HBM ML71BS6 User manual

Operating Manual

English

ML71BS6

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbm.com

Mat.: 7-2002.0572

DVS: A00851_03_E00_02 HBM: public

06.2018

EHottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

ML71BS6 A00851_03_E00_02 HBM: public 3

English

1 Safety instructions 4........................................

2 Markings used 6............................................

2.1 The markings used in this document 6..........................

2.2 Symbols on the product 6.....................................

3 Introduction 7..............................................

4 Connections 8..............................................

4.1 Pin assignment 8............................................

5 Front panel 9...............................................

6 Parameterization 10..........................................

6.1 Settings CAN1 /CAN2 10......................................

6.1.1 Panel output signals CAN 1 12.................................

7 Menu structure in set‐up mode 15............................

8 CAN protocol 16.............................................

8.1 Measurement signal transmission 16............................

8.1.1 Absolute values in Float 16.....................................

8.1.2 In digits as Long 16...........................................

8.1.3 In digits as Word 16...........................................

8.1.4 Identifier assignment 17.......................................

Safety instructions

4A00851_03_E00_02 HBM: public ML71BS6

1 Safety instructions

Use in accordance with the regulations

The ML71BS6 CAN bus module is to be used exclusively for measurement

tasks and directly related control tasks. Use for any purpose other than the

above shall be deemed to be not in accordance with the regulations.

To ensure safe operation, the device may only be operated in accordance with

the information given in the Operating Manual. It is also essential to comply

with the legal and safety requirements for the application concerned during

use. The same applies to the use of accessories.

General dangers of failing to follow the safety instructions

The ML71BS6 CAN bus module complies with the state of the art and is

fail‐safe. The device may give rise to further dangers if it is inappropriately

installed and operated by untrained personnel.

Any person instructed to carry out installation, commissioning, maintenance or

repair of the device must have read and understood the Operating Manual and

in particular the technical safety instructions.

Remaining dangers

The scope of performance and supply of the ML71BS6 only covers part of the

range of measurement technology. In addition, equipment planners, installers

and operators should plan, implement and respond to the safety engineering

considerations of measurement technique in such a way as to minimise

remaining dangers. Prevailing regulations must be complied with at all times.

There must be reference to the remaining dangers connected with

measurement technique.

Working safely

Error messages must only be acknowledged when the cause of the error has

been removed and no further danger exists.

The device complies with the safety requirements of DIN EN 61010‐Part 1

(VDE 0411‐Part 1); Protection Class I.

Safety instructions

ML71BS6 A00851_03_E00_02 HBM: public 5

To ensure adequate immunity from interference, use only Greenline shielded

ducting (see HBM offprint ”Greenline shielding design, EMC‐compliant measur

ing cable; G36.35.0)

Conversions and modifications

No modifications that affect the design or the technical safety of the ML71BS6

CAN bus module may be carried out without our express agreement. Any

modification shall exclude all liability on our part for any resulting damage.

In particular any repair or soldering work on motherboards is prohibited. When

exchanging complete modules, use only original parts from HBM.

Qualified personnel

This instrument must only to be installed and used by qualified personnel,

strictly in accordance with the technical data and the safety requirements and

regulations listed. It is also essential to comply with the legal and safety

requirements for the application concerned during use. The same applies to

the use of accessories.

Qualified personnel means persons entrusted with the installation, assembly,

commissioning and operation of the product who possess the appropriate

qualifications for their function.

Maintenance and repair work on an open device with the power on must only

be carried out by trained personnel who are aware of the danger involved.

Markings used

6A00851_03_E00_02 HBM: public ML71BS6

2 Markings used

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to

follow these instructions in order to prevent accidents and damage to property.

