LINKUP LP400 User manual

Operator’s Manual | LP400 1

LP400

OPERATOR’S MANUAL

Conveyor Assembly, Operation & Maintenance

2Operator’s Manual | LP400

Operator’s Manual | LP400 3

CONTENTS

CONTENTS...............................................................................................3

INTRODUCTION .......................................................................................4

1. INSTRUCTIONS FOR SAFETY ............................................................5

2. PROTECTING THE ENVIRONMENT....................................................6

3. STANDARD OF MANUFACTURE.........................................................6

4. TOOLS / PPE REQUIRED FOR SITE ASSEMBLY...............................6

4.1 TOOLS REQUIRED FOR SITE ASSEMBLY.............................6

4.2 RECOMMENDED MINIMUM PPE.............................................6

5. LIFTING & POSITIONING .....................................................................7

5.1 LIFTING CONVEYOR SECTIONS ............................................7

5.2 MECHANICAL LIFTING ............................................................7

5.3 SUPPORTING CONVEYOR ON SITE ......................................8

6. DELIVERY & SITE SET-UP...................................................................8

6.1 DELIVERY.................................................................................8

6.2 SITE SET-UP.............................................................................9

6.3 HOPPER ASSEMBLY .............................................................14

6.4 HOPPER MOUNTING .............................................................15

6.5 CONTROL BOX.......................................................................16

6.6 CONTROL BOX WIRING DIAGRAM.......................................17

4Operator’s Manual | LP400

INTRODUCTION

The LINKUP®Conveyor range is designed to provide years of reliable service

throughout its working life.

The unique design of the LINKUP®Conveyor range is the result of over 50 years

of research and hands-on experience in the conveyor industry. Experience,

attention to detail, a commitment to quality and excellent service results in

customer satisfaction every time.

IMPORTANT

Read, understand, and obey these safety rules and operating

instructions before operating this machine.

Only competent authorized personnel shall be permitted to operate

this machine. This manual should be considered a permanent part of

your machine and should always remain with the machine. If you

have any questions, please contact the manufacturer:

InterQuip USA LLC

4 Duke Place

Norwalk, CT 06854

(203) 322-2600

info@interquip.net

Operator’s Manual | LP400 5

1. INSTRUCTIONS FOR SAFETY

When using LINKUP® Conveyors, all

safety recommendations, assembly

instructions, and operating instructions

found in this Operator’s Manual MUST be

followed when using the equipment. All

persons who use equipment must be

acquainted with this manual and must be

aware of any potential hazards. Equipment

should not be used by children at any time

and should always be watched and

managed by competent personnel. When

equipment is being used within close

proximity to personnel, suitable taped

off areas should be in place to establish

a safety zone area.

It's imperative that you observe the

accident prevention regulations in force in

your state, province or locale, including the

general rules of occupational health and

safety.

The manufacturer shall not be liable for any

changes made to the equipment or any

damage resulting from such changes.

Use Common Sense and Planning When Installing and Operating the Machine.

Keep Hands and Limbs Away from Moving Belt.

Always Wear Correct PPE.

•Failure to follow instructions listed below may result in electric shock,

fire and/or serious injury. Always isolate from electrical supply before

carrying out maintenance, including changing the belt.

•Always have a designated covered in walkway when using equipment

over pedestrians.

•It is not recommended to erect the equipment in high wind or icy

weather conditions.

•Check that all components for your conveyor insulation is current prior

to starting the installation.

•EQUIPMENT IS HEAVY. Minimum of 2 persons required to handle

each section. Use lifting equipment if necessary, and follow proper

manual lifting procedures to prevent back injury.

BE AWARE OF THE FOLLOWING: DO NOT CLIMB ON CONVEYORS!

•ELECTROCUTION HAZARDS

•EXPLOSION AND FIRE HAZARDS

•SETUP HAZARDS

•FALL HAZARDS

•COMPONENT DAMAGE HAZARD

6Operator’s Manual | LP400

2. PROTECTING THE ENVIRONMENT

Built into the design and the manufacturing of the Conveyor, recycling

unwanted materials has been carried out instead of disposing of them

as waste. Packaging should be sorted, taken to the local recycling

center, and disposed of in an environmentally safe way. This Conveyor

has been designed to assist in recycling materials on site where at all

possible.

3. STANDARD OF MANUFACTURE

The LINKUP®Conveyor range has been Planned, Designed, and Built with Safety in mind.

Pinch points and trap points have been Guarded by Design, where at all possible without

restricting the maximum operational capacity of the conveyor function. With the relevant

health and safety regulations built into the design, the LINKUP® Range of conveyors are

known for their safety and well-being for the Operator.

