HBD PV500-0007M1 User manual

PV500 Series solar pump Inverter

User's manual

Ver:2.00

PV500 series solar pumping inverters

Contents

-1-

Contents

Contents........................................................................................................................................................ 1

1 Safety precautions................................................................................................................................2

1.1 Safety definition............................................................................................................................2

1.2 Warning symbols..........................................................................................................................2

1.3 Safety guidelines.......................................................................................................................... 3

2 Product overview.................................................................................................................................. 5

2.1 Unpacking inspection.................................................................................................................. 5

2.2 Name plate....................................................................................................................................5

2.3 Type designation key................................................................................................................... 5

2.4 Product specifications..................................................................................................................6

2.5 Rated specifications.....................................................................................................................7

3 Installation guidelines.........................................................................................................................12

3.1 Mechanical installation.............................................................................................................. 12

3.2 Standard wiring.......................................................................................................................... 14

4 Keypad operation procedure.............................................................................................................20

4.1 Keypad introduction................................................................................................................... 20

4.2 Keypad operation.......................................................................................................................22

5 Commissioning guidelines.................................................................................................................24

5.1 Inspection before operation...................................................................................................... 24

5.2 Trial run....................................................................................................................................... 24

5.3 Parameter settings.....................................................................................................................24

5.4 Advanced settings......................................................................................................................24

6 Function parameters.......................................................................................................................... 26

6.1 Common function parameters for solar pumping inverter control........................................26

6.2 Parameters of special functions...............................................................................................45

7 Fault diagnosis and solution............................................................................................................. 62

Appendix E Further information................................................................................................................ 68

E.1 Product and service inquiries................................................................................................... 68

E.2 Feedback of OUR Inverters manuals...................................................................................... 68

E.3 Document library on the Internet..............................................................................................68

PV500 series solar pumping inverters

Safety precautions

-2-

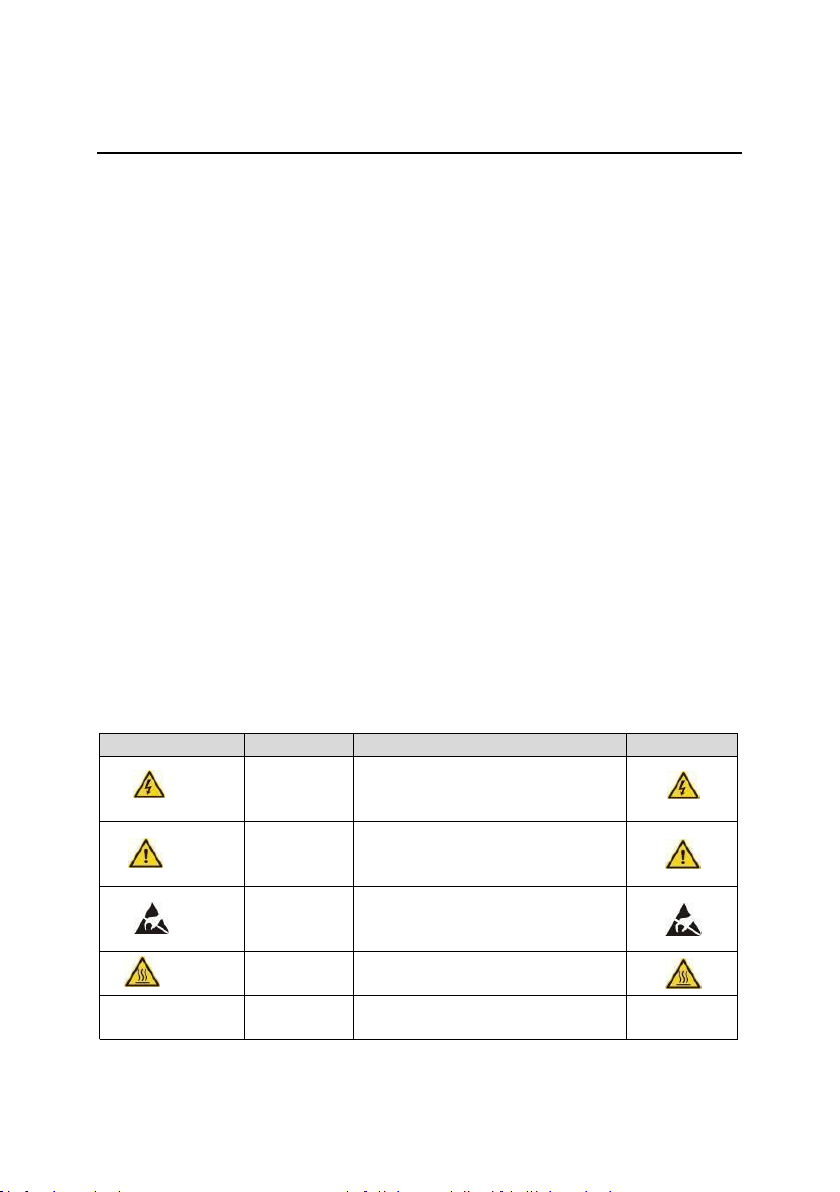

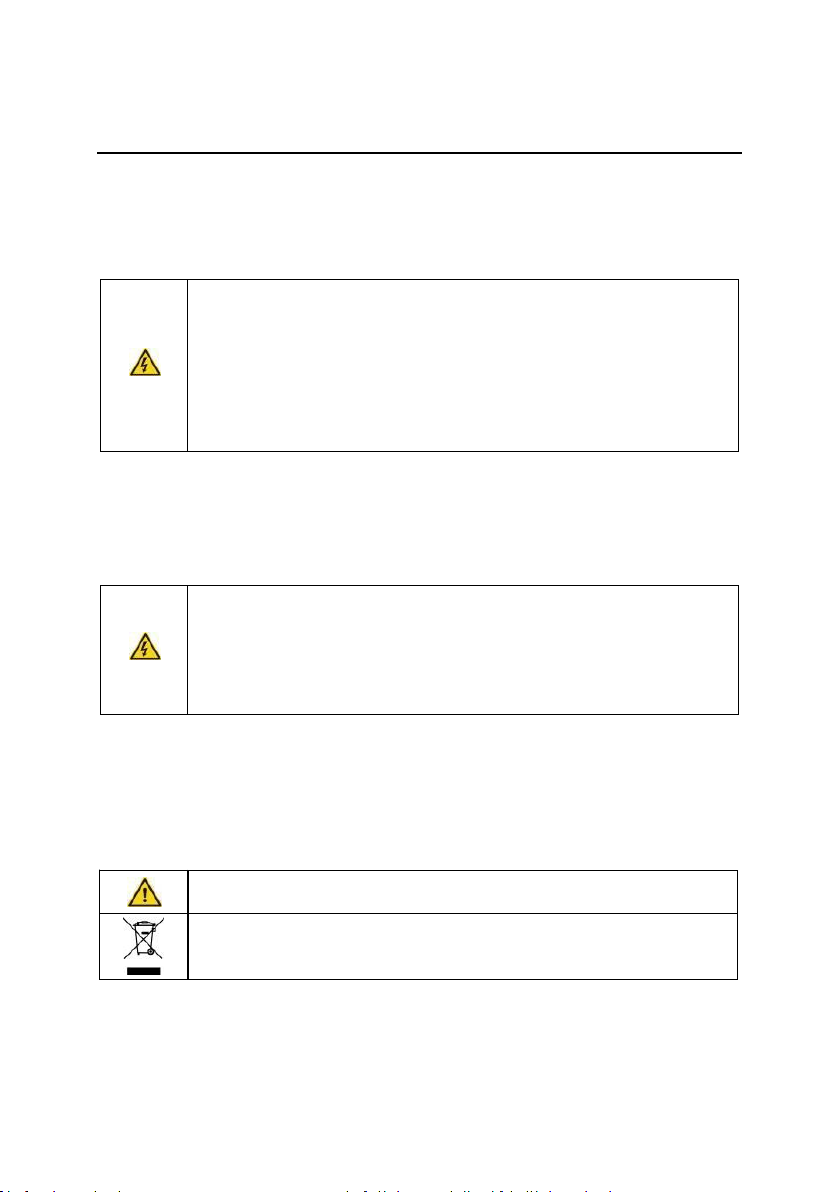

Symbols

Name

Instruction

Abbreviation

Danger

Danger

Serious physical injury or even

death may occur if not follow the

relative requirements

Warning

Warning

Physical injury or damage to the

devices may occur if not follow the

relative requirements

Do not

Electrostatic

discharge

Damage to the PCBA board may

occur if not follow the relative

requirements

Hot sides

Hot sides

Sides of the device may become

hot. Do not touch.

