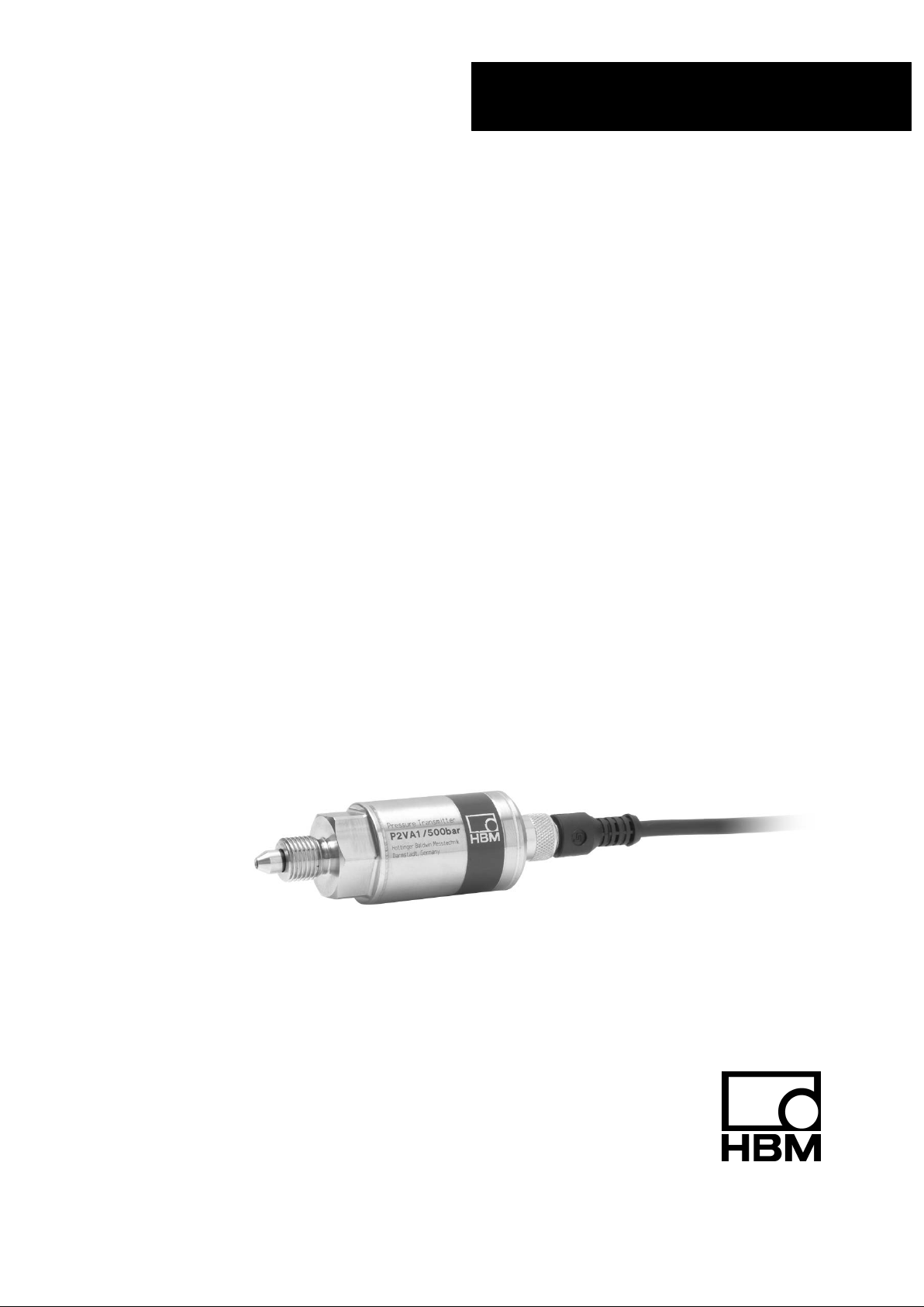

HBM P2VA1 User manual

A1564-5.5 en/de

Pressure transmitter

Drucktransmitter

P2VA1

P2VA2

Mounting Instructions

Montageanleitung

English Page 3 - 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deutsch Seite 23 - 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