•Each section can be manhandled with two people for assembly on site.

•Manufactured to a high standard of fabrication

•Welded and constructed by trained and coded welders

•Built with UL®approved components.

•Designed and Built in the USA

4. TOOLS / PPE REQUIRED FOR SITE ASSEMBLY

4.1 TOOLS REQUIRED FOR SITE ASSEMBLY

•Adjustable Wrench

•Socket Wrench Set

4.2 RECOMMENDED MINIMUM PPE

•Hard Hat

•Gloves

•Goggles

•Safety Footwear

Operator’s Manual | LP400 7

5. LIFTING & POSITIONING

5.1 LIFTING CONVEYOR SECTIONS

•At least 2 people should handle individual sections

•Sections and components over 50 lbs. will require mechanical handling.

WARNING!

OBSERVE CORRECT LIFTING PROCEDURES AT ALL TIMES.

LINKUP®400 Sections

Length

Width

Height

Weight

Head Unit with Drum Motor

76 ¼“

28”

12 ½”

228 lbs

Tail / Base Tension Unit

76 ¼“

28”

12 ½”

160 lbs

Intermediate Section

74 ¼“

21 ¾”

12 ½”

103 lbs

Hopper

39”

39”

14”

95 lbs

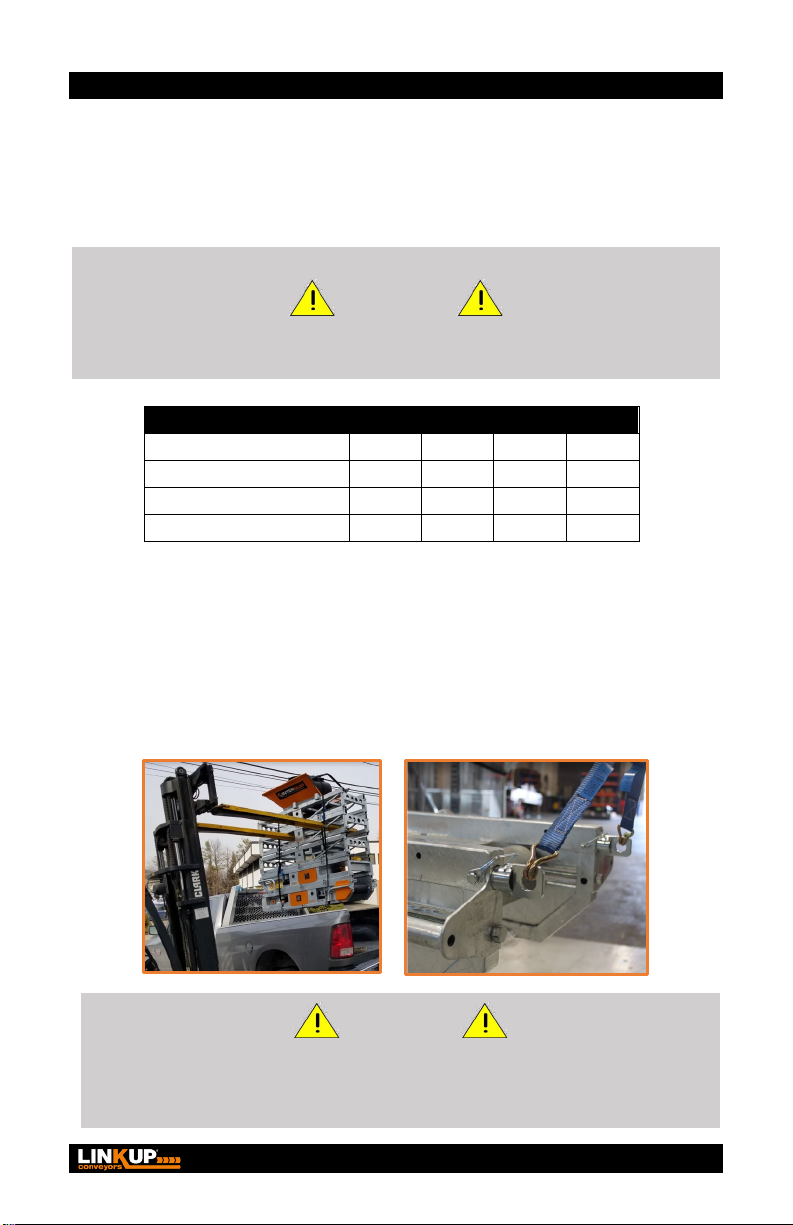

5.2 MECHANICAL LIFTING

•Conveyors and conveyor sections that need to mechanically lifted

on-site will need to be done by a confident/trained personal. All

lifting chains and straps should be safely attached through

conveyor frame or scaffold tube holes that are within the main

conveyor frame.