Note

Note

Physical hurt may occur if not follow

the relative requirements

Note

1 Safety precautions

Please read this manual carefully and follow all safety precautions before moving, installing,

operating and servicing the inverter. If ignored, physical injury or death may occur, or damage

may occur to the devices.

If any physical injury or death or damage to the devices occurs for ignoring to the safety

precautions in the manual, our company will not be responsible for any damages and we are

not legally bound in any manner.

1.1 Safety definition

Danger:

Serious physical injury or even death may occur if not follow

relevant requirements

Warning:

Physical injury or damage to the devices may occur if not follow

relevant requirements

Note:

Physical hurt may occur if not follow relevant requirements

Qualified

electricians:

People working on the device should take part in professional

electrical and safety training, receive the certification and be

familiar with all steps and requirements of installing,

commissioning, operating and maintaining the device to avoid

any emergency.

1.2 Warning symbols

Warnings caution you about conditions which can result in serious injury or death and/or

damage to the equipment, and advice on how to avoid the danger. Following warning symbols

are used in this manual:

PV500 series solar pumping inverters

Safety precautions

-3-

1.3 Safety guidelines

● Only qualified electricians are allowed to operate on the inverter.

● Do not carry out any wiring and inspection or changing components when

the power supply is applied. Ensure all input power supply is disconnected

before wiring and checking and always wait for at least the time designated

on the inverter or until the DC bus voltage is less than 36V. Below is the

table of the waiting time:

Inverter model

Minimum waiting time

1PH 220V

0.4kW-2.2kW

5 minutes

3PH 220V

4kW-7.5kW

5 minutes

3PH 380V

0.75kW-37kW

5 minutes

● Do not refit the inverter unauthorized; otherwise fire, electric shock or other

injury may occur.

● The base of the radiator may become hot during running. Do not touch to

avoid hurt.

● The electrical parts and components inside the inverter are electrostatic.

Take measurements to avoid electrostatic discharge during relevant

operation.

1.3.1

Delivery and installation

● Please install the inverter on fire-retardant material and keep the inverter

away from combustible materials.

● Do not operate on the inverter if there is any damage or components loss

to the inverter.

● Do not touch the inverter with wet items or body, otherwise electric shock

may occur.

Note:

● Select appropriate moving and installing tools to ensure a safe and normal running of

the inverter and avoid physical injury or death. For physical safety, the erector should

take some mechanical protective measurements, such as wearing safety shoes and

working uniforms.

● Do not carry the inverter by its cover. The cover may fall off.

● Ensure to avoid physical shock or vibration during delivery and installation.

● Install away from children and other public places.

● The inverter cannot meet the requirements of low voltage protection in IEC61800-5-1 if

the altitude of installation site is above 2000m.

● The leakage current of the inverter may be above 3.5mA during operation. Ground with

proper techniques and ensure the grounding resistor is less than 10Ω. The conductivity

of PE grounding conductor is the same as that of the phase conductor (with the same

cross sectional area).

PV500 series solar pumping inverters

Safety precautions

-4-

● (+) and (-) are DC power supply input terminals. R, S and T (L,N) are AC power supply

input terminals. U, V and W are output terminals. Please connect the input power

cables and motor cables with proper techniques; otherwise the damage to the inverter

may occur.

1.3.2

Commissioning and running

●Disconnect all power supplies applied to the inverter before the terminal

wiring and wait for at least the designated time after disconnecting the

power supply.

●High voltage is present inside the inverter during running. Do not carry out

any operation except for the keypad setting.

●The inverter cannot be used as “Emergency-stop device”.

If the inverter is used to break the motor suddenly, a mechanical braking

device should be provided.

Note:

● Do not switch on or off the input power supply of the inverter frequently.

● For inverters that have been stored for a long time, check and fix the capacitance and

try to run it again before utilization.

● Cover the front board before running, otherwise electric shock may occur.

1.3.3

Maintenance and replacement of components

● Only qualified electricians are allowed to perform the maintenance,

inspection, and components replacement of the inverter.

● Disconnect all power supplies to the inverter before the terminal wiring.

Wait for at least the time designated on the inverter after disconnection.

●Take measures to avoid screws, cables and other conductive materials to

fall into the inverter during maintenance and component replacement.

Note:

● Please select proper torque to tighten screws.

● Keep the inverter, parts and components away from combustible materials during

maintenance and component replacement.

● Do not carry out any isolation voltage-endurance test on the inverter and do not

measure the control circuit of the inverter by megameter.

1.3.4

Scrap treatment

●

There are heavy metals in the inverter. Deal with it as industrial

effluent.

●

When the life cycle ends, the product should enter the recycling

system. Dispose of it separately at an appropriate collection point

instead of placing it in the normal waste stream.

PV500 series solar pumping inverters

Product overview

-5-

2 Product overview

2.1 Unpacking inspection

Check as follows after receiving products:

1. Check that there are no damage and humidification to the package. If not, please

contact with local agents or Our offices.

2. Check the information on the type designation label on the outside of the package to

verify that the drive is of the correct type. If not, please contact with local dealers or Our

offices.

3. Check that there are no signs of water in the package and no signs of damage or breach

to the inverter. If not, please contact with local dealers or Our offices.

4. Check the information on the type designation label on the outside of the package to

verify that the name plate is of the correct type. If not, please contact with local dealers or

Our offices.

5. Check to ensure the accessories (including user’s manual and control keypad) inside

the device is complete. If not, please contact with local dealers or Our offices.

