Ehong EH-MC10 User manual

Shanghai Ehong Technologies Inc

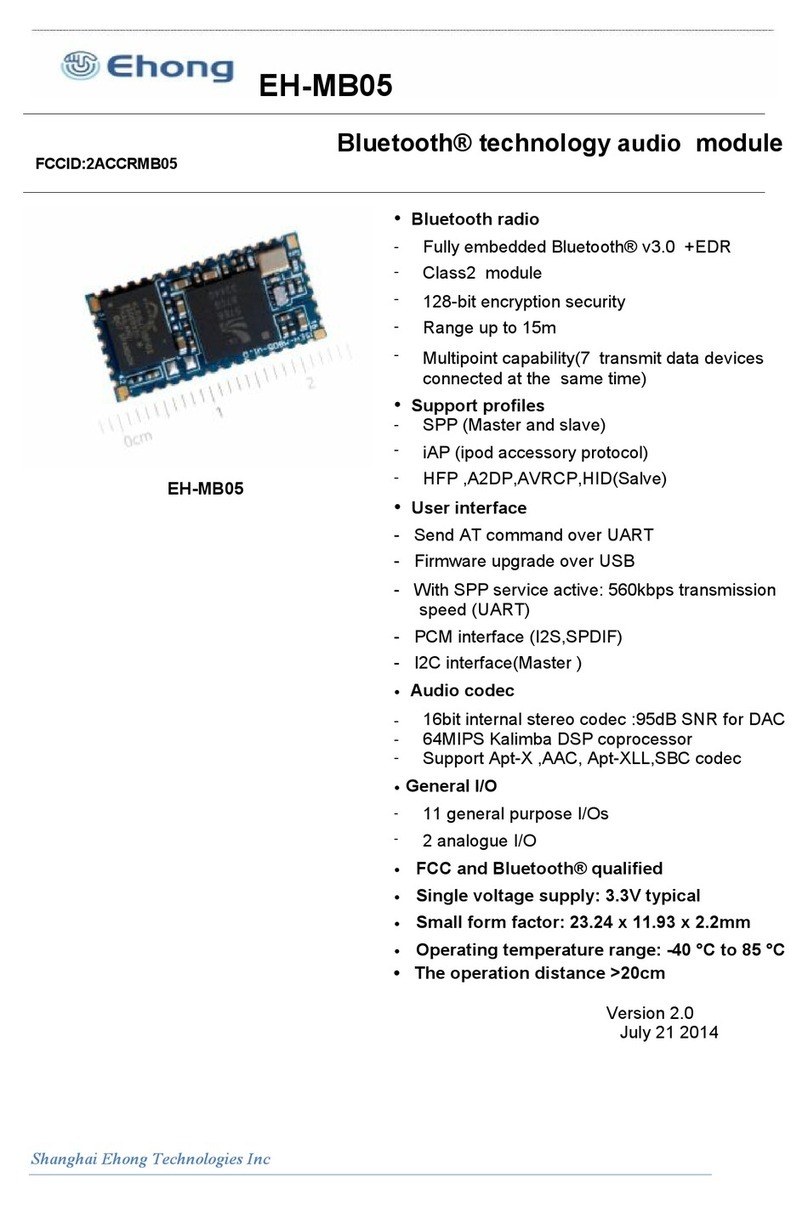

EH-MC10

Bluetooth® technology low energy

module

•

Bluetooth® radio

- Fully embedded Bluetooth® v4.0 single mode

- TX power +6 dbm,-92.5dbm RX sensitivity

- 128-bit encryption security

- Range up to 100m

- Integrated chip antenna or U.FL port

- Multipoint capability(2devices at master)

•

Support profiles

- BLE (Master and slave)

- The generic attribute profile (GATT)

- Health care, Sports and fitness, Proximity

sensing profiles

- Alerts and timer profiles

•

User interface

- Send AT command over UART

-Firmware upgrade over the air (OTA)

-Transmit data: 300kbps transmission speed

(UART)

- I2C interface(Master )

-SPI

-PWM(4 channel)

•

General

I/O

-

10 general purpose I/Os

-

3 analogue I/O

(10bit ADC)

•

FCC and Bluetooth® qualified

•

Single voltage supply: 3.3V typical

•

Small form factor: 17.70 x 11.95x 2.2mm

•

Operating temperature range: -30 °C to 80 °C

Version 2.0

July 21 2014

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

1. Contents

1. Description..................................................................................................................................................3

