HCL SM-FT-3000 Instruction Manual

SM-FT-3000 Banding Tool

Operation, Parts & Safety Manual

Original Instructions

www.hclfasteners.com

www.hclfasteners.com

Tooling

Index

Health & Safety

1.1 Warning & Safety Instructions

Continuous Tightening Tool

2.1 Preparation

2.2 Tensioning Table

2.3 Operation

Maintenance

3.1 Servicing

3.2 Parts List

3.3 Troubleshooting

CE Marking

4.1 EC Declaration of Conformity

Depending on set up, this tool is designed to assemble:

– Smart® Tie 20mm (¾˝)

– Smart® Tie 32mm (1¼˝)

– Smart® Band 19mm (¾˝) Hybrid & Compact

– Smart® Band 32mm (1¼˝) Hybrid & Compact systems.

Follow the instructions described to achieve safe operation.

www.hclfasteners.com

Read these instructions carefully:

Whilst Smart®Band and Smart®Tie are considered to be

signicantly safer than alternative metallic solutions, failure

to follow these instructions can still result in personal injury.

General safety considerations:

1. STRAP BREAKAGE HAZARD

Smart®Band is free from sharp metallic edges however it is important to understand that improper operation of the tool or

sharp corners on the load can result in strap breakage during tensioning that could result in the following:

– A sudden loss of balance causing you to fall

– Both tool and strap ying violently towards your face

Failure to place the strap properly around the load, an unstable or shifted load, could result in a sudden loss of strap tension

during tensioning. This could result in a sudden loss of balance causing you to fall.

Positioning yourself in-line with the strap during tensioning, can result in personal injury from ying strap or tool. When

tensioning, position yourself to one side of the strap and keep all bystanders away.

2. STRAP TENSION HAZARD

Smart® Band tools create very high tensions. Ensure body parts cannot be trapped during installation to prevent a crush

injury.

3. EYE INJURY HAZARD

Failure to wear safety glasses with side shields can result in eye injury or blindness. Always wear safety glasses

with side shields which conform to ANSI Standard Z87.1 or EN 166.

4. CUT HAZARD

Although the Smart® Band is not metallic and therefore signicantly less likely to cause cuts to hands or ngers,

it is still strongly recommended that the operator wear protective gloves.

5. NOISE HAZARD

When using the tool, ear protection must be worn.

At the operator’s position:

– A-weighted sound pressure level, LpA = 80dBA (uncertainty, KpA = 4 dBA)

– A-weighted sound power level, LWA = 91 dBA (uncertainty, KWA = 4 dBA)

– Vibration level is less than 2.5 ms-2.

6. TOOL CARE (for further information see Maintenance section)

– Always use an FRL (Filter, Regulator, Lubricator) Unit

– Inspect and clean the tool daily. Replace all worn or broken parts

– Lubricate all moving parts approximately every 5000 tting cycles

– On air powered tools always disconnect the pneumatic connection to the tool when performing part removal and

replacement procedures. NEVER connect a pneumatic source to a disassembled tool unless otherwise specied

– If used in a marine environment, wash off with fresh water after use, allow to dry then spray with light oil and wipe down.

– To avoid tool damage in prolonged use, set the tool up on a counter-balance.

– Never put away a wet or damp tool.

7. WORK AREA

Keep work areas uncluttered and well lit. For prolonged use and to avoid unnecessary strain on your back, set the tool up on

a counter-balance.

TOOL WEIGHTS

Smart® Band 19mm (¾˝) &

Smart® Tie 20mm (¾˝) tools

– 8.3kg

Smart® Band 32mm (1¼˝)

– 7.5kg

Smart® Tie 32mm (1¼˝)

– 9.1kg

Health & Safety - Warning & Safety Instructions

1.1

www.hclfasteners.com

Air Preparation

To perform correctly, this pneumatic tool requires a continuous

ow of clean, dry and lubricated air at a suitable pressure.

Air Flow

Air motors inevitably need high ow requirements and this

should be taken into consideration before set up.

Smart® Band 19mm (¾˝) Hybrid & Compact and Smart®Tie

20mm (¾˝) tools – Requires a continuous air ow of 935 l/min

(33 CFM).

Note: A pneumatic supply hose with internal bore of at least

10mm (⅜˝) must be used to allow an adequate volume of

compressed air to supply the tool.

Smart® Band 32mm (1¼˝) Hybrid & Compact and Smart®Tie

32mm (1¼˝) tools – Requires a continuous air ow of

1,000 l/min (35 CFM).

Note: A pneumatic supply hose with internal bore of at least

10mm (⅜˝) must be used to allow an adequate volume of

compressed air to supply the tool.

IMPORTANT – THE TOOL WILL NOT OPERATE TO

SPECIFICATION UNLESS THE MINIMUM AIRFLOW AND AIR

REGULATION REQUIREMENTS HAVE BEEN MET.

Air Filter

For best results, use a 50 micron lter or better.

Pressure Regulator

A pressure regulator is essential for controlling the performance

of the tool and should be mounted as close to the tool as

possible, preferably within 5m (15ft). The maximum allowable

static pressure (tool not running) for the tool is 0.7 MPa (7.0

bar). The recommended pressures (see section 2.2) are given as

Dynamic pressures (when the tool is running).

