Table of contents DYNAMIC MODULES WITH RACK AND PINION DRIVES

2 / 68 Line Tech AG

Table of contents

1 General information............................................................................................ 4

1.1 Information about these assembly instructions........................................................... 4

1.2 Notes on use............................................................................................................... 5

1.3 Structure of the warnings............................................................................................ 6

1.4 Symbols used ............................................................................................................. 8

1.5 Disclaimer ................................................................................................................... 9

1.6 Spare parts ................................................................................................................. 11

1.7 Warranty conditions .................................................................................................... 11

1.8 Customer service and product monitoring .................................................................. 12

1.9 Other applicable documents ....................................................................................... 12

2 Safety ................................................................................................................... 13

2.1 Introduction ................................................................................................................. 13

2.2 Intended use ............................................................................................................... 13

2.3 Foreseeable misuse.................................................................................................... 13

2.4 Responsibilities of the operating company ................................................................. 14

2.5 Personnel requirements.............................................................................................. 15

2.5.1 General personnel requirements .................................................................. 15

2.5.2 Qualifications ................................................................................................ 15

2.5.3 Unauthorized personnel................................................................................ 15

2.6 Personal protective equipment ................................................................................... 15

2.7 Residual risks.............................................................................................................. 17

2.7.1 Note .............................................................................................................. 17

2.7.2 Mechanical hazards...................................................................................... 17

2.7.3 Hazards at the operating site........................................................................ 17

2.7.4 Hazards due to noise.................................................................................... 18

2.8 Environmental protection ............................................................................................ 18