WARNING!

ENSURE THAT YOUR CONVEYOR IS CORRECTLY AND SAFELY

LIFTED AT ALL TIMES. ENSURE THAT NOBODY IS UNDERNEATH

THE CONVEYOR WHEN IT IS BEING LIFTED.

8Operator’s Manual | LP400

5.3 SUPPORTING CONVEYOR ON SITE

•Standard single support legs are provided to assist in supporting the

Conveyor on-site with on-site supports required by others as needed.

Scaffolding holes are provided within the conveyor frame to assist when

building into scaffolding. Further securing points are placed on lifting

handles each end of the Conveyor.

•Recommended supporting points on each length of Conveyor are as

follows:

12' Long = 2# Supports one at each end.

18' Long = 2# Supports one at each end.

24' Long = 3# Supports one at each end and one in the center.

30' Long = 3# Supports one at each end and one in the center.

HELPFUL TIPS & RECOMMENDATIONS

THE CONVEYOR SHOULD BE SUPPORTED AT REGULAR INTERVALS.

KEEP A CLEAR SPACE UNDER THE CONVEYOR TO PREVENT MATERIAL BUILD UP.

CHECK SUPPORTS OF CONVEYORS REGULARLY FOR SAFE SUITABILITY.

6. DELIVERY & SITE SET-UP

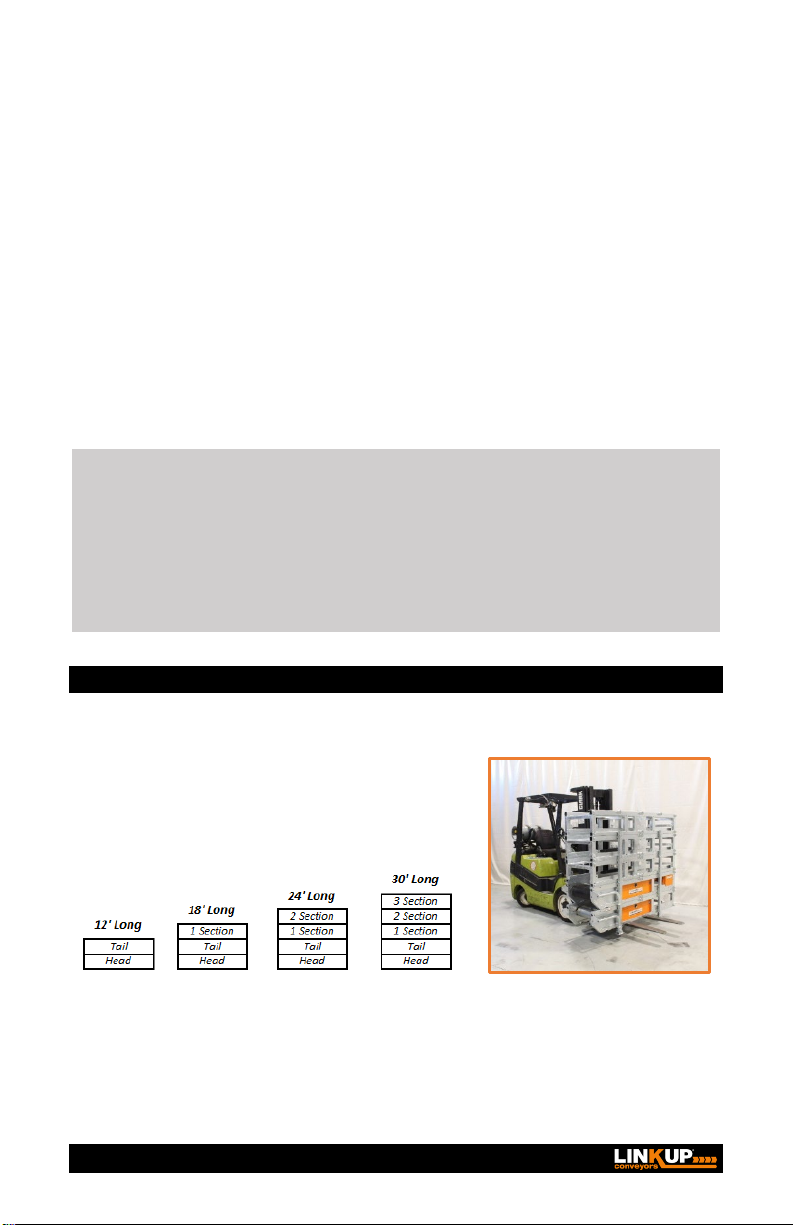

6.1 DELIVERY

LINKUP® 400 Conveyors are shipped to site

in 6' long stacks one conveyor per stack

complete with belt ready for your installation

as follows:

Each conveyor can be lifted with a fork truck on-site. They can then be positioned as close

to the final location as possible. Check that you have received the correct length and

number of conveyors and hoppers, etc. Acquaint the assembly team with this Operator's

Manual.