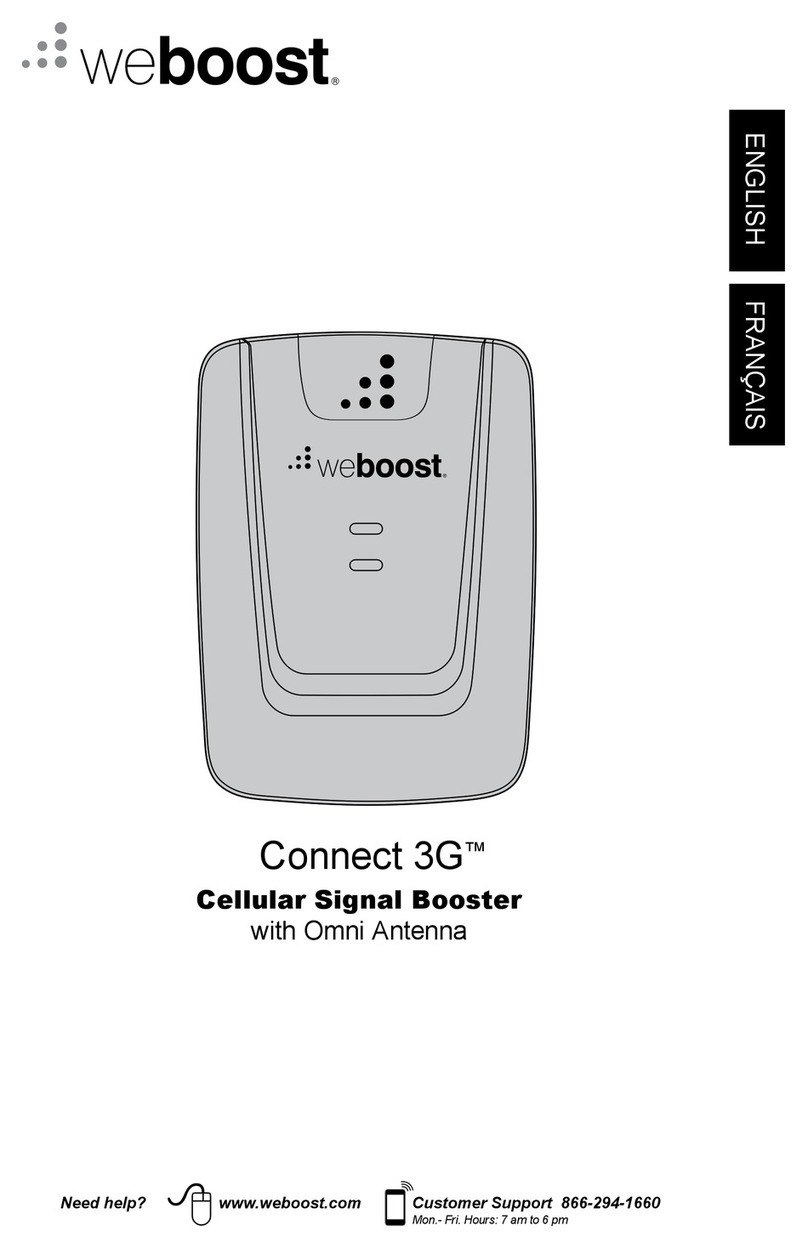

Symbol Significance

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important

information about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See….

Italics are used to emphasize and highlight text and

references to other chapters and external documents.

2.2 Symbols on the product

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the rele

vant EC directives (the declaration of conformity is avail

able at http://www.hbm.com/HBMdoc).

Introduction

ML71BS6 A00851_03_E00_02 HBM: public 7

3 Introduction

The ML71BS6 is an MGCplus system module that takes measurement data

from the MGC and outputs it as CAN messages. It records up to 128

measured values per CAN port, scales them and outputs them at the CAN bus.

Two independent CAN interfaces per channel and two different physical layers

(ISO 11898-24V and a ”low‐speed” link based on the Philips TJA1053

transceiver module) are supported.

The measurement data to be transmitted can be selected either by using the

AB22A/AB32 display and control panel or by using the “MGCplus Assistant”

software from HBM.

Connections

8A00851_03_E00_02 HBM: public ML71BS6

4 Connections

4.1 Pin assignment

The CAN bus is connected to the AP71 connection board by a 9‐pin Sub‐D

connector. You can connect two independent CAN field bus systems (female

connectors CAN1 and CAN2). Both the CAN interfaces are used to output the

MGCplus measurement data. Each of the interfaces can be assigned up to 128

measured values.

Connectors (male) CAN1/CAN2

1

5

6

9

CAN Shield

CAN_GND

CAN_L CAN_H

GND

CAN_V+

Physical layer:

High: Standard CAN speeds up to 1MBaud acc. to ISO11898

(24 V dielectric strength).

Low: Low-speed bus for in‐car communication up to 100 kBaud

(CAN_V+ must be connected to 12 V)

Fig. 4.1 CAN connection

Connections

ML71BS6 A00851_03_E00_02 HBM: public 9

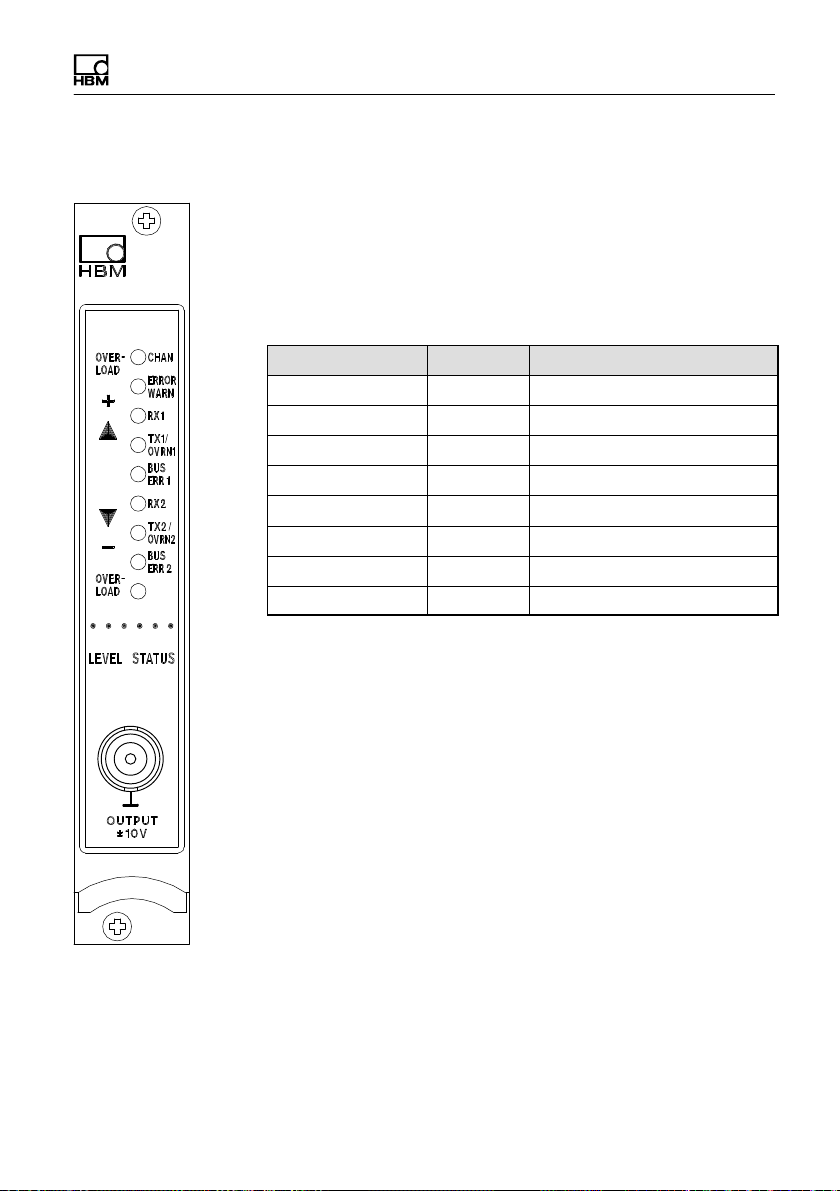

5 Front panel

The front panel LEDs have a dual function:

In Level mode, the signal level at the analogue output is

displayed.

In Status mode, the LEDs are assigned as shown below:

LED caption Colour Meaning in Status mode

CHAN. yellow Channel selected

ERROR/WARN. red error/warning

Rx1 - not used

Tx1/OVRN1 red/yellow CAN protocol transmitted

BUSERR1 red Bus error at CAN1

Rx2 yellow not used

Tx2/OVRN2 red/yellow CAN protocol transmitted

BUSERR2 red Bus error at CAN2

Analog output (BNC connector (female))

Any voltage from -10 V to +10 V can be output through

the female BNC connector by interface command.

ML71

BS6

Connections

10 A00851_03_E00_02 HBM: public ML71BS6

6 Parameterization

6.1 Settings CAN1 /CAN2

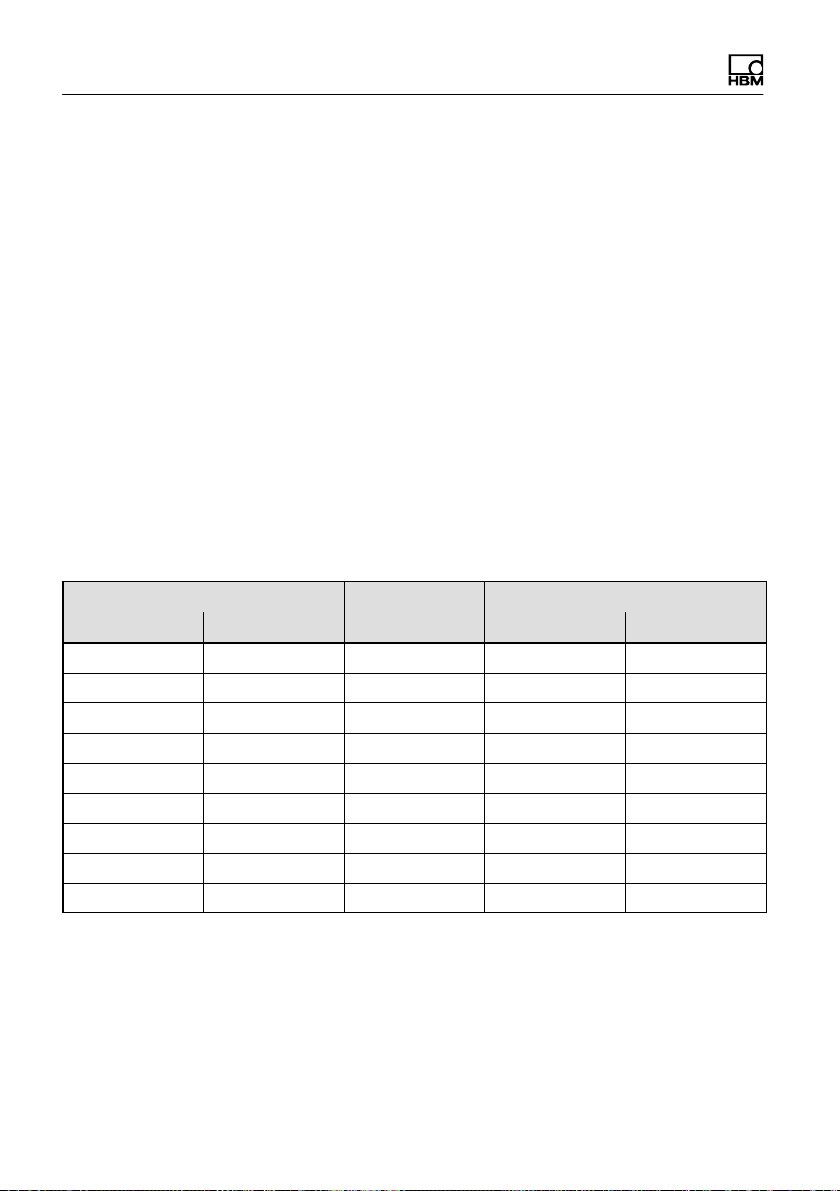

The baud rate, the transmission formats, the number of signals and the output

rate of the 1st CAN bus are set here. The same menu is applied

correspondingly to the 2nd CAN bus.

The maximum number of signals for a bus is 128 signals.

The following output rates are offered for selection depending on the number of

output signals. In the case of the 2nd CAN port, please note that the maximum

possible output rates can only be achieved if no signals have been selected at

CAN port1.

If a selected rate cannot be achieved, the messages will be output as quickly

as possible and an error message will be generated. Transmission will then not

be at a fixed frequency.

Number of signals

Format

Output rate [Hz]

CAN1 CAN2 Port1 Port2

4 4 INT16 2400 800

4 4 INT32 2400 600

4 4 Float32 2400 400

8 8 INT16 1200 800

8 8 INT32 1200 400

8 8 Float32 1200 300

16 16 INT16 600 600

16 16 INT32 600 300

16 16 Float32 600 300

The first ID of a range can be set. The last ID is derived from this and from the

number of signals.

