HBK HBM Bruel & Kjaer MCS10 User manual

MCS10

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0111.0015

DVS: A04466 05 Y00 03

07.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

MCS10

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

MCS10

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 4................................................

2 Scope of supply 6...................................................

3 Markings used 7....................................................

3.1 The markings used in this document 7.................................

3.2 Symbols used on the sensor 7........................................

4 Application 9.......................................................

5 Structure and mode of operation 10....................................

6 Mechanical installation 11............................................

6.1 Important precautions during installation 11..............................

6.2 Conditions on site 11.................................................

6.3 Mounting the sensor 12...............................................

6.4 Quality of the customer's own attachment parts 14........................

6.5 Recommended fits for the customer's own attachment parts 15.............

6.6 Mounting position and force application 16..............................

7 Crosstalk 19........................................................

7.1 General information 19...............................................

8 Electrical connection 20..............................................

8.1 General information 20...............................................

8.2 EMC protection 20...................................................

8.2.1 Notes on installation 20...............................................

8.2.2 Notes on cabling 20..................................................

8.3 Pin assignment 21...................................................

9 TEDS transducer identification 23......................................

10 Maintenance 24.....................................................

11 Waste disposal & environmental protection 25...........................

12 Dimensions 26......................................................

12.1 MCS10-005-3C 26....................................................

12.2 MCS10-005-6C 27....................................................

12.3 MCS10-010-3C, MCS10-025-3C, MCS10-050-3C 28........................

12.4 MCS10-010-6C, MCS10-025-6C, MCS10-050-6C 29........................

3

MCS10

TABLE OF CONTENTS

12.5 MCS10-100-3C 30....................................................

12.6 MCS10-100-6C 31....................................................

12.7 MCS10-200-3C 32....................................................

12.8 MCS10-200-6C 33....................................................

12.9 Cable outlet for a three-component transducer 34.........................

12.10 Cable outlet for a six-component transducer 34...........................

12.11 Cable connection 35..................................................

13 Ordering number and accessories 36...................................

13.1 Ordering number MSC10 36...........................................

13.2 Connection cable K-KAB-M and 1-KAB146-6 38...........................

14 Specifications 40....................................................

MCS10

SAFETY INSTRUCTIONS

4

1 SAFETY INSTRUCTIONS

Appropriate use

The MCS10 multicomponent sensor is used to measure up to six loads, such as axial

force Fz, lateral forces Fx, Fy, bending moments Mx, My, and torsional moment Mz, in the

positive and negative signal direction. Although this only applies in the context of the

range stated in the specifications. Use for any purpose other than the above is deemed to

be non-designated use.

Multicomponent sensors may only be installed by qualified personnel in compliance with

the specifications and with the safety requirements and regulations of these mounting

instructions. It is also essential to observe the applicable legal and safety regulations for

the application concerned. The same also applies to the use of accessories.

The sensor is not intended for use as a safety component. For safe and trouble-free oper

ation, this sensor must not only be correctly transported, stored, sited and mounted but

must also be carefully operated and maintained.

Load-carrying capacity limits

The information in the technical data sheets must be complied with when using multi

component sensors. The respective specified maximum loads in particular must never be

exceeded. The following values set out in the specifications must not be exceeded:

SLimit forces and moments

SBreaking forces and moments

SPermissible dynamic loads

STemperature limits

SLimits of electrical load-carrying capacity

Use as a machine element

The multicomponent sensor can be used as a machine element. When used in this man

ner, it must be noted that, to favor greater sensitivity, transducers were not designed with

the safety factors usual in mechanical engineering. Please refer here to the technical

data and load-carrying capacity limits.

Accident prevention

In cases where a breakage or malfunction of the transducer would cause injury to per

sons or damage to equipment, the user must take appropriate additional safety mea

sures that meet at least the requirements of applicable safety and accident prevention

regulations issued by the German Social Accident Insurance Institutions (e.g. automatic

emergency shutdown, overload protection, catch straps or chains, or other fall protec

tion).

5

MCS10

SAFETY INSTRUCTIONS

Additional safety precautions

Multicomponent sensors cannot (as passive transducers) implement any safety-relevant

cutoffs. This requires additional components and constructive measures, for which the

installer and operator of the plant is responsible. The electronics conditioning the mea

surement signal should be designed so that measurement signal failure does not subse

quently cause damage.

The scope of supply and performance of the sensor covers only a small area of measure

ment technology. In addition, equipment planners, installers and operators should plan,

implement and respond to safety engineering considerations in such a way as to mini

mize residual dangers. Pertinent national and local regulations must be complied with.

