HCL PT-CB-02 Instruction Manual

Hose Clamp Electro-

Pneumatic Control Unit

Operation, Parts & Safety Manual

Original Instructions

www.hclfasteners.com

Tooling

Index

Operation

1.1 Warning & Safety Instructions

1.2 Pneumatic Tool Conrol Unit

Touch Screen

2.1 Administrator

2.2 User

2.3 Set Up

2.4 Run, Warning and Advice

Reference

3.1 Control Unit Schematic

3.2 Control Unit Wiring Diagram

3.3 Control Unit Pneumatic Diagram

CE Marking

4.1 EC Declaration of Conformity

The control unit is designed to be used with the following pneumatic tools:

Piston Tool

Calliper Tool

Calliper Tool Dry Cycle

Ezyclik Calliper Tool

Ezyclik Caliper Tool Dry Cycle

www.hclfasteners.com

Read these instructions carefully:

ELECTRICAL

An Electrical supply represents a source of considerable potential energy. Precautions should be taken to prevent accidents.

– Electrical supplies must be disconnected before any adjustments, maintenance or dismantling.

– The Maximum allowable electrical supply should be observed.

COMPRESSED AIR

A compressed air supply represents a source of considerable potential energy. Precautions should be taken to prevent

accidents.

– Maximum operating pressure – 9.9 Bar

– Recommendedairowintounit–>50L/min.

Note.Iftheairowisnotachievablealongertimedelaymayneedtobesettoallowthejawsorpistontoclosefully.

– Usea50micronlterorbetter.

– Input air must be non-lubricated.

– Compressed air should never impinge in the body.

– Ports and pipes etc. should never be blocked by hand.

– Beforeconnectinganypneumaticequipmenttoacompressedairsupply,mountings,ttings,pipeworkandelectrical

connections should be checked for security, and all or any protective transit plugs removed.

– Nopipeworkalterationsorremovalofttingsshouldbeattemptedwithairsuppliesconnected

– Compressed air supplies must be disconnected before any adjustments, maintenance or dismantling.

– The maximum allowable operating pressures should be observed.

TRAINING

The control unit must not be used by persons not properly trained in its use. Be certain that you receive proper training from

youremployer.IfyouhaveanyquestionscontactyourHCLrepresentative.

WEIGHT

Control Unit – 6.7Kg

NOISE

– Soundpressurelevelislessthan70dB

– Vibrationlevelislessthan2.5ms-2

Operation - Warning & Safety Instructions

1.1

www.hclfasteners.com

Introduction

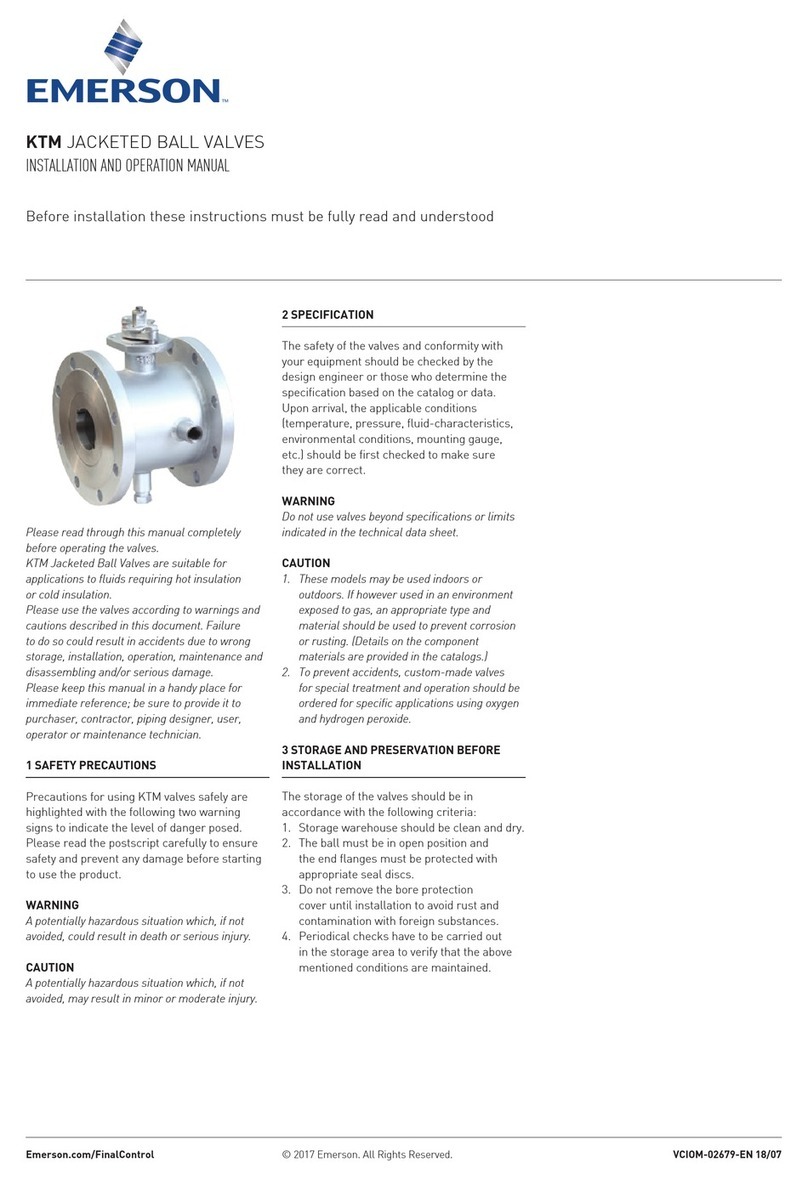

Developed exclusively for the range of Herbie Clip

and Ezyclik pneumatic tools, the Pneumatic Control

system gives a greater level of air pressure control.

Features

In the drive to eliminate error from production lines the

control system has a number of features including:

HMI touch screen control

Digital control of air pressure – to maintain a

consistent tightening force

Digital control of clamping time – to maintain a

consistent tightening time

Dry cycle detection (tool option) – Detects tool use

without a clip being in place

In process advisory information screens

Batch and unit count control

Supervisory control

Adjustable orientation of the HMI screen

External Signal Output

A 24v output signal can be supplied to the production

line once the prescribed number of clamps has been

tightened.

Low Maintenance

TheControlUnithasnospecicmaintenance

scheduleandHCLFastenersprovidefullbackupand

servicing support.