Connections

ML71BS6 A00851_03_E00_02 HBM: public 11

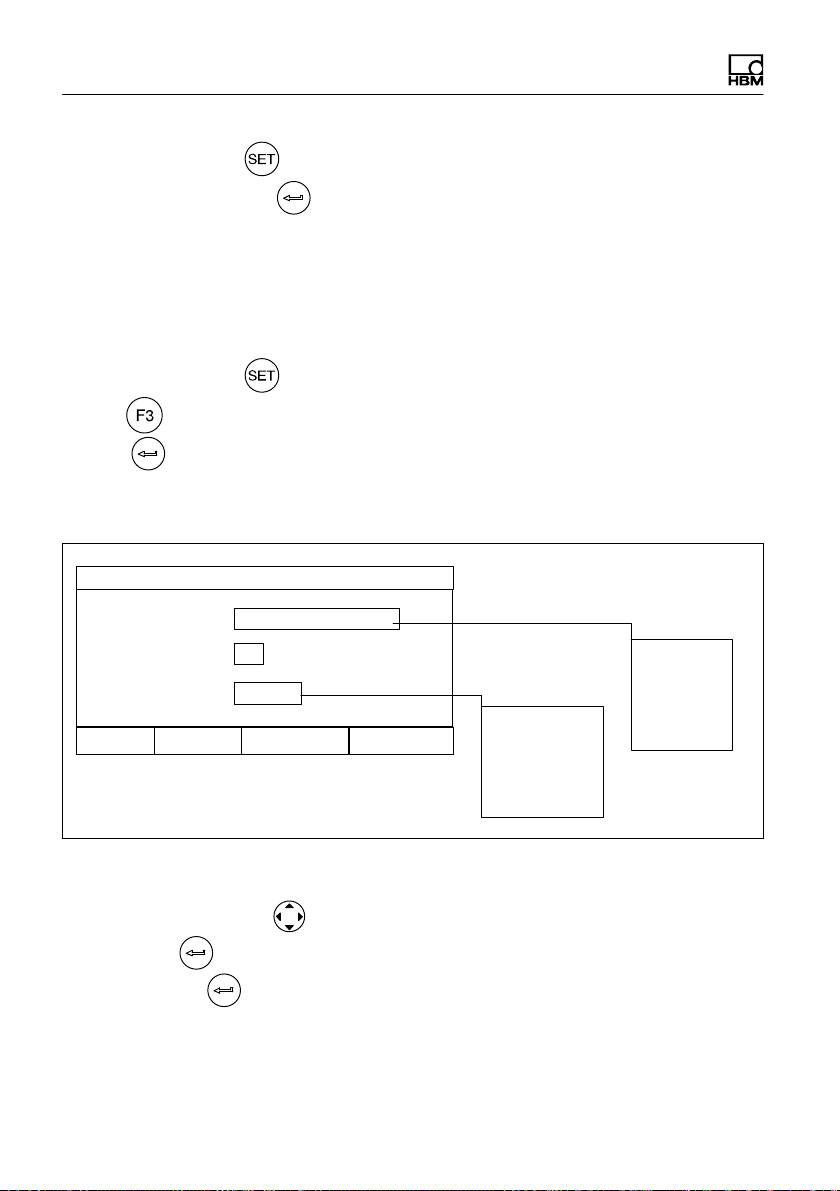

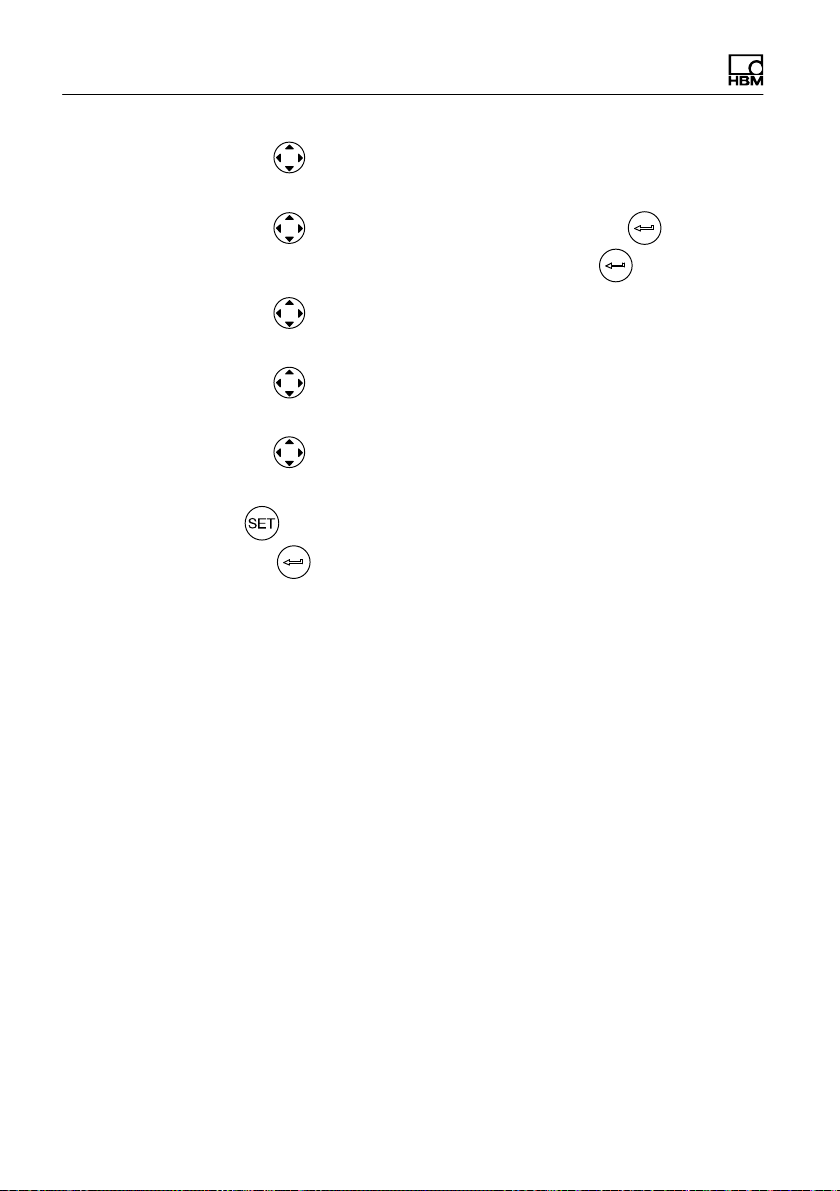

1. Use the shift key to change to set‐up mode and then press the function

key . Use the cursor keys to select “Settings CAN1” and confirm

with .

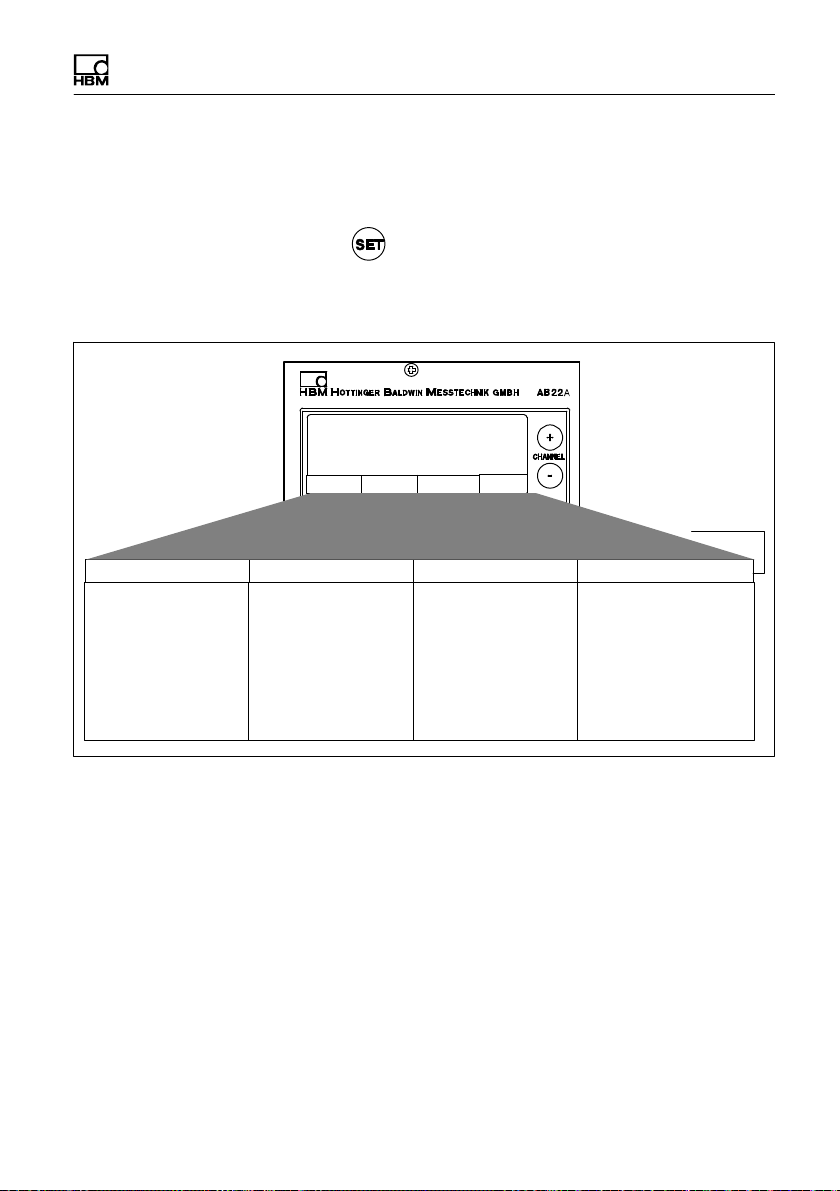

Settings CAN1 CHANNEL3

1000 kBaud

System Display Parameters Options

Float

8

1200 1/2

Baud rate

Format

Number of signals

Output rate

ID range used

1000 kBaud

667 kBaud

.

.

10 kBaud

Float

32-bit integers

16-bit integers

1 1/s

10 1/s

.

.

1200 1/s

First ID

Last ID

Reset CAN1 port

640

641

Fig. 6.1 CAN1 / CAN2 dialogue window

2. Use the cursor keys to choose the baud rate selection field. Use to

call the selection list and choose the desired baud rate. Confirm with .

3. Select the output rate in the same way as for 2.

4. Use the cursor keys to select the “Number of signals” edit field and en

ter the desired figure.

5. Select the output rate in the same way as for 2.

6. Use the cursor keys to select the “First ID” edit field and enter the de

sired figure. The “Last ID” edit field is set automatically.

Connections

12 A00851_03_E00_02 HBM: public ML71BS6

7. Use the shift key to change to measuring mode and confirm the fol

low‐up question with .