P2VA1, P2VA2

A1564-5.5 en/de HBM

Contents Page

English

Safety instructions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Scope of supply 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Application 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Mechanical installation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Electrical connection of the P2VA1/A2 12. . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Electrical signal 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 TEDS transducer identification 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Measuring dynamic pressures 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Specifications (to DIN 16086) 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Dimensions 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P2VA1, P2VA2

4

A1564-5.5 en/deHBM

Safety instructions

Appropriate use

The P2V pressure transmitter is to be used exclusively for pressure measure

ment tasks and directly related control tasks. Use for any purpose other than

the above shall be deemed to be inappropriate.

In the interests of safety, the device should only be operated as described in

the Operating Manual. It is also essential to observe the appropriate legal and

safety regulations for the application concerned during use. The same applies

to the use of accessories.

We hereby declare that this device conforms to the requirements of Pressure

Directive 97/23/EC, the European Parliament and Council Directive of May 29

1997, which approximates the legal provisions of the Member States concern

ing pressure equipment.

The pressure transmitter is not a safety element within the meaning of its use

as intended. Proper and safe operation of this pressure transmitter requires

proper transportation, correct storage, assembly and mounting and careful

operation.

It is not appropriate for use as an “accessory with a safety function”, in

accordance with the regulations and this must be assessed by the user (within

the meaning of Pressure Equipment Directive 97/23/EC) for the particular situ

ation.

General dangers of failing to follow the safety instructions

The P2V pressure transmitter corresponds to the state of the art and is

failsafe. The device may give rise to further dangers if it is inappropriately

installed and operated by untrained personnel.

Any person instructed to carry out installation, commissioning, maintenance or

repair of the device must have read and understood the Operating Manual

and in particular the technical safety instructions.

Accident prevention

You must make sure that the line is not under pressure when installing or

removing the pressure transmitter.

Remaining dangers

The scope of supply and performance of the transducer covers only a small

area of measurement technology. In addition, equipment planners, installers

and operators should plan, implement and respond to the safety engineering

considerations of pressure measurement technology in such a way as to min

imize remaining dangers. Prevailing regulations must be complied with at all

5

P2VA1, P2VA2

A1564-5.5 en/de HBM

times. There must be reference to the remaining dangers associated with

pressure measurement technology.

Although the P2V is designed for maximum safety, safety engineering regula

tions demand that burst protection is implemented around the transducer.

The transducer must be protected against mechanical loads or knocks.

The resistance of the steel of the measuring body only applies if temperatures

are never allowed to fall below or rise above the limits specified in the data

sheet.

If these temperature limits are exceeded, in the event of fire, for example, the

transducer will be unusable.

A significant change in the zero signal shows that the device has come to the

end of its service life.

Remaining dangers are indicated in this operating manual by the following

symbols:

Symbol: DANGER

Meaning: Maximum danger level

Warns of an imminently dangerous situation in which failure to comply with

safety requirements will result in death or serious physical injury.

Symbol: WARNING

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements can result in death or serious physical injury.

Symbol: CAUTION

Meaning: Potentially dangerous situation

Warns of a potentially dangerous situation in which failure to comply with

safety requirements could lead to damage to property, slight or moderate

physical injury.

P2VA1, P2VA2

6

A1564-5.5 en/deHBM

Symbol: NOTE

Means that important information about the product or its handling is being

given.

Symbol:

Meaning: CE mark

The CE mark enables the manufacturer to guarantee that the product com

plies with the requirements of the relevant EC directives (the Declaration of

Conformity can be found at http://www.hbm.com/HBMdoc).

Conversions and modifications

The P2V/xxx pressure transmitter must not be modified from the design or

safety engineering point of view except with our express agreement. Any

modification shall exclude all liability on our part for any damage resulting

there from.

Qualified personnel

The pressure transmitter is only to be installed and used by qualified person

nel strictly in accordance with the technical data and with the safety rules and

regulations which follow. It is also essential to observe the appropriate legal

and safety regulations for the application concerned during use. The same

applies to the use of accessories.

Qualified personnel means persons entrusted with the installation, assembly,

commissioning and operation of the product, who possess the appropriate

qualifications for their function.