1 or 2-Preset Program Options

The Control Unit program allows the user to save the

following process parameters within the Set Up pages:

– Clamp Time

– Tool Pressure

– Clamp Count (number of clamps per production

assembly)

– Batch Count (number of production assemblies in

batch)

If required, the Control Unit can also be set up with the

ability to save 2 different sets of

process parameters.

Operation - Pneumatic Tool Control Unit

1.2

www.hclfasteners.com

Start Up

Connect the Control Box to electrical and

compressed air supplies. Connect the tool to the

Control box. In both cases refer to the images

shown in the ‘Pneumatic Tool Control unit’ section

of this manual

Switch on the power to the control box

The ‘Start Up’ screen is displayed

This will switch to the Main screen automatically

after a short time but can be switched manually by

touching the screen during this period

Language

TheLanguagerequiredcanbechosenbyselecting

theagonthestartscreen

Select the required language

Select ‘Back’ to return to the Start screen

➜

➜

➜ ➜

AdministratorLogin

IntheStartscreenselect‘Login’

The‘UserLogin’Screenisdisplayed

The control box is supplied with a default

Administrator level login

Fromthe‘User’dropdownmenuselect‘Admin’

Enter default password 1234

Select‘Login’

Note.Forsecurityreasonsitisadvisedthatthe

default User ‘Admin’ is deleted once administrative

users have been set up on the control box

‘Command succcessful’ message is displayed

withinthe‘UserLogin’screen

If incorrect login details entered ‘Command

Unsuccessful’ message is displayed

➜ ➜

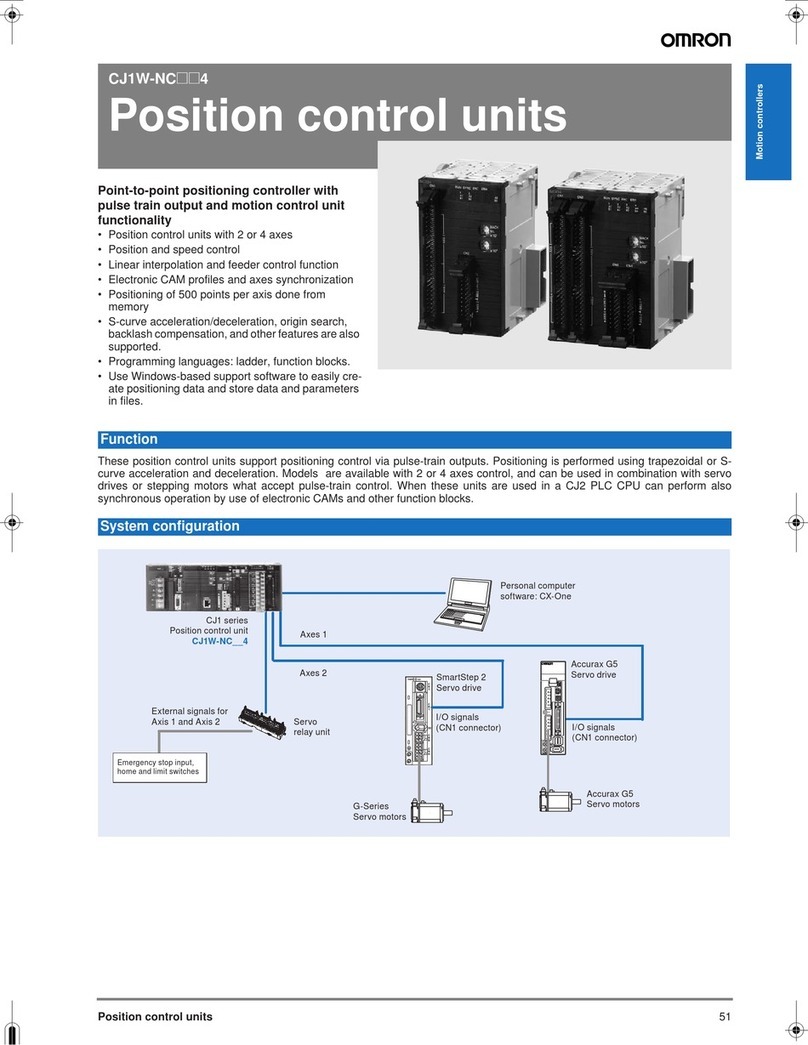

Touch Screen - Administrator

2.1

www.hclfasteners.com

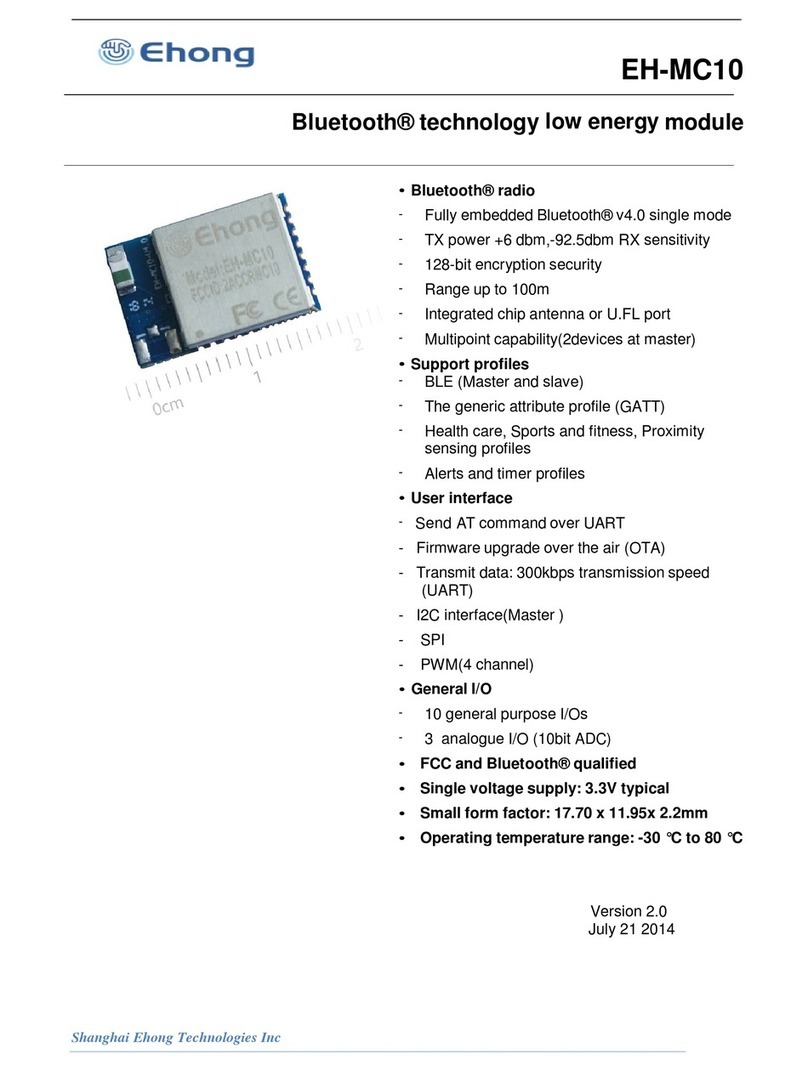

Create New User

In the ‘Admin’ screen select ‘Create New User’