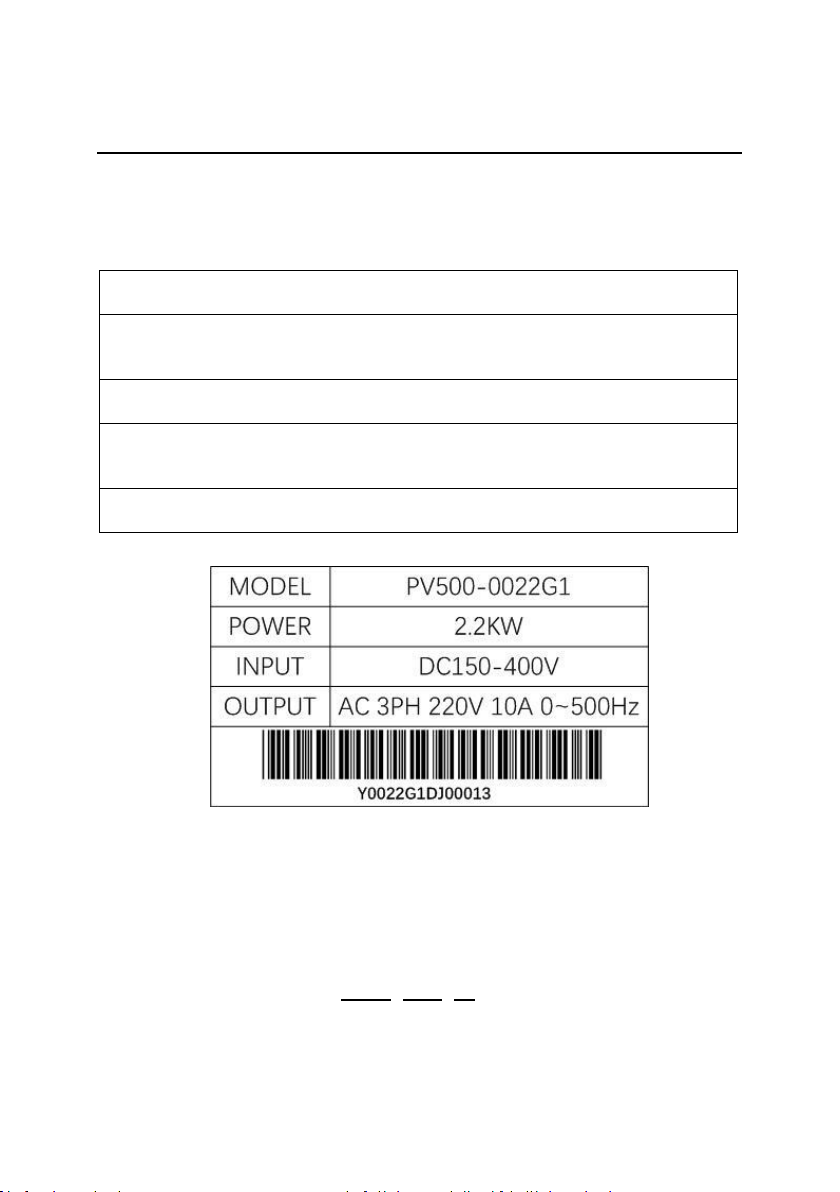

2.2 Name plate

Figure 2-1 Name plate

Note: This is the example of PV500 standard products and the CE\TUV\IP20 certifications are

marked according to the reality.

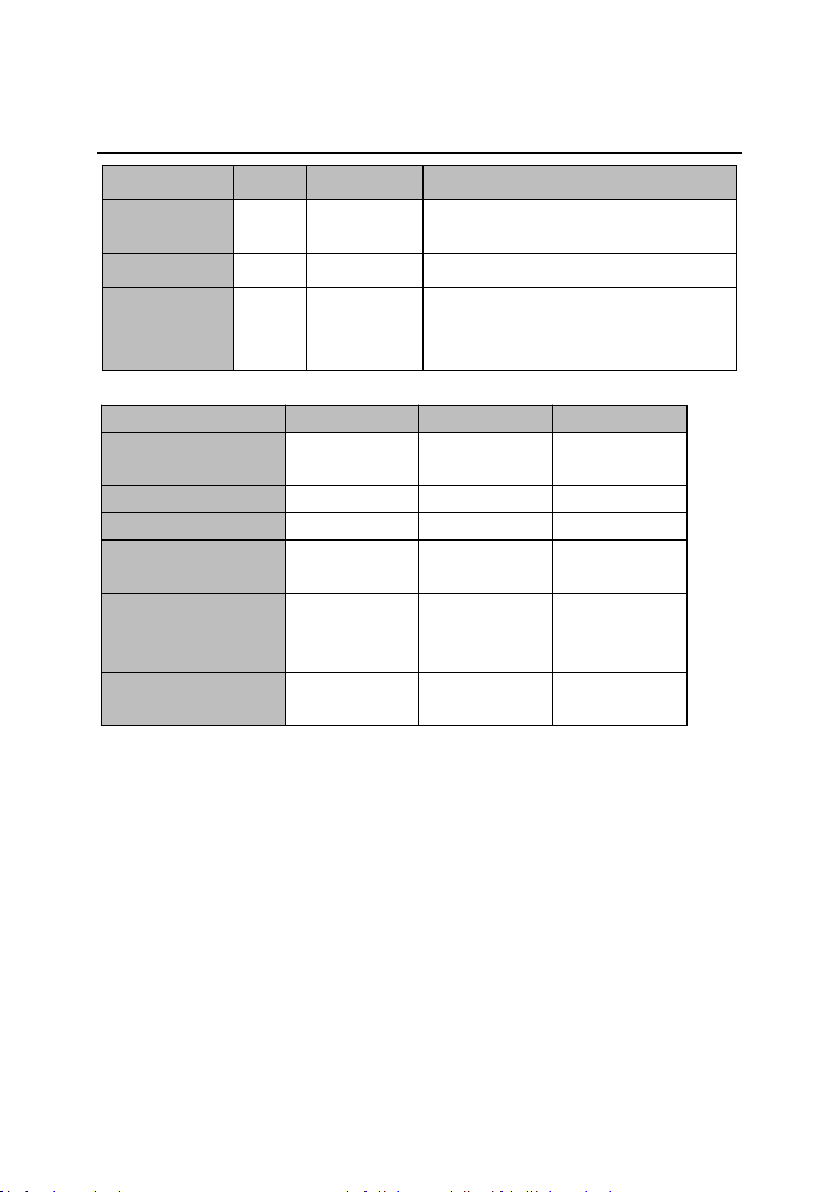

2.3 Type designation key

The type designation contains information on the inverter. The user can find the type

designation on the type designation label attached to the inverter or the simple name plate.

PV500 – 0055 – G1

① ② ③

PV500 series solar pumping inverters

Product overview

-6-

Key

Sign

Description

Remarks

Product

abbreviation

①

Product

abbreviation

PV500 Series.

Rated power

②

Power range

0.75—55kW

Voltage

degree

③

Voltage

degree

G1: AC 1PH 220V(-15%)~240(+10%)

G2: AC 3PH 220V(-15%)~240(+10%)

G3: AC 3PH 380V(-15%)~440(+10%)

2.4 Product specifications

Model

G1

G2

G3

AC input voltage (V)

220(-15%)~240

(+10%) (1PH)

220(-15%)~240

(+10%) (3PH)

380(-15%)~440

(+10%) (3PH)

Max. DC voltage (V)

400

400

800

Start-up voltage (V)

200

200

300

Lowest working

voltage (V)

150

150

250

Recommended DC

input voltage range

(V)

200~400

200~400

300~750

Recommended MPP

voltage (V)