Air Lubricator

The tool should be lubricated with 6 to 8 drops of oil per minute

of continuous use, in order to maintain the life of the air motor

and prevent seizing. Lubricators should always be mounted as

close to the tool as possible, preferably within 3m (10ft). Always

mount the lubricator at least as high, or preferably higher than

the tool. HCL recommend allowing 100ml/1000 strap ttings

FOR MORE INFORMATION REFER TO THE PNEUMATIC

NUTRUNNER TOOL MANUAL

Continuous Tightening Tool - Preparation

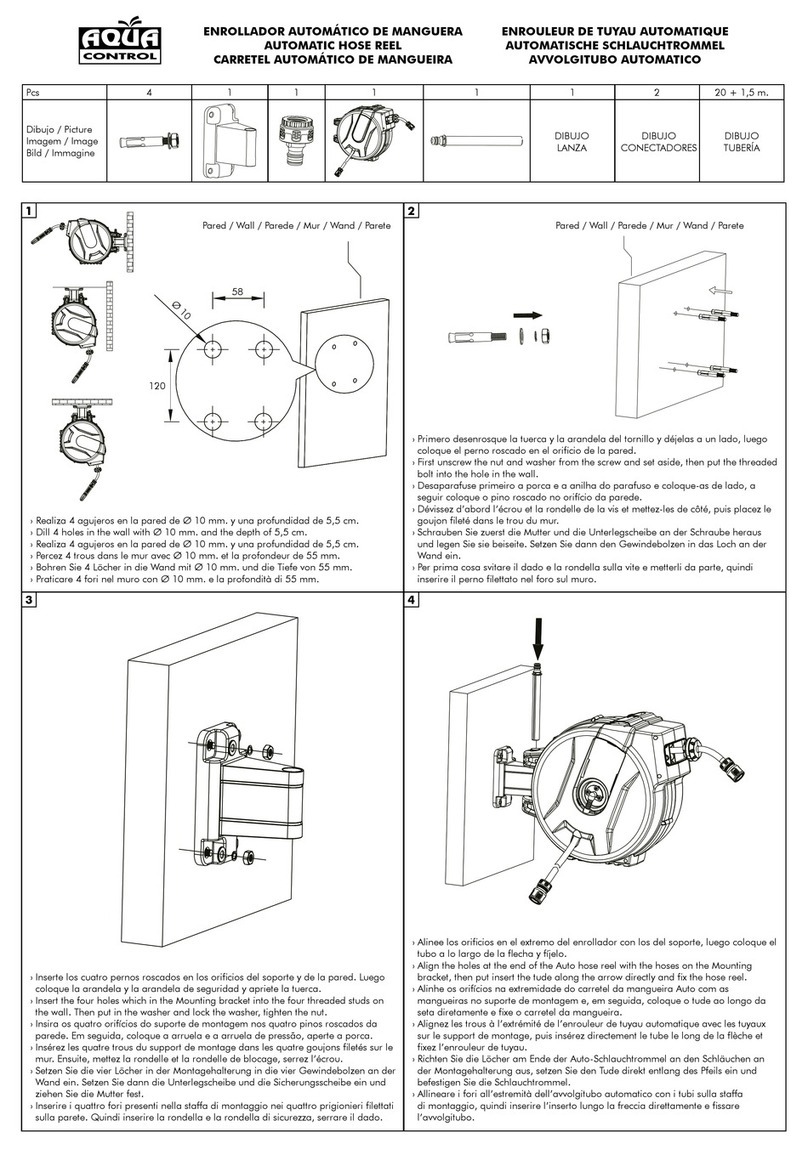

LUBRICATED AIR INPUT

TRIGGER

LIFTING EYES

CUTTING BUTTON

BAND EXIT SLOT

BAND ENTRY SLOT

All tools are supplied with a 5m supply hose.

KNOB FOR VERIFYING AND

ADJUSTING OIL DROPS

PRESSURE REGULATOR

AIR FILTER

KNOB FOR ADJUSTING PRESSURE

AIR LUBRICATOR

AIR ISOLATION VALVE

*IMPORTANT* – Risk of seizure if not adhered to.

2.1

www.hclfasteners.com

MPa

(N/mm2)

Psi

(lb/in2)Bar

x 0.1x 0.006895

x 10x 145.03

x 0.06895

x 14.503

Recommended Pressure Settings

WARNING – Do not exceed the maximum pressure settings recommended for the system being applied

Smart®Tie Diameter Max

Speed

Dynamic

Pressure1

Max System Force

(During Tightening)

Min Retention Force2

(After Tightening)

Size Material mm MPa Nkgf lbf N kgf lbf

20mm (¾˝)

PA66 (Nylon 6.6)

100 310

rpm

0.60 3800 388 854 1800 184 405

PA12 (Nylon 12) 0.50 3000 306 674 1400 143 315

PPS (Polyphenylene Sulphide) 0.60 3000 306 674 1400 143 315

PK (Polyketone) 0.60 3000 306 674 1500 153 337

32mm (1¼˝)

PA66 (Nylon 6.6)

200 66

rpm

TBC TBC TBC TBC TBC TBC TBC

PA12 (Nylon 12) 0.55 6000 612 1349 2000 204 450

PPS (Polyphenylene Sulphide) 0.55 5500 561 1236 2000 204 450

PK (Polyketone) 0.65 7000 714 1574 2000 204 450

Smart®Band Hybrid * and Compact Diameter Max

Speed

Dynamic

Pressure1

Max System Force

(During Tightening)

Min Retention Force2

(After Tightening)

Size Material mm MPa Nkgf lbf N kgf lbf

19mm (¾˝)

PA66 (Nylon 6.6)

600

143

rpm

0.45 6000 612 1349 3500 357 787

PA12GF (Nylon 12 Glass-lled) 0.60 7000 714 1574 3500 357 787

POM (Acetal) 0.60 6500 663 1461 3500 357 787

PPS (Polyphenylene Sulphide) 0.60 7000 714 1574 3500 357 787

32mm (1¼˝)

PA66 (Nylon 6.6)

210

rpm

0.55 16500 1683 3709 13500 1377 3035

PA12GF (Nylon 12 Glass-lled) 0.55 16500 1683 3709 9000 918 2023

POM (Acetal) 0.45 12500 1275 2810 7500 765 1686

PPS (Polyphenylene Sulphide) 0.55 16500 1683 3709 9000 918 2023

32mm and 19mm Hybrid Buckle

Pressure

Conversion

Triangle

Important Notes:

1) Dynamic pressure means that the input pressure is set when the tool is running. The static

pressure (when the tool is NOT running) will be higher than the dynamic pressure. The input

pressure may need to be reduced depending on the aggressive nature of the application.

2) The nal retention force has been measured on a 600mm diameter steel pipe for Smart®Band

and a 200mm diameter steel pipe for Smart® Ties.

This gure may be lower for smaller diameters, or higher for larger diameters.

Continuous Tightening Tool - Tensioning

2.2

www.hclfasteners.com

3

Wrap band around the application

4

Insert band into other end of buckle

1

Insert band into xed end of the buckle*

*Does not apply to Smart®Band Compact

2

Pull back band to engage latch and push latch

down onto band*

*Does not apply to Smart®Band Compact

WARNING – Ensure latch is fully engaged

with band before tightening. Latch not fully

engaged could lead to premature failure of

system when tightening

TEETH ENGAGED

Continuous Tightening Tool - Operation

2.3

www.hclfasteners.com

6

SM-FT-3000-32 tool with trigger operation

shown for reference. All other tool variants

have a button to operate the tool

Insert tool onto band, whilst holding down

trigger – The tool will tighten the band and then

stall

*Keep trigger / button held down*

SM-FT-3000-32 Shown for reference (Trigger)

8

*Keep trigger / button held down*

SM-FT-3000-32 Shown for reference (Trigger)

Once the band is cut, release the Cutting

Button – The tool will eject the excess length of

band

Smart®Band assembly complete

7

*Keep trigger / button held down*

SM-FT-3000-32 Shown for reference (Trigger)

Press the cutting button for 2 seconds

or until the blade has completely cut

through the band

WARNING – To avoid trapping of ngers,

keep both hands on the tool while the strap is

being tightened

5

Pull band tight by hand, making sure teeth are

fully engaged with band

CUT BUTTON

TRIGGER

Continuous Tightening Tool - Operation

2.3

www.hclfasteners.com

1

Remove any blockages from Gripping wheel

teeth.

To access all of the teeth, connect air line and

press trigger to rotate Gripping wheel – ensure

that the air line is removed before clearing

any blockages.

2

Remove the M5 Capscrews (2x)

and the Band guide.

WARNING – Never service the tool whilst

connected to a pressurised air line

3

Remove the M4 Capscrews (4x) and the Blade

housing.

4

Remove, clean and grease the Blade housing,

Blade and Blade spring.

*Reassemble tool as reverse of disassembly*

Maintenance - Servicing – Gripping Wheel & Blade

3.1

www.hclfasteners.com

For maintenance of Pneumatic Nutrunner,

please refer to manufacturers manual

5

Remove the Banjo bolt and hose from the top

of the Cutting piston.

6

Remove the M4 Capscrews (7x) and the

Cutting cylinder.

WARNING – Never service the tool whilst

connected to a pressurised air line

7

Remove the Piston assembly from the Cutting

cylinder.