– OR – ‘Back’ To return to the previous screen

In the ‘Admin – New User’ screen enter the name of

thenewuserinthe‘Name’eld

Enter the new users password in the ‘Password’

eld

Decide if the new user is a ‘User’ or if they also have

‘Admin’ authority

Selecteitherthe‘User’or‘Admin’elds

Note. When selecting ‘Admin’ both the ‘Admin’ and

‘User’eldsarehighlighted

Whenselecting‘User’onlythe‘User’eldis

highlighted

Select ‘Create’ – OR – Back’ To return to the

previous screen

In the ‘Admin’ screen the ‘Command Successful’

message is displayed

Select ‘Back’ To return to the previous screen

➜ ➜

➜ ➜

➜

AdministratorLogin(cont)

Start screen opens with the addition of an ‘Admin’

button

Administrator Actions

LoginasanAdministratorviathefrontscreen.See

AdministratorLoginsection

When logged in as an Administrator the front screen

has the option of the ‘ADMIN’ button.

Select ‘Admin’

The ‘Admin’ screen is displayed

To return to the previous page select the ‘Back’

button

➜

Touch Screen - Administrator

2.1

www.hclfasteners.com

In the ‘Admin’ screen the ‘Command Successful’

message is displayed

Select ‘Back’ To return to the previous screen

Change User Password

In the ‘Admin’ screen select ‘Change User Password’

– OR – ‘Back’ To return to the previous screen

In the ‘Admin – Change User Password’ screen

enter the name of the user in the ‘Name’ drop down

menu

Enter the users new password in the ‘Password’

eld

Entertheusersnewpasswordinthe‘Conrm

Password’eld

➜ ➜ ➜

Delete User

In the ‘Admin’ screen select ‘Delete User’

To return to the previous page select the ‘Back’

button

In the ‘Admin – Delete User’ screen select the name

of the user to be deleted in the ‘Name’ drop down

menu

Select ‘Delete’ – OR – ‘Back’ To return to the

previous screen

Inthe‘Admin–DeleteUser’screenaconrmation

message is displayed

Select ‘OK or Cancel’ – OR – ‘Back’ To return to the

previous screen

➜ ➜ ➜

Touch Screen - Administrator

2.1

www.hclfasteners.com

UserLogin–EquipmentSwitchOn

Inthe‘Start’screenSelect‘Login’

The‘UserLogin’screenisdisplayed

Select the user form the ‘User’ drop down menu

Enter the associated password

Select‘Login’

‘Command Successful’ advice message displayed

on screen

If incorrect login details entered ‘Command

Unsuccessful’ message displayed on screen –

Select ‘Close’

Depending on the type of user logged in the Start

screen opens with either:

‘Change User’ and ‘Change Password’ or ‘Change

User’ and ‘Admin’ options

➜ ➜ ➜ ➜

Change User Password (cont)

Change Password box is displayed

Select ‘Change Password’ – OR – Back’ To return to

the previous screen

In the ‘Admin – Change Password’ screen a

conrmationmessageisdisplayed

‘PleaseConrmOperation’

Select ‘OK or Cancel’

In the ‘Admin – Change Password’ screen the

‘Command Successful’ message is displayed

Select ‘Back’ To return to the previous screen

➜ ➜ ➜

Touch Screen - User

2.2

www.hclfasteners.com

UserLogin–EquipmentSwitch

On (cont)

Change User

In Start screen Select ‘Change User’

The‘UserLogin’screenisdisplayed

SelectLogout

Select the user from the ‘User’ drop down menu

Enter the associated password

Select‘Login’

➜➜ ➜

‘Command Successful’ advice message displayed

on screen

If incorrect login details entered ‘Command

Unsuccessful’ message displayed on screen

The start screen is displayed after a short time

delay

Change Password

Select ‘Change Password’

➜ ➜ ➜

Touch Screen - User

2.2

www.hclfasteners.com

Inthe‘UserLogin’screenSelect‘Logout’

Inthe‘UserLogin’screenthe‘Command

Successful’ message is displayed

Select ‘Close’