Operator’s Manual | LP400 9

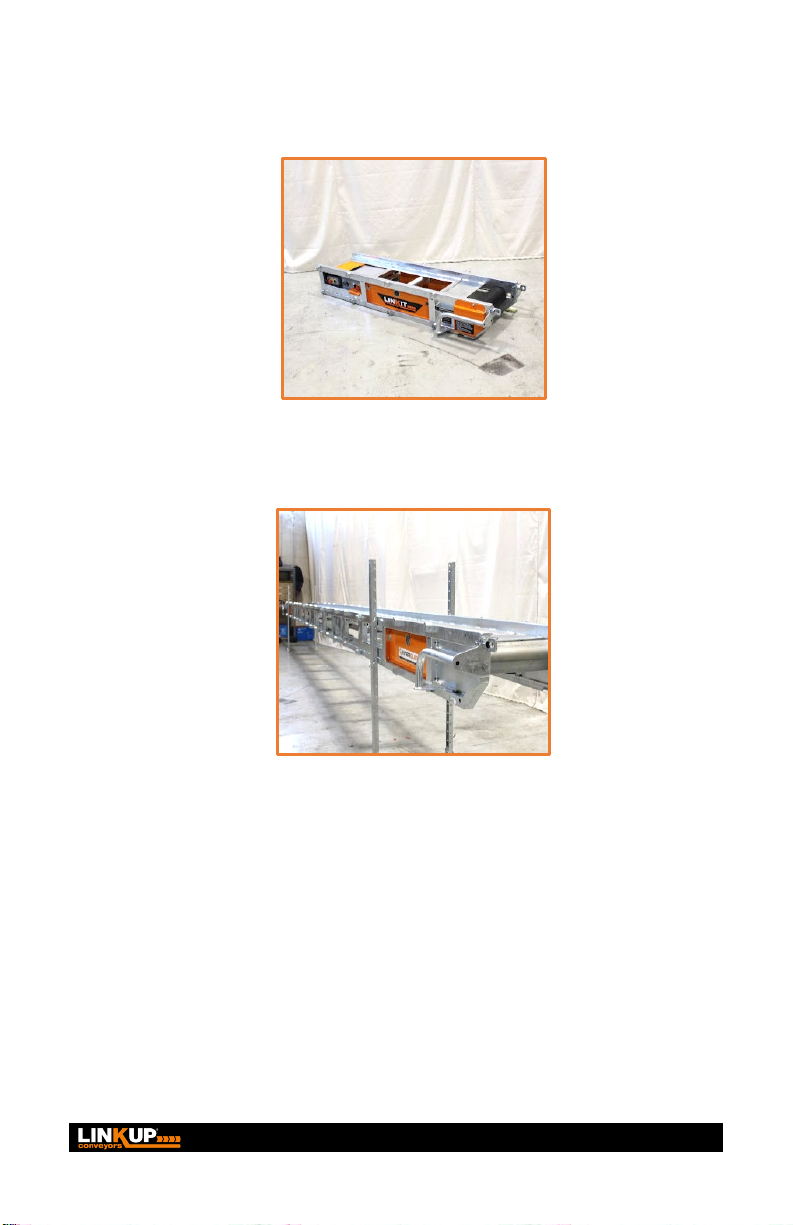

6.2 SITE SET-UP

1. Unwrap and dismantle the conveyors from the shipping stack.

2. Select the tail unit, (Non-Drive roller) and position in the

approximate area for Feeding/Loading.

3. Select the intermediate section(s) and attach and bolt to the tail

unit and secure bolts tightly.

10 Operator’s Manual | LP400

4. Position the first set of support legs, ensuring the conveyor is

clear from the ground to give a material free area under the

conveyor to provide a space to keep clean from material buildup.

5. Continue with the further sections as needed, supporting as need

along its length.

Operator’s Manual | LP400 11

6. Select the Head Drive unit, which is the most substantial section,

and lifting assistance may be needed depending on the site

conditions. Position and secured to the main sections.

7. Ensure the conveyor is safely positioned and supported.

Supports can be from below or from above, depending on the site

conditions and what is available on the site.