330

330

550

PV500 series solar pumping inverters

Product overview

-7-

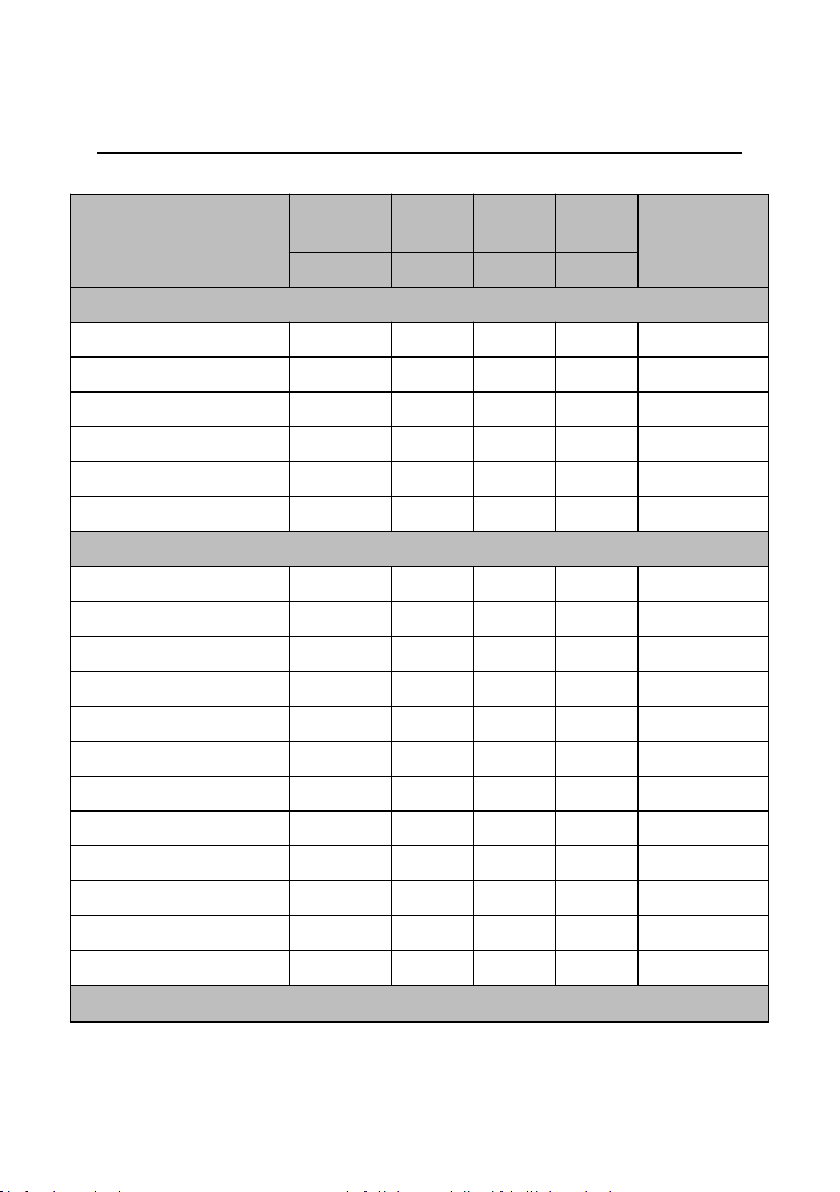

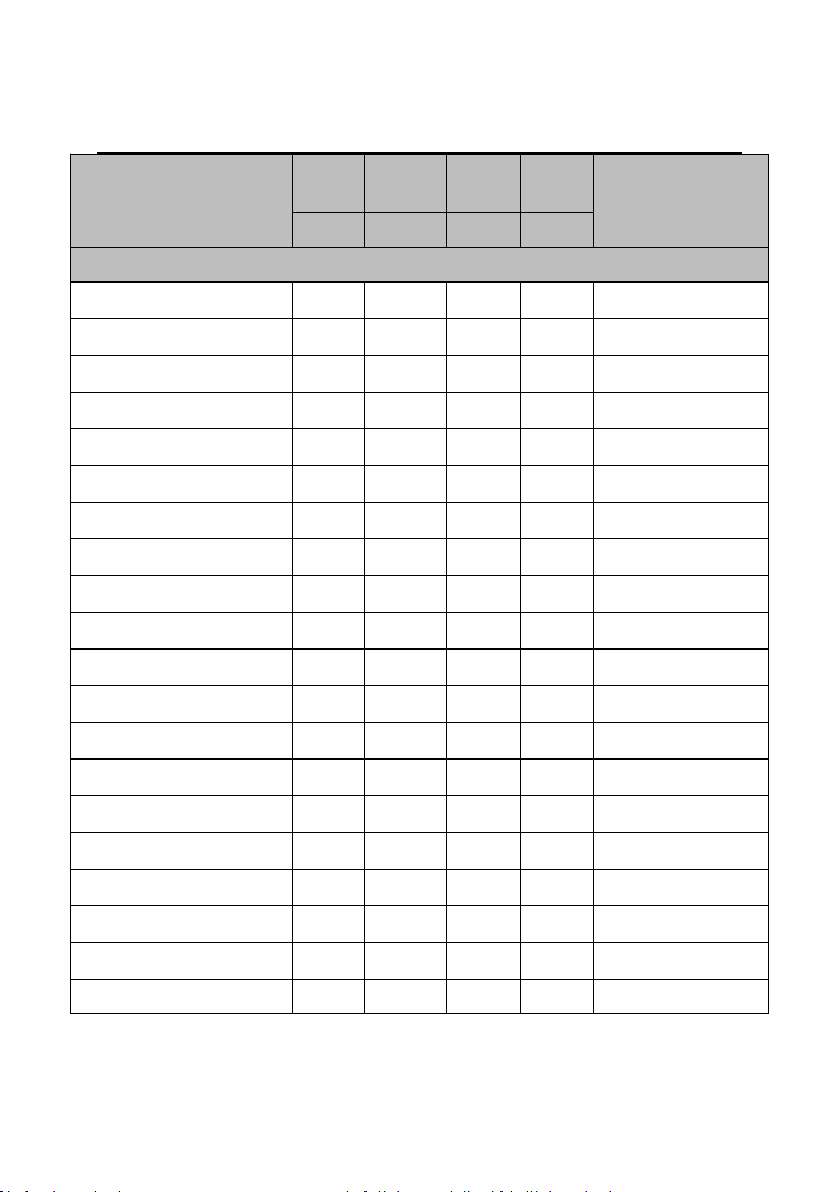

2.5 Rated specifications

Type

Drive

motor

Power

capacity

Input

current

Output

current

Shape case

kW

kVA

A

A

Single-phase power supply: 220V, 50/60Hz

PV500-0004M1

0.4

0.5

5.4

2.5

000

PV500-0007M1

0.75

1

8.2

4

000

PV500-0015M1

1.5

2

14

7

000

PV500-0007G1

0.75

1

4.2

4

001

PV500-0015G1

1.5

2

14

7

001

PV500-0022G1

2.2

3

23

10

001

Three -phase power supply: 220V, 50/60Hz

PV500-0040G2

4

5

18.1

16

002

PV500-0055G2

5.5

7.5

28

25

003

PV500-0075G2

7.5

10

37.1

32

003

PV500-0110G2

11

15

49.8

45

004

PV500-0150G2

15

20

65.4

60

004

PV500-0185G2

18.5

25

81.6

75

004

PV500-0220G2

22

30

97.7

90

005

PV500-0300G2

30

40

122.1

110

005

PV500-0370G2

37

50

157

150

006

PV500-0450G2

45

60

185

170

006

PV500-0550G2

55

70

215

210

007

PV500-0750G2

75

100

320

300

007

Input specification

PV500 series solar pumping inverters

Product overview

-8-

PV Input

Maximum Input DC Voltage

400VDC

Recommended MPPT Voltage

Range

250~350VDC

Recommended Input Operation

Voltage

310VDC

Grid or backup generator input

Input voltage

Single phase 220V(-15%~30%)

Output specification

Rated output voltage

3PH 220V

Output frequency

0~500.00Hz(default: 0~50.00Hz)

Protection

Built-in Protection

Lighting Protection, over-current, overvoltage, output phase-

lose, under-load, under-voltage, short circuit, overheating,

water pump run dry etc.