The front screen is displayed

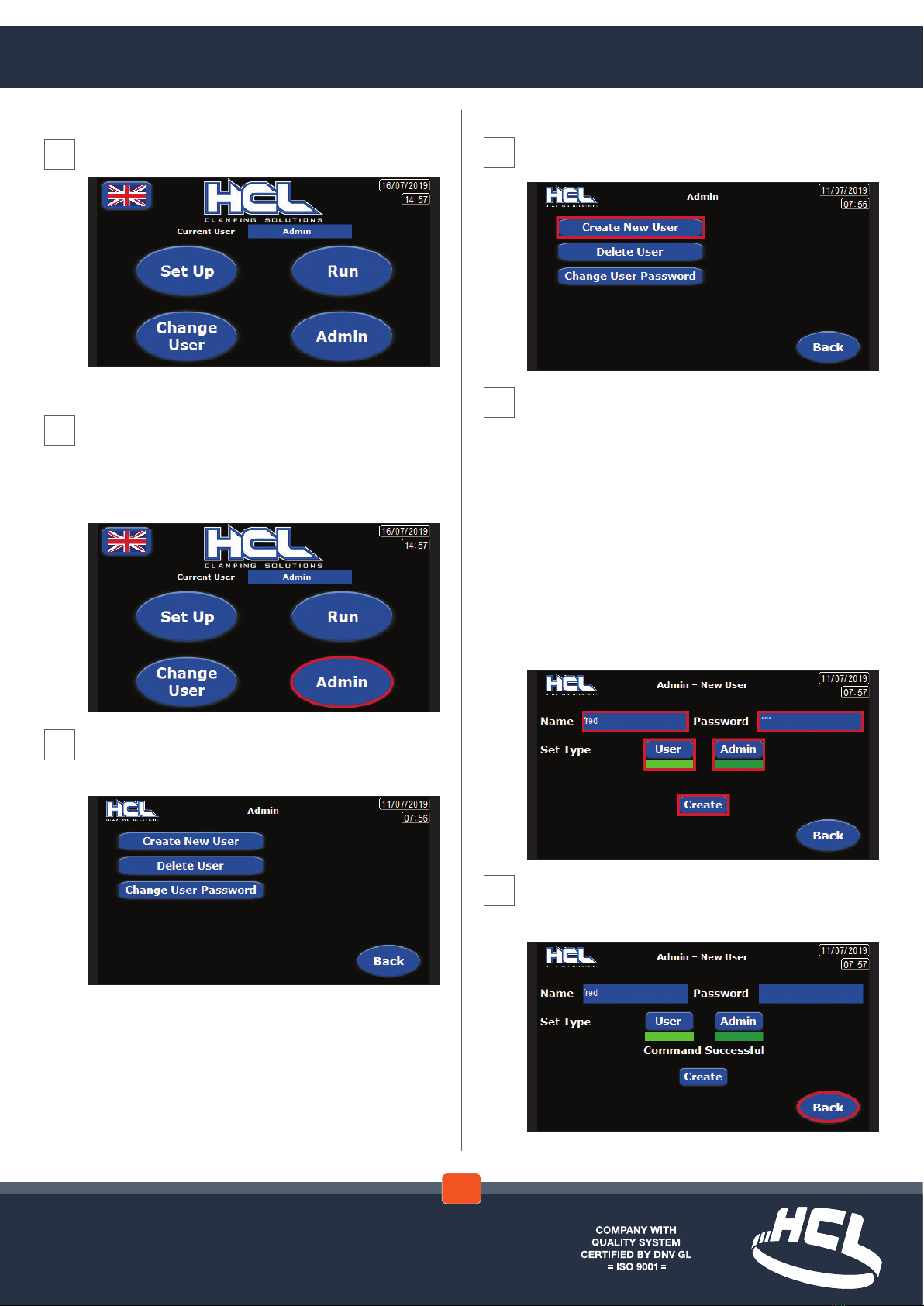

Set Up

In Start screen Select ‘Set Up’

➜ ➜ ➜ ➜

Change Password (cont)

The ‘Current User – Password Change’ screen is

displayed

Enter ‘Current Password’

Enter ‘New Password’

Enter‘ConrmPassword’

The‘ChangePassword’eldisdisplayed

Note.Ifthe‘ChangePassword’eldisnotdisplayed

there is an error with the information entered in the

passwordelds

Select ‘Change Password’ – OR – Select ‘Back’ to

return to the previous screen

The‘Pleaseconrmtheoperation’messageis

displayed

Select ‘OK’ or ‘Cancel’

Logout

In Start screen Select ‘Change User’

➜ ➜ ➜

Touch Screen - User / Set Up

2.3

www.hclfasteners.com

Set Up (cont)

The ‘Set Up – Select Program’ screen is displayed

Select program

Clamp Time

In the ‘Set-Up – Program #’ screen select ‘Set Clamp

Time’

The ‘Set-Up – Program # – Clamp Time’ screen is

displayed

Selectthe‘ClampTime’eld.Theon-screenkeypad

will be displayed

Enter the desired clamp time

Select ‘Run #’ to use equipment – OR – Select

‘Back’ to return to the previous screen

➜

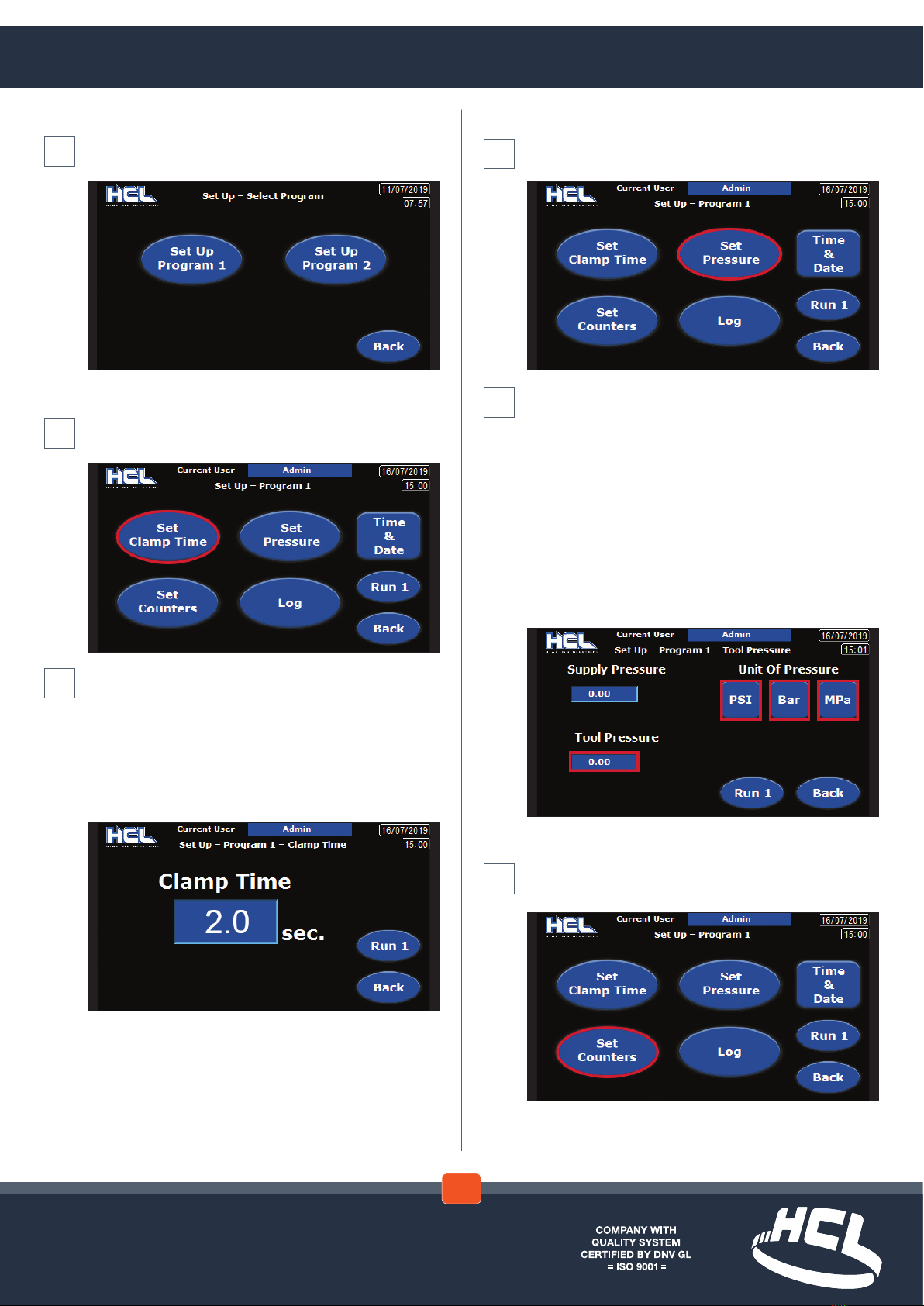

Set Pressure

In the ‘Set-Up – Program #’ screen select ‘Set

Pressure’