General dangers of failing to follow the safety instructions

The multicomponent sensor corresponds to the state of the art and is failsafe. Residual

dangers may be involved if transducers are mounted, set up, installed and operated inap

propriately, or by untrained personnel. Everyone involved with siting, starting-up, maintain

ing or repairing a multicomponent sensor must have read and understood the mounting

instructions and in particular the technical safety instructions. Transducers can be dam

aged or destroyed by non-designated use, or by non-compliance with the mounting and

operating instructions, these safety instructions or any other applicable safety regula

tions (BG safety and accident prevention regulations) when using the transducers. Trans

ducers can break, particularly in the case of overloading. The breakage of a transducer

can also cause damage to property or injury to persons in the vicinity of the transducer.

Conversions and modifications

The design or safety engineering of the sensor must not be modified without our express

permission. Any modification shall exclude all liability on our part for any damage result

ing therefrom.

Qualified personnel

Qualified personnel are persons entrusted with the setup, mounting, startup and opera

tion of the product, who have the appropriate qualifications for their function.

This includes people who meet at least one of the three following requirements:

1. They know about the safety concepts of automation and as project personnel, are

familiar with these concepts

2. As automation plant operating personnel, they have been instructed how to handle the

machinery. They are familiar with the operation of the equipment and technologies

described in this documentation.

3. As commissioning engineers or service engineers, they have successfully completed

the training to

qualify them to repair the automation systems. They are also authorized to operate,

ground and label circuits and equipment in accordance with safety engineering stan

dards.

MCS10

SCOPE OF SUPPLY

6

2 SCOPE OF SUPPLY

SSensor in accordance with the ordering code

STest certificate of the individual components for the positive signal direction

SMounting instructions

7

MCS10

MARKINGS USED

3 MARKINGS USED

3.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

3.2 Symbols used on the sensor

Read and note the data in this manual

CE mark

T The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EU direc

tives (the EU declaration of conformity can be found on the HBK

website at www.hbm.com).

MCS10

MARKINGS USED

8

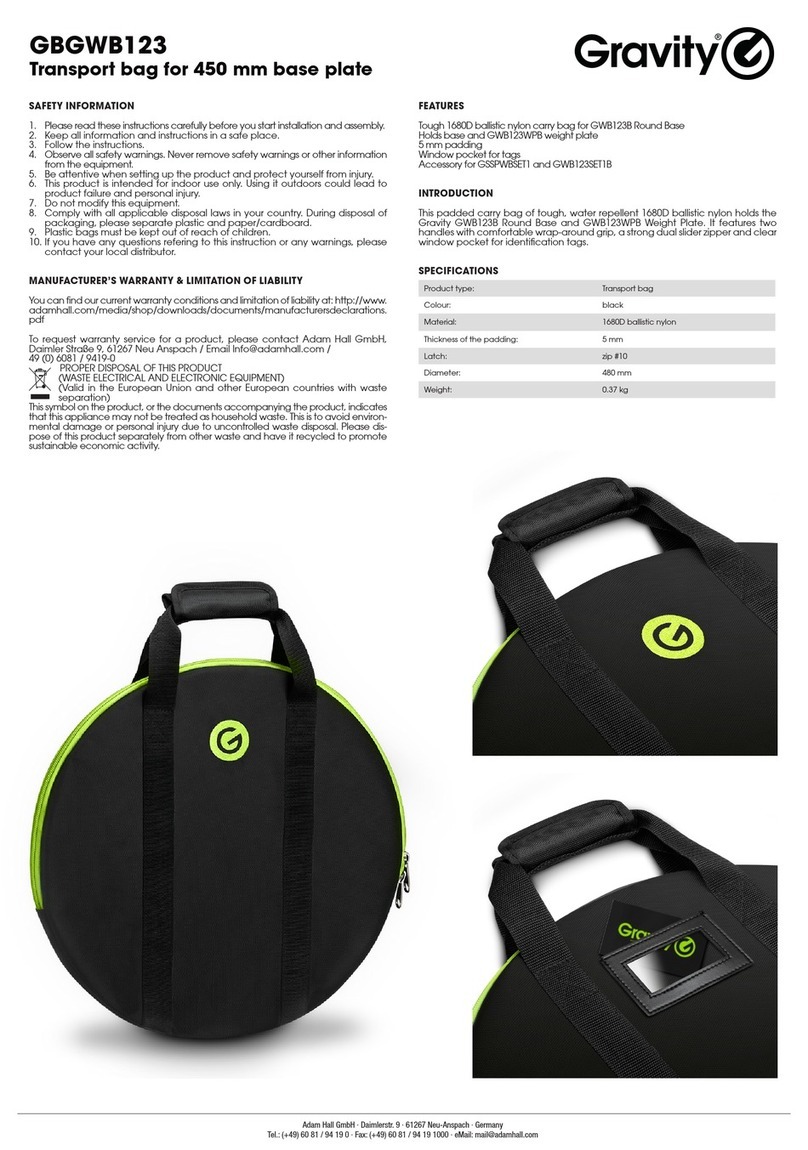

Statutory waste disposal mark

The electrical and electronic devices that bear this symbol are

subject to the European waste electrical and electronic equip

ment directive 2002/96/EC.