8

Clean and grease the Cutting piston, Piston

shaft and DU bearing.

*Reassemble tool as reverse of disassembly*

Maintenance - Servicing – Cutting Piston

3.1

www.hclfasteners.com

Maintenance - Parts List – SM-FT-3000-32

ITEM PART NUMBER TITLE QTY

1 PRT1129 PLATE, LEFT 1

2 NRB_22_30_13 BEARING, NEEDLE ROLLER, 22IDx30ODx13LG

(RNA_4903-2RS) 1

3 PRT1130 WASHER, THRUST 2

4 PRT1131 WHEEL, GRIPPING, 32mm 1

5PRT1132 PLATE, RIGHT 1

6NRB_22_30_13 BEARING, NEEDLE ROLLER, 22IDx30ODx13LG

(RNA_4903-2RS) 1

7PRT1251 PIN, Ø6x60LG 2

8 PRT1141 PLATE, BAND DEFLECTION 1

9CPS_M6X60_SS CAPSCREW, SKT HD, M6x60LG, SS 2

10 PRT1133 PLATE, TORQUE REACTION 1

11 CPS_M6X25_SS CAPSCREW, SKT HD, M6x25LG, SS 4

12 PRT1142 PLATE, BLADE SURROUND 1

13 PRT1295 FRONT END, CAST, 32mm, CHAMFERED SLOT 1

14 CPS_M4X25_SS CAPSCREW, SKT HD, M4x25LG, SS 4

15 PRT1048 BLADE, CUTTING, 32mm 1

16 PRT1049 SPRING, COMPRESSION 1

17 PRT1143 BASE PLATE, CUTTING CYLINDER 1

18 DUB_010_012_015 BEARING, DU, 10IDx12ODx15LG 1

19 PRT1144 DEFLECTION PLATE, SHEET METAL 1

20 CPS_M5X8_SS CAPSCREW, SKT HD, M5x8LG, SS 4

21 PRT1179 BAND GUIDE, SHEETMETAL 1

22 CPS_M5X16_SS CAPSCREW, SKT HD, M5x16LG, SS 4

23 PRT1145 WAVE SPRING, CREST TO CREST 1

24 PRT1146 PISTON, CUTTING 1

25 ORG_10763X262_BS156_N70A O-RING, BS156, 107.63IDx2.62CS, NITRILE 70A 1

26 PRT1147 SHAFT, CUTTING PISTON 1

27 PRT1148 CYLINDER, CUTTING 1

28 CPS_M4X14_SS CAPSCREW, SKT HD, M4x14LG, SS 7

29 PRT1134 PNEUMATIC VALVE, 3/2, NORMALLY-CLOSED, M5 PORTS 1

30 PRT1135 SILENCER, M5 1

31 PRT1136 FLOW CONTROLLER, METER-IN, ELBOW, M5 to 4mm

ONE-TOUCH 1

32 PRT1137 BARB ELBOW, M5 to 4mm 2

33 PRT1138 PU TUBE, OD 4mm, 150mm LONG, BLACK 1

34 PRT1139 PU TUBE, OD 4mm, 20mm LONG, BLACK 1

35 PRT1140 PU TUBE, OD 4mm, 150mm LONG, BLACK 1

36 CPS_M2-5X20_SS CAPSCREW, SKT HD, M2.5x20LG, SS 2

37 PRT1149 COVER, SHEETMETAL 1

38 PRT1150 HANDLE 1

39 CPS_M8X12_SS CAPSCREW, SKT HD, M8x12LG, SS 2

40 PRT1151 FOOT, ANTI-VIBRATION 2

41 CPS_M6X16_SS CAPSCREW, SKT HD, M6x16LG, SS 2

ITEM PART NUMBER TITLE QTY

42 NUT_NYLOC_HEX_M6_SS NUT, NYLOC, HEXAGON, M6, SS 2

43 PRT1152 PNEUMATIC VALVE, 3/2, 4mm BARB, BLACK PUSH

BUTTON 1

44 PRT1153 PNEUMATIC VALVE, 3/2, ⅜” BSPT PORTS 1

45 PRT1154 ADAPTOR ELBOW, ⅜” BSPT MALE TO ⅜” 60° CONE 1

46 PRT1440 SILENCER, FLUSH, ⅜” BSPP 1

47 PRT1156 ELBOW, INPUT ADAPTOR 1

48 PRT1329 ADAPTOR, M5 TO DOUBLE 4mm ONE-TOUCH 1

49 PRT1160 FLOW CONTROLLER, METER-OUT, ELBOW, ⅛” BSPT to

4mm ONE-TOUCH 1

50 CPS_M4X40_SS CAPSCREW, SKT HD, M4x40LG, SS 2

51 NUT_NYLOC_HEX_M4_SS NUT, NYLOC, HEXAGON, M4, SS 2

52 PRT1158 SPACER 1

53 PRT1159 BULKHEAD ADAPTOR, ¼” BSPP FEMALE TO 4mm ONE-

TOUCH 1

54 PRT1161 CONNECTOR, Y-PIECE, EQUAL SIZE, 4mm ONE-TOUCH 1

55 PRT1162 QUICK EXHAUST VALVE, 4mm to 4mm ONE-TOUCH 1

56 PRT1163 PU TUBE, OD 4mm, 70mm LONG, BLACK 1

57 PRT1164 PU TUBE, OD 4mm, 75mm LONG, BLACK 1

58 PRT1165 PU TUBE, OD 4mm, 180mm LONG, BLACK 1

59 PRT1167 PU TUBE, OD 4mm, 135mm LONG, BLACK 1

60 CPS_M5X10_SS CAPSCREW, SKT HD, M5x10LG, SS 7

61 PRT1168 NUTRUNNER, CLECO 55NL-2T-4 1

62 PRT1441 ADAPTOR, ½” NPT MALE TO ⅜” FEMALE 1

63 PRT1170 PLATE, REACTION CLAMP 1

64 CPS_M8X40_SS CAPSCREW, SKT HD, M8x40LG, SS 2

65 PRT1334 FLOW CONTROLLER, METER-IN, ELBOW, ⅜” NPT 1

66 PRT1288 ADAPTOR, ⅜” NPT MALE TO ⅜” 60° CONE 1

67 PRT1171 HOSE TAIL, BLOCK 90°, ⅜” 60° FEMALE CONE 1

68 PRT1172 FERRULE, ⅜” 2

69 PRT1174 HOSE TAIL, STRAIGHT, ⅜” 60° FEMALE CONE 1

70 PRT1173 HOSE, 2-PLY STEEL BRAID, ⅜” 1

71 WAS_DOWTY_1-4 WASHER, DOWTY, ¼” 4

72 PRT1175 HOSE TAIL, BANJO FITTING, ¼” 2

73 PRT1177 FERRULE, ¼” 2

74 PRT1178 HOSE, 1-PLY STEEL BRAID, ¼” 1

75 PRT1176 BOLT, BANJO, ¼” 2

76 PRT1298 BRACKET, LIFTING EYE 1

77 BHS_M8X16_SS BUTTONHEAD SCREW, SKT HD, M8x16LG, SS 1

78 EYE_NUT_M8_SS NUT, LIFTING EYE, M8x1.25, SS 2

79 WAS_FLAT_M8_SS WASHER, FLAT, M8, SS 1

80 CPS_M8X16_SS CAPSCREW, SKT HD, M8x16LG, SS 1

81 CPS_M8X70_SS CAPSCREW, SKT HD, M8x70LG, SS 1

3.2

www.hclfasteners.com