The ‘Set-Up – Program # - Tool Pressure’ screen is

displayed

Select the ‘Unit Of Pressure’ type:

PSI , Bar or MPa

The‘SupplyPressure’eldisadvisoryandcannot

be set

Selectthe‘ToolPressure’eld.Theon-screen

keypad will be displayed

Enter the desired tool pressure

Select ‘Run #’ to use equipment – OR – Select

‘Back’ to return to the previous screen

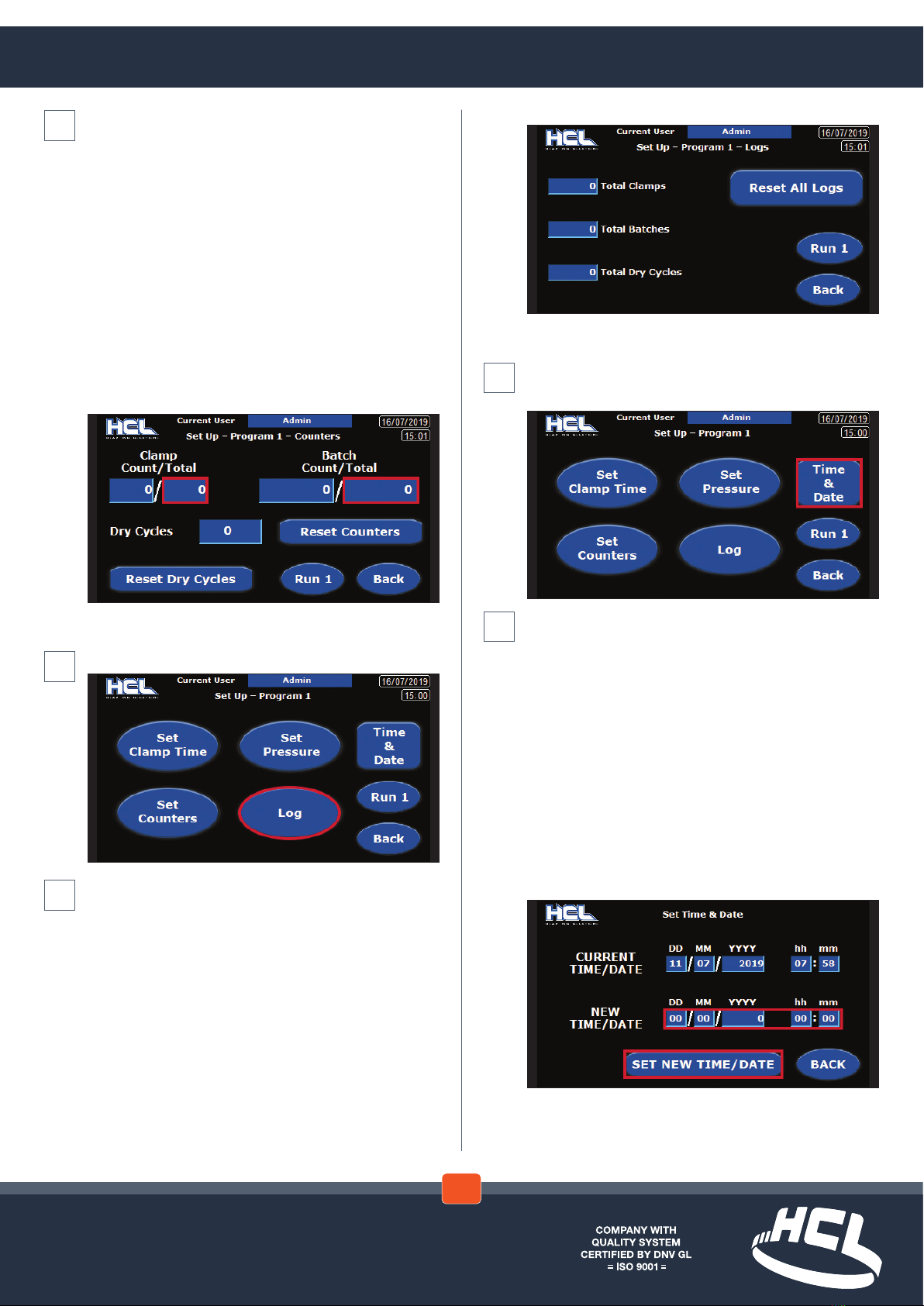

Set Counters

In the ‘Set-Up – Program #’ screen select ‘Set

Counters’

➜

➜ ➜

➜ ➜

Touch Screen - Set Up

2.3

www.hclfasteners.com

Set Time & Date

In the ‘Set-Up – Program #’ screen select ‘Time &

Date’

In the ‘Set Time & Date’ screen

The‘CurrentTime/Date’–‘DD’/‘MM’/‘YYYY’and

‘hh’:‘mm’eldsareadvisoryandcannotbeset

Inthe‘NewTime/Date’theeldsfor‘DD’/‘MM’/

‘YYYY’and‘hh’:‘mm’canbeindividuallyselected.