Recalibration and repair

When you send the transducer back to HBM for calibration or repair, please

specify which pressure medium is being used. It is always possible that resid

ual medium could be trapped in the measuring aperture. We need this inform

ation so that we can take appropriate action and choose the correct cleaning

agent, where necessary. If we do not know the media, we may have to refuse

to calibrate or repair.

7

P2VA1, P2VA2

A1564-5.5 en/de HBM

1 Scope of supply

The scope of supply for the standard version includes:

•1 x pressure transducer

voltage output:

Order No.: 1-P2VA1/100...7000 bar or

current output:

Order No.: 1-P2VA2/100...7000 bar

•1 x 5 m cable, female cable connector, M12x1 with shielding,

5-pin. Polyurethane

Order No.: 1-KAB166-5

•For pressure transducer 1-P2VA1/100...2000 bar or

1-P2VA2/100...2000 bar in addition:

1 pack with 2 x 58-degree tapered seals with retaining spring1)

Order No.: 2-9278.0371

•1 x Mounting Instructions

Options to be ordered:

Connection adapter for measuring ranges less than 3000 bar

•Connection adapter G1/4"external thread, M20x1.5 external thread

Order No.: 1-Adapt-G1/4-M20

•Connection adapter G1/4"external thread, G1/2"external thread

Order No.: 1-Adapt-G1/4-G1/2

•Pack with 2 x 58-degree tapered seals with retaining spring 1)

Order No.: 2-9278-0371

•5 m cable, female cable connector, M21x1 with shielding,

5-pin. Polyurethane

Order No.: 1-KAB166-5 2)

•20 m cable, female cable connector, M21x1 with shielding,

5-pin. Polyurethane

Order No.: 1-KAB166-20

1) for measuring ranges of 100 bar to 2000 bar

2) as a spare or for an additional need

P2VA1, P2VA2

8

A1564-5.5 en/deHBM

2 Application

In the measuring system, the P2V transducer corresponds to HBM's proven

passive strain gage absolute pressure transducers, with a measuring body

made from one piece of material. A high-quality analog sensor amplifier and a

digital control for signal correction are also integrated in the enclosure.

All that is seen of this circuitry on the outside is what looks like an active

sensor output with 0.5 to 10 volts (or a 3-wire current output of 4 to 20 mA.) .

The additional microcontroller monitors the sensor temperature and the cur

rent pressure and generates correction signals, so that systematic sensor

errors such as temperature coefficients and the linearity deviation can be

compensated for internally. The individual adjustment and correction data can

be transferred to the transducer during production. HBM's TEDS digital identi

fication system is also available (compatible with the 1-wire EEPROM

DS2433, MikroLan from Messrs Maxim / Dallas).