The symbol indicates that, in accordance with national and local

environmental protection and material recovery and recycling

regulations, old devices that can no longer be used must be dis

posed of separately and not with normal household garbage

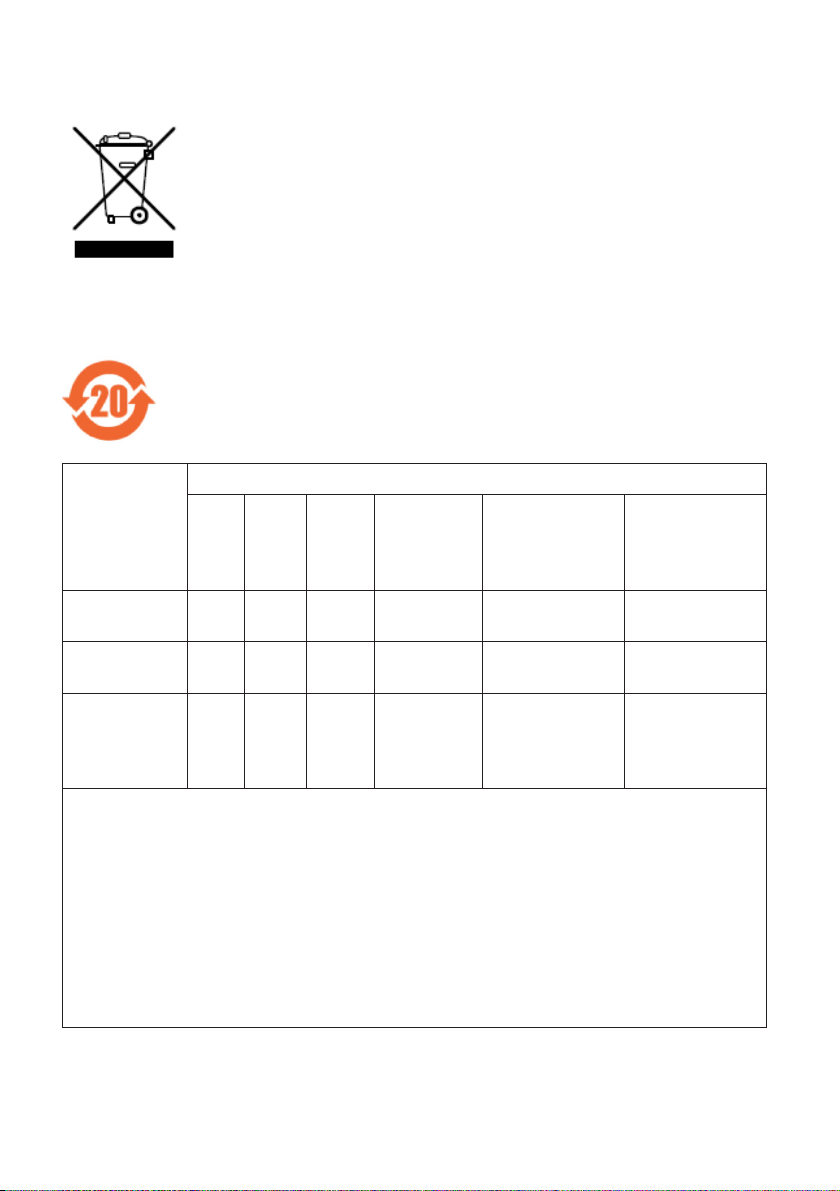

Marking in accordance with the requirements of SJ/T 11364-2014 and SJ/T

11363-2006 („China RoHS-2“)

Marking for products which contain hazardous substances

above the maximum concentration limit.

Part Name

Hazardous Substances

Lead

(Pb)

Mer

cury

(Hg)

Cad

mium

(Cd)

Hexavalent

Chromium

(Cr (VI))

Polybrominated

biphenyls

(PBB)

Polybrominated

diphenyl ethers

(PBDE)

Measure

ment Body O O O O O O

Metal

Housing O O O O O O

Small Parts

(e.g. screws,

pins,

sockets)

X O O O O O

This table is prepared in accordance with the provisions of SJ/T 11364.

SJ/T 11364

O: Indicates that said hazardous substance contained in all of the homogeneous mate

rials for this part is below the limit requirement of GB/T 26572.

!"#$"%&'()*+&$GB/T

26572,+-./0

X: Indicates that said hazardous substance contained in at least one of the homoge

neous materials used for this part is above the limit requirement of GB/T 26572.

!"#12$"34&'()*+56 GB/T

26572,+-.

9

MCS10

APPLICATION

4 APPLICATION

The multicomponent sensor measures forces and torques both statically and dynamically

in each loading direction. The sum of dynamic load and static initial load must however

not exceed the maximum capacity.

The sensor is maintenance-free and can be installed even in difficult to access points.