Foreachselectiontheon-screenkeypadwillbe

displayed

Enterthedesiredgurefor‘DD’/‘MM’/‘YYYY’and

‘hh’ : ‘mm’

Select‘SetNewTime/Date’

The newly entered selections will become the

‘CurrentTime/Date’

Select ‘Back’ to return to the previous screen

➜ ➜

The ‘Set-Up – Program # - Counters’ screen is

displayed

Note.The‘ClampCount’and‘BatchCount’eldsare

advisory only and cannot be set

Selectthe‘ClampCountTotal’eld.Theon-screen

keypad will be displayed

Enter the desired ‘Clamp Count Total’ per batch

Repeatforthe‘BatchCountTotal’eld

The counters can be zeroed by selecting ‘Reset

Counters’

The‘DryCycles’eldisadvisoryandcannotbeset

but can be zeroed by selecting ‘Reset Dry Cycle’

Select ‘Run #’ to use equipment – OR – Select

‘Back’ to return to the previous screen

SetLogs

Inthe‘Set-Up–Program#’pageselect‘Log’

Inthe‘Set-Up–Program#–Logs’screen

The ‘Total Clamps’, ‘Total Batches’ and ‘Total Dry

Cycles’eldsareadvisoryandcannotbeset.They

canbezeroedbyselecting‘ResetAllLogs’

Select ‘Run #’ to use equipment – OR – Select

‘Back’ to return to the previous screen

➜ ➜ ➜

Touch Screen - Set Up

2.3

www.hclfasteners.com

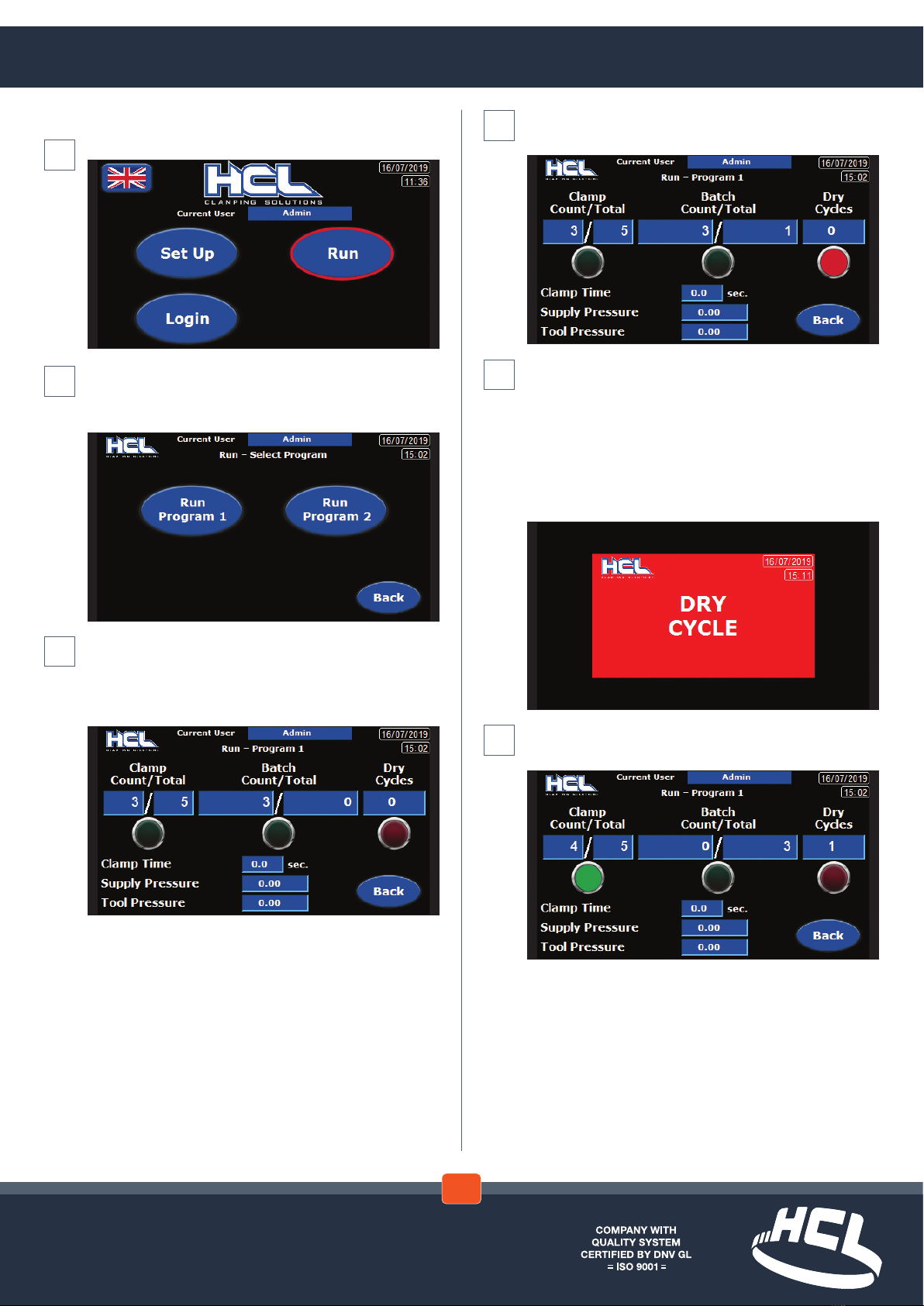

If a ‘Dry Cycle is registered the indicator light

illuminates red

To accompany the red indicator light on the ‘Run –

Program #’ screen an on screen message box ‘Dry

Cycle’ is displayed

This Indicates that the tool has been operated but

hasnotttedaHoseClampunit

Message disappears on screen after completion of

the operation cycle

On completion of a good clamp cycle the ‘Clamp

Count/Totalindicatorlightwillbeilluminatedgreen

➜ ➜ ➜

Run

In the ‘Start’ screen select ‘Run

The ‘Run – Select Program’ screen is displayed

Select the program number required –OR – Select

‘Back’ to return to the previous screen

The ‘Run – Program #’ page is displayed

The‘ClampCount/Total’,‘BatchCount/Total’,‘Dry

Cycles’, ‘Clamp Time’, ‘Supply Pressure’ and ‘Tool

Pressure’eldsareadvisoryandcannotbeset

➜ ➜ ➜

Touch Screen - Run, Warning and Advice Screens

2.4

www.hclfasteners.com

Warning and Advice Screens

‘SupplyPressureTooLow’warning

Check supply pressure and adjust

Should a user try to access the ‘Set Up’ screens

without being logged in a warning message is

displayed ‘Password Protected – Access Denied’

Select‘Close’toreturntotheFrontscreen

➜ ➜

Run (cont)

Oncompletionofthe‘BatchTotal’the‘BatchCount/

Total indicator light will also be illuminated green

To accompany the ‘Batch Total’ green indicator light

an on screen message box ‘Batch Complete’ is

displayed

Select ‘Press To Clear’ to return to the previous page

The ‘Run - Program#’ screen is displayed with the

count totals reverting to zero

➜ ➜ ➜

Touch Screen - Run, Warning and Advice Screens

2.4

www.hclfasteners.com

Reference - Control Unit Schematic

SUPPLY

NFF

V1EX

SUPPLY

R1 EX

240vAC

AIR

AIR TO

TOOL

TOOL

159

250

300

Note. The orientation of the HMI unit is adjustable

by 90, 180 and 270 degrees. This is to allow the

control unit to be located in the most suitable

position for the operator and also for access to

services.

