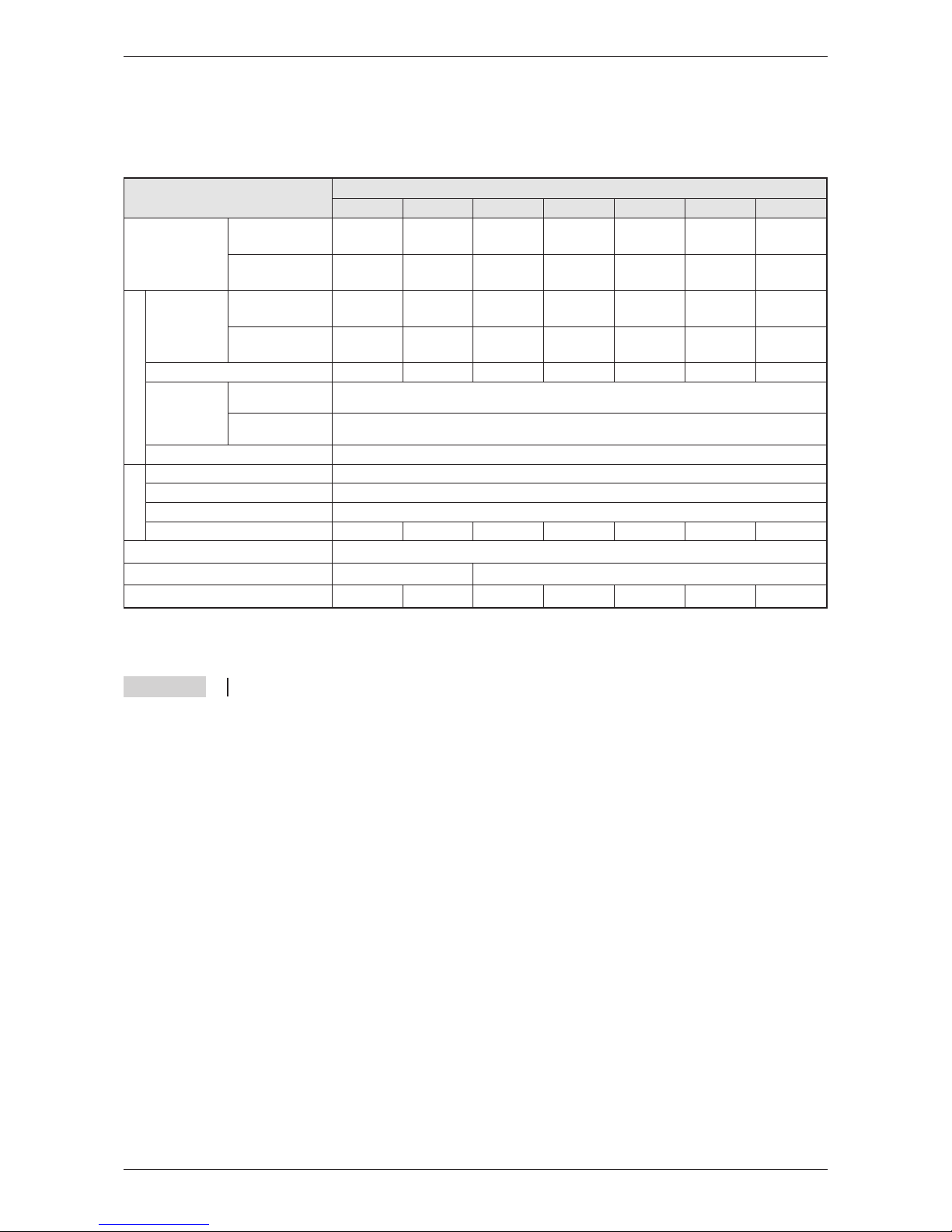

2.3 Model Specifications FR-E 500 EC

The following datas refer to the frequency inverters FR-E 520S EC und FR-E 540 EC.