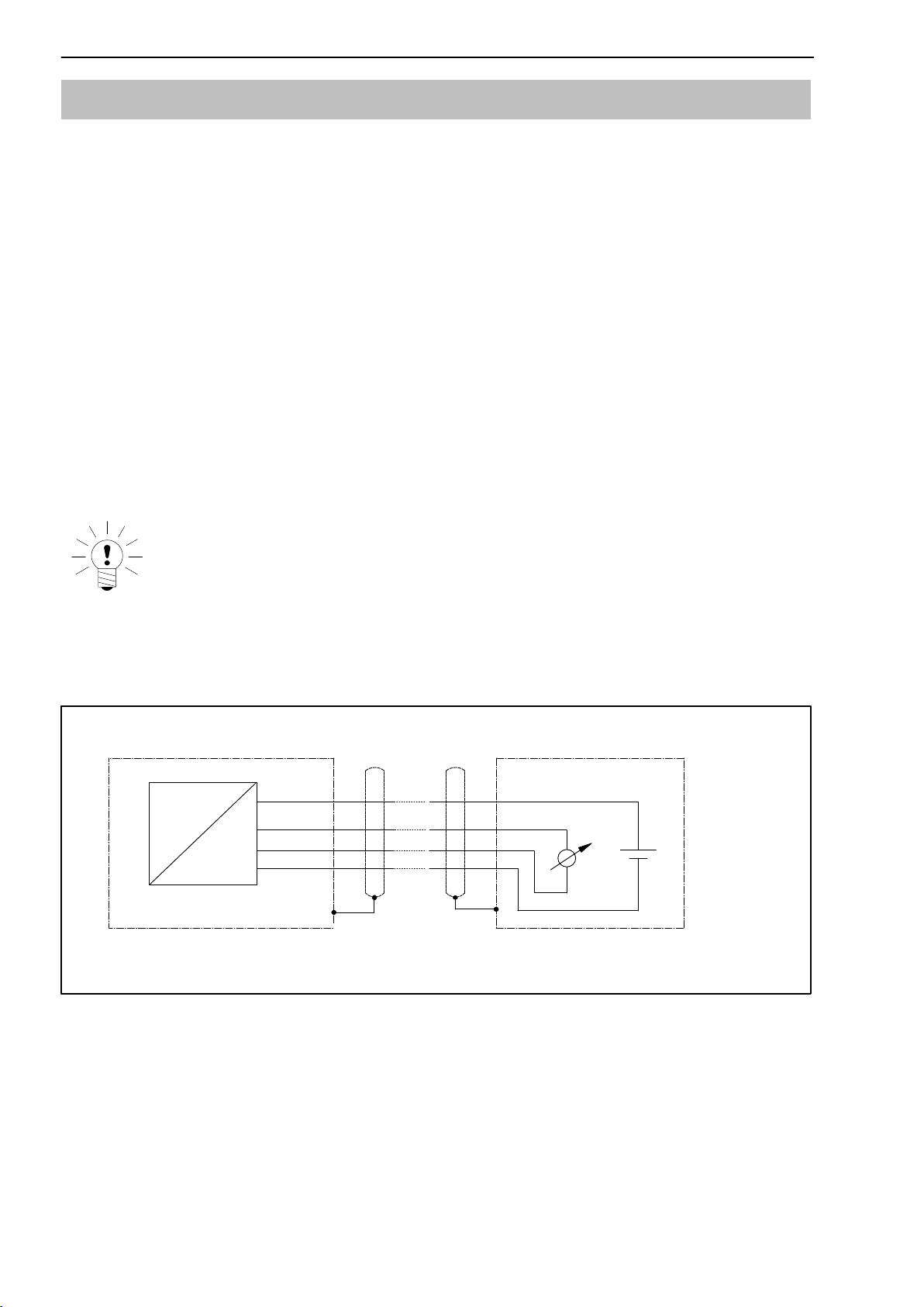

NOTE:

The 0 V power supply (pin 3) and 0 V output (pin 2) lines are

linked internally.

+UB

+Uout/Iout

0 V

P

U

Enclosure Enclosure

Fig. 2.1: Electrical connection diagram

9

P2VA1, P2VA2

A1564-5.5 en/de HBM

Blow-off opening:

The transducer housing features a blow-off opening under the blue label (see

figure):

Blow-off opening

This safety device enables overpressure to be reduced in a controlled way in

the event of bursting of the sensing element. This prevents overloading of the

sensor housing. The blow-off opening opens at approx. 10 bar.

P2VA1, P2VA2

10

A1564-5.5 en/deHBM

3 Mechanical installation

CAUTION

Before installing the P2V, check that the threaded connector and

the thread in its mating component are sound and without

burrs. The parts must be easy to join together.

The pressure transducer can be screwed in wherever required. If the transducer

is used to measure dynamic pressure characteristics in liquids, it should be

installed with the pressure connection pointing upward, so that it not possible for

an air cushion to build up in the measuring tube that could, for example, heat up

unacceptably in the event of adiabatic effects as a result of dynamic loads.

Transducers with measuring ranges of 100 ... 2000 bar are connected with their

G1/4"external thread pressure connection. A 58°tapered seal made of 1.4301

corrosion-resistant material is supplied for this purpose.

The G1/4"pressure connection thread with the tapered seal is suitable for the

usual 17 mm hole depth and a drilled diameter of 4 mm (with a margin of

between 0 and 0.5x45°, also see Specifications).