Maintenance - Parts List – SM-FT-3000-32

74

73

72

71

27

14

13

25

24

26

8

22

17

18

21

20

75 3 2 12 16 15 4 6 7 10 11 5 29 32 31

9 28 60 38 39 52 37 43 42 40 41 53 57 56 58 55 59 30 45 33 51 49 44 50

80

78

76

81

62

65

68

35

36

48

47

34 63 69 61 64 70

66

67

541

77

46

79

23

19

3.2

www.hclfasteners.com

Maintenance - Parts List – SM-FT-3000-19

ITEM PART NUMBER TITLE QTY

1PRT1262 PLATE, LEFT 1

2 NRB_22_30_ 13 BEARING, NEEDLE ROLLER, 22IDx300Dx13LG (RNA_4903-2RS) 1

3 PRT1130 WASHER, THRUST 2

4PRT1263 WHEEL, GRIPPING, 19mm 1

5 PRT1264 PLATE, RIGHT 1

6NRB_22_30_ 13 BEARING, NEEDLE ROLLER, 22IDx30ODx13LG (RNA_4903-2RS) 1

7PRT1266 PIN, Ø6x45LG 2

8 PRT1414 PLATE, TORQUE REACTION 1

9CPS_M6X25_SS CAPSCREW, SKT HD, M6x25LG, SS 4

10 PRT1267 PLATE, BAND DEFLECTION 1

11 CPS_M6X45_SS CAPSCREW, SKT HD, M6x45LG, SS 2

12 PRT1268 PLATE, BLADE SURROUND 1

13 CPS_M4X14_SS CAPSCREW, SKT HD, M4x14LG, SS 4

14 PRT1377 FRONT END, CAST, 19mm, CHAMFERED SLOT 1

15 CPS_M4X16_SS CAPSCREW, SKT HD, M4x16LG, SS 4

16 PRT1057 BLADE, CUTTING, 19mm 1

17 PRT1049 SPRING, COMPRESSION 1

18 PRT1269 BASE PLATE, CUTTING CYLINDER 1

19 DUB_010_012_015 BEARING, DU, 10IDx12ODx15LG 1

20 PRT1270 DEFLECTION PLATE, SHEETMETAL 1

21 CPS_M5X8_SS CAPSCREW, SKT HD, M5x8LG, SS 4

22 PRT1271 BAND GUIDE, SHEETMETAL 1

23 CPS_M5X16_SS CAPSCREW, SKT HD, M5x16LG, SS 4

24 PRT1145 WAVE SPRING, CREST TO CREST 1

25 PRT1272 PISTON, CUTTING 1

26 ORG_08380X262_BS643_N70A O-RING, BS643, 83.80IDx2.62CS, NITRILE 70A 1

27 PRT1147 SHAFT, CUTTING PISTON 1

28 PRT1273 CYLINDER, CUTTING 1

29 CPS_M4X14_SS CAPSCREW, SKT HD, M4x14LG, SS 7

30 PRT1413 NUTRUNNER, MODEC, MR08RV0073AFCA1C 1

31 PRT1411 PLATE, REACTION CLAMP 1

32 CPS_M8X45_SS CAPSCREW, SKT HD, M8x45LG, SS 2

33 PRT1382 HYDRAULIC ADAPTOR, G¼˝ MALE TO G⅜˝ 60° CONE 1

34 PRT1397 ADAPTOR ELBOW, ¼˝ BSPT MALE TO ¼˝ 60° CONE 1

35 PRT1430 SILENCER, FLOW CONTROLLER, G⅜˝ 1

36 PRT1416 LOWER COVER PLATE 1

37 PRT1134 PNEUMATIC VALVE, 3/2, NORMALLY-CLOSED, M5 PORTS 1

38 PRT1384 BARB STRAIGHT, MS TO 4mm 1

39 PRT1137 BARB ELBOW, M5 to 4mm 1

40 PRT1135 SILENCER, M5 1

41 PRT1136 FLOW CONTROLLER, METER-IN, ELBOW, M5 to 4mm ONE-

TOUCH 1

42 PRT1386 PNEUMATIC VALVE, 3/2, NORMALLY-OPEN, M5 PORTS 1

43 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

44 PRT1137 BARB ELBOW, M5 to 4mm 1

45 PRT1135 SILENCER, M5 1

46 PRT1136 FLOW CONTROLLER, METER-IN, ELBOW, M5 to 4mm ONE-

TOUCH 1

47 PRT1386 PNEUMATIC VALVE, 3/2, NORMALLY-OPEN, M5 PORTS 1

48 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

49 PRT1137 BARB ELBOW, M5 to 4mm 1

50 PRT1135 SILENCER, M5 1

51 PRT1385 FLOW CONTROLLER, METER-OUT, ELBOW, M5 to 4mm ONE-

TOUCH 1

52 PRT1404 M2.5, STUDDING 2

ITEM PART NUMBER TITLE QTY

53 NUT_NYLOC_HEX_M2-5_SS NUT, NYLOC, HEXAGON, M2-5, SS 4

54 PRT1162 QUICK EXHAUST VALVE, 4mm to 4mm ONE-TOUCH 1

55 PRT1152 PNEUMATIC VALVE, 3/2, 4mm BARB, BLACK PUSH BUTTON 2

56 PRT1387 PNEUMATIC VALVE, 5/3, G¼˝ PORTS 1

57 PRT1399 SILENCER, ¼˝ BSP 2

58 PRT1279 ADAPTOR ELBOW, ¼˝ BSPT MALE TO ⅜˝ 60° CONE 1

59 PRT1401 ¼˝ NIPPLE 1

60 PRT1157 BUSH, REDUCER, ⅛˝ BSPT TO M5 2

61 PRT1137 BARB ELBOW, M5 TO 4mm 3

62 PRT1281 ELBOW, INPUT ADAPTOR 1

63 PRT1400 ¼˝ BSP MALE TO ¼˝ BSP FEMALE, STRAIGHT ADAPTOR 1

64 PRT1405 FIXING SUB PLATE 1

65 CPS_M3X40_SS CAPSCREW, SKT HD, M3x40LG, SS 3

66 PRT1381 MANIFOLD, PNEUMATIC 1

67 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

68 PRT1137 BARB ELBOW, MS TO 4mm 4

69 PRT1381 MANIFOLD, PNEUMATIC 1

70 PRT1137 BARB ELBOW, M5 TO 4mm 1

71 PRT1384 BARB STRAIGHT, M5 TO 4mm 3

72 PRT1383 PLUG, M5 1

73 CPS_M3X12_SS CAPSCREW, SKT HD, M3x12LG, SS 4

74 PRT1415 TOP COVER PLATE 1

75 PRT1159 BULKHEAD ADAPTOR, ¼˝ BSPP FEMALE TO 4mm ONE-TOUCH 1

76 PRT1150 HANDLE 1

77 CPS_M8X12_SS CAPSCREW, SKT HD, M8x12LG, SS 2

78 PRT1370 FOOT, ANTI-VIBRATION 2

79 BHS_M8X12_SS BUTTONHEAD SCREW, SKT HD, M8x12LG, SS 2

80 PRT1398 SPACER 1

81 CPS_M4X12_SS CAPSCREW, SKT HD, M4x12LG, SS 2