8. FIT THE STANDARD ENDLESS (VULCANIZED JOINT) BELT:

•Ensure that the drum on the Base Tension Unit is as far

forward (towards the motor end) as possible.

•Roll out the belt to its full length alongside the assembled

conveyor.

•Lift one end of the belt up and loop over the tail drum of the

base tension unit. This should be carried out with a minimum

of two people.

12 Operator’s Manual | LP400

•Mechanically lift one side of the conveyor or lift conveyor to

give room to enable the belt to be fed under the conveyor

frame and over the temporary support trestles. As the belt is

being inserted into the frame, ensure the cleats are pointing

down, and the belt is returning on the return blocks ether side

along the conveyor length.

•Loop the other end of the belt over the head unit drum. Useful

Hint: In some instances where access is tight or difficult, it

may be advantageous to use a leaver bar.

•Ensure that the belt is centrally positioned on the head and

tail drums and along the length of the conveyor, both top and

underside.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

An endless belt is provided as standard. If a clipped belt is

requested or supplied, follow these instructions:

•FITTING A CLIPPED BELT is done by feeding the belt in

from the top/drive drum of conveyor if possible, on the

underside of the frame with the cleats pointing in the down

position.

•Ensure the returning belt rides over the side slide bars and

bring belt around the tail drum and up the conveyor to a

position that the belt pin can be inserted.

•Wrap the remaining belt around the drive drum and down the

top of the conveyor to meet the two ends together.

•Join the two ends and insert the hinge pin and secure the pin

with crimping the two retaining washers on each end of the

hinge pin if the ends of the belt don’t meet adjust the tail drum

to release the belt as needed.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Washer

Clamped

End of hinge

pin within the

width of belt

Operator’s Manual | LP400 13

9. Tensioning of the Belt takes place at the tail drum. Adjust drum

tensioning stud bars each side evenly (A). Turning clockwise will

pull the tail drum back to tension the belt. Anticlockwise will

loosen the belt when required. Adjust (A) Evenly each side to

matching measurement each side from drum shaft to the

mainframe.

10. Tracking of the Tail Drum should be carried out as described

above, ensuring that when the belt is running in its main direction

of use, the belt must be adjusted to run within the center of the

conveyor frame and tail drum.

11. Tracking of the Head Drum should be adjusted from one side

(A) to ensure the belt is run within the center of the conveyor

frame and tail drum. Release 2 bolts (B) adjust and re-secure

when adjustment is complete.

(A)

Adjusting

Stud Bar

Tail Drum

(A)

(B)