PV500 series solar pumping inverters

Product overview

-9-

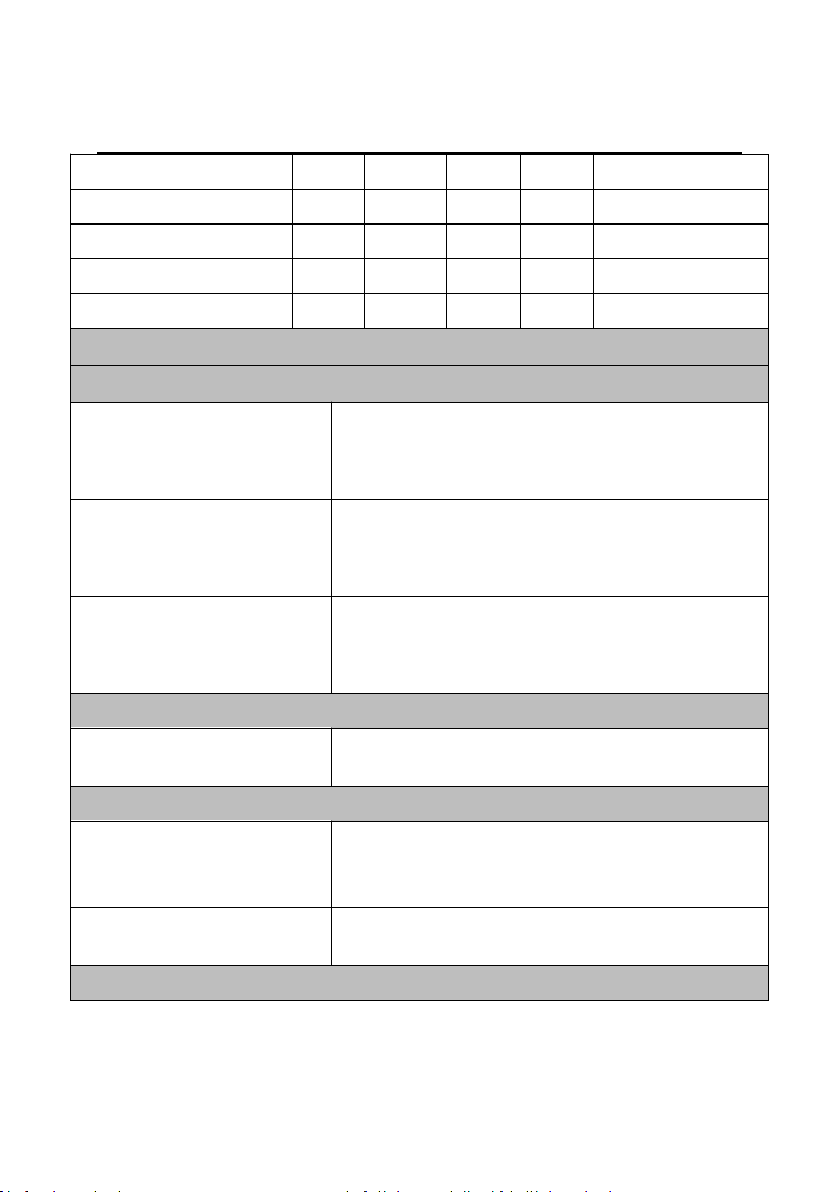

Type

Drive

motor

Power

capacity

Input

current

Output

current

Shape case

kW

kVA

A

A

Three-phase power supply: 380V, 50/60Hz

PV500-0007G3

0.75

1

3.4

2.1

001

PV500-0015G3

1.5

2

5

3.8

001

PV500-0022G3

2.2

3

5.8

5

001

PV500-0040G3

4

5

10.5

9

002

PV500-0055G3

5.5

7.5

14.6

13

002

PV500-0075G3

7.5

10

20.5

17

002

PV500-0110G3

11

15

26

25

003

PV500-0150G3

15

20

35

32

003

PV500-0185G3

18.5

25

38.5

38

003

PV500-0220G3

22

30

46.5

45

004

PV500-0300G3

30

40

62

60

004

PV500-0370G3

37

50

76

75

004

PV500-0450G3

45

60

92

90

005

PV500-0550G3

55

70

113

110

005

PV500-0750G3

75

100

157

150

006

PV500-0930G3

93

125

180

170

006

PV500-1100G3

110

150

214

210

007

PV500-1320G3

132

175

256

250

007

PV500-1600G3

160

210

307

300

007

PV500-1850G3

185

250

385

340

008

PV500 series solar pumping inverters

Product overview

-10-

PV500-2000G3

200

260

385

380

008

PV500-2200G3

220

300

430

415

008

PV500-2500G3

250

350

468

470

008

PV500-2800G3

280

370

525

520

008

PV500-3150G3

315

400

590

585

009

Input specification

PV Input

Maximum Input DC Voltage

800VDC

Recommended MPPT Voltage

Range

450~600VDC

Recommended Input Operation

Voltage

540VDC

Grid or backup generator input

Input Voltage

Three phase 380V(-15%~30%)

Output specification

Rated output voltage

3PH 380V

Output frequency

0~500.00Hz(Default 0~50.00Hz)

Protection

PV500 series solar pumping inverters

Product overview

-11-

Built-in Protection

Lighting Protection, over-current, overvoltage, output phase-

lose, under-load, under-voltage, short circuit, overheating,

water pump run dry etc.

General Parameters

Application Site

No direct sunshine, no dust、corrosive gas、combustible

gas、oil mist、steam、dripping or salinity etc.

Altitude

0~2000 m

Derated use above 1000m,per 100m, the rated output

current decrease 1%.

Environment Temperature

-10℃~40℃(Environment Temperature be 40℃~50℃,

please keep derated use.)

Humidity

5~95%,non-condensation

Vibration

less than 5.9 m/s2(0.6g)

Storage Temperature

-20℃~+70℃

Efficiency

Rated Power Run≥93%

Installation

Wall or rail mounting

Protection Grade

IP20

Cooling

Forced Air Cooling

PV500 series solar pumping inverters

Installation guidelines

-12-

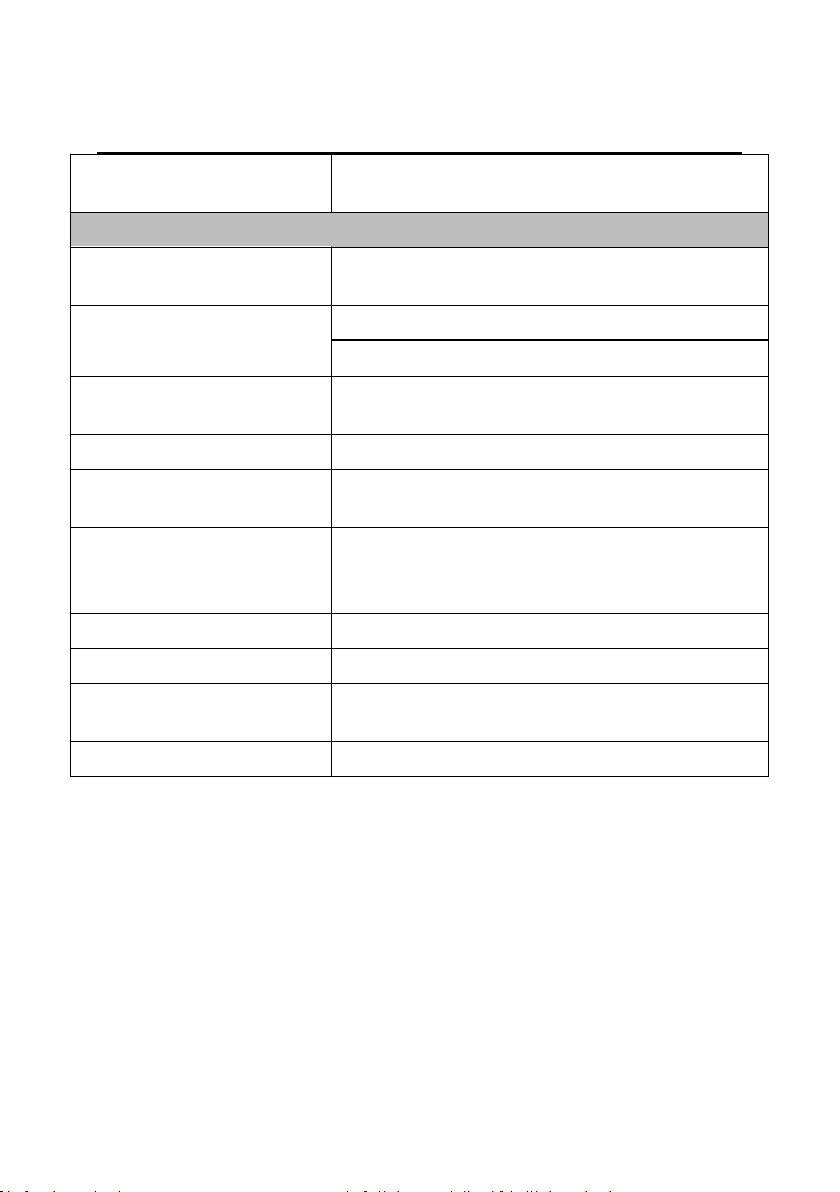

Environment

Conditions

Installation site

Indoor

Environment

temperature

The ambient temperature of inverter is -10℃~50℃while air

temperature change should be less than 0.5℃per minute.