2. Applications................................................................................................................................................4

3. EH-MC10 Product numbering..................................................................................................................4

4. Electrical Characteristics .........................................................................................................................4

4.1. Recommended Operation Conditions.................................................................................................4

4.2.Absolute Maximum Rating...................................................................................................................5

4.3. Input/Output Terminal Characteristics ................................................................................................5

4.4. Power Consumption.............................................................................................................................6

5. Pinout and Terminal Description.............................................................................................................7

5.1. Pin Configuration..................................................................................................................................7

6. Physical Interfaces ....................................................................................................................................9

6.1. Power Supply........................................................................................................................................9

6.2. PIO.........................................................................................................................................................9

6.3. AIO.........................................................................................................................................................9

6.4. PWM......................................................................................................................................................9

6.5. UART...................................................................................................................................................10

6.6. I2C Master...........................................................................................................................................10

6.7. SPI Master..........................................................................................................................................10

6.8. SPI Debug...........................................................................................................................................11

7. Reference Design.....................................................................................................................................11

8. Layout and Soldering Considerations.................................................................................................11

8.1. Soldering Recommendations ............................................................................................................11

8.2. Layout Guidelines...............................................................................................................................12

9. Mechanical and PCB Footprint Characteristics .................................................................................13

10. Reflow Profile........................................................................................................................................14

11. Contact Information.............................................................................................................................15

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

2. Table of Tables

TABLE 1: RECOMMENDED OPERATION CONDITIONS...............................................................................................4

TABLE 2:ABSOLUTE MAXIMUM RATING................................................................................................................5

TABLE 3: DIGITAL I/O CHARACTERISTICS...............................................................................................................5

TABLE 4: AIO CHARACTERISTICS...........................................................................................................................5

TABLE 5ESDPROTECTION ...................................................................................................................................6

TABLE 6: CURRENT CONSUMPTION........................................................................................................................6

TABLE 7:PINTERMINAL DESCRIPTION.................................................................................................................8

TABLE 8: POSSIBLE UART SETTINGS..................................................................................................................10

3. Table of Figures

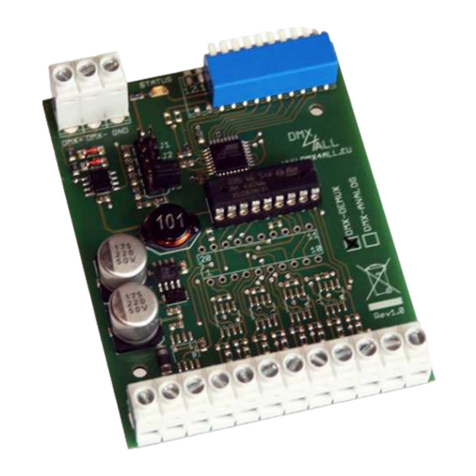

FIGURE 1:PINOUT OF EH-MC10 ........................................................................................................................7

-FIGURE 2:POWER SUPPLY PCB DESIGN ....................................................................................................9

FIGURE 3:CONNECTION TO HOST DEVICE ........................................................................................................10

FIGURE 4:REFERENCE DESIGN.........................................................................................................................11

FIGURE 5: CLEARANCE AREA OF ANTENNA...........................................................................................................12

FIGURE 6:PHYSICAL DIMENSIONS AND RECOMMENDED FOOTPRINT (UNIT:MM,DEVIATION:0.02MM)...............13

FIGURE 7: RECOMMENDED REFLOW PROFILE .....................................................................................................14

1. Description

EH-MC10 Bluetooth® low energy single mode module is a single mode device targeted for

low power sensors and accessories.

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

The module offers all Bluetooth® low energy features: radio, stack, profiles and application

space for customer applications, so no external processor is needed. The module also provides

flexible hardware interfaces to connect sensors, simple user interfaces or even

displays directly to the module.

The module can be powered directly with a standard 3V coin cell batteries or pair of AAA

batteries. In lowest power sleep mode it consumes only 600nA and will wake up in few hundred

microseconds.

After buying Bluetooth® module, we provide free technical support APP of iOS system or APP

Android system.