The electrical measurement signals can be transmitted to remote measuring points and

control rooms.

The housing protects the application from moisture and various media. No load or force

may be applied to the sensor via the housing.

The MCS10 multicomponent sensor is reliably protected against electromagnetic inter

ference. It has been tested in accordance with harmonized European standards. The

product carries the CE mark.

MCS10

STRUCTURE AND MODE OF OPERATION

10

5 STRUCTURE AND MODE OF OPERATION

The MCS10 multicomponent sensor is designed with a monolithic measuring body on

which strain gages (SG) are installed. The measuring body is enclosed in a housing. On

the housing is a terminal box with connector plugs for the measuring bridge power supply

and transferring output signals.

11

MCS10

MECHANICAL INSTALLATION

6 MECHANICAL INSTALLATION

6.1 Important precautions during installation

Notice

Transducers are precision measuring instruments and must be handled carefully. Knocking

or dropping them can lead to unexpected overloading with permanent

damage, even when in measuring mode. Make sure that the transducer cannot be over

loaded, including while it is being mounted. The specifications list the permissible limits

for mechanical stresses.

SHandle the transducer with care.

SEnsure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is overloaded. This can cause danger for

the operating

personnel of the system in which the transducer is installed.

Implement appropriate safety measures to avoid overloading and to protect against

resulting dangers.

SIf alternating loads are expected, use a (medium strength) threadlocker to glue the

screws into the counter thread to exclude prestressing loss due to screw slackening.

SComplying with the mounting dimensions is essential for correct operation.

Important

Even if the unit is installed correctly, the zero point adjustment made at the factory can

shift by up to approx. 0.5% of the sensitivity. If this value is exceeded, we advise you to

check the mounting conditions. If the residual zero drift when the unit is removed is greater

than 1% of the sensitivity, please send the transducer back to the Darmstadt factory for

testing.

6.2 Conditions on site

Protect the transducer from weather conditions such as rain, snow, ice, and salt water.

Ambient temperature

There is wide ranging compensation for the effects of temperature on the zero signal and

on sensitivity (see the “Specifications” chapter, starting on page 40). To obtain optimum

MCS10

MECHANICAL INSTALLATION

12

measurement results, the nominal (rated) temperature range must be observed. Constant

or very slowly changing temperatures are best.

Temperature gradients in the transducer, which can result from cooling or heating on one

side, have an effect on the zero point of the transducer. A radiation shield and all-round

thermal insulation produce noticeable improvements, but they must not be allowed to set

up a force shunt.

Moisture and corrosion protection

The multicomponent sensor is encapsulated and therefore very insensitive to moisture.

The sensor attains protection class IP67 as per DIN EN 60259. Nevertheless, sensors

must be protected against the long-term effects of exposure to moisture.

The sensor must be protected against aggressive chemicals that could attack it.

Deposits

Dust, dirt and other foreign matter must not be allowed to accumulate sufficiently to

divert some of the measuring force onto the housing, thus distorting the measured value

(force shunt).

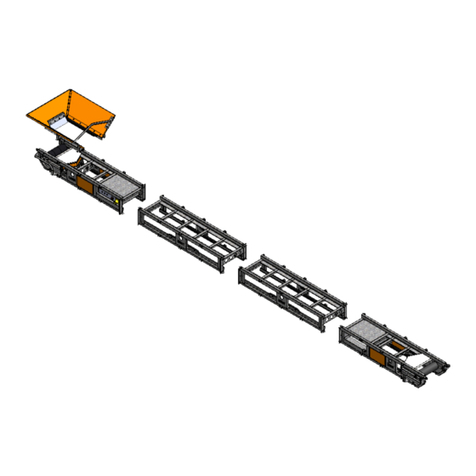

6.3 Mounting the sensor

Use the internal centering to center the sensor to the customer's own attachment parts

(see Fig. 6.1).

1. Use the positioning pins provided to align the sensor to the top and bottom of the con

necting flange. It is advisable not to exceed a phase angle error tolerance of ±0.1° for

the elongated holes on the customer's own attachment parts (aligning the axis of the

pins to the axis of the force).

2. Use hexagon socket screws per DIN EN ISO 4762 of property class 8.8, 10.9 or 12.9

(see Tab. 6.1) to connect the flange. The screw length is dependent of the customer's

own attachment parts.

We recommend DIN EN ISO4762 cylinder head screws, blackened, smoothheaded,

lightly oiled (μtot = 0.125), permitted size and shape variance as per DIN ISO 4759,

Part 1, product class A.

3. Fasten all screws with the specified torque (see Tab. 6.1). Fit the screws by tightening

them diagonally in two steps (50% and 100% of the full tightening torque).