14 Operator’s Manual | LP400

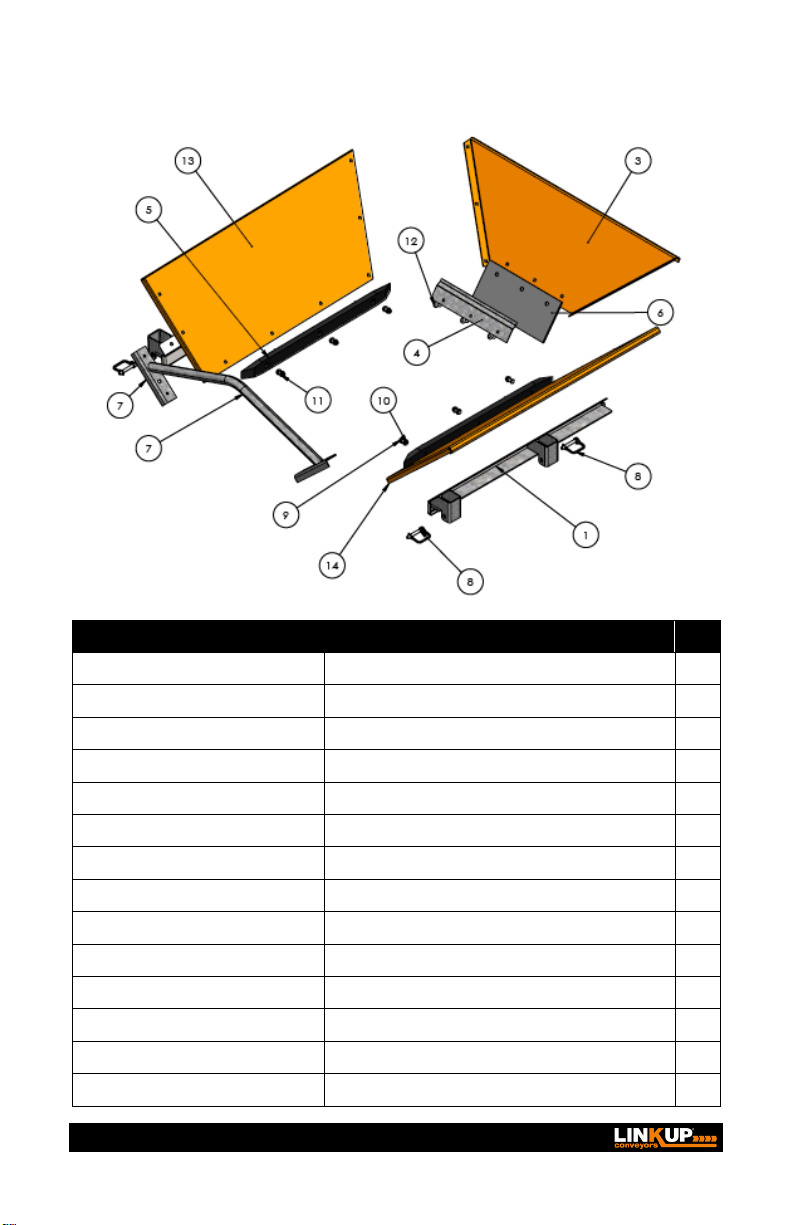

6.3 HOPPER ASSEMBLY

No. Part No. Description Qty

1 LP407-01 Hopper Bracket Assembly Left Side 1

2 LP407-02 Hopper Bracket Assembly Right Side 1

3 LP407-04 Hopper Rear Panel 1

4 LP407-07 Flap Bracket 1

5 LP400-SP-02 Machined Nylon Return Wear Strip 2

6 LP407-00-05 Reinforced Rubber Flap 1

7 LP407-03 Hopper Brace Bar Assembly 1

8 FX-PIN-8MM-BZP Zinc-Plated Steel Pin with Wire Lock 4

9 FX-BOLT-M8-25-PS-BZP-8.8 Bolt M8 25mm Plain Steel Bright Zinc Plated 8.8 6

10 FX-WASHER-M8-CF-BZP C Form Washer M10 Plain Steel Bright Zinc Plated 12

11 FX-LNUT-M8-BZP Locking Nut M10 Steel Bright Zinc Plated 8.8 6

12 FX-CBOLT-M8-20-PS-BZP-4.8 Coach Bolt M10 30mm Plain Steel Bright Zinc Plated 8.8 3

13 LP407-05 Hopper Side Panel 1 1

14 LP407-06 Hopper Side Panel 2 1

Operator’s Manual | LP400 15

6.4 HOPPER MOUNTING

Standard Hopper can be placed along the conveyor length in either

direction locating the brackets and securing 4 pins, two on each side

(A) to connect.

When using the hopper along its length, the area of the belt entering

the hopper must be zoned off for safety and performance of conveyor.

(A)