The tapered seal is fixed accurately and securely in the measuring aperture of

the transmitter by means of the small, stainless steel retaining spring that is

among the items supplied for each seal. The device can thus be fitted and

sealed extremely efficiently.

Transducers with measuring ranges of 3000 bar and higher are connected with

their M16x1.5 external thread pressure connection directly to conventional high

pressure pipes with their 58°taper.

CAUTION:

During installation, screwing torque must not be applied over the

enclosure or the cable entry. Wrenches (SW 24) must be used to

screw-fasten the pressure transmitter. The permissible tightening

torque for measuring ranges 100 ... 2000 bar is 30 Nm; for measur

ing ranges 3000 and 7000 bar, the permissible tightening torque is

30 ... 50 Nm

11

P2VA1, P2VA2

A1564-5.5 en/de HBM

DANGER:

Before removing the P2V pressure transmitter, you must check that

the line is not pressurized.

P2VA1, P2VA2

12

A1564-5.5 en/deHBM

4 Electrical connection of the P2VA1/A2

An external amplifier is connected to the P2V in accordance with Fig. 4.1.

NOTE:

The inputs and outputs of the P2V are protected against short cir

cuits and reverse polarity.

1

3

2

Supply voltage 15 to 30 V DC 1)

Transducer identification

TEDS DATA

Supply voltage 0 V 2)

Output 0 V

Output 0.5 to 10 V (4 to 20 mA for the P2VA2)

5

brown

blue

black

white

gray

4

Connections 2 and 3 are internally linked.

3

5

4

12

1) Operating on a SELV circuit (separated extra-low

voltage)

2) also ground for TEDS

Connection

cable wire

assignments

Fig. 4.1: Pin assignment of the P2V

CAUTION:

Using the TEDS memory: Because of the electrical specifications,

voltages > 6 V must never be applied to the TEDS memory. Never

connect the supply voltage of the P2V with TEDS pin 5. This

would destroy the memory.

13

P2VA1, P2VA2

A1564-5.5 en/de HBM

If the P2V is connected with the HBM MGCplus amplifier system, the connec

tion is made via AP01i, as shown in Fig. 4.2.

2

1

8

9

Cable wire colors: wh= white; bk= black; bu= blue; rd= red; ye = yellow; gn= green; gr= gray

AP01i

(ML01B)

bn

wh

bu

bk

gy

1

2

3

4

5

15

4

8

9

15

P2VA1

15 V

0 V (TEDS)

0.5 - 10 V

TEDS

6

Connector side view

of transducer

1

24

5

3

2

1

8

9

AP01i

(ML01B)

bn

wh

bu

bk

gy

1

2

3

4

5

6

4

5

9

15

P2VA2

15 V

0 V (TEDS)

4 ... 20 mA

TEDS

Connector side view

of transducer

1

24

5

3

Voltage output

Current output

Fig. 4.2: Connection with TEDS to AP01i

P2VA1, P2VA2

14

A1564-5.5 en/deHBM

NOTE:

The 0 V power supply (pin 3) and 0 V output (pin 2) lines are

linked internally.

The transducer is designed for direct voltage operation (15 to 30 volts).

The circuit is intended for operating with a separated extra-low voltage (SELV

circuit). It is not intended for connection to a dc network in accordance with

EN 61010-1.

Should the equipment be operated on a dc voltage network, additional pre

cautions must be taken to discharge excess voltages.

NOTE:

The P2V meets EMC guideline requirements (a condition of the

transducer being granted the CE mark).

To prevent measured value errors when there is heavy high-fre

quency interference, a shielded connection cable with a metal

female cable connector must be used, with the cable shielding

connected to the entire surface of the female cable connector. The

enclosed HBM connection cable meets this requirement.

4.1 Electrical signal

The output signal of the P2VA1 pressure transmitter at 0 pressure is 0.5 V, for

the P2VA2 pressure transmitter, it is 4 mA.

The output signal of the P2VA1 pressure transmitter at nominal (rated) pres

sure is 10 V and for the P2VA2 it is 20 mA. Accordingly the output signal span

(sensitivity) for the P2VA1 is 9.5 V and for the P2VA2, 16 mA.