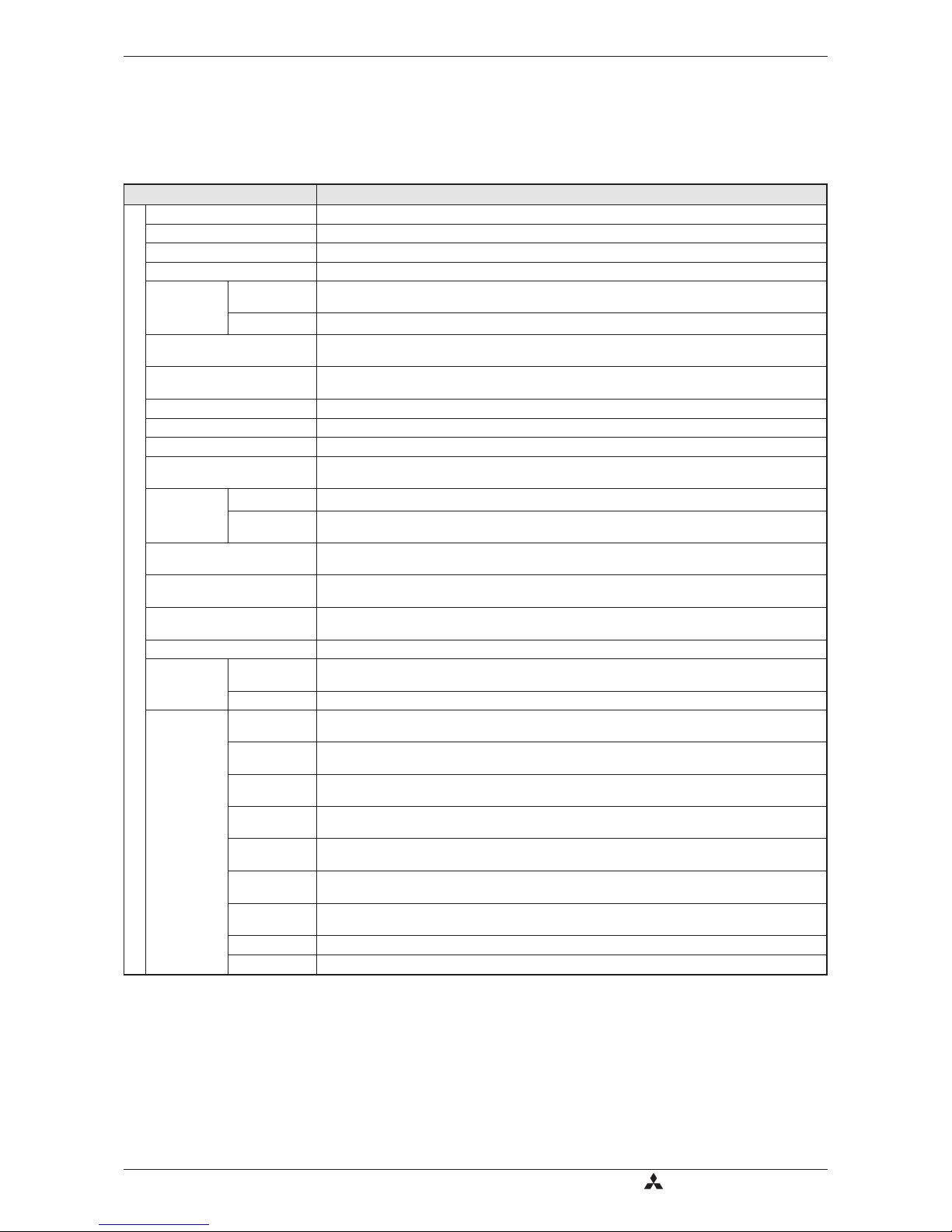

Specifications

10 MITSUBISHI ELECTRIC

Type Description

Control signals

Control method Extended flux vector control with online auto tuning of motor data or V/f control

Modulation control Sine evaluated PWM, Soft PWM

Carrier frequency 0.7–14.5kHz (user adjustable)

Frequency range 0.2–400Hz

Frequency

resolution

Analog From terminals 2-5: 1/500 of maximum set frequency (input 5V DC); 1/1000

(input 10V, 20mA DC)

Digital 0.01Hz / 50Hz

Frequency precision ±0.5% of max. output frequency (temperature range 25°C ± 10°C) during analog input;

±0.01% of max. output frequency during digital input

Voltage/

Frequency characteristics

Base frequency adjustable from 0 to 400Hz;

constant torque or variable torque selectable

Possible starting torque ≥150% / 1Hz, ≥200% / 3Hz (for vector control or slip compensation)

Torque boost Manual torque boost; selectable between 0–30%

Acceleration/deceleration time 0.01; 0.1 to 3600s individual settings

Acceleration/deceleration

characteristics Linear or S-form course, user selectable

Braking/

torque

Regenerative 0.4k and 0.75k: 100% or more; 1.5k: 50% or more; 2.2k to 7.5k: 20% or more

DC-braking Braking time and braking moment adjustable,

Operating frequency: 0–120Hz, operating time: 0–10s, voltage: 0–30%

Current stall prevention

operation level Operation current level setting possible (0–200% variable), enable/disable selection

Voltage stall prevention

operation level Operation level is fixed, enable/disable selection

High-response current

restriction level Operation level is fixed, enable/disable selection

Motor protection Electronic motor protection relay (rated current user adjustable)

Frequency

setting values

Analog

input 0–5V DC, 0–10V DC, 0/4–20mA

Digital From control panel (parameter unit), RS485 or network

Input

signals

Starting signal Individual selection of forward / reverse run

Starting signal self retaining input

Multi-speed

selection

Up to 15 set speeds (each speed can be set between 0 and 400Hz;

speed can be changed via control panel or during operation)

2nd function Selects 2nd function (acceleration time, deceleration time, torque boost,

base frequency, electronic overcurrent protection)

Selection of

current input Frequency setting via current input signal 0/4 to 20mA DC

External

thermal input Stopping the inverter with an externally mounted thermal relay

PU<->external

operation Switch over between the operating modes “PU” and “External”

V/F<->flux

vector control External switching between V/F control and general-purpose flux vector control

Output stop Instant cutoff of inverter output (frequency and voltage)

Error reset The error indication (alarm signal) is reset with the reset of the protective function