82 PRT1158 SPACER 1

83 PRT1353 HOSE, 2-PLY STEEL BRAID, ⅜˝ 1

84 PRT1172 FERRULE, ⅜˝ 2

85 PRT1171 HOSE TAIL. BLOCK 90°, ⅜˝ 60° FEMALE CONE 1

86 PRT1174 HOSE TAIL. STRAIGHT, ⅜˝ 60° FEMALE CONE 1

87 PRT1407 HOSE TAIL, BLOCK 90°, ¼˝ 60° FEMALE CONE 1

88 PRT1408 FERRULE, ¼˝2

89 PRT1409 HOSE TAIL, STRAIGHT, ¼˝ 60° FEMALE CONE 1

90 PRT1406 HOSE, 2-PLY STEEL BRAID, ¼˝1

91 PRT1412 BLANKING PLUG 2

92 PRT1410 BRACKET, LIFTING EYE 1

93 CPS_M8X70_SS CAPSCREW, SKT HD, M8x70LG, SS 1

94 EYE_NUT_M8_SS NUT, LIFTING EYE, M8x1.25, SS 2

95 BHS_M8X16_SS BUTTONHEAD SCREW, SKT HD, M8x16LG, SS 1

96 PRT1371 FOOT, ANTI-VIBRATION 1

97 BHS_M8X12_SS BUTTONHEAD SCREW, SKT HD, M8x12LG, SS 1

98 WAS_FLAT_M8_SS WASHER, FLAT, M8, SS 1

99 CPS_M8X16_SS CAPSCREW, SKT HD, M8x16LG, SS 1

100 CPS_M5X10_SS CAPSCREW, SKT HD, M5x10LG, SS 6

101 WAS_DOWTY_1-4 WASHER, DOWTY, ¼˝4

102 PRT1175 HOSE TAIL, BANJO FITTING, ¼˝2

103 PRT1177 FERRULE, ¼˝2

104 PRT1293 HOSE, 1-PLY STEEL BRAID, ¼˝1

105 PRT1176 BOLT, BANJO, ¼˝2

3.2

www.hclfasteners.com

Maintenance - Parts List – SM-FT-3000-19

105

101

2

28

3

26

1

25

11

27

79

24

75

51

18

19

103 104 15 14 13 12 17 16 4 10 6 7 8 9 5

36 53 81 82 100 49 80 78 46 44 41 39 37 42 40 45 88 87 50 59 90 89 65

96

73

68

54

34

33

69

72

63

64

62

67 66 30 31 32 94

35

71

4774

92

48

97 98 93

57

56

60

61

85

84

83

86

58

55

29

91

22

20

21

76

77

95102

23

52 38 43

70

3.2

www.hclfasteners.com

Maintenance - Parts List – SM-FT-3000-20ST

ITEM PART NUMBER TITLE QTY

1ASM1063 LEFT PLATE BEARING ASSEMBLY 1

2 PRT1130 WASHER, THRUST 2

3 PRT1249 WHEEL, GRIPPING, 20mm SMART TIE 1

4ASM1064 RIGHT PLATE BEARING ASSEMBLY 1

5 PRT1266 PIN, Ø6x45LG 2

6 PRT1265 PLATE, TORQUE REACTION 1

7CPS_M6X25_SS CAPSCREW, SKT HD, M6x25LG, SS 4

8PRT1267 PLATE, BAND DEFLECTION 1

9CPS_M6X45_SS CAPSCREW, SKT HD, M6x45LG, SS 2

10 PRT1268 PLATE, BLADE SURROUND 1

11 CPS_M4X14_SS CAPSCREW, SKT HD, M4x14LG, SS 4

12 PRT1377 FRONT END, CAST, 19mm, CHAMFERED SLOT 1

13 CPS_M4X16_SS CAPSCREW, SKT HD, M4x16LG, SS 4

14 PRT1057 BLADE, CUTTING, 19mm 1

15 PRT1049 SPRING, COMPRESSION 1

16 PRT1269 BASE PLATE, CUTTING CYLINDER 1

17 DUB_010_012_015 BEARING, DU, 10IDx12ODx15LG 1

18 PRT1270 DEFLECTION PLATE, SHEETMETAL 1

19 CPS_M5X8_SS CAPSCREW, SKT HD, M5x8LG, SS 4

20 PRT1271 BAND GUIDE, SHEETMETAL 1

21 CPS_M5X16_SS CAPSCREW, SKT HD, M5x16LG, SS 4

22 PRT1145 WAVE SPRING, CREST TO CREST 1

23 PRT1272 PISTON, CUTTING 1

24 ORG_08380X262_BS643_N70A O-RING, BS643, 83.80IDx2.62CS, NITRILE 70A 1

25 PRT1147 SHAFT, CUTTING PISTON 1

26 PRT1273 CYLINDER, CUTTING 1

27 CPS_M4X14_SS CAPSCREW, SKT HD, M4x14LG, SS 7

28 PRT1376 NUTRUNNER, MODEC 1

29 PRT1411 PLATE, REACTION CLAMP 1

30 CPS_M8X45_SS CAPSCREW, SKT HD, M8x45LG, SS 2

31 PRT1382 HYDRAULIC ADAPTOR, G¼˝ MALE TO G⅜˝ 60° CONE 1

32 PRT1397 ADAPTOR ELBOW, ¼˝ BSPT MALE TO ¼˝ 60° CONE 1

33 PRT1430 SILENCER, FLOW CONTROLLER, G⅜˝ 1

34 PRT1416 LOWER COVER PLATE 1

35 PRT1134 PNEUMATIC VALVE, 3/2, NORMALLY-CLOSED, M5 PORTS 1

36 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

37 PRT1137 BARB ELBOW, M5 to 4mm 1

38 PRT1135 SILENCER, M5 1

39 PRT1136 FLOW CONTROLLER, METER-IN, ELBOW, M5 to 4mm ONE-

TOUCH 1

40 PRT1386 PNEUMATIC VALVE, 3/2, NORMALLY-OPEN, M5 PORTS 1

41 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

42 PRT1137 BARB ELBOW, M5 to 4mm 1

43 PRT1135 SILENCER, M5 1

44 PRT1136 FLOW CONTROLLER, METER-IN, ELBOW, M5 to 4mm ONE-

TOUCH 1

45 PRT1386 PNEUMATIC VALVE, 3/2, NORMALLY-OPEN, M5 PORTS 1

46 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

47 PRT1137 BARB ELBOW, M5 to 4mm 1

48 PRT1135 SILENCER, M5 1

49 PRT1385 FLOW CONTROLLER, METER-OUT, ELBOW, M5 to 4mm ONE-

TOUCH 1

50 PRT1404 M2.5, STUDDING 2

51 NUT_NYLOC_HEX_M2-5_SS NUT, NYLOC, HEXAGON, M2-5, SS 4

52 PRT1162 QUICK EXHAUST VALVE, 4mm to 4mm ONE-TOUCH 1

ITEM PART NUMBER TITLE QTY

53 PRT1152 PNEUMATIC VALVE, 3/2, 4mm BARB, BLACK PUSH BUTTON 2

54 PRT1387 PNEUMATIC VALVE, 5/3, G¼˝ PORTS 1