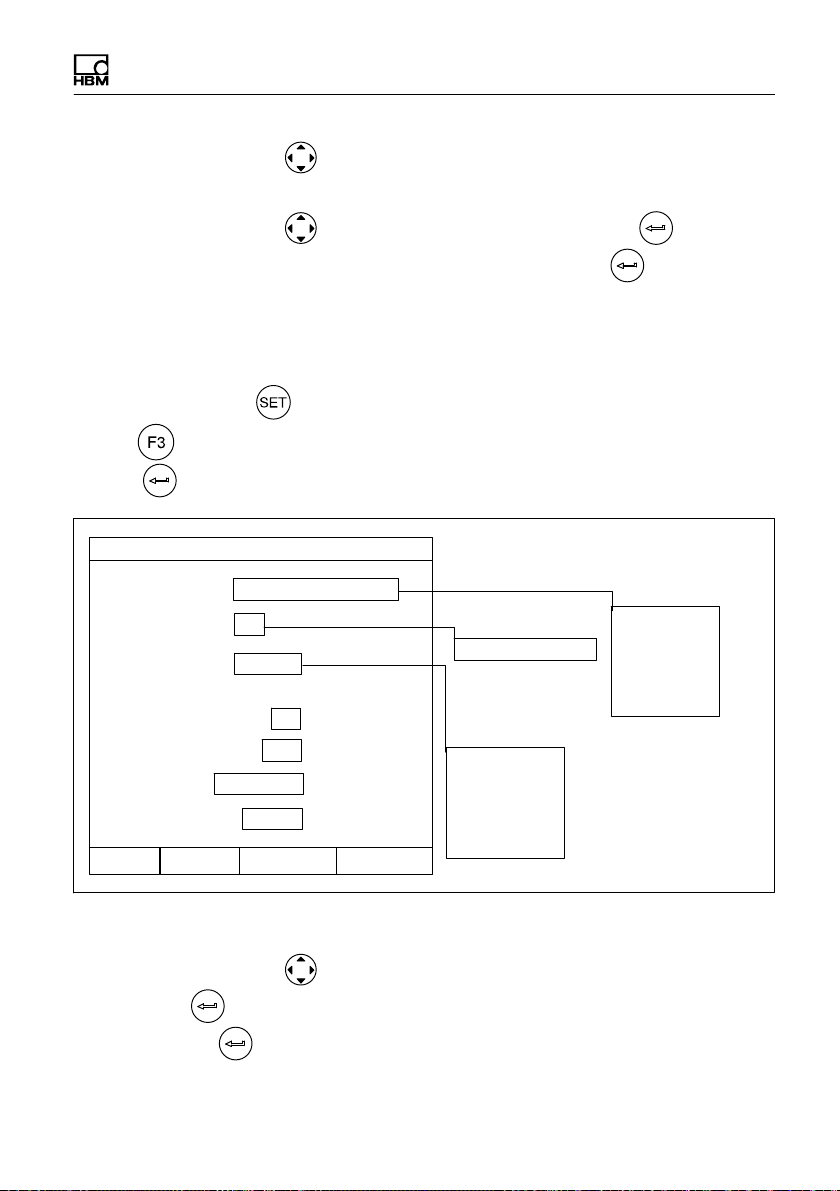

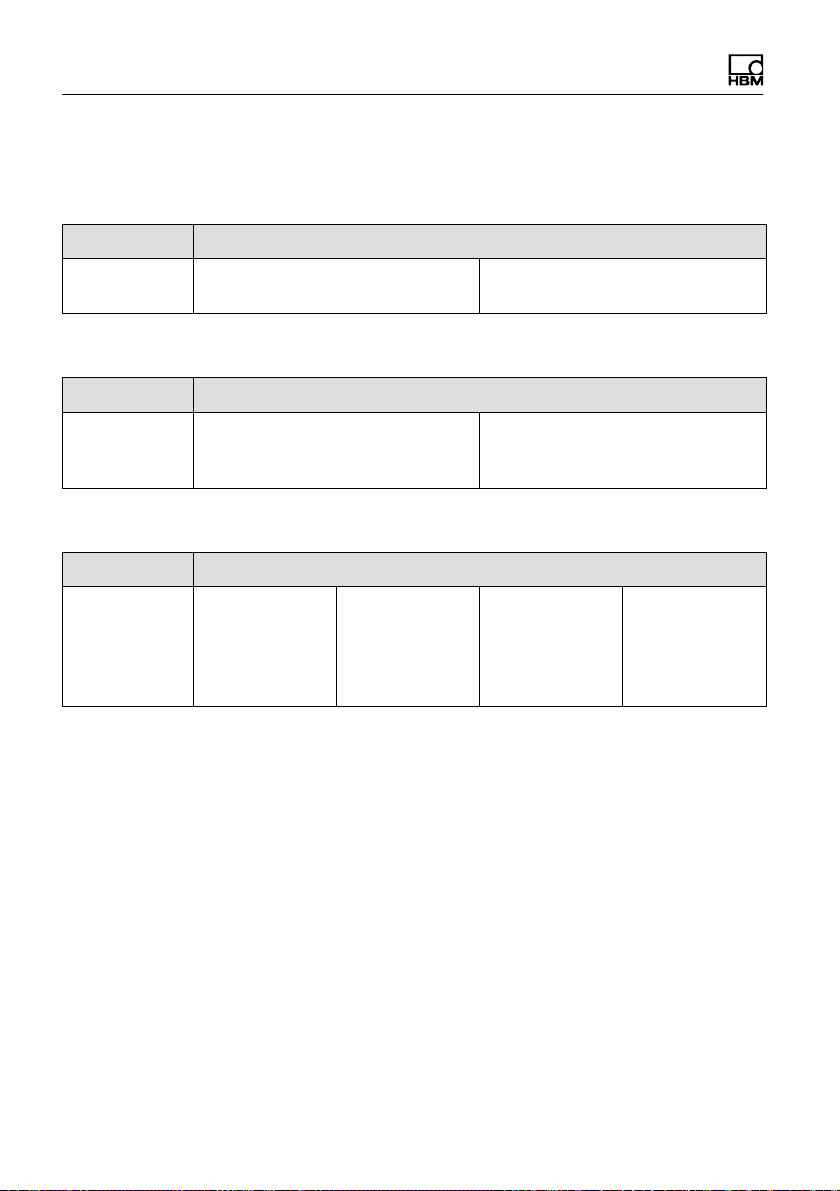

6.1.1 Panel output signals CAN 1

This is where to set the sources for the signals to be transmitted and if

necessary, scaling for the output values.

1. Use the shift key to change to set-up mode and then press the function

key . Use the cursor keys to select “Sources CAN1” and confirm

with .

Format 1; Absolute values Float

Sources CAN1 CHANNEL 3

CAN signal 1

System Display Parameters Options

Gross

Source for

MGC channel

Signal

CAN signal 1

CAN signal 2

.

.

CAN signal n

Gross

Net

Store1

Store2

Combined PV

8

Fig. 6.2 CAN1 / CAN 2 output signals dialogue window

2. Use the cursor keys to select the “Source for MGC channel” selection

field. Use to call the selection list and choose the desired CAN signal.

Confirm with .

Connections

ML71BS6 A00851_03_E00_02 HBM: public 13

3. Use the cursor keys to select the MGC channel field and enter the de

sired channel (e.g. 8.1).

4. Use the cursor keys to select the “Signal” edit field. Use to call the

selection list and choose the desired signal. Confirm with .

Formats 2 and 3; 32‐bit integers and 16‐bit integers

You must also specify scaling here.

1. Use the shift key to change to set-up mode and then press the function

key . Use the cursor keys to select “Sources CAN1” and confirm

with .

Sources CAN1 CHANNEL 3

CAN signal 1

System Display Parameters Options

Gross

0

Source for

MGC channel

Signal

Scaling

Point 1

CAN signal 1

CAN signal 2

.

.

CAN signal n

Gross

Net

Store1

Store2

Combined PV

Point 2

dig

10

7680000 dig

1000

8

kN

kN

Channel 8 to 128

Fig. 6.3 CAN1 / CAN 2 output signals dialogue window

2. Use the cursor keys to select the “Source for MGC channel” selection

field. Use to call the selection list and choose the desired signal.

Confirm with .

Connections

14 A00851_03_E00_02 HBM: public ML71BS6

3. Use the cursor keys to select the MGC channel field and enter the de

sired channel (e.g. 8.1).

4. Use the cursor keys to select the “Signal” edit field. Use to call the

selection list and choose the desired signal. Confirm with .

5. Use the cursor keys to select the “Point 1” edit field and enter the digit

value.

6. Use the cursor keys to select the next edit field and enter the value of

the accompanying physical unit.

7. Use the cursor keys to select the “Point 2” edit field and proceed in the

same way as for points 5 and 6.