13

MCS10

MECHANICAL INSTALLATION

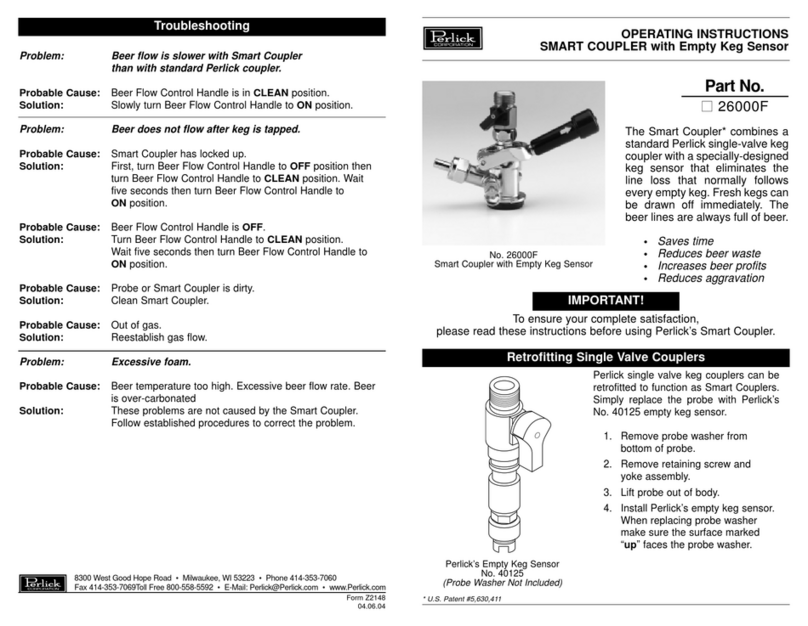

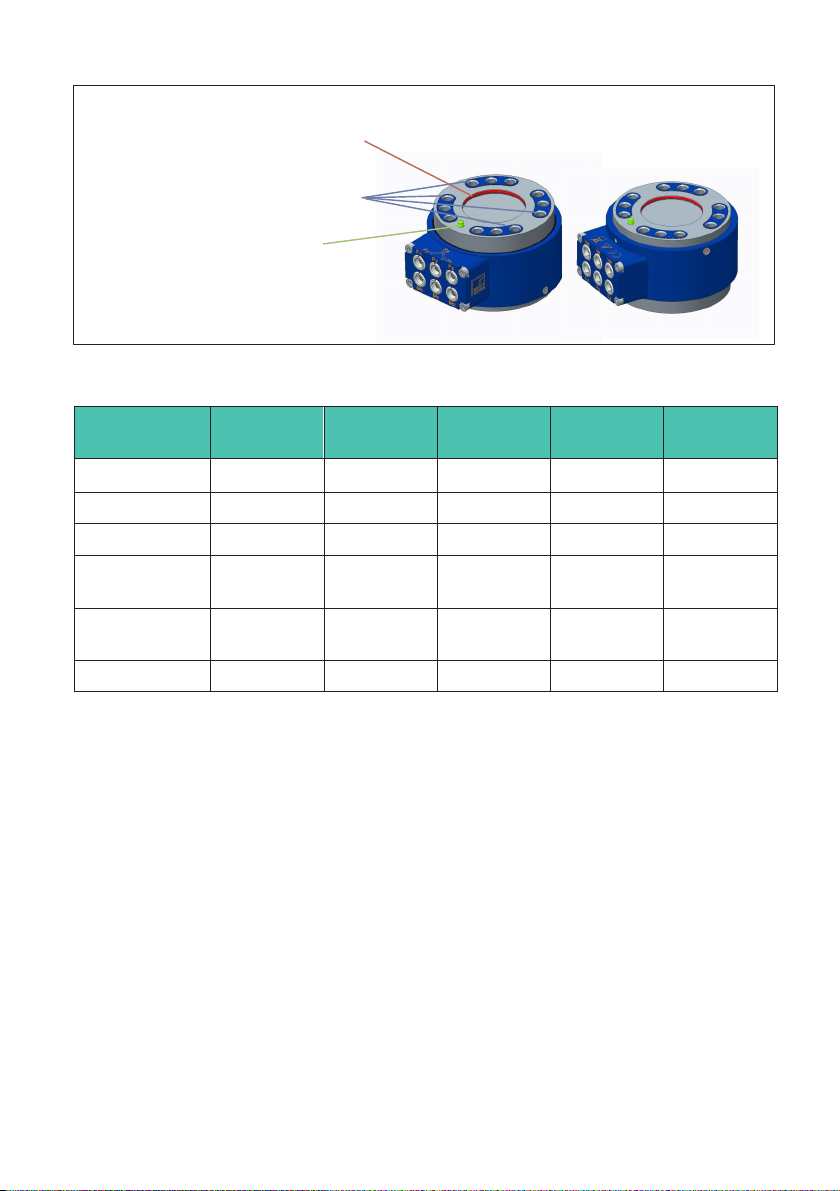

"red marking" →Internal centering surface

We recommend using this centering surface

to center the customer's own load applica

tion/mounting parts.

