

improvement or other reasons.

(4) The content of Catalogs is subject to change without notice.

2. Note on applications

(1) If using IDEC products in combination with other products, confirm the

applicable laws / regulations and standards.

Also, confirm that IDEC products are compatible with your systems, machines,

devices, and the like by using under the actual conditions. IDEC shall bear no

liability whatsoever regarding the compatibility with IDEC products.

(2) The usage examples and application examples listed in Catalogs are for

reference purposes only. Therefore, when introducing a product, confirm the

performance and safety of the instruments, devices, and the like before use.

Furthermore, regarding these examples, IDEC does not grant license to use

IDEC products to you, and IDEC offers no warranties regarding the ownership

of intellectual property rights or non-infringement upon the intellectual

property rights of third parties.

(3) When using IDEC products, be cautious when implementing the following.

i. Use of IDEC products with sufficient allowance for rating and

performance

ii. Safety design, including redundant design and malfunction prevention

design that prevents other danger and damage even in the event that an

IDEC product fails

iii. Wiring and installation that ensures the IDEC product used in your

system, machine, device, or the like can perform and function according

to its specifications

(4) Continuing to use an IDEC product even after the performance has

deteriorated can result in abnormal heat, smoke, fires, and the like due to

insulation deterioration or the like. Perform periodic maintenance for IDEC

products and the systems, machines, devices, and the like in which they are

used.

(5) IDEC products are developed and manufactured as general-purpose products

for general industrial products. They are not intended for use in the following

applications, and in the event that you use an IDEC product for these

applications, unless otherwise agreed upon between you and IDEC, IDEC shall

provide no guarantees whatsoever regarding IDEC products.

i. Use in applications that require a high degree of safety, including nuclear

power control equipment, transportation equipment (railroads / airplanes

/ ships / vehicles / vehicle instruments, etc.), equipment for use in outer

space, elevating equipment, medical instruments, safety devices, or

any other equipment, instruments, or the like that could endanger life or

human health

ii. Use in applications that require a high degree of reliability, such as

provision systems for gas / waterworks / electricity, etc., systems that

operate continuously for 24 hours, and settlement systems

iii. Use in applications where the product may be handled or used deviating

from the specifications or conditions / environment listed in the Catalogs,

such as equipment used outdoors or applications in environments

subject to chemical pollution or electromagnetic interference

If you would like to use IDEC products in the above applications, be sure

to consult with an IDEC sales representative.

3. Inspections

We ask that you implement inspections for IDEC products you purchase without

delay, as well as thoroughly keep in mind management/maintenance regarding

handling of the product before and during the inspection.

4. Warranty

(1) Warranty period

The warranty period for IDEC products shall be five (5) years after purchase or

delivery to the specified location. However, this shall not apply in cases where

there is a different specification in the Catalogs or there is another agreement

in place between you and IDEC.

(2) Warranty scope

Should a failure occur in an IDEC product during the above warranty period

for reasons attributable to IDEC, then IDEC shall replace or repair that

product, free of charge, at the purchase location / delivery location of the

product, or an IDEC service base. However, failures caused by the following

reasons shall be deemed outside the scope of this warranty.

i. The product was handled or used deviating from the conditions /

environment listed in the Catalogs

ii. The failure was caused by reasons other than an IDEC product

iii. Modification or repair was performed by a party other than IDEC

iv. The failure was caused by a software program of a party other than

IDEC

v. The product was used outside of its original purpose

vi. Replacement of maintenance parts, installation of accessories, or the like

was not performed properly in accordance with the user’s manual and

Catalogs

vii. The failure could not have been predicted with the scientific and

technical standards at the time when the product was shipped from

IDEC

viii. The failure was due to other causes not attributable to IDEC (including

cases of force majeure such as natural disasters and other disasters)

Furthermore, the warranty described here refers to a warranty on the IDEC

product as a unit, and damages induced by the failure of an IDEC product are

excluded from this warranty.

5. Limitation of liability

The warranty listed in this Agreement is the full and complete warranty for IDEC

products, and IDEC shall bear no liability whatsoever regarding special damages,

indirect damages, incidental damages, or passive damages that occurred due to an

IDEC product.

6. Service scope

The prices of IDEC products do not include the cost of services, such as dispatching

technicians. Therefore, separate fees are required in the following cases.

(1) Instructions for installation / adjustment and accompaniment at test operation

(including creating application software and testing operation, etc.)

(2) Maintenance inspections, adjustments, and repairs

(3) Technical instructions and technical training

(4) Product tests or inspections specified by you

The above content assumes transactions and usage within your region. Please

consult with an IDEC sales representative regarding transactions and usage outside

of your region. Also, IDEC provides no guarantees whatsoever regarding IDEC

products sold outside your region.

Ordering Terms and Conditions

Thank you for using IDEC Products.

By purchasing products listed in our catalogs, datasheets, and the like (hereinafter referred to as “Catalogs”) you agree to be bound by these terms and conditions. Please read

and agree to the terms and conditions before placing your order.

Specications and other descriptions in this brochure are subject to change without notice.

Information in this catalog is current as of June, 2021.

2021 IDEC Corporation, All Rights Reserved.

EP1751-2-A

apac.idec.com

IDEC CONTROLS INDIA PRIVATE LIMITED

2201A, 22nd Floor, WTC Bangalore,

Brigade Gateway, Rajaji Nagar Extension,

Malleswaram, Bengaluru, KA 560055 India

Tel: +91-80679-35328

E-mail: [email protected]

IDEC ASIA (THAILAND) CO., LTD.

20th Fl., Sorachai Bldg., No.23/78, Soi Sukhumvit 63,

Sukhumvit Rd., Klongton-nua, Wattana, Bangkok 10110

Tel: +662-392-9765, Fax: +662-392-9768

E-mail: [email protected]

IDEC IZUMI ASIA PTE. LTD.

No. 31, Tannery Lane #05-01, HB Centre 2,

Singapore 347788

Tel: +65-6746-1155,

Fax: +65-6844-5995

E-mail: [email protected]

This manual suits for next models

12

Table of contents

Other IDEC Power Supply manuals

Popular Power Supply manuals by other brands

Technology Dynamics

Technology Dynamics TCP Series Connection diagram & user manual

American Magnetics

American Magnetics 430 Installation, operation and maintenance instructions

GW Instek

GW Instek SPD-3606 user manual

Puls

Puls QS10.241-A1 installation manual

Skyrc

Skyrc eFuel 1200WATTS instruction manual

Altronix

Altronix SMP3CTX220 Series installation guide