HBX Snowmelt Sensor

© HBX Control Systems Inc. 2014 Page 3

RECEIPT & INSPECTION

The SNO-0110/SNO-0111 has gone through rigorous

quality control tests at the factory before shipment.

After receipt and before installation perform the

following checks:

Receipt

After receiving, inspect the unit for any possible

physical damage that may have occurred during

transportation.

Inspection

After unpacking the unit make sure the boxes

contain:

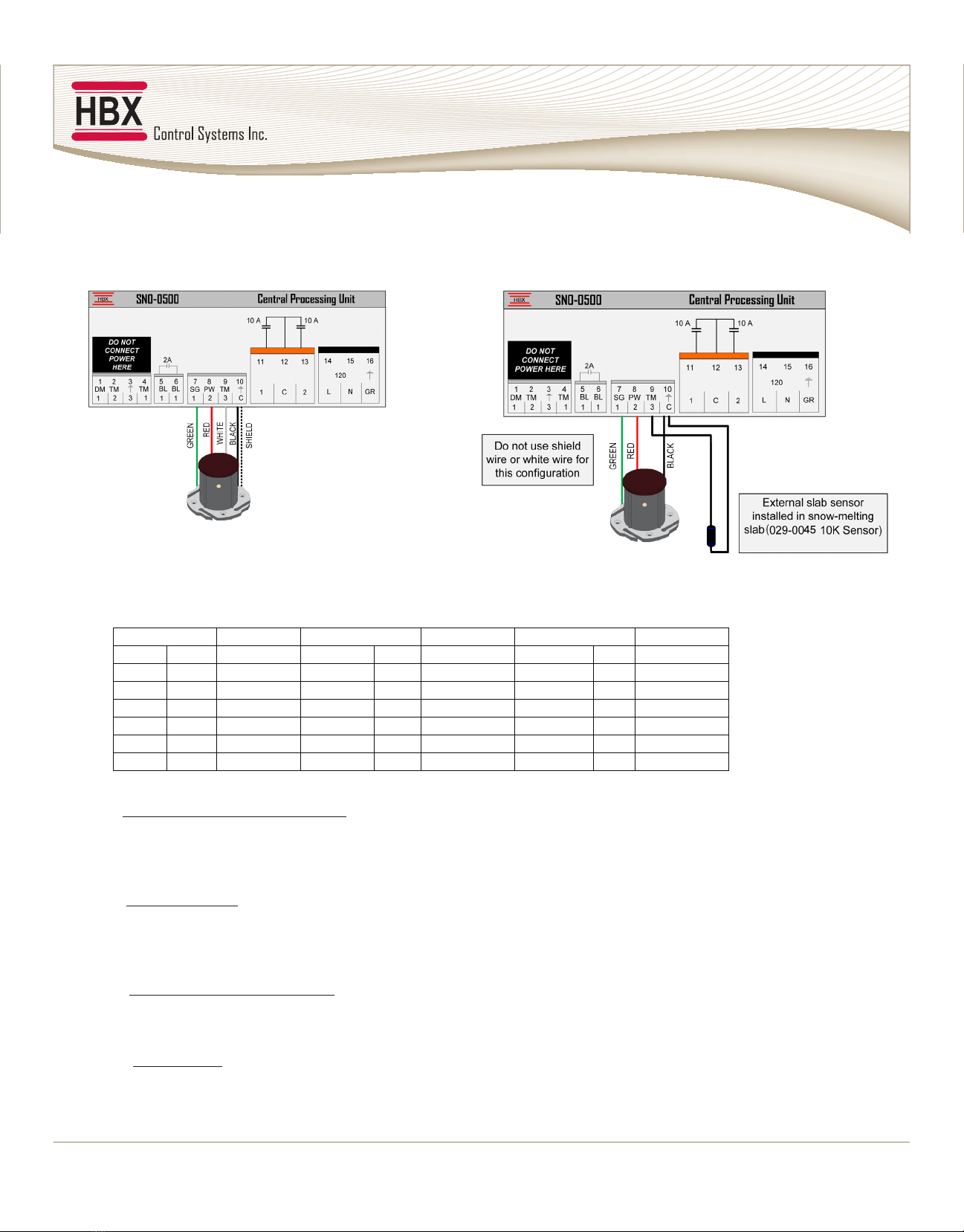

SNO-0110 Package:

• Optical snowmelt sensor

• 30 meters of 22AWG 2 pair shielded cable

• 4 x Stainless steel 4 x 25mm machine screws

• 3 meters Universal Sensor

SNO-0111 Package:

• Sensor socket

• Cover plate (dud sensor)

• 4 x Stainless steel 4 x 25mm machine screws

• Remote Slab Sensor

DESCRIPTION

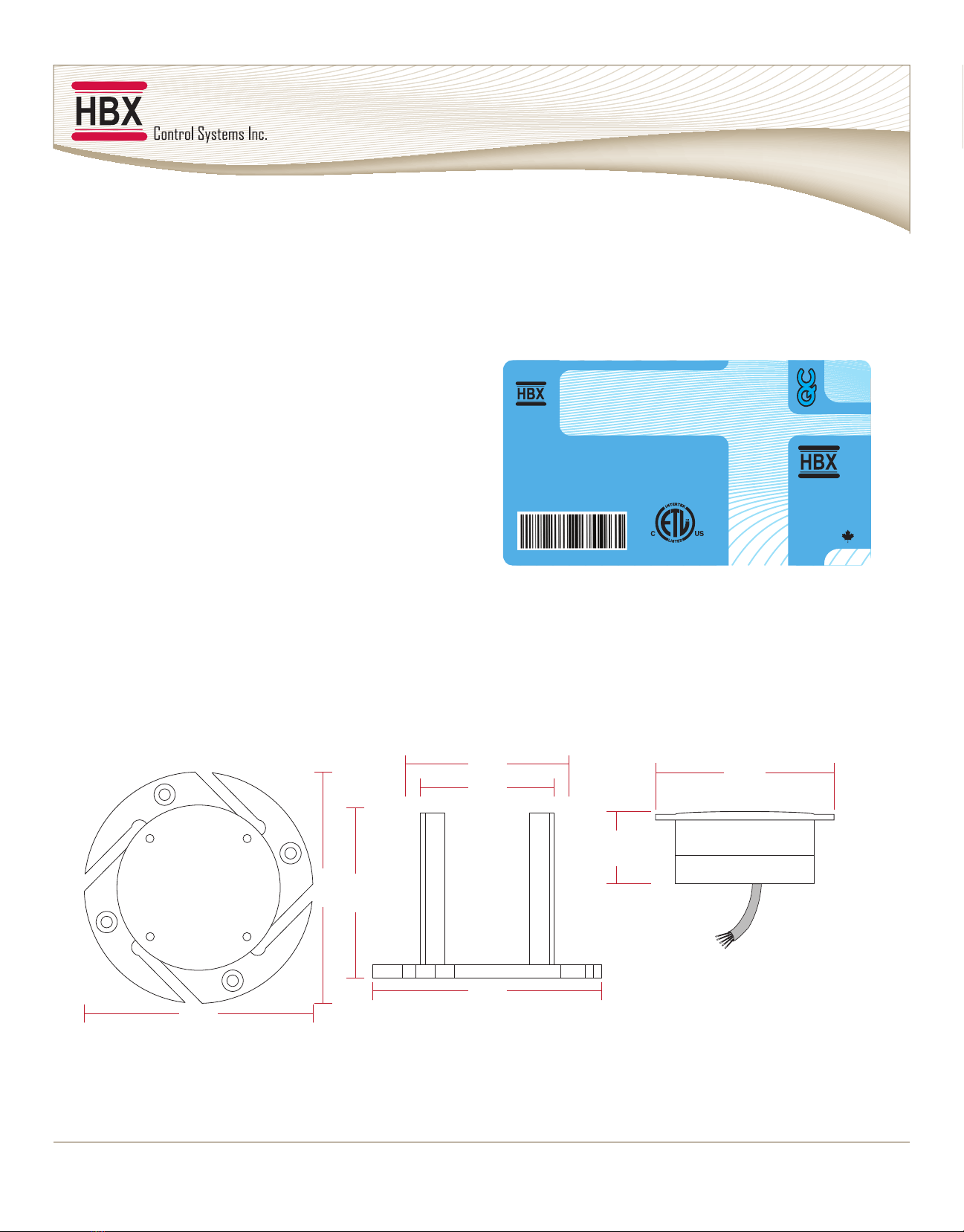

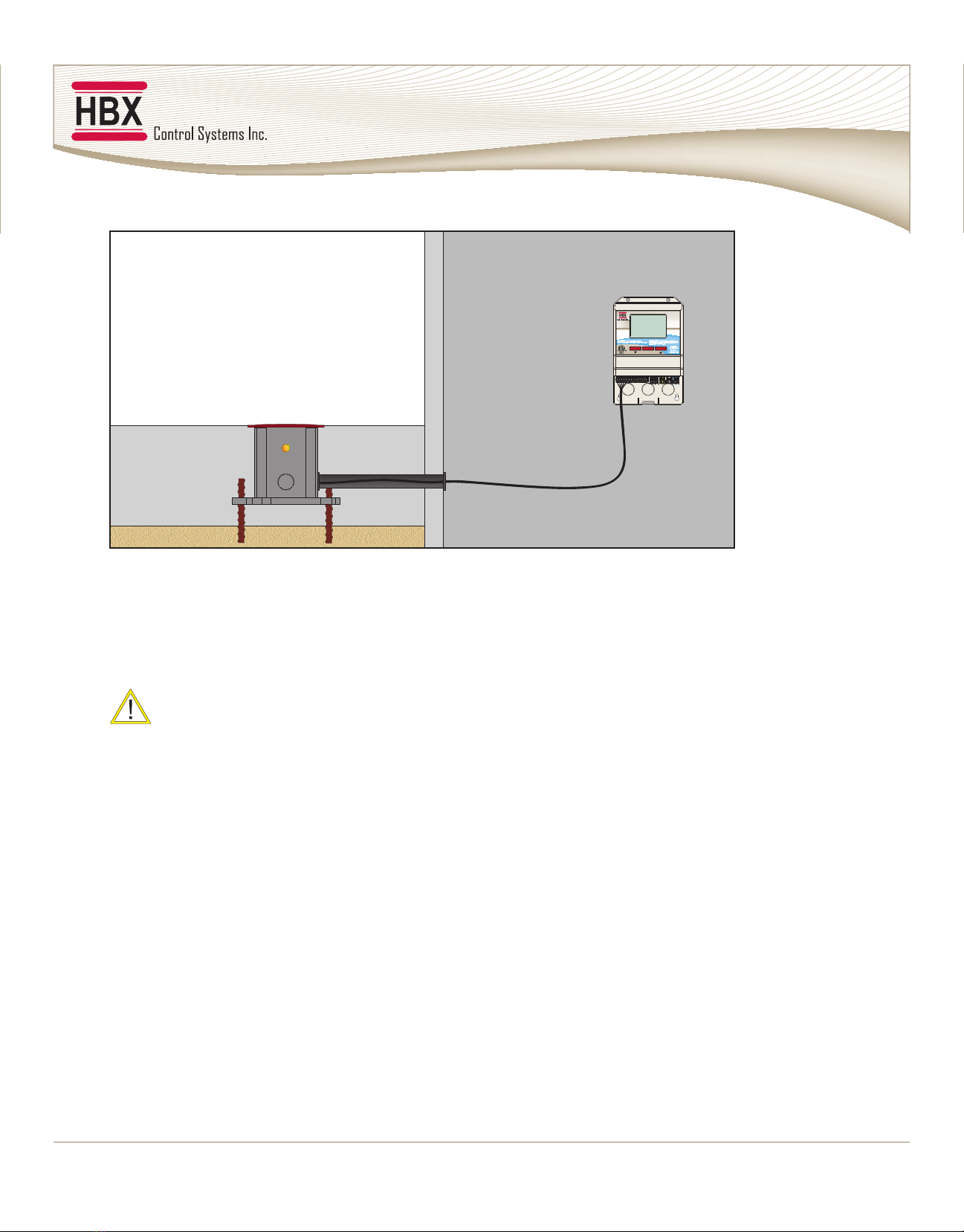

Together the SNO-0110 (sensor & cable) and the

SNO-0111 (socket and cover plate) make up the

sensor portions of the HBX Snowmelt System. The

SNO-0110 snow/ice sensor is an optical design that

is capable of sensing snow conditions. This allows

the user to set a preferred starting condition for

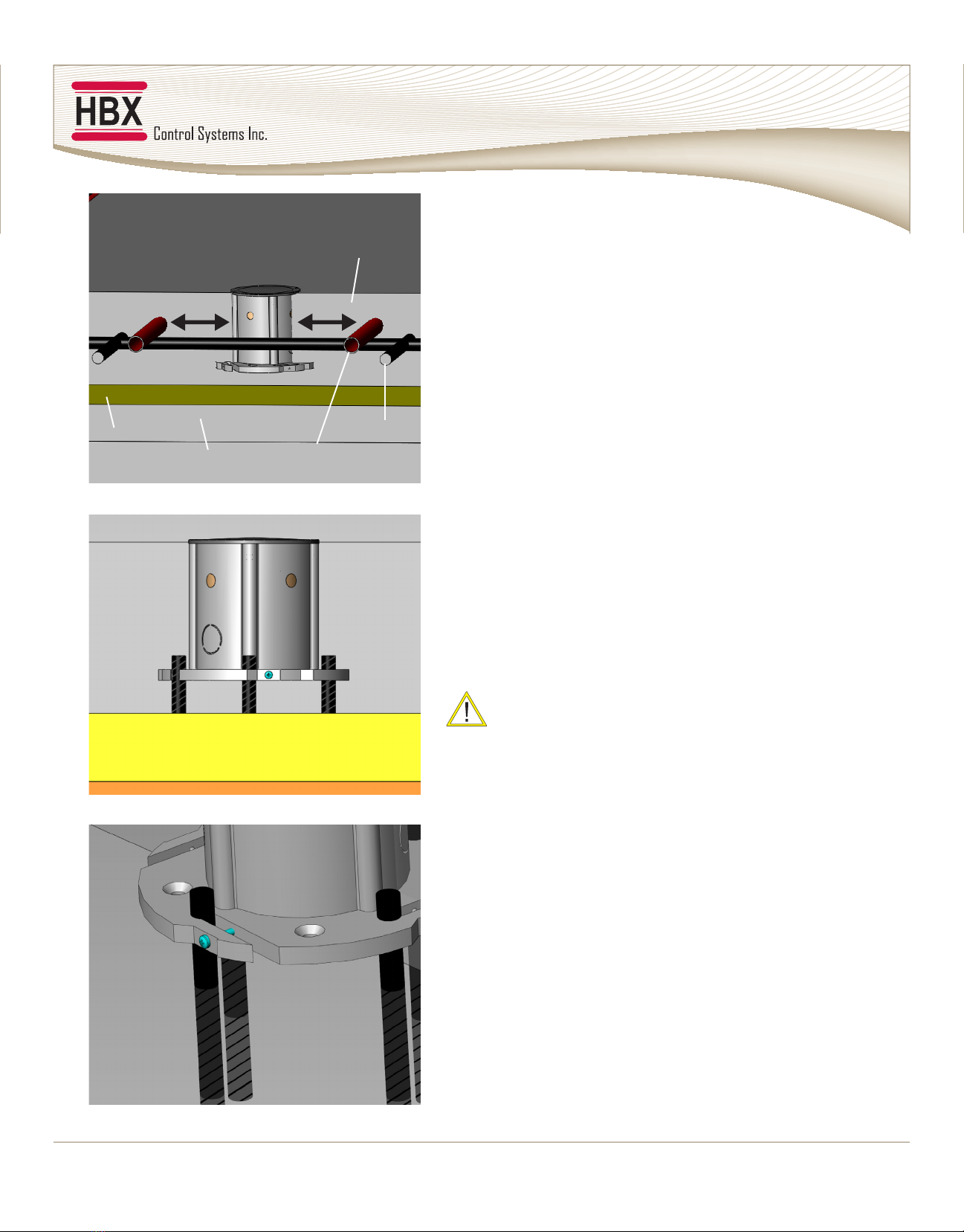

the snowmelt system. The SNO-0110 is design to

be mounted in the slab however because of the

optical design it can also be remotely installed.

The SNO-0111 socket and cover plate allows for the

concrete, asphalt, etc. to be poured prior to the

installation of the Snowmelt Control, and the SNO-

0110 snow/ice sensor.

Only suitably qualied individuals with

formal training in electrical and HVAC

controls should attempt the installation

of this equipment. Incorrect wiring

and installation will affect the warranty

provided with this unit. Wiring must be

completed in accordance with the

codes and practices applicable to the

jurisdiction for the actual installation.

SAFETY SYMBOLS & WARNING

Point of Interest

This point claries pertinent information,

or brings your attention to an action

that may have adverse effects on the

installation process.

Moderate Hazard

This action may cause personal injury or

have adverse effects on the installation

process if handled incorrectly.

Drawing Reference

Refer to the specied electrical or

mechanical drawing at the back of the

manual.

INTRODUCTION

This manual will help with the installation, parameter setting, troubleshooting and general maintenance

requirements for the snowmelt sensor, socket and cover plate. To guarantee the safe and reliable operation

ofyoursnowmeltsystem,youmustrstreadthismanualindetailandtakeparticularnotetoanyandall

warnings.

HBX SNO-0111/ SNO-0100 SNOWMELT SENSOR/ SOCKET AND COVER PLATE