This feature requires the removal of the control

unit front cover to enable the HMI unit to be

repositioned.

Ensure that the Control Unit is turned off before

gaining access. Refer to the Warning & Safety

Instructions within this manual.

3.1

www.hclfasteners.com

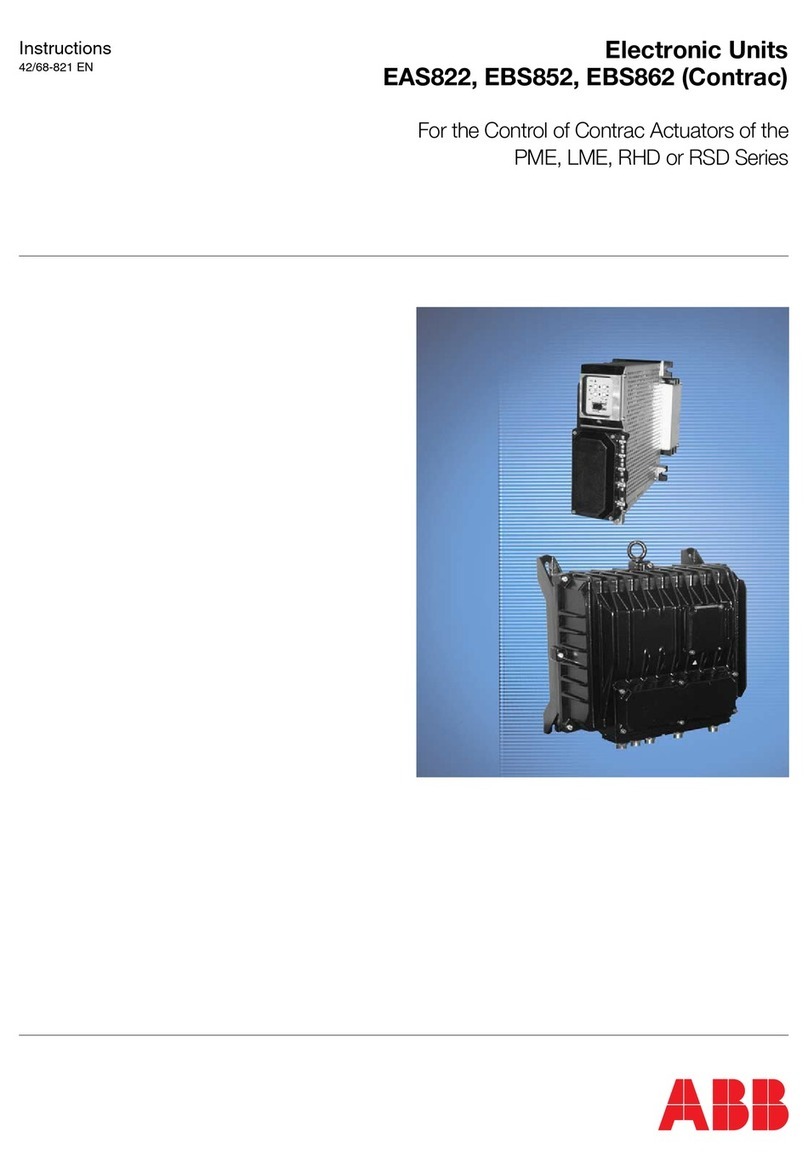

A 2

A 1

F 1 - 5 A

NL

-V+ V

P S U

3 5 W 2 4 V dc

- F 2

1 A (T )

0 - 5 Vdc

PSE5 4 0 - R 0 6

BLU

BLK

B R N

C O M3

0 V

G N D

24V

W ein te k MT 8 0 5 0 iE

0 V

0 V

AO 1 -V

AO 0 -V

O u t p u t

A n a lo g u e

T MC 2 A Q2 V

- F 3

0 . 5 A(T )

IT V 1 0 5 0 -3 1 2 C N 4

(0 .0 0 6 - 0 .9 9 M Pa )