The inverter will be derated once ambient temperature exceeds 40℃. It

is not recommended to use the inverter if ambient temperature is above

50℃.

To ensure reliability, do not use the inverter if the ambient temperature

changes frequently.

Provide cooling fan or air conditioner to control the internal ambient

temperature below the required one if the inverter is used in a close

space such as in the control cabinet.

When the temperature is too low, if the inverter needs to restart to run

after a long stop, it is necessary to provide an external heating device to

increase the internal temperature, otherwise damage to the devices may

occur.

Humidity

RH≤90%. No condensation is allowed.

Storage

temperature

-40°C~+70°C. The temperature change rate is less than 1°C/minute.

3 Installation guidelines

The chapter describes the mechanical installation and electric installation.

● Only qualified electricians are allowed to carry out what described in this

chapter. Please operate as the instructions in Safety precautions.

Ignoring these may cause physical injury or death or damage to the

devices.

● Ensure the power supply of the inverter is disconnected during the

operation. Wait for at least the time designated after the disconnection if

the power supply is applied.

● The installation and design of the inverter should be complied with the

requirement of the local laws and regulations in the installation site. If the

installation infringes the requirement, our company will exempt from any

responsibility. Additionally, if users do not comply with the suggestion,

some damage beyond the assured maintenance range may occur.

3.1 Mechanical installation

3.1.1

Installation environment

The installation environment is the safeguard for a full performance and long-term stable

functions of the inverter. Check the installation environment as follows:

PV500 series solar pumping inverters

Installation guidelines

-13-

Environment

Conditions

Running

environment

condition

The installation site of the inverter should:

Keep away from the electromagnetic radiation source;

Keep away from contaminative air, such as corrosive gas, oil mist and

flammable gas;

Ensure foreign objects, such as metal power, dust, oil, water cannot

enter into the inverter(do not install the inverter on the flammable

materials such as wood);

Keep away from direct sunlight, oil mist, steam and vibration

environment.

Pollution

Pollution degree 2

Altitude

Below 1000m

If the altitude is above 1000m, please derate 1% for every additional

100m.

Vibration

≤ 5.8m/s2(0.6g)

Installation

direction

The inverter should be installed on an upright position to ensure

sufficient cooling effect.

Note:

PV500 series inverters should be installed in a clean and ventilated environment

according to enclosure classification.

Cooling air must be clean, free from corrosive materials and electrically conductive dust.

3.1.2

Installation direction

The inverter may be installed on the wall or in a cabinet.

The inverter needs be installed in the vertical position. Check the installation site according to

the requirements below. See Appendix D Dimension drawings for frame details.