2. Applications

Sports and fitness

Healthcare

Home entertainment

Office and mobile accessories

Automotive

Commercial

Watches

Human interface devices

3. EH-MC10 Product numbering

EH-MC10X

A. EH ------------- Company Name(EHong)

B. MC10 ------------ Module Name

C. X ------------ A = Antenna B =U.FL

4. Electrical Characteristics

4.1. Recommended Operation Conditions

Table 1: Recommended Operation Conditions

Operating Condition

Min

Typical

Max

Unit

Operating Temperature Range -30 -- +80 °C

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

Battery (VDD_BAT) operation 1.8 -- +3.6 V

I/O Supply Voltage (VDD_PIO) 1.2 -- +3.6 V

AIO input 0 - +1.3 V

Frequency range 2402 2480 MHz

Table 2:Absolute Maximum Rating

4.2. Absolute Maximum Rating

* Short-term operation up to a maximum of 10% of product lifetime is permissible without damage, but output

regulation and other specifications are not guaranteed in excess of 4.2V.

4.3. Input/Output Terminal Characteristics

Table 3: Digital I/O Characteristics

Input Voltage Levels

Min

Typical

Max

Unit

V

IL

input logic level low

-0.4

-

0.4

V

VIH input logic level high 0.7 x VDD - VDD + 0.4 V

Tr/Tf- - 25 ns

Output Voltage Levels

Min

Typical

Max

Unit

V

OL

output logic level low, l

OL

= 4.0mA

-

-

0.4

V

V

OH

output logic level high, l

OH

= -4.0mA

0.75 x VDD

-

--

V

T

r

/T

f

-

-

5

ns

Input and Tri-state Current

Min

Typical

Max

Unit

With strong pull-up

-150

-40

-10

μA

With strong pull-down

10

40

150

μA

With weak pull-up

-5.0

-1.0

-0.33

μA

With weak pull-down

0.33

+1.0

5.0

μA

C

I

Input Capacitance

1.0

-

5.0

pF

Table 4: AIO Characteristics

Rating Min Max Unit

Storage Temperature -40 +85 °C

Battery (VBAT) operation* 1.8 3.6 V

I/O supply voltage

-0.4

+3.6

V

Other Terminal Voltages except RF Vss-0.4

VBAT+0

.4 V

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

Input Voltage Levels

Min

Typical

Max

Unit

AIO 0 - 1.3 V

Table 5 ESD Protection

Condition

Class

Max Rating

Human Body Model Contact Discharge per JEDEC

EIA/JESD22-A114

2

2000V (all

pins)

Machine Model Contact Discharge per JEDEC EIA/JESD22-

A115

200V

200V (all

pins)

Charged Device Model Contact Discharge per JEDEC

EIA/JESD22-C101

III

500V (all

pins)

4.4. Power Consumption

The current consumption are measured at the VBAT

Table 6: Current Consumption

Mode Description

Total typical current

at 3.3V (average)

Dormant

All functions are shutdown. To wake up toggle

the WAKE pin

<600nA

Hibernate

All functions are shutdown except for the sleep

clock. The module can wake up on a timer on

the sleep clock.

<1.5uA

Deep sleep

VDD=3.3V 1ms wake up time

<5uA

Idea

VDD=3.3V <1us wake up time

1mA

RF RX /TX active

(0dBm)

VDD=3.3V VDD_PIO=3.3V

~16mA @3V peak

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

5. Pinout and Terminal Description

5.1. Pin Configuration

Figure 1:Pinout of EH-MC10

Symbol

Pin

PAD Type Description

GND

1

Ground Ground

AIO2

2

Bidirectional analogue

10bit Analogue

programmable I/O line

AIO1

3

Bidirectional analogue

10bit Analogue

programmable I/O line

AIO0

4

Bidirectional analogue

10bit Analogue

programmable I/O line

UART_TX

5

CMOS output, tristate, with weak

internal pull-up

UART data output

UART_RX

6

CMOS input with weak internal pull-

down

UART data input

PIO3

7

Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

PWM or LED Controls

PIO4

8

Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

PWM or LED Controls

PIO5/SPI_CLK

9

Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

Or debug SPI_CLK select

by SPI_PIO_SEL

GND

10

Ground

Ground

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

I2C_SDA

11

Bi-directional tristate with weak

internal pull-up

I2C data input/output or

SPI serial flash data

output(SF_OUT)