The displayed pressure is calculated from:

P2VA1: Pabs = ( Uout -0.5 V ) * nominal (rated) pressure / 9.5 V

P2VA1: Pabs = ( Uout -4 V ) * nominal (rated) pressure / 16 mA

15

P2VA1, P2VA2

A1564-5.5 en/de HBM

4.2 TEDS transducer identification

At connection 5 (to ground at 3), there is a digital identification system avail

able. The basis for this is a 1-wire EEPROM DS2433, from Messrs Maxim/

Dallas.

TEDS stands for “Transducer Electronic Data Sheet”. An electronic data sheet

is stored in the transducer as defined in the IEEE 1451.4 standard, making it

possible for the measuring amplifier to be set up automatically. A suitably

equipped amplifier imports the transducer characteristics (electronic data

sheet), translates them into its own settings and measurement can then start.

HBM provides you with the TEDS Editor for storing your data. This is included

in the software for the MGCplus Setup Assistant.

The Editor also makes it possible to manage the different user rights, to pro

tect the fundamental transducer data from being inadvertently overwritten.

Contents of the TEDS memory as defined in IEEE 1451.4:

The information in the TEDS memory is organized into templates which are

prestructured to store defined groups of data in table form. Only the entered

values are stored in the TEDS memory itself.

The amplifier firmware assigns the interpretation of the respective numerical

values. This places a very low demand on the TEDS memory.

The memory contents are divided into four areas:

Area 1:

An internationally unique identification number (cannot be changed).

Area 2:

The base area (basic TEDS), to the configuration defined in standard

IEEE1451.4. The transducer type, the manufacturer and the transducer serial

number are contained here.

Area 3:

Data specified by the manufacturer are contained in this area:

The data specifies

- the transducer type,

- the measured quantity,

- the electrical output signal,

- the required excitation.

Area 4:

The actual user can modify the last of these areas with, for instance:

- a short comment in text form,

- filter settings,

- zero value.

P2VA1, P2VA2

16

A1564-5.5 en/deHBM

Example:

The TEDS content of sensor P2VA1/500 bar with ident. no. 081310277, man

ufactured in August 2004

TEDS

Manufacturer HBM

Model P2V (voltage output)

Version letter

Version number 8

Serial number 1310277

Template: High Level Voltage Output sensor

Transducer Electrical Signal Type Voltage Sensor

Minimum Pressure 0.000 Pa

Maximum Pressure 50.000M Pa

Minimum Electrical Value 500.00000m V

Maximum Electrical Value 10.00000 V

Mapping Method Linear

AC or DC Coupling DC

Output Impedance of the Sensor 10.00k Ohm

Transducer Response Time 1.0000000u sec

Excitation Level (Nominal) 24.0 V

Excitation Level (Minimum) 15.0 V

Excitation Level (Maximum) 30.0 V

Excitation Voltage Type DC

Maximum current draw at nominal excita

tion level 25.12m A

Calibration Date 3-Aug-2004

Calibration Initials HBM

Calibration Period (Days) 0 days

Measurement location ID 0

Template: HBM Channel name

Channel name P2VA1 / 500 bar

5 Measuring dynamic pressures

During dynamic loading, the maximum pressures should not be greater than

the nominal pressure.

The transducers are designed for these loads, but the actual conditions from

the operating load and the typical spread require safety measures against the

transducer bursting.

Calibration related to static pressures is also applicable when measuring

dynamic pressures.