"blue marking" →Load application surface

This is the only surface for force application

and output.

"green marking" →Positioning pin

Please use the centering pin for positioning

and aligning the load application/mounting

parts to the sensor.

Transducer top

(measuring side)

Transducer bottom

(fixed side)

Fig. 6.1 Mechanical interface description

Measurement

range

MCS10-005 MCS10-010 MCS10-025

& -050

MCS10-100 MCS10-200

Centering Ø30 H8 Ø45 H8 Ø45 H8 Ø60 H8 Ø60 H8

Alignment pin Ø2.5 m6 Ø4 m6 Ø4 m6 Ø4 m6 Ø4 m6

Screw thread M5 M8 M8 M10 M12

Tightening

torque

6 Nm 25 Nm 36 Nm 72 Nm 145 Nm

Property

classes

8.8 8.8 10.9 10.9 12.9

Number 12 12 12 12 12

Tab. 6.1 Fastening screw characteristics

MCS10

MECHANICAL INSTALLATION

14

Load application plate

Centering washer

Positioning pin

(fixed to the sensor)

Min. gap 1 mm

Multicomponent sensor

Mounting base

Min. gap 1 mm

Fig. 6.2 Typical assembly

Important

Dry screw connections can result in different and higher coefficients of friction (see

VDI 2230, for example). This means a change to the required tightening torques. The

required tightening torques can also change if you use screws with a surface or property

class other than that specified in Table 1, as this affects the coefficient of friction.

6.4 Quality of the customer's own attachment parts

The customers' own attachment parts (contact surfaces) must meet the following condi

tions to achieve optimum and repeatable measurement results:

15

MCS10

MECHANICAL INSTALLATION

SThey must be sufficiently stiff so that they do not deform under load. The general rule

here is that the thickness of the connection elements should be approximately one

third of the transducer height.

The contact surface has ideal flatness and stiffness if a tolerance of 0.005 mm is not

exceeded both without load and under load.

SThey must be paint-free.

SThey must be made of steel and have a minimum hardness of 40HRC. For types

MCS10-005 and MCS10-010, a titanium customer-side construction is also possible.

The hardness of the stainless steel transducer body is at least 42HRC for steel and

about 30HRC for titanium.

SThey should have a surface roughness of ≤ Ra1.6. Ideally, the surface should be

ground. Ensure plane parallelism.