I2C_SCL

12

Input with weak internal pull-up

I2C clock or SPI serial

flash clock output

(SF_CLK)

PIO2

13

Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

PIO6/SPI_CSB

14 Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

Or debug chip select,

selected by SPI_PIO_SEL

PIO7/SPI_MOSI

15 Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

Or debug SPI_MOSI,

selected by SPI_PIO_SEL

VCC_PIO

16

Powered PIO power supply

PIO8/SPI_MISO

17 Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

Or debug SPI_MISO,

selected by SPI_PIO_SEL

PIO9

18 Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

PWM or LED Controls

GND

19

Ground Ground

PIO10

20 Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

PWM or LED Controls

PIO11

21

Bi-directional with programmable

strength internal pull-up/down

Programmable

input/output line

SPI_PIO_S

22

Input with strong internal pull-down Selects SPI debug on (8:5)

NP

23

NP NP

VBAT

24

Power supply

Button cell battery or DC

1.8V to 3.6V

GND

25

Ground Ground

NP

26

NP NP

WAKE_UP

27 Input has no internal pull-up or pull-

down use external pull-down

Set high to wake the

module from hibernate.

Use an external pull-down

for this pin.

GND

28

Ground Ground

Table 7:PIN Terminal Description

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

6. Physical Interfaces

6.1. Power Supply

- The module power supply 3v coin cell batteries or DC 3.3v

- Power supply pin connection capacitor to chip and pin as far as possible close

- Capacitor decouples power to the chip

- Capacitor prevents noise coupling back to power plane.

-

Figure 2:Power Supply PCB Design

6.2. PIO

10 PIOs are provided (4 are multiplexed with SPI debug interface). They are powered

from VDD_PIO.

PIO lines are software-configurable as weak pull-up, weak pull-down, strong pull-up or

strong pull-down.

Note:

At reset all PIO lines are inputs with weak pull-downs.

Any of the PIO lines can be configured as interrupt request lines or as wake-up lines from sleep

modes.

6.3. AIO

3 AIOs are provided. They can be connected to internal 10 bits ADC. Their functions

depend on software. They can be used to read or output a voltage between 0V to 1.3V.

Each of them can be used as a digital output with special firmware.

6.4. PWM

4 PIOs (PIO3, PIO4, PIO9, and PIO10) can be driven by internal PWM module. The

PWM module also works while the module is sleep. So it can be used as a LED flasher.

These functions are controlled by special firmware.

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

6.5. UART

This is a standard UART interface for communicating with other serial devices. The

UART interface provides a simple mechanism for communicating with other serial

devices using the RS232 protocol.

Table 8: Possible UART Settings

Figure 3:Connection To Host device

6.6. I2C Master

The module can act as an I2C master when configured by software. Any two PIOs can

be configured as I2C_SCL and I2C_SDA.

6.7. SPI Master

The module can act as an SPI master (mode 0) when configured by software. Any four

PIOs can be configured as SPI_CLK, SPI_CS#, SPI_DIN and SPI_DOUT. The clock

rate of the software SPI is around 470kHz.

Parameter

Possible Values

Baud Rate Minimum

1200 baud (≤2%Error)

9600 baud (≤1%Error)

Maximum

2M baud (≤1%Error)

Flow Control

RTS/CTS or None

Parity

None, Odd or Even

Number of Stop Bits

1 or 2

Bits per Byte 8

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

6.8. SPI Debug

The SPI Debug interface is chosen when SPI_PIO_S is high. The interface is used to

program and debug the module. So always place test points or header on PCB for this

interface and SPI_PIO_SEL.

7. Reference Design

Figure 4:Reference Design

8. Layout and Soldering Considerations

8.1. Soldering Recommendations

EH-MC10 is compatible with industrial standard reflow profile for Pb-free solders. The

reflow profile used is dependent on the thermal mass of the entire populated PCB, heat

transfer efficiency of the oven and particular type of solder paste used. Consult the

datasheet of particular solder paste for profile configurations.

Comply will give following recommendations for soldering the module to ensure reliable

solder joint and operation of the module after soldering. Since the profile used is

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

process and layout dependent, the optimum profile should be studied case by case.

Thus following recommendation should be taken as a starting point guide.

Refer to technical documentations of particular solder paste for profile

configurations

Avoid using more than one flow.