55 PRT1399 SILENCER, ¼˝ BSP 2

56 PRT1279 ADAPTOR ELBOW, ¼˝ BSPT MALE TO ⅜˝ 60° CONE 1

57 PRT1401 ¼˝ NIPPLE 1

58 PRT1157 BUSH, REDUCER, ⅛˝ BSPT TO M5 2

59 PRT1137 BARB ELBOW, M5 to 4mm 3

60 PRT1281 ELBOW, INPUT ADAPTOR 1

61 PRT1400 ¼˝ BSP MALE TO ¼˝ BSP FEMALE, STRAIGHT ADAPTOR 1

62 PRT1405 FIXING SUB PLATE 1

63 CPS_M3X40_SS CAPSCREW, SKT HD, M3x40LG, SS 3

64 PRT1381 MANIFOLD, PNEUMATIC 1

65 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

66 PRT1137 BARB ELBOW, M5 to 4mm 4

67 PRT1381 MANIFOLD, PNEUMATIC 1

68 PRT1137 BARB ELBOW, M5 to 4mm 1

69 PRT1384 BARB STRAIGHT, M5 TO 4mm 3

70 PRT1383 PLUG, M5 1

71 CPS_M3X12_SS CAPSCREW, SKT HD, M3x12LG, SS 4

72 PRT1415 TOP COVER PLATE 1

73 PRT1159 BULKHEAD ADAPTOR, ¼˝ BSPP FEMALE TO 4mm ONE-TOUCH 1

74 PRT1150 HANDLE 1

75 CPS_M8X12_SS CAPSCREW, SKT HD, M8x12LG, SS 2

76 PRT1370 FOOT, ANTI-VIBRATION 2

77 BHS_M8X12_SS BUTTONHEAD SCREW, SKT HD, M8x12LG, SS 2

78 PRT1398 SPACER 1

79 CPS_M4X12_SS CAPSCREW, SKT HD, M4x12LG, SS 2

80 PRT1158 SPACER 1

81 PRT1353 HOSE, 2-PLY STEEL BRAID, ⅜˝ 1

82 PRT1172 FERRULE, ⅜˝ 2

83 PRT1171 HOSE TAIL, BLOCK 90°, ⅜˝ 60° FEMALE CONE 1

84 PRT1174 HOSE TAIL, STRAIGHT, ⅜˝ 60° FEMALE CONE 1

85 PRT1407 HOSE TAIL, BLOCK 90°, ¼˝ 60° FEMALE CONE 1

86 PRT1408 FERRULE, ¼˝ 2

87 PRT1409 HOSE TAIL, STRAIGHT, ¼˝ 60° FEMALE CONE 1

88 PRT1406 HOSE, 2-PLY STEEL BRAID, ¼˝ 1

89 PRT1412 BLANKING PLUG 2

90 PRT1410 BRACKET, LIFTING EYE 1

91 CPS_M8X70_SS CAPSCREW, SKT HD, M8x70LG, SS 1

92 EYE_NUT_M8_SS NUT, LIFTING EYE, M8x1.25, SS 2

93 BHS_M8X16_SS BUTTONHEAD SCREW, SKT HD, M8x16LG, SS 1

94 PRT1371 FOOT, ANTI-VIBRATION 1

95 BHS_M8X12_SS BUTTONHEAD SCREW, SKT HD, M8x12LG, SS 1

96 WAS_FLAT_M8_SS WASHER, FLAT, M8, SS 1

97 CPS_M8X16_SS CAPSCREW, SKT HD, M8x16LG, SS 1

98 CPS_M5X10_SS CAPSCREW, SKT HD, M5x10LG, SS 6

99 WAS_DOWTY_1-4 WASHER, DOWTY, ¼˝ 4

100 PRT1175 HOSE TAIL, BANJO FITTING, ¼˝ 2

101 PRT1177 FERRULE, ¼˝ 2

102 PRT1293 HOSE, 1-PLY STEEL BRAID, ¼˝1

103 PRT1176 BOLT, BANJO, ¼˝ 2

3.2

www.hclfasteners.com

Maintenance - Parts List – SM-FT-3000-20ST

100

2

26

12

1

24

23

25

9

21

89

73

16

53

17

27

101 103 102 13 11 10 15 14 3 8 6 5 7 46 4

75 34 51 79 80 49 98 76 50 78 44 42 39 37 40 35 38 36 41 86 85 47 45 88

96

70

32

31

33

67

61

62

60

55

52 65 64 28 71 29

69

68

43

77

20

18

19

74

72 48 87 57 63

58

59

82

81

84

56

83

54

30 93 92 91 90 95

94

66

99

22

3.2

www.hclfasteners.com

Maintenance - Parts List – SM-FT-3000-32ST

ITEM PART NUMBER TITLE QTY

1 PRT1129 PLATE, LEFT 1

2 NRB_22_30_ 13 BEARING, NEEDLE ROLLER, 22IDx300Dx13LG (RNA_4903-2RS) 1

3 PRT1130 WASHER, THRUST 2

4PRT1352 WHEEL GRIPPING, 32mm SMART TIE 1

5PRT1132 PLATE, RIGHT 1

6NRB_22_30_ 13 BEARING, NEEDLE ROLLER, 22IDx300Dx13LG (RNA_4903-2RS) 1

7PRT1251 PIN, Ø6x60LG 2

8 PRT1141 PLATE, BAND DEFLECTION 1

9CPS_M6X60_SS CAPSCREW, SKT HD, M6x60LG, SS 2

10 PRT1396 PLATE, TORQUE REACTION 1

11 CPS_M6X25_SS CAPSCREW, SKT HD, M6x2SLG, SS 4

12 PRT1142 PLATE, BLADE SURROUND 1

13 PRT1295 FRONT END, CAST, 32mm, CHAMFERED SLOT 1

14 CPS_M4X25_SS CAPSCREW, SKT HD, M4x25LG, SS 4

15 PRT1048 BLADE, CUTTING, 32mm 1

16 PRT1049 SPRING, COMPRESSION 1

17 PRT1143 BASE PLATE, CUTTING CYLINDER 1

18 DUB_010_012_015 BEARING, DU, 10ID x120D x15LG 1

19 PRT1144 DEFLECTION PLATE, SHEET METAL 1

20 CPS_M5X8_SS CAPSCREW, SKT HD, M5x8LG, SS 4

21 PRT1179 BAND GUIDE, SHEETMETAL 1

22 CPS_M5X16_SS CAPSCREW, SKT HD, M5x16LG, SS 4

23 PRT1145 WAVE SPRING, CREST TO CREST 1

24 PRT1146 PISTON, CUTTING 1

25 ORG_10763X262_BS156_N70A O-RING, BS156, 107.63IDx2.62CS, NITRILE 70A 1

26 PRT1147 SHAFT, CUTTING PISTON 1

27 PRT1148 CYLINDER, CUTTING 1

28 CPS_M4X14_SS CAPSCREW, SKT HD, M4x14LG, SS 7

29 PRT1395 NUTRUNNER, MODEC 1

30 PRT1411 PLATE, REACTION CLAMP 1

31 CPS_M8X45_SS CAPSCREW, SKT HD, M8x45LG, SS 2

32 PRT1382 HYDRAULIC ADAPTOR, G¼˝ MALE TO G⅜˝ 60° CONE 1

33 PRT1397 ADAPTOR ELBOW, ¼˝ BSPT MALE TO ⅜˝ 60° CONE 1