16 Operator’s Manual | LP400

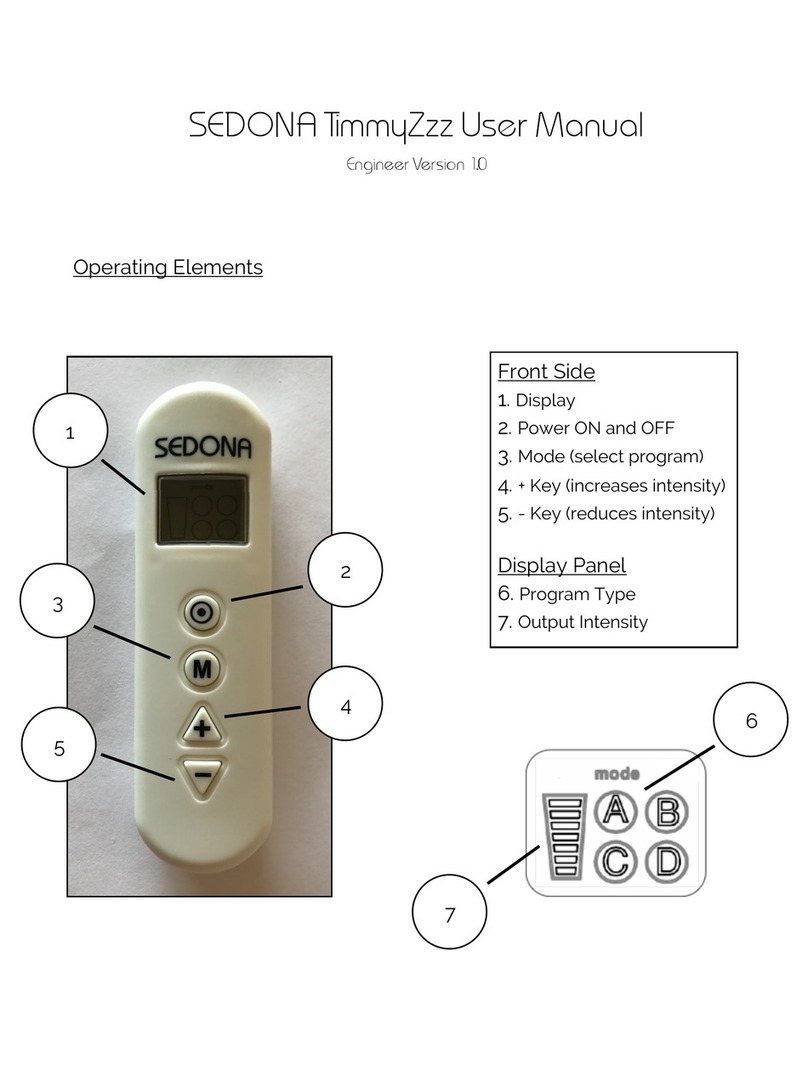

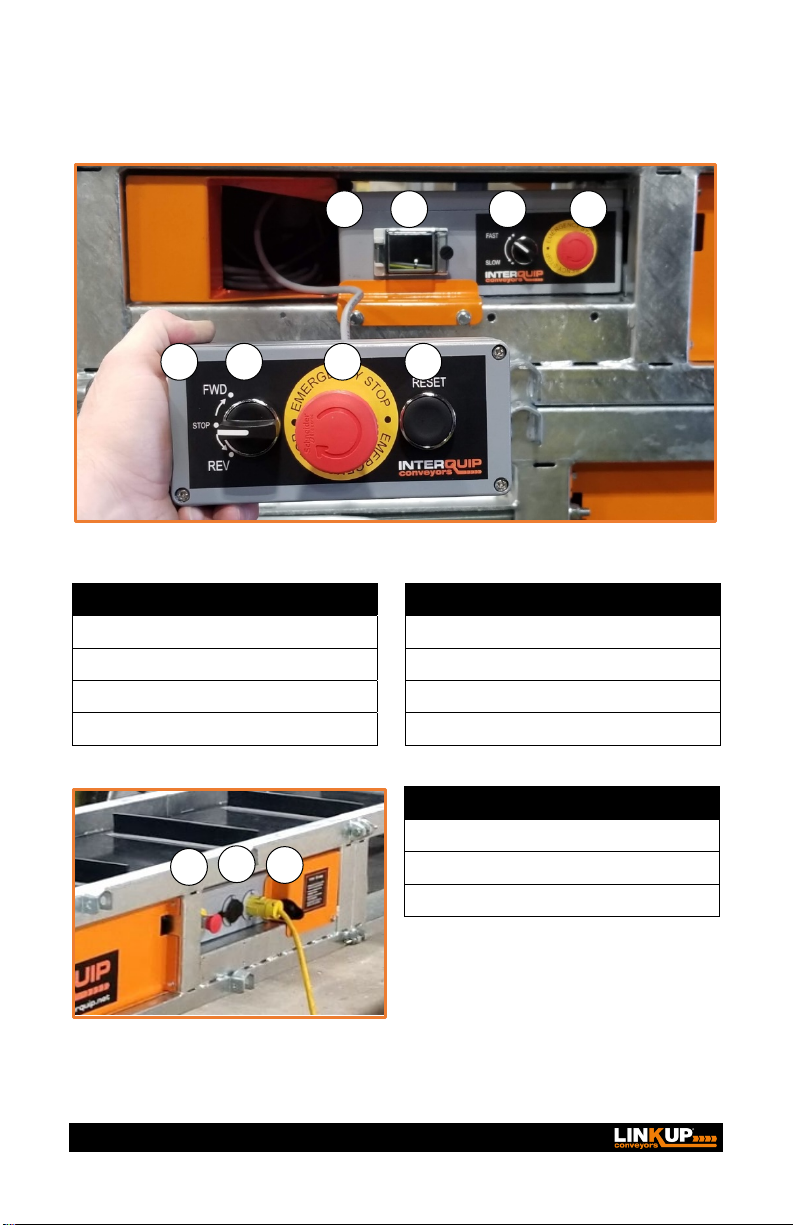

6.5 CONTROL BOX

No. Description

No. Description

1 Removable Control Box

5Pendant Control Box on 15FT Lead

2 Digital Display Sight Glass

6 Forward/Reverse Directional Control

3 Two Speed Controls

7 Emergency Stop

4 Emergency Stop

8 Reset Control

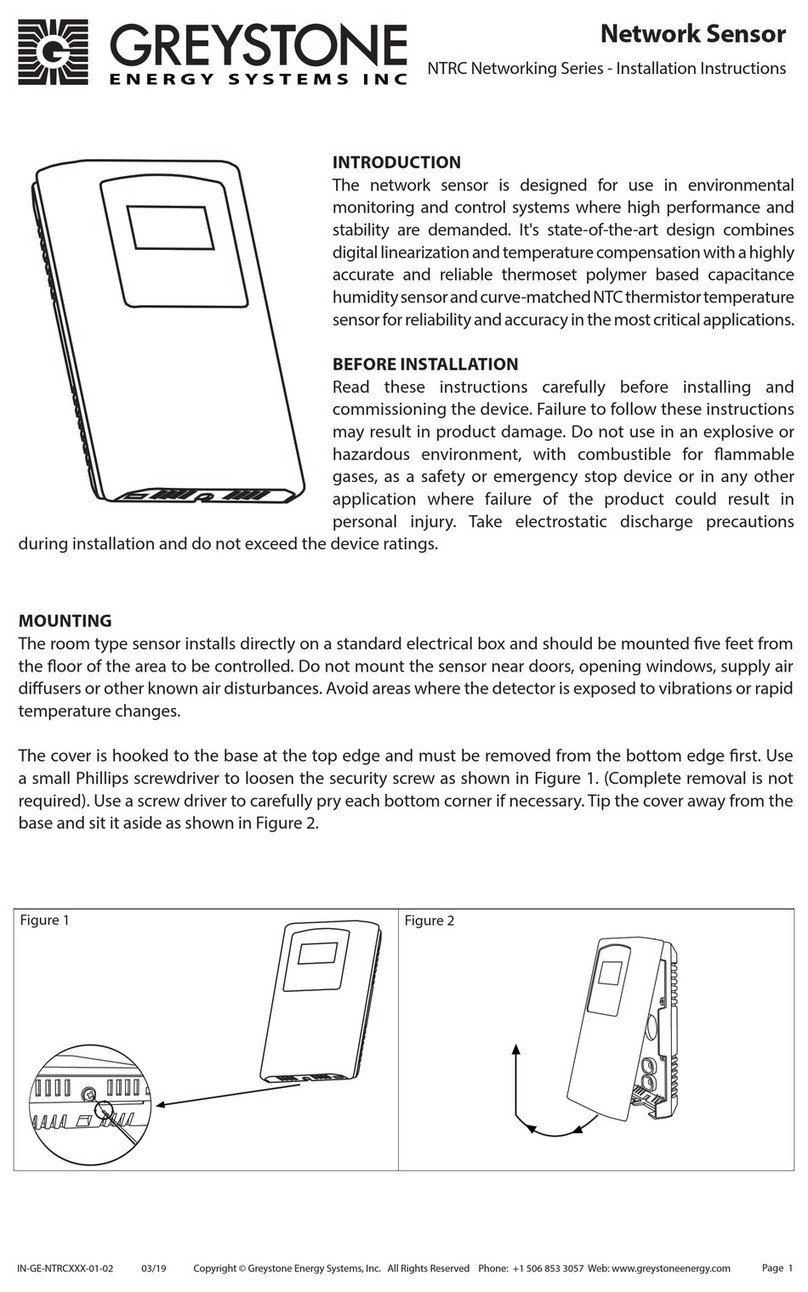

No. Description

9 Emergency Stop

10 110V Power OUT (to next unit)

11 100V 20AMP Power IN

1

2

3

4

5

6

7

8

9

10

11

Operator’s Manual | LP400 17

6.6 CONTROL BOX WIRING DIAGRAM

WARNING!

ALL ELECTRICAL WORK MUST BE CARRIED OUT BY A QUALIFIED ELECTRICIAN

AND SHALL COMPLY WITH RELEVANT STANDARDS AND LEGISLATION.

18 Operator’s Manual | LP400

Operator’s Manual | LP400 19

20 Operator’s Manual | LP400

LP400

OPERATOR’S MANUAL

Rev.1 : 2020-12-07

InterQuip USA LLC

4 Duke Place

Norwalk, CT 06854

(203) 322-2600

info@interquip.net

Table of contents

Popular Accessories manuals by other brands

Bamo

Bamo MAXIMAT VK C instruction manual

Klarstein

Klarstein 10032797 manual

Greystone Energy Systems

Greystone Energy Systems NTRC Networking Series installation instructions

Quasar

Quasar QFI-SWITCH Installation

Sensopart

Sensopart FT 50 RLA 70-L8 Mounting and operating instructions

ActiVHeat

ActiVHeat 9BHWSL3 Series user manual