Reliability of the solder joint and self-alignment of the component are dependent on

the solder volume. Minimum of 150um stencil thickness is recommended.

Aperture size of the stencil should be 1:1 with the pad size.

A low residue, “no clean” solder paste should be used due to low mounted height of

the component.

8.2. Layout Guidelines

For optimal performance of the antenna place the module at the corner of the PCB as shown in the figure

3. Do not place any metal (traces, components, battery etc.) within the clearance area of the antenna.

Connect all the GND pins directly to a solid GND plane. Place the GND vias as close to the GND pins as

possible. Use good layout practices to avoid any excessive noise coupling to signal lines or supply

voltage lines. Avoid placing plastic or any other dielectric material closer than 6 mm from the antenna.

Any dielectric closer than 6 mm from the antenna will detune the antenna to lower frequencies.

Figure 5: Clearance area of antenna

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

9. Mechanical and PCB Footprint Characteristics

Figure 6 :Physical Dimensions and Recommended Footprint (Unit: mm, Deviation:0.02mm)

Bluetooth Low Energy Module

Shanghai Ehong Technologies Co., Ltd

10. Reflow Profile

The soldering profile depends on various parameters necessitating a set up for each application.

The data here is given only for guidance on solder reflow.

210

217

℃

250

A

B

C

D

1

2

0

25

3

4

5

6

min

E

Figure 7: Recommended Reflow Profile

Pre-heat zone (A) — This zone raises the temperature at a controlled rate, typically 0.5 – 2

°C/s. The purpose of this zone is to preheat the PCB board and components to 120 ~ 150 °C.

This stage is required to distribute the heat uniformly to the PCB board and completely remove

solvent to reduce the heat shock to components.

Equilibrium Zone 1 (B) — In this stage the flux becomes soft and uniformly encapsulates

solder particles and spread over PCB board, preventing them from being re-oxidized. Also with

elevation of temperature and liquefaction of flux, each activator and rosin get activated and start

eliminating oxide film formed on the surface of each solder particle and PCB board. The

temperature is recommended to be 150°to 210°for 60 to 120 second for this zone.

Equilibrium Zone 2 (c) (optional) — In order to resolve the upright component issue, it is

recommended to keep the temperature in 210 – 217 °for about 20 to 30 second.

Reflow Zone (D) — The profile in the figure is designed for Sn/Ag3.0/Cu0.5. It can be a

reference for other lead-free solder. The peak temperature should be high enough to achieve

good wetting but not so high as to cause component discoloration or damage. Excessive

soldering time can lead to intermetallic growth which can result in a brittle joint. The

recommended peak temperature (Tp) is 230 ~ 250 °C. The soldering time should be 30 to 90

second when the temperature is above 217 °C.

Cooling Zone (E) — The cooling ate should be fast, to keep the solder grains small which will

give a longerlasting joint. Typical cooling rate should be 4 °C.

FCC Statement:

This equipment has been tested and found to comply with the limits for Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver is

connected.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Note: Modifications to this product will void the user’s authority to operate this equipment.

RF Radiation Exposure Statement:

1.This Transmitter must not be co located or operating in conjunction with any other antenna or‐

transmitter.

2.This equipment complies with FCC RF radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with a minimum distance of 20

centimeters between the radiator and your body.

FCC Information to OEM integrator

The OEM integrator has to be aware not to provide information to the end user regarding how to

install or remove this RF module in the user manual of the end product.

The user manual which is provided by OEM integrators for end users must include the following

information in a prominent location.

1.To comply with FCC RF exposure compliance requirements, the antenna used for this

transmitter must be installed to provide a separation distance of at least 20 cm from all persons

and must not be co located or operating in conjunction with any other antenna or transmitter,‐

except in accordance with FCC multi transmitter product procedures.‐

2. Only those antennas with same type and lesser gain filed under this FCC ID number can be

used with this device.

3. The regulatory label on the final system must include the statement: “Contains FCC ID: xxxx or

using electronic labeling method as documented in KDB 784748.

4. The final system integrator must ensure there is no instruction provided in the user manual or

customer documentation indicating how to install or remove the transmitter module except such

device has implemented two ways authentication between module and the host system‐

Other manuals for EH-MC10

1

Table of contents

Other Ehong Control Unit manuals