34 PRT1430 SILENCER, FLOW CONTROLLER, G⅜˝ 1

35 PRT1403 LOWER COVER PLATE 1

36 PRT1134 PNEUMATIC VALVE, 3/2, NORMALLY-CLOSED. M5 PORTS 1

37 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

38 PRT1137 BARB ELBOW, M5 TO 4mm 1

39 PRT1135 SILENCER, M5 1

40 PRT1136 FLOW CONTROLLER, METER-IN, ELBOW, M5 TO 4mm ONE-

TOUCH 1

41 PRT1386 PNEUMATIC VALVE, 3/2, NORMALLY-OPEN, M5 PORTS 1

42 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

43 PRT1137 BARB ELBOW, M5 TO 4mm 1

44 PRT1135 SILENCER, M5 1

45 PRT1136 FLOW CONTROLLER, METER-IN. ELBOW , M5 to 4mm ONE-

TOUCH 1

46 PRT1386 PNEUMATIC VALVE. 3/2. NORMALLY-OPEN, M5 PORTS 1

47 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

48 PRT1137 BARB ELBOW , M5 to 4mm 1

49 PRT1135 SILENCER, M5 1

50 PRT1385 FLOW CONTROLLER, METER-OUT, ELBOW, M5 to 4mm ONE-

TOUCH 1

51 PRT1404 M2.5, STUDDING 2

52 NUT_NYLOC_HEX_M2-5_SS NUT, NYLOC, HEXAGON, M2-5, SS 4

ITEM PART NUMBER TITLE QTY

53 PRT1162 QUICK EXHAUST VALVE, 4mm TO 4mm ONE-TOUCH 1

54 PRT1152 PNEUMATIC VALVE, 3/2, 4mm BARB, BLACK PUSH BUTTON 2

55 PRT1387 PNEUMATIC VALVE, 5/3, G¼˝ PORTS 1

56 PRT1399 SILENCER, ¼˝ BSP 2

57 PRT1279 ADAPTOR ELBOW, ¼˝ BSPT MALE TO ⅜˝ 60° CONE 1

58 PRT1401 ¼˝ NIPPLE 1

59 PRT1157 BUSH, REDUCER, ⅛˝ BSPT TO M5 2

60 PRT1137 BARB ELBOW, M5 TO 4mm 3

61 PRT1281 ELBOW, INPUT ADAPTOR 1

62 PRT1400 ¼˝ BSP MALE TO ¼˝ BSP FEMALE, STRAIGHT ADAPTOR 1

63 PRT1405 FIXING SUB PLATE 1

64 CPS_M3X40_SS CAPSCREW, SKT HD, M3x40LG, SS 3

65 PRT1381 MANIFOLD, PNEUMATIC 1

66 PRT1384 BARB STRAIGHT, M5 TO 4mm 1

67 PRT1137 BARB ELBOW, M5 TO 4mm 4

68 PRT1381 MANIFOLD, PNEUMATIC 1

69 PRT1137 BARB ELBOW, M5 TO 4mm 1

70 PRT1384 BARB STRAIGHT, M5 TO 4mm 3

71 PRT1383 PLUG, M5 1

72 CPS_M3X12_SS CAPSCREW, SKT HD, M3x12LG, SS 4

73 PRT1402 TOP COVER PLATE 1

74 PRT1159 BULKHEAD ADAPTOR, ¼˝ BSPP FEMALE TO 4mm ONE-TOUCH 1

75 PRT1150 HANDLE 1

76 CPS_M8X12_SS CAPSCREW, SKT HD, M8x12LG, SS 2

77 PRT1370 FOOT, ANTI-VIBRATION 2

78 BHS_M8X12_SS BUTTONHEAD SCREW, SKT HD, M8x12LG, SS 2

79 PRT1398 SPACER 1

80 CPS_M4X12_SS CAPSCREW, SKT HD, M4x12LG, SS 2

81 PRT1158 SPACER 1

82 PRT1353 HOSE, 2-PLY STEEL BRAID, ⅜˝ 1

83 PRT1172 FERRULE, ⅜˝ 2

84 PRT1171 HOSE TAIL. BLOCK 90°, ⅜˝ 60° FEMALE CONE 1

85 PRT1174 HOSE TAIL. STRAIGHT, ⅜˝ 60° FEMALE CONE 1

86 PRT1407 HOSE TAIL, BLOCK 90°, ¼˝ 60° FEMALE CONE 1

87 PRT1408 FERRULE, ¼˝ 2

88 PRT1409 HOSE TAIL, STRAIGHT, ¼˝ 60° FEMALE CONE 1

89 PRT1406 HOSE, 2-PLY STEEL BRAID, ¼˝ 1

90 PRT1410 BRACKET, LIFTING EYE 1

91 CPS_M8X70_SS CAPSCREW, SKT HD, M8x70LG, SS 1

92 EYE_NUT_M8_SS NUT, LIFTING EYE, M8x1.25, SS 2

93 BHS_M8X16_SS BUTTONHEAD SCREW, SKT HD, M8x16LG, SS 1

94 PRT1371 FOOT, ANTI-VIBRATION 1

95 BHS_M8X12_SS BUTTONHEAD SCREW, SKT HD, M8x12LG, SS 1

96 WAS_FLAT_M8_SS WASHER, FLAT, M8, SS 1

97 CPS_M8X16_SS CAPSCREW, SKT HD, M8x16LG, SS 1

98 CPS_M5X10_SS CAPSCREW, SKT HD, M5x10LG, SS 7

99 PRT1412 BLANKING PLUG 2

100 WAS_DOWTY_1-4 WASHER, DOWTY, ¼˝ 4

101 PRT1175 HOSE TAIL, BANJO FITTING, ¼˝ 2

102 PRT1177 FERRULE, ¼˝ 2

103 PRT1178 HOSE, 1-PLY STEEL BRAID, ¼˝ 1

104 PRT1176 BOLT, BANJO, ¼˝ 2

3.2

www.hclfasteners.com

102

103

101

100

27

1

25

24

9

26

99

22

78

74

17

18

104 14 3 2 13 12 16 15 4 8 6 7 10 11 52

76 73 80 81 35 51 98 45 77 79 43 41 40 38 36 44 37 42 86 87 89 48 46 49

91

94

65

67

33

34

68

71

69

62

5 47 66 29 30 31

32

70

39

21

50

54

72

20

75

28 58 88 64 57 55

63

61

56

60

84

83

59

82

56

53

85

93 92 90 95 96 97

19

23

Maintenance - Parts List – SM-FT-3000-32ST

3.2

www.hclfasteners.com

Symptom 1: Smart®Band or Smart® Tie failure during tting

Failure Mode & Possible Cause Solution

1. Band/Buckle breaks due to incorrect input pressure Set correct input pressure (Refer to Section 2.3, Tensioning Table)

2. Buckle breaks due to incorrect tool positioning during tting Ensure tool is correctly positioned in buckle. Do not lift tool away from application during tightening

(Refer to Section 2.2, step 6)