0 - 1 0 V d c

B R N

BLU

W H I

BLK

1 4A 2

A 1 1 3 +

I0

Q 0 Q 1 V-Q 3 Q 5 V +Q 40 V

0 V

I1 I8

A I0

PE

0 V

I5

Q 6Q 2

I2 I4

24V

S E R I A L

I6

A I1

C O M I3 I7

S chneid er M2 2 1 - T M2 2 1 C 1 6 T

1 4A 2

A 1 1 3 +

85-230VAC

3

1 2

1 - 4 Tr ig g e r

0 V

4

1

2 - 3 D ry C y c l e

+ 2 4 V

3

S KT 1

S KT 2

2 3

2 0

801

2

1

8 0 0

2 2

_

0

2 1

802

803

3

Reference - Control Unit Wiring Diagram

3.2

www.hclfasteners.com

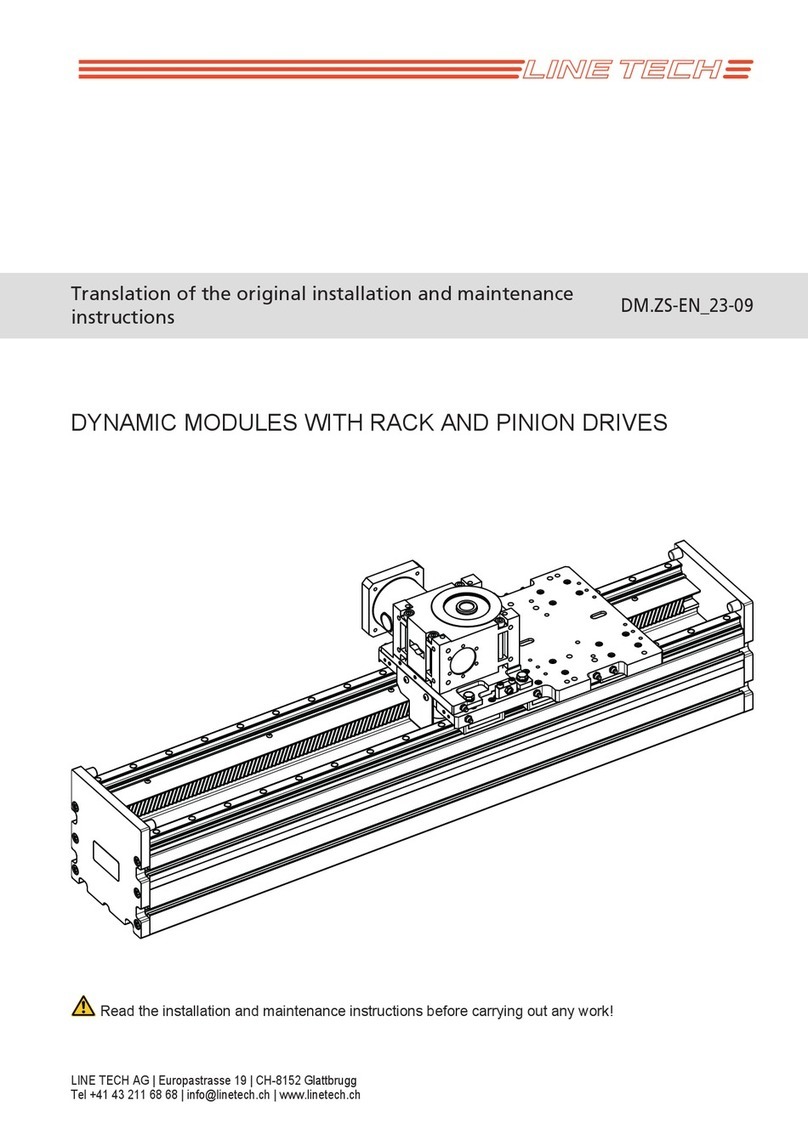

V

E X H

S U P

P R

A

Too l

S u p ply

6 m m O D

6 m m O D

6 m m O D

6 m m O D 6 m m O D

Reference - Control Unit Pneumatic Diagram

3.3

www.hclfasteners.com

Name of manufacturer: HCLFastenersLtd

Address of manufacturer: FirstAvenue,WesteldIndustrialEstate,Radstock,Bath,BA34BS,UK

Telephone: +44(0)1761417714

Email: [email protected]

WeherebydeclarethatthefollowingmachineryisinconformitywiththeMachineryDirective2006/42/EC:

Machinery description: Control Unit

Part No: PT-CB-02

Serial No: PT-CB-02- -

Applied Harmonised Standards:

Ref. No. Title

BS EN 12100:2010 Safety of machinery. General principles for design.

Risk assessment and risk reduction

BS EN ISO 4414:2010 Pneumaticuidpower.Generalrulesandsafetyrequirements

for systems and their components

InAccordancewithBSENISO/IEC17050-1:2010

BSENISO4414:2010 Pneumaticuidpower.Generalrulesrelatingtosystems

BSEN60204-1:2018 SafetyofMachinery.Electricalequipment&machines

BSEN50565-1:2014 Useforcableswithratedvoltagenotexceeding450/750V

I hereby declare that the equipment named above has been designed to comply with the relevant sections

oftheabovereferencedspecicationsandisinaccordancewiththerequirementsoftheDirective.

Name: David Coles

Position: Managing Director

Address: FirstAvenue,WesteldIndustrialEstate,Radstock,Bath,BA34BS,UK

Date: 1stJuly2018

The technical documentation for the machinery is available from the above address.

Year of

manufacture

Consecutive

number

Document reference

No. CE-1000

CE Marking - EC Declaration of Conformity

EC Declaration of Conformity

In accordance with EN ISO 17050-1-2004

4.1

Considerable effort has been made to ensure that this product conforms to our high quality standards. However, should you

experience any diculties, please contact your Sales representative providing samples and the serial code specied on the tool.

HCL – UK & Rest of the World

Tel:+44(0)1761417714

Fax:+44(0)1761417710

HCL – North America

Tel:281-717-1145

Fax:281-717-1146

Email: [email protected]

Visit www.hclfasteners.com to view our complete range of products.

November2020

©HCLFasteners.AllRightsReserved.

Your attention is drawn to the following:

HCLwarrantsthatanewHCLbandingtoolwilloperateperfunctionalspecicationsforaperiodofsixty(60)days

after the date of shipment to the owners place of business. Normal wearing parts, as outlined in the Operations,

Parts&Safetymanual,arealsocoveredbyasixty(60)daywarrantyunless,inHCL’sjudgement,thesepartshave

beensubjectedtoabnormalorextremeusage.HCL’ssoleliabilityhereunderwillbetorepairorreplace,without

charge,F.O.B.HCL,BathUK,anytoolwhichprovestonotoperateperfunctionalspecicationswithinthestated

period.HCLreservestherighttoreplaceanytoolwhichprovesnottooperateperfunctionalspecications

withaneworlike-newtoolofthesamemodel,ifinHCL’sjudgementsuchreplacementisappropriate.Anynew

replacementorlikenewreplacementtoolprovidedtoanownerwillcarryafullsixty(60)daywarranty.Anywarranty

repairedtoolwillcarryawarrantyforthebalanceoftimeremainingontheinitialsixty(60)daywarranty.This

warrantywillbeextendedtocompensateforthetimethetoolisinHCL’spossessionforwarrantyrepairs.

This warranty is void as to any tool which has been:

a)usedonnon-genuineHCLhoseclamps

b)subjectedtomis-use,misapplication,accidentdamage,orrepairedwithotherthangenuineHCLreplacement

parts.

c) improperly maintained, or adjusted, or damaged in transit or handling.

d)usedwithimproperlyltered,regulated,unlubricatedair.

e)inHCL’sopinion,alteredinawaythataffectsordetractsfromtheperformanceofthetool.

HCLMAKESNOWARRANTY,EXPRESSEDORIMPLIED,RELATINGTOMERCHANTABILITY,FITNESSOR

OTHERWISEEXCEPTASSTATEDABOVEANDHCL’SLIABILITYASASSUMEDABOVEISINLIEUOFALLOTHERS

ARISINGOUTOFORINCONNECTIONWITHTHEUSEANDPERFORMANCEOFTHETOOL.ITISEXPRESSLY

UNDERSTOODTHATHCLSHALLINNOEVENTBELIABLEFORANYINDIRECTORCONSEQUENTIALDAMAGES

INCLUDING,BUTNOTLIMITEDTO,DAMAGESWHICHMAYARISEFROMLOSSOFANTICIPATEDPROFITSOR

PRODUCTION,SPOILAGEOFMATERIALS,INCREASEDCOSTSOFOPERATIONOROTHERWISE.

Table of contents