8. Use the shift key to change to measuring mode and confirm the fol

low‐up question with .

Menu structure in set‐up mode

ML71BS6 A00851_03_E00_02 HBM: public 15

7 Menu structure in set‐up mode

The set-ups for the MGCplus unit are subdivided into groups according to their

function. Pressing the shift key takes you to the set‐up dialogue, and the

selection bar is displayed.

System-specific set

tings that in most

cases are only car

ried out during the

initial start‐up or for a

new measurement

task.

User-defined display

settings such as the

required method of

representing values,

function key assign

ment or the specifi

cation of channel

names.

Output signal CAN1

Output signal CAN2

Settings CAN1

Settings CAN2

Version

Display in Setup

mode

Setup for channel 3

Display Parameters OptionsSystem

Setup menu

DisplaySystem Parameters Options

You will find more notes on working with the AB22A display and control panel

in the “MGCplus with AB22A/AB32” manual.

CAN protocol

16 A00851_03_E00_02 HBM: public ML71BS6

8 CAN protocol

Up to 128 measured values can be transmitted at each bus.

A number of signals is assigned to each bus. This determines the signal trans

mission rate at the particular CAN port (in the case of CAN port 2, the operat

ing mode of CAN port 1 is also a factor).

8.1 Measurement signal transmission

The operating priority for the two CAN ports is different. CAN port 1 always

takes priority, to ensure that the transmission pattern of the data sent from

here is exactly periodic. When sending a synch signal, the values sent thus far

are valid here. CAN port 2 has the lower priority. Measurement signals can be

transmitted in the following three formats.

8.1.1 Absolute values in Float

In each 8-byte CAN message, 2 signals are transmitted as Float values

(32-bit). This is dealing with scaled measured values.

8.1.2 In digits as Long

In each CAN message, 2 of these values are transmitted as Long (32‐bit), with

the MSByte1) always being 0. Digital value scaling can be preset by using two

point calibrations.

8.1.3 In digits as Word

In each CAN message, 4 of these values are transmitted as Words (16‐bit).

Digital value scaling can be preset by using two point calibrations.

CAN protocol

ML71BS6 A00851_03_E00_02 HBM: public 17

8.1.4 Identifier assignment

Default assignment

The possible formats are sent out for the same signal under different

identifiers, so that fixed scaling can be assigned in the receiver of a specific ID.