3. Band breaks due to repeated relaxing and re-tightening Only tighten the band once

4. Band pulls out of xed end of buckle Ensure that latch is fully engaged with band before tensioning (Refer to Section 2.2,

step 2)

5. Buckle breaks due to being positioned in mid-air or around

too small a radius

Position Buckle on suitable radius (Refer to Banding Products Technical Booklet; Section 2.2 Technical

– Installation Design), or reduce pressure to an acceptable level

6. Band breaks due to being positioned around too small a

radius

Position Band on suitable radius (Refer to Banding Products Technical Booklet; Section 2.2 Technical

– Installation Design)

Symptom 2: Inadequate Smart®Band or Smart®Tie tension

Possible Cause Solution

1. Input pressure incorrect Check supply pressure. Set regulator to correct pressure.

2. Tool requires servicing Service tting tool (Refer to Section 3.1, Servicing)

3. Incorrect supply hose diameter Use supply hose of at least 10mm (3⁄8”) for 19mm version or 13mm (½”) for 32mm version

4. No lubrication in FRL unit Add appropriate lubricant or t lubricator unit

5. Regulator at limit of travel Insucient supply pressure. Increase

Symptom 3: Tool does not grip Smart®Band or Smart®Tie

Possible Cause Solution

1. Excess band tail from buckle too short Remove band and replace with a longer length

2. Gripping wheel teeth dirty or clogged Clean Gripping wheel teeth (Refer to Section 3.1, Servicing)

Symptom 4: Smart®Band or Smart®Tie does not feed through tool

Possible Cause Solution

1. Blockage in tool, e.g. band Remove Blade housing then clear blockage (Refer to Section 3.1, Servicing)

2. Blade stuck down Remove, clean and grease the Blade housing, Blade and Blade spring. Remove, clean and grease

Cutting Piston if required (Refer to Section 3.1, Servicing)

Symptom 5: Tool does not cut

Possible Cause Solution

1. Blockage in tool, e.g. band Remove Blade housing then clear blockage (Refer to Section 3.1, Servicing)

2. Blade worn or damaged Replace or re-sharpen blade (Refer to Section 3.1, Servicing)

3. Incorrect input pressure Set correct input pressure (Refer to Section 2.3, Tensioning Table)

4. Incorrect supply hose diameter Use supply hose of at least 10mm (3⁄8”) for 19mm version or 13mm (½”) for 32mm version

5. No lubrication in FRL unit Add appropriate lubricant or t lubricator unit

6. Regulator at limit of travel Insucient supply pressure. Increase

Maintenance - Troubleshooting

3.3

www.hclfasteners.com

Name of manufacturer: HCL Fasteners Ltd

Address of manufacturer: First Avenue, Westeld Industrial Estate, Radstock, Bath, BA3 4BS, UK

Telephone: +44 (0)1761 417714

Email: [email protected]

We hereby declare that the following machinery is in conformity with the Machinery Directive 2006/42/EC:

Machinery description: Banding Tool

Part No: SM-FT-3000-

Serial No: BFT-3000- -

Applied Harmonised Standards:

Ref. No. Title Edition

BS EN 12100 Safety of machinery. General principles for design. 2010

Risk assessment and risk reduction

BS EN ISO 4414 Pneumatic uid power. General rules and safety requirements 2010

for systems and their components

I hereby declare that the equipment named above has been designed to comply with the relevant sections of the above

referenced specications and is in accordance with the requirements of the Directive.

Signed by:

Name: David Coles

Position: Managing Director

Address: First Avenue, Westeld Industrial Estate, Radstock, Bath, BA3 4BS, UK

Date: 1st January 2015

The technical documentation for the machinery is available from the above address.

Year of

manufacture

Consecutive

number

20ST: Smart® Tie Tool 20mm (¾˝)

32ST: Smart® Tie Tool 32mm (1¼˝)

19: Smart® Band 19mm Hybrid & Compact (¾˝)

32: Smart® Band 32mm Hybrid & Compact (1¼˝)

Document reference

No. CE-1000

CE Marking - EC Declaration of Conformity

EC Declaration of Conformity

In accordance with EN ISO 17050-1-2004

4.1

Your attention is drawn to the following:

HCL warrants that a new HCL banding tool will operate per functional specications for a period of sixty (60) days

after the date of shipment to the owners place of business. Normal wearing parts, as outlined in the Operations,

Parts & Safety manual, are also covered by a sixty (60) day warranty unless, in HCL’s judgement, these parts have

been subjected to abnormal or extreme usage. HCL’s sole liability hereunder will be to repair or replace, without

charge, F.O.B. HCL, Bath UK, any tool which proves to not operate per functional specications within the stated

period. HCL reserves the right to replace any tool which proves not to operate per functional specications

with a new or like-new tool of the same model, if in HCL’s judgement such replacement is appropriate. Any new

replacement or like new replacement tool provided to an owner will carry a full sixty (60) day warranty. Any warranty

repaired tool will carry a warranty for the balance of time remaining on the initial sixty (60) day warranty. This

warranty will be extended to compensate for the time the tool is in HCL’s possession for warranty repairs.

This warranty is void as to any tool which has been:

a) subjected to mis-use, misapplication, accident damage, or repaired with other than genuine HCL

replacement parts.

b) improperly maintained, or adjusted, or damaged in transit or handling.

c) used with improperly ltered, regulated, unlubricated air.

d) in HCL’s opinion, altered in a way that affects or detracts from the performance of the tool.

HCL MAKES NO WARRANTY, EXPRESSED OR IMPLIED, RELATING TO MERCHANTABILITY, FITNESS OR

OTHERWISE EXCEPT AS STATED ABOVE AND HCL’S LIABILITY AS ASSUMED ABOVE IS IN LIEU OF ALL OTHERS

ARISING OUT OF OR IN CONNECTION WITH THE USE AND PERFORMANCE OF THE TOOL. IT IS EXPRESSLY

UNDERSTOOD THAT HCL SHALL IN NO EVENT BE LIABLE FOR ANY INDIRECT OR CONSEQUENTIAL DAMAGES

INCLUDING, BUT NOT LIMITED TO, DAMAGES WHICH MAY ARISE FROM LOSS OF ANTICIPATED PROFITS OR

PRODUCTION, SPOILAGE OF MATERIALS, INCREASED COSTS OF OPERATION OR OTHERWISE.

Considerable effort has been made to ensure that this product conforms to our high quality standards. However, should you

experience any diculties, please contact your Sales representative providing samples and the serial code specied on the tool.

HCL – UK & Rest of the World

Tel: +44 (0)1761 417714

Fax: +44 (0)1761 417710

Email: [email protected]

HCL – North America

Tel: 281-717-1145

Fax: 281-717-1146

Email: [email protected]

Visit www.hclfasteners.com to view our complete range of products.

November 2020

©HCL Fasteners. All Rights Reserved.

Table of contents

Other HCL Tools manuals

Popular Tools manuals by other brands

Raisbeck Engineering

Raisbeck Engineering BEECHCRAFT KING AIR C90 Pilot operating handbook

Dremel

Dremel 225 Attachment instructions

Parkside

Parkside PDMH 4500 A4 Operation and safety notes

Cleco

Cleco CellClutch CLBA Series instruction manual

Wedge Clamp Systems Inc.

Wedge Clamp Systems Inc. WS-1000 operating manual

Milwaukee

Milwaukee FUEL FTR Original instructions