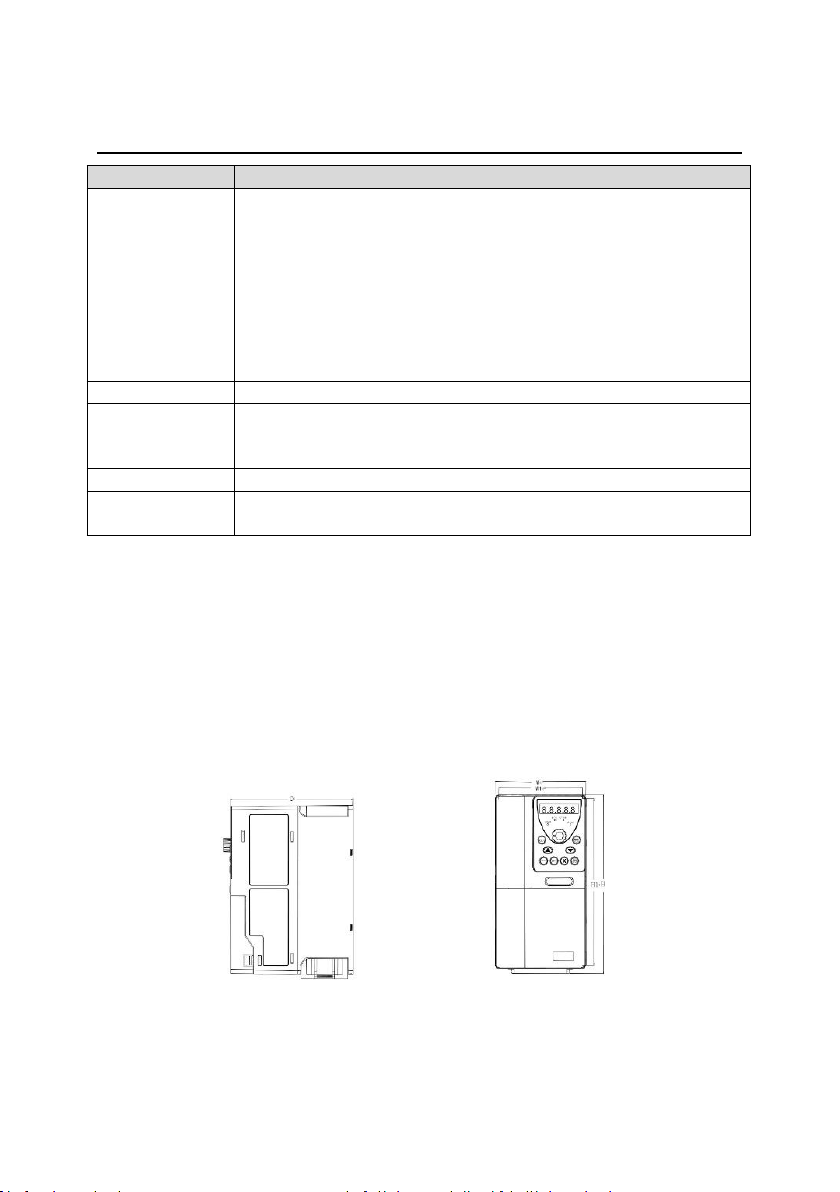

3.1.3

Installation manner

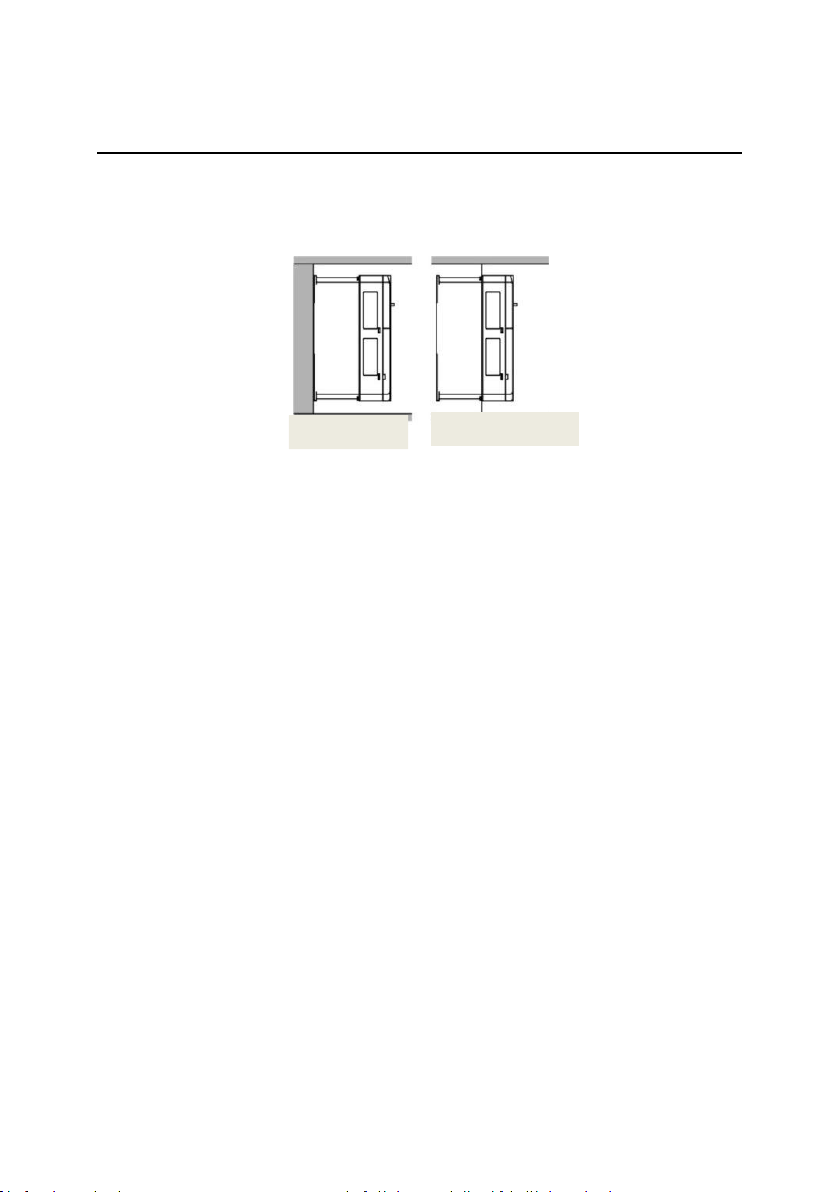

(1)

The inverters ≤ 2.2kW support wall mounting and rail mounting.

a)

Wall mounting b) Rail mounting

PV500 series solar pumping inverters

Installation guidelines

-14-

Figure 3-1 Installation manners

Note: The minimum space of A and B is 100mm. H is 36.6mm and W is 35.0mm.

(2)

The inverters ≥ 4kW support wall mounting and flange mounting.

Wall mounting Flange installation

Figure 3-2 installation manners

1)

Mark the locations of installation holes. For details about the holes, see the inverter

dimension diagram in the appendix.

2)

Fix the screws or bolts into the marked locations.

3)

Lean the inverter against the wall.

4)

Fasten the tightening screws on the wall.

3.2 Standard wiring

3.2.1

Terminals of main circuit

The figure below shows the standard wiring of inverter.

PV500 series solar pumping inverters

Installation guidelines

-15-

Figure 3-3 Standard wiring diagram

● The DC breaker Q1 must be installed as the protection switch for PV input.

● In parallel connection, the combination box special for PV must be used.

● When the distance between the PV input component and inverter exceeds

10 meters, type-II surge protection devices must be configured at the DC

side.

● When the distance between the pump and inverter exceeds 50 meters, it is

recommended to configure output reactors. See appendix A.4 for the

output reactor model selection.

● The inverter automatically runs after being powered on. If parameters need

to be set, follow the parameter setting instructions in chapter 5.

● Before connecting the braking resistor cable, remove the yellow labels of

PB, (+), and (-) from the terminal blocks. Otherwise, poor connection may

occur.

PV500 series solar pumping inverters

Installation guidelines

-16-

Terminals of main circuit

Terminal

Name

Function

R, S, T

(L, N)

AC input

3PH (1PH) AC input terminals, connected to the grid

Note: Use the screws equipped with the inverter for

wiring.

(+), (-)

PV input

Solar cell panel input terminals

U, V, W

Inverter

output

3PH/1PH AC output terminals, connected to the pump

motor

Note: 1PH motors must connect to terminals U and W.

Safety

grounding

Safety protection grounding terminal. Each inverter

must be grounded

Description for G1 single-phase output models

1)

Generally, the output terminals U and W of the inverter connect to the phase cables of the

single-phase motor.

2)

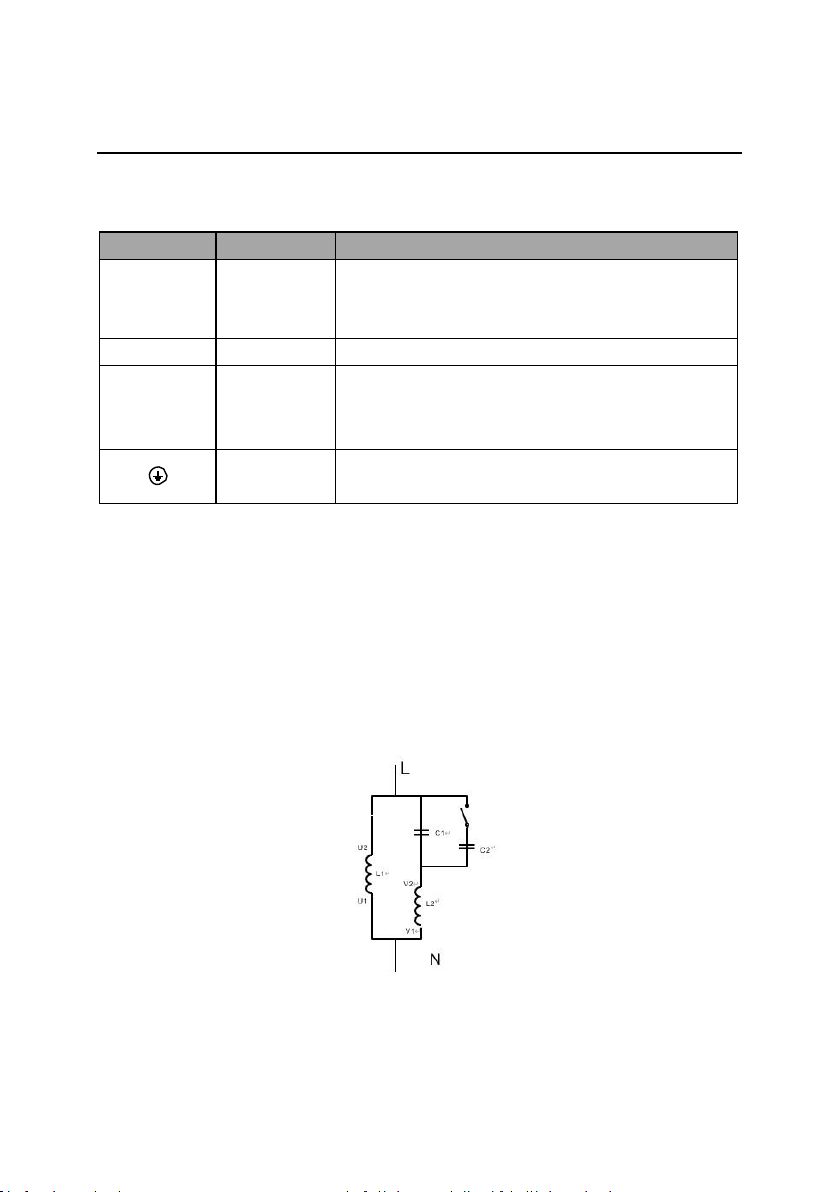

If the single-phase pump cannot be started, the two-phase control method must be used,

and the start-up and running capacitors (if any) of the motor must be removed. The figure

below shows the internal wiring of the common single-phase motor. In the figure, L1, L2, C1,

and C2 indicate the running winding, start-up winding, running capacitor, and start-up

capacitor. When the motor speed exceeds 75% of the rated speed, the start-up capacitor is

switched off.