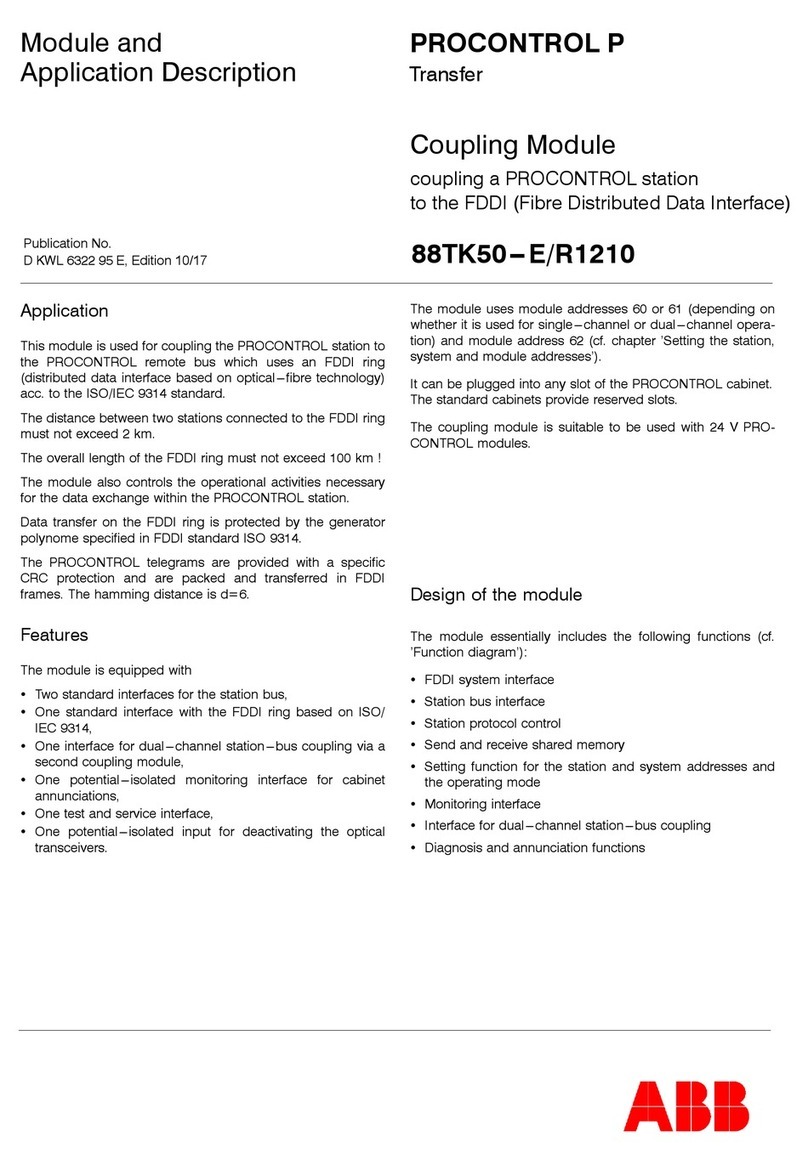

3 Structure and function ....................................................................................... 19

3.1 Product overview ........................................................................................................ 19

3.2 Product description ..................................................................................................... 20

3.3 Product description ..................................................................................................... 21

3.4 Type plate ................................................................................................................... 22

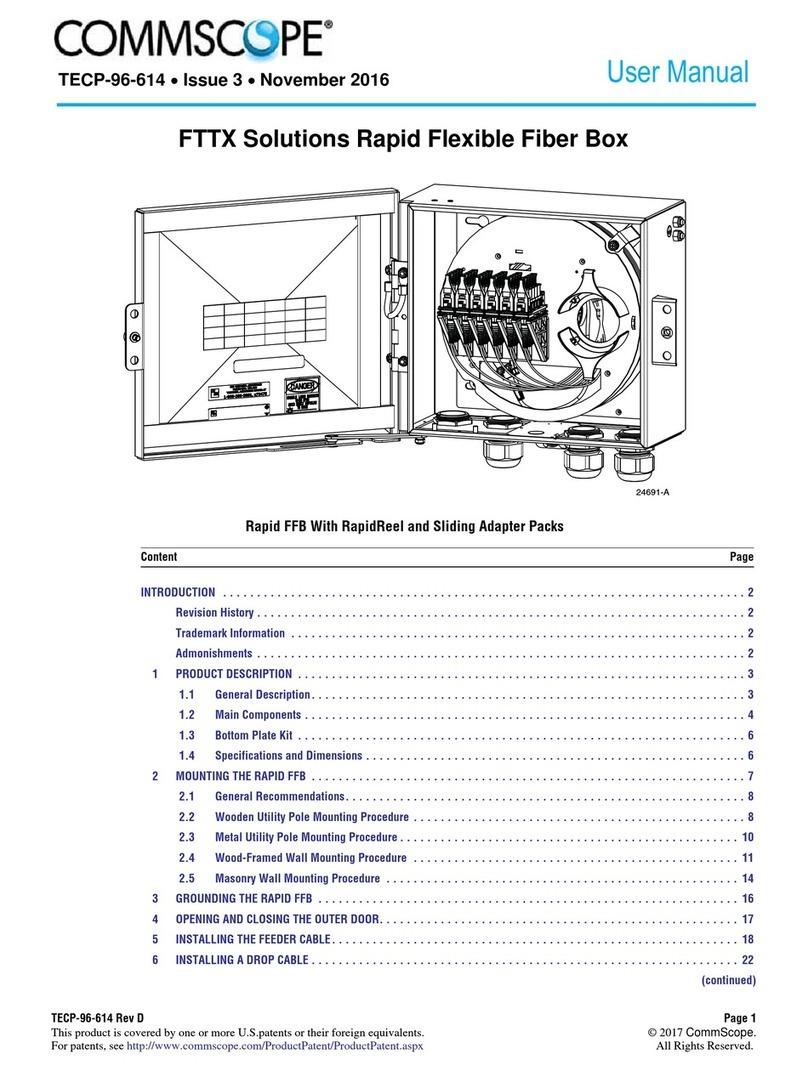

4 Transport ............................................................................................................. 23

4.1 Safety.......................................................................................................................... 23

4.2 Transportation with a forklift truck............................................................................... 24

4.3 Transport with the crane ............................................................................................. 24

4.4 Transport inspection and scope of delivery ................................................................ 24

4.5 Storage ....................................................................................................................... 25

5 Assembly............................................................................................................. 26

5.1 Safety.......................................................................................................................... 26