The synch message at CAN port 1 has the identifier 80h2) and does not

contain any data bytes.

1) Most significant byte 2) This hexadecimal number corresponds to

the decimal value 128

Measurement data messages CAN port 1

Absolute values in Float (identifier: default values)

Identifier 8-byte data field

0x200-0x23F 4-byte measured value 1

(absolute Float)

4-byte measured value 2

(absolute Float

In digits from 7680000 (= 24-bit) as Long

Identifier 8-byte data field

0x240-0x27F 4-byte measured value 1

(signed integers in digits from

7680000)

4-byte measured value 1

(signed integers in digits from

7680000)

In digits from 30000 (= 16-bit) as Word

Identifier 8-byte data field

0x280-0x29F 2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

CAN protocol

18 A00851_03_E00_02 HBM: public ML71BS6

Measurement data messages CAN port 2

Absolute values in Float

Identifier 8-byte data field

0x300-0x33F 4-byte measured value 1

(absolute Float)

4-byte measured value 2

(absolute Float)

In digits from 7680000 (= 24-bit) as Long

Identifier 8-byte data field

0x340-0x37F 4-byte measured value 1

(signed integers in digits from

7680000)

4-byte measured value 1

(signed integers in digits from

7680000)

In digits from 30000 (= 16-bit) as Word

Identifier 8-byte data field

0x380-0x39F 2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

2-byte mea

sured value 1

(signed inte

gers in digits

from 30000)

Adjusting the ranges

As a variant to the default setting, you can choose the start of the ID range you

are using for the selected format at the particular CAN bus.

CAN protocol

ML71BS6 A00851_03_E00_02 HBM: public 19

www.hbm.com

HBM Test and Measurement

Tel. +49 6151 803-0

Fax +49 6151 803-9100

measure and predict with confidence

A00851_03_E00_02 7-2002.0572 HBM: public

Other manuals for ML71BS6

1

Table of contents

Popular Network Hardware manuals by other brands

ADC

ADC HiGain H2TU-C-319 List 4E Quick installation

R.V.R. Elettronica

R.V.R. Elettronica PTX30-UHT Installation, Technical and Maintenance Manual

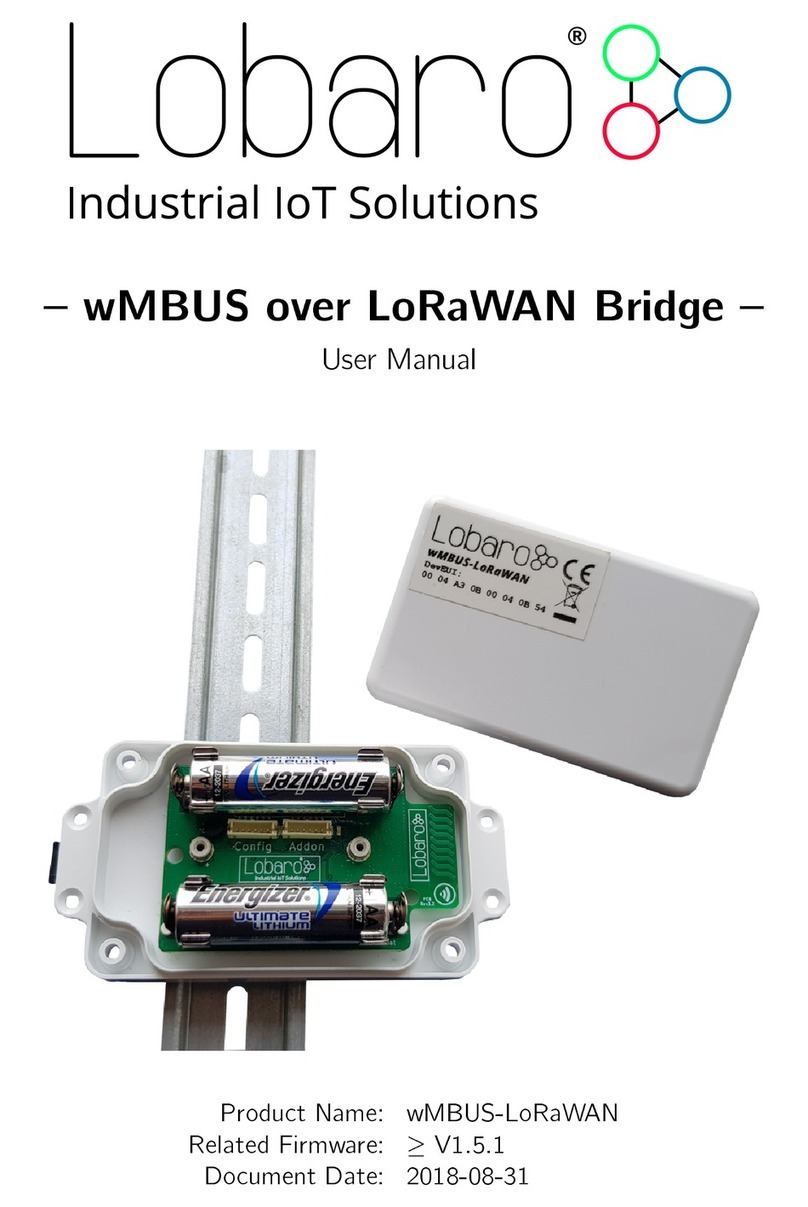

Lobaro

Lobaro wMBUS-LoRaWAN user manual

Cabletron Systems

Cabletron Systems 9F241-12 Appendix

Idis

Idis DR-6316PS-A quick guide

HIK VISION

HIK VISION 1200KI instruction manual