17

P2VA1, P2VA2

A1564-5.5 en/de HBM

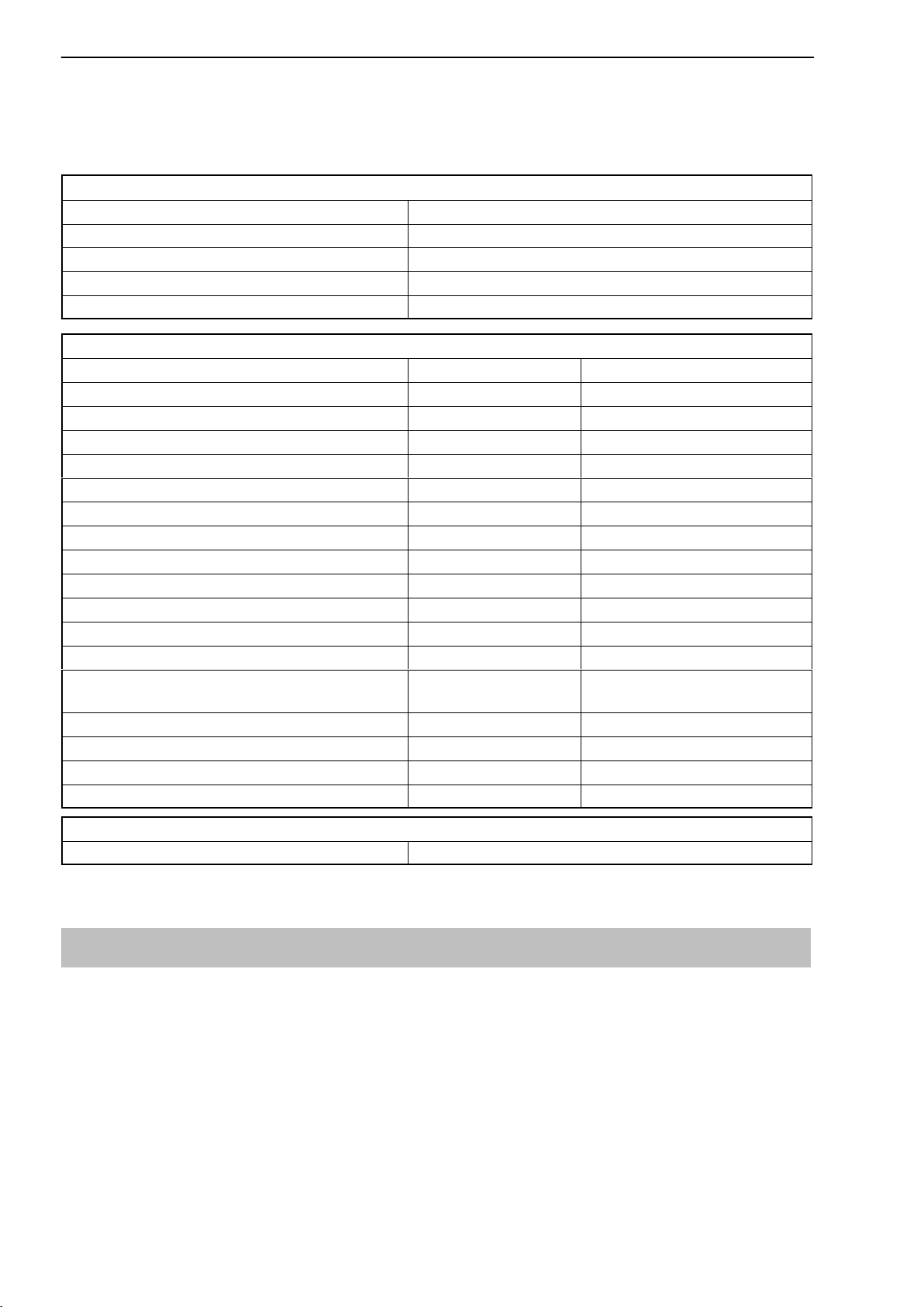

6 Specifications (to DIN 16086)

Type P2VA1 (output signal in V) 1)

P2VA2 (output signal in mA) 1)

Measuring ranges bar 100 200, 500, 1000,

2000, 3000 5000, 7000

Input quantities

Pressure type Absolute pressure

Accuracy class 0.2 0.3

Initial value bar 0

Operating range at reference temperature %0 to approx. 110

%0 to approx. 105

Overload limit at reference temperature % 150

Test pressure % 200 150

Dynamic loading

Permissible pressure

Permissible vibration amplitude

(dyn. load according to DIN 50100)

%

%100

70

Dead volume approx. cm30.8

Control volume, approx. mm31.5

Materials from which components in

contact with the measurement media are

made

1.4542, 1.4301

Output characteristics

Transducer identification TEDS

Signal span (sensitivity) V0.5 ...10

mA 4...20 (16)