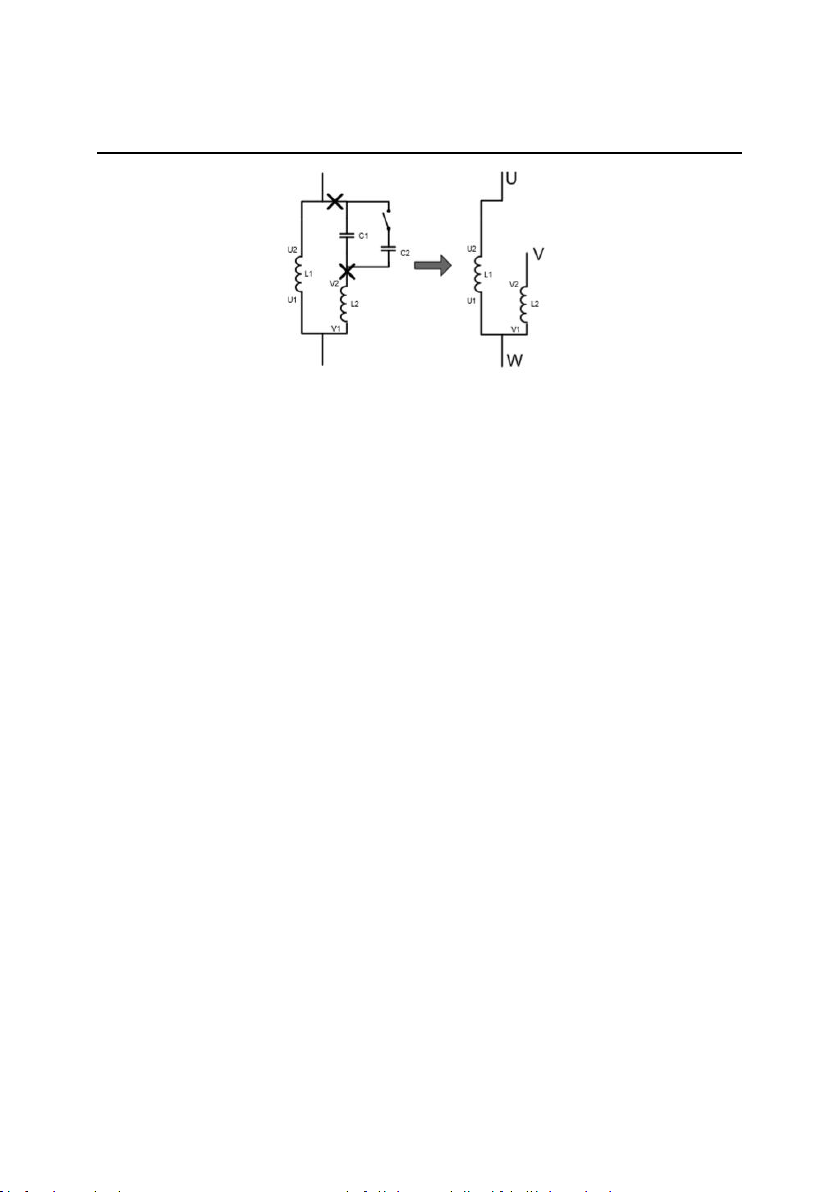

Internal wiring of the single-phase motor winding after removing the starting and running

capacitor:

PV500 series solar pumping inverters

Installation guidelines

-17-

U1 and V1 are the common terminals of the windings. Connect them to the output terminal W

of the solar pumping inverter. Connect U2 to the output terminal U of the inverter. Connect V2

to the output terminal V of the inverter. (Note: Use the screws equipped with the inverter.)

Connect DI4 of the inverter to COM in short circuited manner.

PV500 series solar pumping inverters

Installation guidelines

-18-

3.2.2

Terminals of control circuit

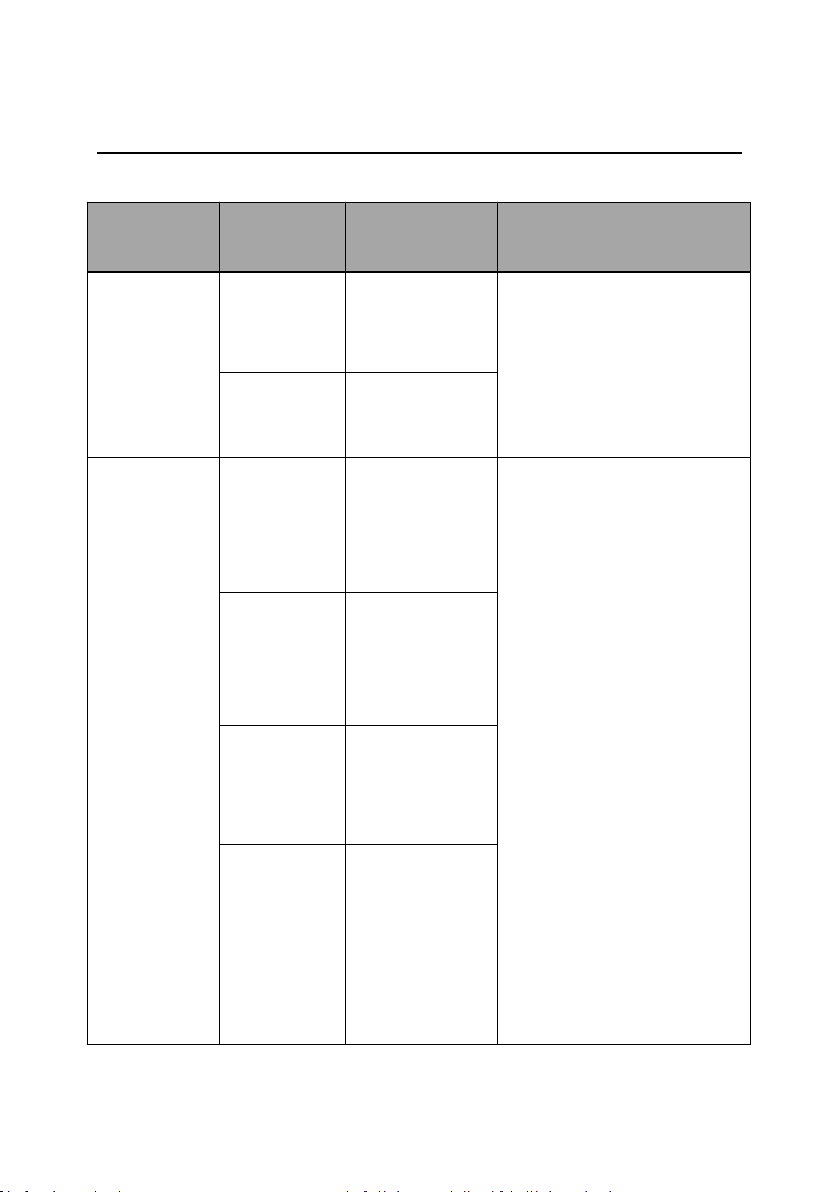

Functions of control terminals

Category

Terminal

symbol

Terminal name

Terminal function

Power supply

24V

24V power supply

It provides the power of

24V±10% and maximum current

of 200mA.

It functions as the working power

supply of digital input and output

or externally connects to the

sensor power supply.

COM

Common terminal

Digital input

DI1

Forced switch to

power frequency

Terminal feature parameters:

1.

Internal impedance: 3.3kΩ

2.

Acceptable voltage input:

12~24V

3.

Maximum input frequency:

1kHz

DI1: Forcible switch to power

frequency (Switching-on indicates

switching to power frequency, and

switching-off indicates input

controlled by the keypad.)

DI2: It connects to the high-

water switch of the normally

open contact by default.

DI3: It connects to the low-water

switch of the normally closed

contact.

DI4: A high electrical level

corresponds to the single-phase

algorithm. A low electrical level

corresponds to the two-phase

algorithm.

DI2

Full-water alarm

DI3

Empty-water

alarm

DI4

Single/two phase

algorithm

switching

This manual suits for next models

18

Table of contents

Other HBD Inverter manuals