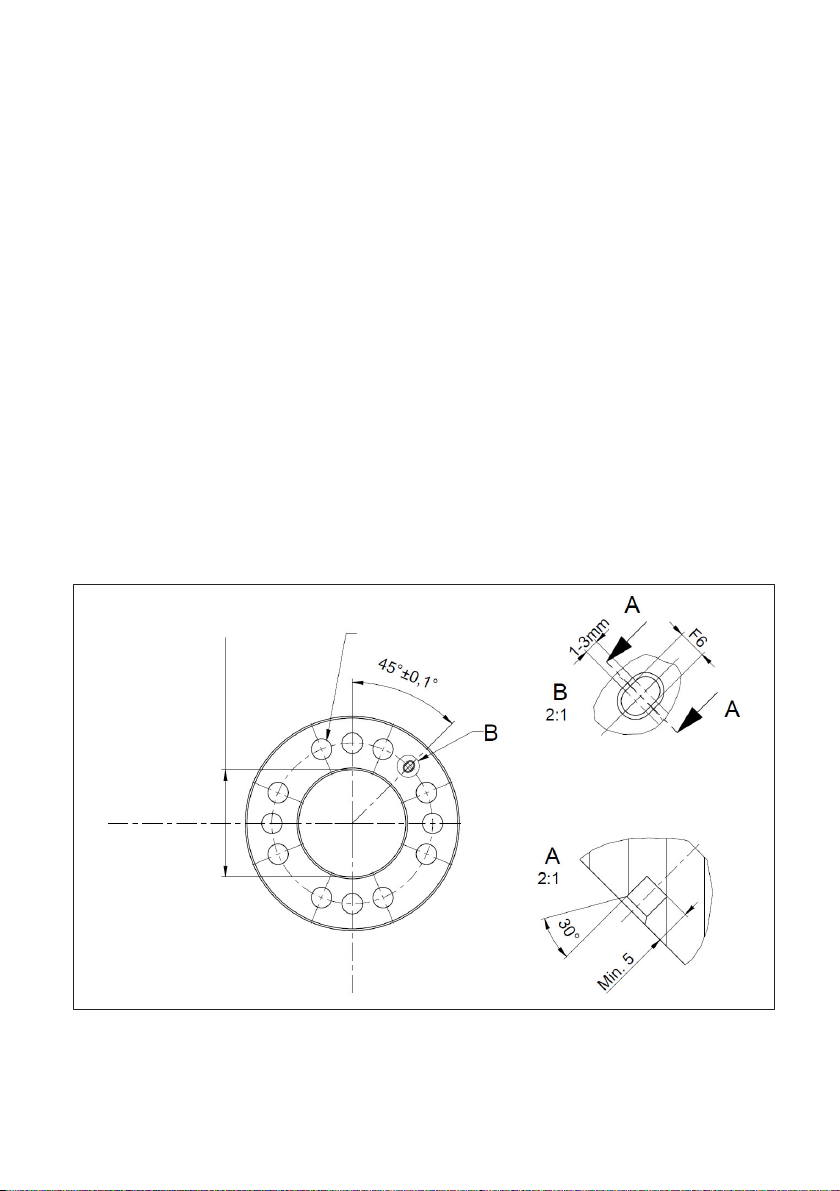

6.5 Recommended fits for the customer's own attachment parts

The fitting dimension of the transducer's internal centering is ØH8, so we recommend

combining the fits H8 and g6 for the load application elements (see Fig. 6.3 and Fig. 6.4).

To stop the transducer getting stuck during installation, an elongated hole should be cho

sen as the counterpart for the alignment pin. This elongated hole should be radially

aligned to the center of the pitch circle and the fit for the width should ideally be F6

(see Fig. 6.3).

lateral force

direction

lateral force

direction

screw through holes

ØH7 or ØH8

internal center

elongated hole for pin

orientation

Fig. 6.3 Load application plate and mounting base

MCS10

MECHANICAL INSTALLATION

16

Fig. 6.4 Centering washer

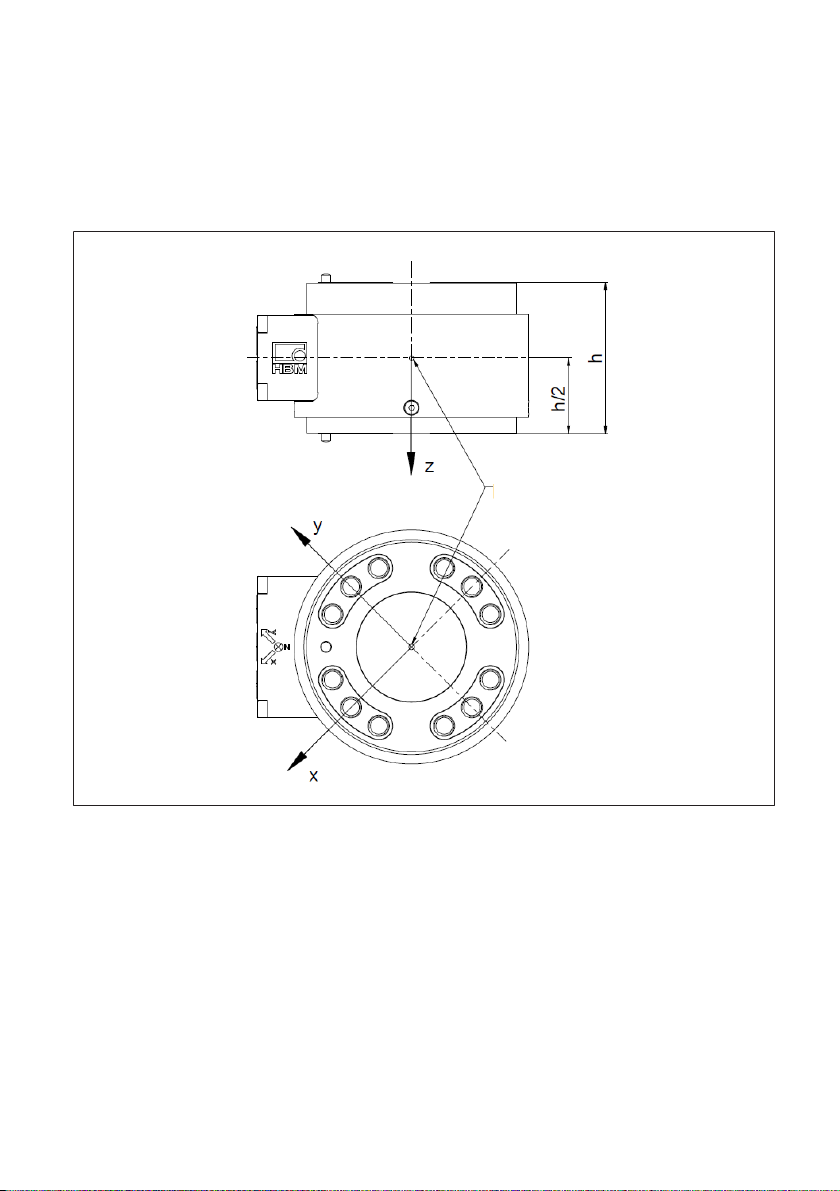

6.6 Mounting position and force application

The mounting position of the multicomponent sensor is determined by the arrows on the

terminal box. If the forces and moments are applied in the direction of the arrow, the con

nected HBM amplifiers will return a positive output signal (see section 12 “Dimensions”,

page 26).

