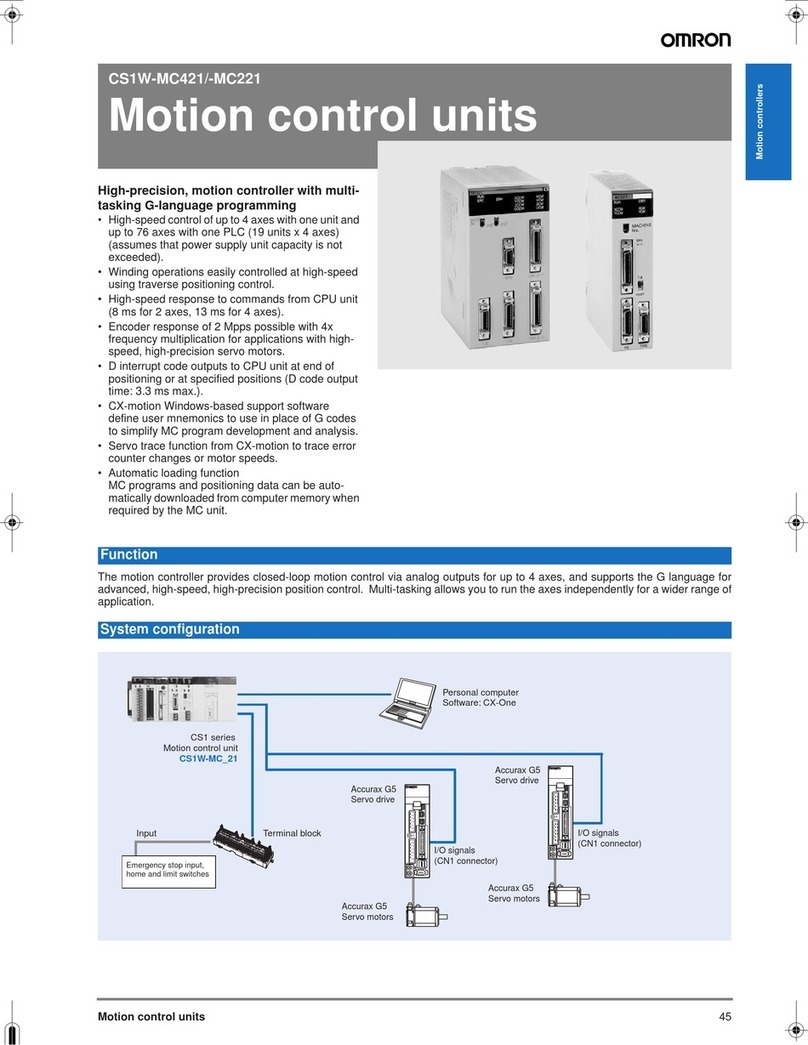

Motion Control Units Product Specifications

2

MC

Unit functions

Automatic Mode

(Executes G-language programs

in the MC Unit.)

Manual Mode

(Executes manual commands

from the CPU Unit or T

eaching

Box.)

Common to Automatic

and Manual Modes

Position control

Speed control

Origin search

Interrupt feeding

Traversing

Arithmetic operations, etc.

Deceleration stop

Origin search (manual)

Standard origin return

Jogging

Error counter reset

Forced origin

Absolute origin setting

Servo lock/Servo unlock

Teaching

Zones

Backlash correction

Override

Present position preset

Electronic gear

Dwell timer

Stop Mode

Pass Mode

In-position

Check OFF Mode

Features

Multitasking

G Language

The

MC Unit is

provided with a multitasking G language, which is the

optimum

language

for motion control. The G language makes it sim

-

ple to create programs for multiaxis

control, without placing a bur

-

den on the CPU Unit’

s ladder diagram program.

Simple and Fast T

raverse Operations

Commands for 2-axis traverse operations enable simple and fast

traverse

operations.

Fast Pick-and-place Operations

After

a positioning command has been output,

the in-position check

OFF function allows the next positioning operation to be started

without waiting for the first positioning operation to be completed.

This

makes it possible to perform high-speed pick-and-place opera

-

tions.

Supports

Absolute Encoders

The MC Unit is compatible with absolute encoders as a standard

feature,

eliminating the need to perform an origin search. Incremen

-

tal

encoders can be used as well.

High-speed Response to Start Commands from CPU Unit

The

response time from when a start

command is received from the

CPU

Unit until the command voltage is output from the MC Unit is

8

ms

for two axes and 13 ms for four axes (MC421 only).

This is 1.5

times

faster than the previous models.

Note: T

wo-axis MC Unit

This function applies to the X axis when a 2-axis, 1-task

configuration

is used.

Four-axis MC Unit

This function applies to the X axis when a 4-axis, 1-task

configuration

is used.

500-kp/s Encoder Response Frequency

The maximum feedback encoder response frequency is 500 kp/s,

so

the MC Unit can be used with high-speed and high-precision ser

-

vomotors. This is double the response frequency of the earlier mod

-

els.

CPU Unit Interrupts

A

CPU

Unit external interrupt task can be started by outputting a D

code (interrupt code) for the CPU Unit when positioning is com-

pleted

or when passing through a particular position.

This feature is

ideal

for high-speed synchronization between the MC Unit and CPU

Unit.

Other

Functions

•

Unlimited Feeding

This function executes unlimited feeding for the specified axis.

Use of this function allows the user to control unlimitedly fed

axes, such as those for turntables or one-way conveyors. The

present value can be increased or decreased within the

specified

range.

•

Synchronous Electronic Gear

Input pulses for a synchronous encoder can be accelerated or

decelerated for each axis at any timing. The acceleration or

deceleration

rate is specified by a numerator/denominator

ratio.

To

provide simple synchronous control,

this function can also be

enabled

or disabled for each axis at any timing.

•Error Counter Reset

After a deceleration command has been completed, the error

counter

reset function forcibly sets the error counter to 0 to stop

the axis operation completely. This function is best suited for

machine

press control in molding and other processes.

•

Multiturn Circular Interpolation

The multiturn circular interpolation function has been added to

the existing circular and helical circular interpolation functions.

This function can be used for applications such as winding

machine

operations.

•

Override (Real T

ime Speed Change)

The speed can be changed during PTP, linear interpolation, or

circular interpolation operations in which the axis stops during

the

positioning operation. (This function is invalid in pass

mode

or

in-position check OFF mode.)

•

Pass Operations

The

acceleration and deceleration times can

be changed during

pass operations. It is possible to specify whether to pass the

operation using the previous acceleration time or pass the

operation

using the deceleration time during

pass operations. It

is

also possible to pass the operation at a constant

acceleration

rate

during single-axis pass operation.