Zero signal, adjustment tolerance Vt"0.02 t"0.010 "0.020

(factory) mA "0.032 t"0.016 "0.032

Sensitivity tolerance Vt"0.02 t"0.010 "0.020

mA "0.032 t"0.016 "0.032

Maximum signal V 10.5

mA 21.6

Effect of temperature on the zero signal

in the nominal (rated) excitation voltage

range per 10K, by reference to the nominal

(rated) sensitivity

% /

10K 0.2

Effect of temperature on sensitivity in

the nominal (rated) excitation voltage range

per 10K, by reference to the actual value

% /

10K 0.2

Characteristic curve deviation (start set

ting)

%0.3

Repeatability according to DIN 1319 %t"0.05

Cut-off frequency

-3 dB

-1 dB kHz

kHz 4.5

2

Burden Ω ≥10000 (min.)

3500 (max.)

1) normal type: P2VA1; italics: P2VA2

P2VA1, P2VA2

18

A1564-5.5 en/deHBM

Auxiliary energy

Reference voltage

Nominal (rated) range V

V24

15 ... 301)

Effect of the supply voltage

when changing from 15 to 30 V % 0.02

Max. current consumption (for the

P2VA2, excluding loop current) mA +25

Max. power consumption Wt1

t2

Ambient conditions

Reference temperature oC +23

Nominal (rated) temperature range °C0 ... + 70

Operating temperature range °C-20 ... + 85

Storage temperature range °C-40 ... +85

Impact resistance (tested to DIN IEC68)

Impact acceleration m/s21000

Impact duration ms 4

Impact form Half sine wave

Vibration resistance (tested to DIN IEC

68) m/s2150

Mechanical specifications

Measuring ranges bar 100, 200, 500,

1000, 2000 3000, 5000, 7000

Pressure connection G1/4 externally M16 x 1.5 internally

Seal Metallic, edge loading, 58°taper.

For the mounting operation, the seal can be

attached to the transducer.

Transducer mounting The seal can be

attached to the

transducer.

Connect directly to a

high-pressure pipe

with a manipulated

pipe end

Tightening torque, max. Nm 30 30...50

Electrical connection M12 x 1 / 5-pin connector

Mounting position Any, but preferably pressure connection

uppermost for venting purposes

Dimensions

Length (without pres. connection and mating

connector)

Maximum diameter

mm

mm

70

30

approx. 80

30

Hexagon, across flats mm 24

Weight without cable, approx. g 150 200

Degree of protection IP67

1) With P2VA2, the permissible dissipation power is exceeded at maximum operating temperature and maximum excitation voltage.

Therefore, the maximum operating temperature is 70 °C instead of 85 °C with P2VA1.

19

P2VA1, P2VA2

A1564-5.5 en/de HBM

Sealing joint (to customer design)

3000 bar and higher:

M16x1.5 internally: High-pressure screw connector M16x1.5, for example, from

Nova Swiss. The transducer has a relief aperture, which exits in the center of a

hexagonal face.

Less than 3000 bar:

G1/4"externally (using the conical seals 58 degree with retaining spring included

for these measuring ranges): The depth to the root of the line aperture should be

17mm, the thread must be at least 13.5mm long. The diameter of the line aper

ture should be 4mm sharp-edged or with a margin (max. 0.5x45°)of 5mm.

Possible up to 1000 bar:

Under the hexagon, sealing is provided by a Usit ring, 14.7x22x1.5. The ring must

be centered and supported by a recess with a depth of 1.3mm and a diameter of

22.2 "0.1mm.

P2VA1, P2VA2

20

A1564-5.5 en/deHBM

7 Dimensions

P2V 100 bar -2000 bar

Installation

example

Tapered seal

with retaining

spring

Production number

10

Ø3.5

Ø7

58o

Pressure

transmitter

Relief

aperture

Tapered seal

with retaining

spring

approx. 70

Ø30

60o

M12x1

Built-in 5-pin

connector

approx. 60

24 a.f.

G 1/4"

Ø6

13

17

Ø4

G1/4"

Bending radius,

static, 25 mm

Other manuals for P2VA1

1

This manual suits for next models

1

Table of contents

Languages:

Other HBM Transmitter manuals