In the three-dimensional coordinate system, the so-called right-hand rule clearly defines

the orientation of the three force directions and the moments rotating clockwise around

the axes of the positive force directions (also see Fig. 6.5).

Fig. 6.5 Right-hand rule

17

MCS10

MECHANICAL INSTALLATION

The point of origin of the multicomponent sensor coordinates is the geometric center of

the sensor (see Fig. 6.6). When preparing the test certificate, the forces (without

moments) and the moments (without forces) are applied on the measuring side and

measured at the point of origin. This is achieved using an appropriately designed load

application adapter. This way, a lateral force does not generate a bending moment, for

example.

Point of origin

Fig. 6.6 Sensor point of origin

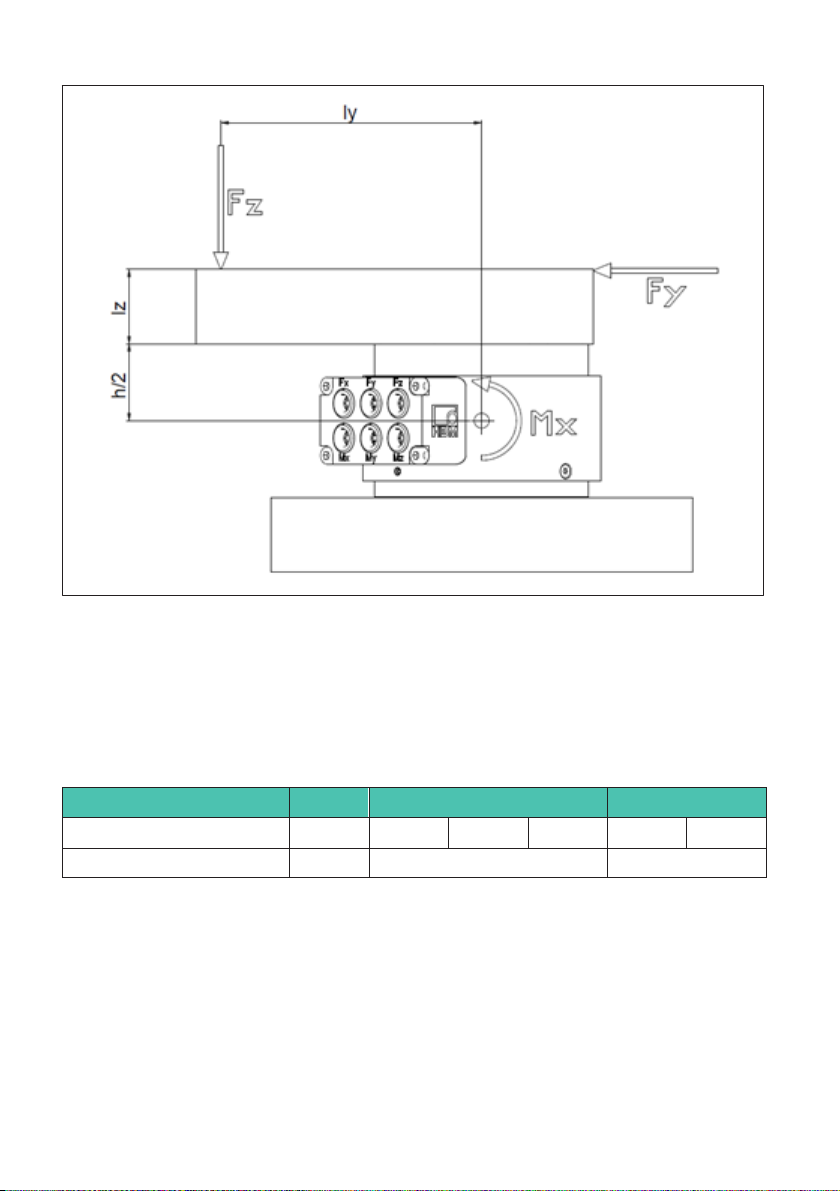

The forces and moments should be applied as near to the sensor as possible. If the force

is applied far away from the sensor, the bending moment increases and can affect the

measurement results of the other components. If the forces are applied in the application

in such a way that they do not go through the point of origin, the moments that are then

generated (force times lever arm) must be observed (see Fig. 6.7).

MCS10

MECHANICAL INSTALLATION

18

Fig. 6.7 Example diagram of forces and the resulting moments

When calculating the bending moment generated by lateral forces, half the height of the

sensor (see also Tab. 6.2) must be taken into account to determine the lever arm, as the

point of origin is at the center of the sensor. The maximum permitted loads stated in the

specifications must be complied with, even if measurement is not taking place in

individual axes.

BG1 BG2 BG3

050 010 025 050 100 200

Sensor height [mm] 45 62 77

Tab. 6.2 Sensor heights

Table of contents

Languages: