HCL Smart Band SM-FT-1000 Instruction Manual

SM-FT-1000 Banding Tool

Operation, Parts & Safety Manual

Original Instructions

Tooling

Index

Health & Safety

1.1 Warning & Safety Instructions

Torque Wrenches

2.1 Options

Operation

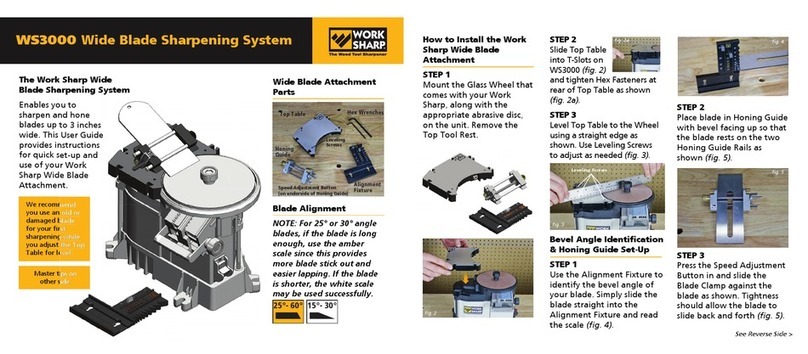

3.1 Using the Tool

3.2 Smart®Band Hybrid & Compact

Servicing

4.1 Servicing

4.2 Troubleshooting

4.3 Parts List

Depending on set up, this tool is designed to assemble the following HCL Smart®products:

– Smart® Tie 20mm (¾˝)

– Smart® Tie 32mm (1¼˝)

– Smart® Band 19mm (¾˝) Hybrid & Compact

– Smart® Band 32mm (1¼˝) Hybrid & Compact

Follow the instructions described to achieve safe operation.

Note: This tool is not suitable for Smart®Band Standard Systems

www.hclfasteners.com

www.hclfasteners.com

Read these instructions carefully:

Whilst Smart®Band and Smart®Tie are considered to be

signicantly safer than alternative metallic solutions, failure

to follow these instructions can still result in personal injury.

General safety considerations:

1. STRAP BREAKAGE HAZARD

Smart®Band and Smart®Tie are free from sharp metallic edges however it is important to understand that improper

operation of the tool or sharp corners on the load can result in strap breakage during tensioning that could result in the

following:

– A sudden loss of balance causing you to fall

– Both tool and strap ying violently towards your face

Failure to place the strap properly around the load, an unstable or shifted load, could result in a sudden loss of strap tension

during tensioning. This could result in a sudden loss of balance causing you to fall.

Positioning yourself in-line with the strap during tensioning, can result in personal injury from ying strap or tool. When

tensioning, position yourself to one side of the strap and keep all bystanders away.

2. TRAINING

This tool must not be used by persons not properly trained in its use. Be certain that you receive proper training from your

employer. If you have any questions contact your HCL representative.

3. EYE INJURY HAZARD

Failure to wear safety glasses with side shields can result in eye injury or blindness. Always wear safety glasses

with side shields which conform to ANSI Standard Z87.1 or EN 166.

4. CUT HAZARD

Although the Smart®Band and Smart® Tie are not metallic and therefore signicantly less likely to cause cuts to

hands or ngers, it is still strongly recommended that the operator wear protective gloves.

5. FALL HAZARD

Maintaining improper footing and/or balance when operating the tool can cause you to fall. Do not use the tool when you

are in an awkward position.

6. TOOL CARE (for further information see Servicing section)

– Inspect and clean the tool daily. Replace all worn or broken parts.

– Lubricate all moving parts approximately every 50 hours of use.

– If used in sea water, wash off immediately with fresh water after use. Dry and lubricate.

Health & Safety - Warning & Safety Instructions

1.1

www.hclfasteners.com

Torque Wrenches - Options

Mountz – FGC-10A (Factory set to speciced torque – Suitable for Marine use).

For use with: Material

Smart®Tie 20mm (¾˝)

PA66 (Nylon 6.6)

PA12 (Nylon 12)

PK

PPS

Smart®Tie 32mm (1¼˝)

PA12 (Nylon 12)

PPS

Smart®Band Hybrid 19mm (¾˝)

Smart®Band Compact 19mm (¾˝)

PA66 (Nylon 6.6)

PA12 (Nylon 12)

PPS

POM (Acetal)

Mountz – FGC-30A (Factory set to speciced torque – Suitable for Marine use).

For use with: Material

Smart®Tie 32mm (1¼˝)PK

Smart®Band Hybrid 32mm (1¼˝)

Smart®Band Compact 32mm (1¼˝)

PA66 (Nylon 6.6)

PA12 (Nylon 12)

PPS

Norbar – TTi20 (Variable torque setting – Not advised for Marine use).

For use with: Material

All product types

PA66 (Nylon 6.6)

PA12 (Nylon 12)

PK

PPS

POM (Acetal)

2.1

www.hclfasteners.com

5

Attach Torque wrench to the square drive at

the rear of the tool.

Optional – Lock Torque wrench to square drive

using a 4mm hexagon key

3

Wrap band around the application...

...and insert band into other end of buckle

4

Pull band tight by hand, making sure teeth are

fully engaged with band

Operation - Using the Tool with Mountz Torque Wrench

1

Insert band fully into xed end of the buckle

2

Pull back band to engage latch teeth and push

down rmly on the latch using the thumb or

nger to ensure full engagement

WARNING – Ensure latch is fully engaged

with band before tightening. Latch not fully

engaged could lead to premature failure of

system when tightening

TEETH ENGAGED

NOTE – Steps 1 & 2 are not applicable to

Smart®Tie

3.1

www.hclfasteners.com

9

Is the yellow marker in the ‘70mm’ position

(tool has run out of movement)?

8

Tighten the band using a winding movement...

...until the Torque wrench ‘CLICKS’

6

Is yellow marker in the ‘0mm’ position?

7

Insert tool onto band...

...and push tool up against buckle

NOTE – The Mountz torque wrench is factory

set to the correct torque requirement for the

specied product being used. The set torque is

marked on the wrench.

The torque wrench does not have a ratchet

facility and will wind clockwise until the set

torque is reached. At this point it will slip over

with a positive click.

NO

YES

CLICK!

Operation - Using the Tool with Mountz Torque Wrench

IMPORTANT – If Mountz type torque wrench is

being utilised follow steps 6-9 followed by 18-20

NO

Go to 6.1

on next

page

YES

Go to 8.1

on next

page

3.1

www.hclfasteners.com

8.2

...until the yellow marker is at the

‘0mm’ position...

8.1

...wind Torque wrench anti-clockwise...

6.1

...wind Torque wrench anti-clockwise...

6.2

...until the yellow marker is at the

‘0mm’ position...

NOTE – In the aniti-clockwise direction, the

torque wrench will click over if enough

resistance is met. This could be experienced if

the tool is forced when reaching the end of its

travel at the ‘0mm’ position.

Go to 7

on previous

page

Go to 8

on previous

page

3.1

www.hclfasteners.com

3.1

www.hclfasteners.com

12

Set Torque Wrench to the required Torque

Refer to the tensioning tables in the

torque setting section for the maximum

recommended torque. See

torque wrench manual for

detailed operating instructions.

For reference the maximum

torque settings for each

material are labelled on the tool

and torque wrench.

13

Attach Torque wrench to the square drive at

the rear of the tool.

Optional – Lock Torque wrench to square drive

using a 4mm hexagon key

10

Wrap band around the application...

...and insert band into other end of buckle

11

Pull band tight by hand, making sure teeth are

fully engaged with band

WARNING – Do not exceed the maximum torque

settings recommended for the Smart®Tie or

Smart®Band system being applied

Operation - Using the Tool with Norbar Torque Wrench

3.1

IMPORTANT – If Norbar type torque wrench is

being utilised follow steps 10-20 and refer to the

torque setting section.

www.hclfasteners.com

17

Is the yellow marker in the ‘70mm’ position

(tool has run out of movement)?

16

Tighten the band using a ratcheting

movement...

...until the Torque wrench ‘CLICKS’

14

Is yellow marker in the ‘0mm’ position?

15

Insert tool onto band...

...and push tool up against buckle

WARNING – Do not wind the Torque wrench

using a smooth continuous movement or

beyond the click point

NO

YES

CLICK!

Operation - Using the Tool with Norbar Torque Wrench

3.1

NO

Go to 14.1

on next

page

YES

Go to 17.1

on next

page

www.hclfasteners.com

17.2

...until the yellow marker is at the

‘0mm’ position...

17.1

...wind Torque wrench anti-clockwise...

14.1

...wind Torque wrench anti-clockwise...

14.2

...until the yellow marker is at the

‘0mm’ position...

3.1

Go to 14

on previous

page

Go to 16

on previous

page

www.hclfasteners.com

19

To remove the excess band, simply take hold

of the cutting handle...

...and push upwards

20

Once cut, remove tool from buckle

Installation is now complete

18

Continue anti-clockwise rotation until the

yellow marker is in the ‘0mm’ position. At this

point the cutting clasp will release the cutting

handle.

Operation - Using the Tool

3.1

www.hclfasteners.com

Nm

kg-m lb-ft

x 1.36x 9.802

x 0.738x 0.102

x 7.23

x 0.138

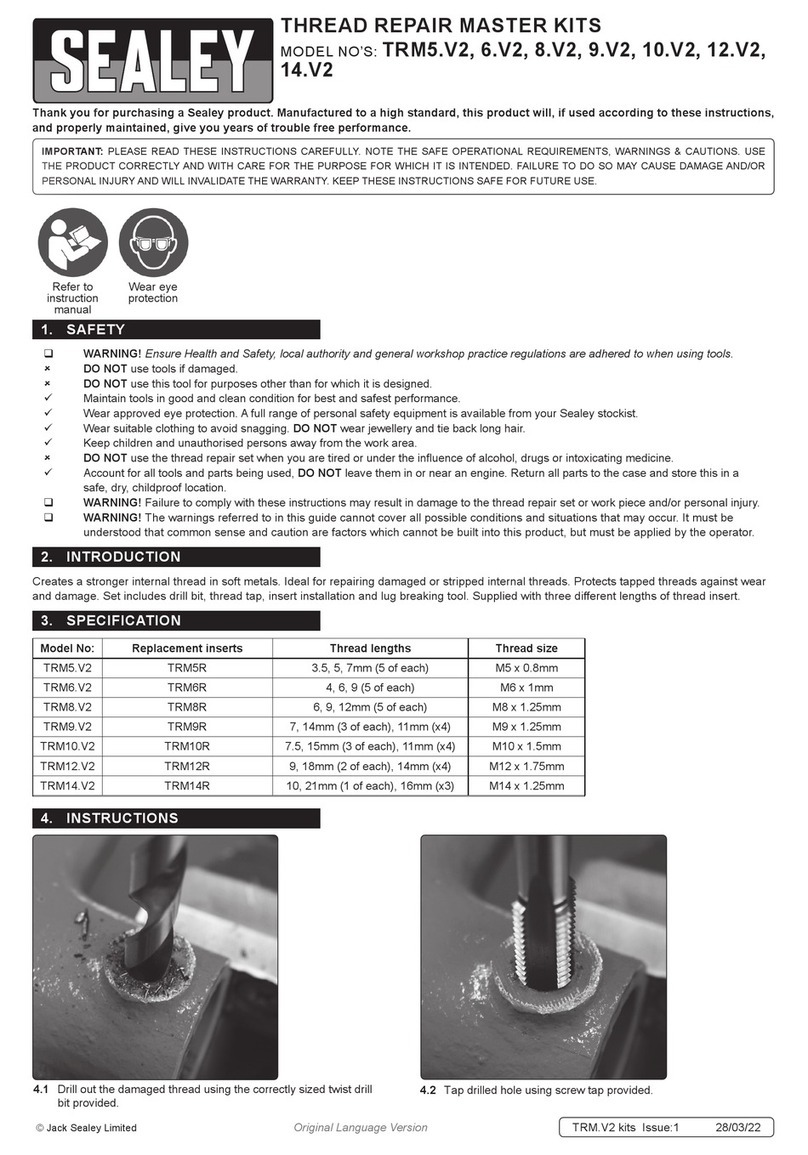

Recommended Torque Settings

*IMPORTANT – From July 2019 a new low torque drive system has been incorporated into the tool giving lower torque

settings than previous tools*

Smart®Tie Diameter Max Input Torque1Max System Force

(During Tightening)

Min Retention Force

(After Tightening)

Size Material mm Nm lb-ft N kgf lbf N kgf lbf

20mm (¾˝)

PA66 (Nylon 6.6)

100

5.5 4.1 3600 367 809 1500 153 337

PA12 (Nylon 12) 4 3.0 3000 306 674 1100 112 247

PK 5 3.7 3600 367 809 1500 153 337

PPS 5 3.7 3400 347 764 1500 153 337

32mm (1¼˝)

PA66 (Nylon 6.6)

200

TBC TBC TBC TBC TBC TBC TBC TBC

PA12 (Nylon 12) 8 6.0 6000 612 1349 2500 255 562

PK 11 8.1 7000 714 1574 4000 408 899

PPS 8 6.0 5500 561 1236 2000 204 450

Smart®Band Hybrid & Smart®Band Compact Diameter Max Input

Torque1

Max System Force

(During Tightening)

Min Retention Force

(After Tightening)

Size Buckle Material Band Material mm Nm lb-ft N kgf lbf N kgf lbf

19mm (¾˝)

PA66 (Nylon 6.6.) PA66 (Nylon 6.6.)

600

7 5.2 6000 612 1349 2500 255 562

PA12GF (Nylon 12 Glass-lled) PA12GF (Nylon 12 Glass-lled) 8 5.9 7000 714 1574 3500 357 787

PPS PPS 8 5.9 7000 714 1574 3500 357 787

POM (Acetal) POM (Acetal) 7 5.2 6000 612 1349 2500 255 562

32mm (1¼˝)

PA66 (Nylon 6.6.) PA66 (Nylon 6.6.) 14 10.3 14000 1428 3147 7000 714 1574

PA12GF (Nylon 12 Glass-lled) PA12GF (Nylon 12 Glass-lled) 14 10.3 14000 1428 3147 7000 714 1574

PPS PPS 14 10.3 12000 1224 2698 7000 714 1574

POM (Acetal) POM (Acetal) 10 7..4 10000 1020 2248 5000 510 1124

1The input torque in the table above is the maximum recommended torque around a cylindrical application. This may need to be reduced depending on the following:

- An irregular shaped application, e.g. an application that has sharp corners around its prole

- An application in high ambient temperatures and direct sunlight, where the temperature of the Smart®Band or Smart®Tie exceeds 40°C

- An application where the Smart®Band buckle is suspended in mid-air, i.e the buckle is not supported underneath

WARNING – The SM-FT-1000 tool range is not suitable for Smart® Band Standard systems. Do not exceed

the maximum torque settings recommended for the Smart®Tie or Smart®Band system being applied

Torque

Conversion

Triangle

Torque Setting - Smart® Band Hybrid & Compact

Note – This section is only required if the Norbar torque wrench is being utilised.

3.2

www.hclfasteners.com

5

Wind the square drive anti-clockwise to

remove threaded shaft from internal housing.

Thoroughly clean all parts.

Apply a general grease suitable

for water contact to male and female threads

as shown

6

Remove M4 Capscrews and Full nuts

(4x each) from split housing. Thoroughly clean

all parts

1

Wind the square drive clockwise until yellow

marker is in the ‘70mm’ position

2

Tap square drive on rear of tool to ensure rear

housing is as far forward as possible (this will

aid the removal of the bolts)

3

Remove M8 Buttonhead screws (4x) using

5mm hexagon key

4

Remove internal sub-assembly

YELLOW MARKER IN

‘70mm’ POSITION

SQUARE DRIVE

Servicing

NOTE – It is advised that a full service is carried

out after every 1000 straps or every year, which

ever is soonest

4.1

www.hclfasteners.com

7

Apply a general grease suitable for water

contact to thrust washers and split housing as

shown

8

Change the Pawl and Blade by rstly removing

the Pin from the Pawl housing

NOTE – Take care to note the orientation of the

spring for reinsertion

9

Remove the Pawl assembly and spring

10

Reassemble Pawl Housing as reverse of

disassembly

Servicing

4.1

www.hclfasteners.com

14

Reassemble tool as reverse of disassembly

12

Ensure cutting handle is in the down position.

Remove Capscrews (4x) using 3mm hexagon

key and remove old front plate

13

Remove existing blade and insert spring into

new blade. Grease Cam and Blade as shown

WARNING – Care must be taken when handling

the sharp blade to avoid injury

15

If the tool has been used subsea it is advised

that it is immediately washed thoroughly by

immersing in clean fresh water. A full service is

advised in this situation. However, if this is not

possible the main thread can be lubricated via

the grease nipple located on the main shaft at

the rear of the tool

11

To take off the cutting blade housing, remove

M6 Capscrew and slide front assembly off

main body. Thoroughly clean all parts

NOTE – Never store the tool wet

Servicing

4.1

www.hclfasteners.com

Symptom 1: Smart®Band or Smart® Tie failure during tting

Failure Mode & Possible Cause Solution

1. System breaks due to cutting whilst in tension

(yellow marker not in ‘0mm’ position)

Do not operate cutter during tightening (Refer to Section 2.1, steps 12-14)

2. Band/Buckle breaks due to incorrect input torque Set correct input torque (Refer to Section 2.2, Tensioning Tables)

3. Buckle breaks due to incorrect tool positioning during tting Ensure tool is correctly positioned in buckle. Do not lift tool away from application during tightening

(Refer to Section 2.1, steps 8-9)

4. Band breaks due to repeated relaxing and re-tightening Only tighten the band once (Refer to Section 2.1, step 10)

5. Band pulls out of xed end of buckle Ensure that latch is fully engaged with band before tensioning (Refer to Section 2.1, step 2)

6. Buckle breaks due to being positioned in mid-air or around too

small a radius

Position Buckle on suitable radius (Refer to Banding Products Technical Booklet). Reduce the input

torque if re-positioning is not possible

7. Band breaks due to being positioned around too small a radius Position Buckle on suitable radius (Refer to Banding Products Technical Booklet). Reduce the input

torque if re-positioning is not possible

Symptom 2: Inadequate Smart®Band or Smart®Tie tension

Possible Cause Solution

1. Tool has hit rear stop (yellow marker in ‘70mm’ position) Wind square drive anti-clockwise until yellow marker is in ‘0mm’ position. Then continue

tightening the band (Refer to Section 2.1, step 11). Then continue tightening the band until the Torque

wrench ‘CLICKS’

2. Input torque incorrect Set Torque Wrench to correct torque (Refer to Section 2.2, Tensioning Tables)

3. Tool requires servicing Service tting tool (Refer to Section 4.1, steps 1-9)

4. Tool under performing (lack of tension) after subsea use Clean & lubricate tool (Refer to Section 4.1)

Symptom 3: Tool does not grip Smart®Band or Smart®Tie

Possible Cause Solution

1. Excess band tail too short Remove band and replace with a longer length

2. Pawl housing not fully forward (yellow marker not in

‘0mm’ position)

Wind square drive anti-clockwise until yellow marker is in ‘0mm’ position (Refer to Section 2.1, step 11)

3. Pawl teeth dirty or clogged Remove internal sub-assembly from tool and clean pawl teeth (Refer to Section 4.1, steps 1-4)

4. Incorrect pawl tted Remove pawl and replace with correct size for band (Refer to Section 3.1, steps 1-3)

5. Pawl stuck in position Remove internal sub-assembly from tool and un-stick pawl (Refer to Section 4.1, steps 1-4). Clean and

re-grease pawl and ensure free movement

Symptom 4: Smart®Band or Smart®Tie does not feed through tool

Possible Cause Solution

1. Blockage in tool, e.g. band Remove internal sub-assembly or front sub-assembly as required, then clear blockage (Refer to Section

4.1, steps 1-4)

2. Pawl stuck in position Remove internal sub-assembly from tool and un-stick pawl (Refer to Section 4.1, steps 1-4). Clean and

re-grease pawl and ensure free movement

3. Pawl Housing not fully forward (green marker not showing) Wind square drive anti-clockwise until yellow marker is in ‘0mm’ position (Refer to Section 2.1, step 11)

4. Blade stuck down Remove and clean blade. Front end may need to be removed. Be careful that blade does not spring out

(Refer to Section 3.2, steps 1-3)

5. Incorrect front end is tted Remove front end and replace with correct one (Refer to Section 3.2, steps 1-3)

Symptom 5: Tool does not cut or it is too dicult to cut

Possible Cause Solution

1. Blockage in tool, e.g. band Remove blade and/or front end as required, then clear blockage (Refer to Section 3.2, steps 1-3)

2. Cam not lubricated (blade may also make ‘screeching’ noise) Grease cam and blade (Refer to Section 4.1, step 9)

3. Blade worn or damaged Replace or re-sharpen blade (Refer to Section 3.2, steps 1-3)

4. Incorrect blade or front end is tted Remove blade and/or front end and replace with correct size for band (Refer to Section 3.2,

steps 1-3)

Servicing - Troubleshooting

4.2

www.hclfasteners.com

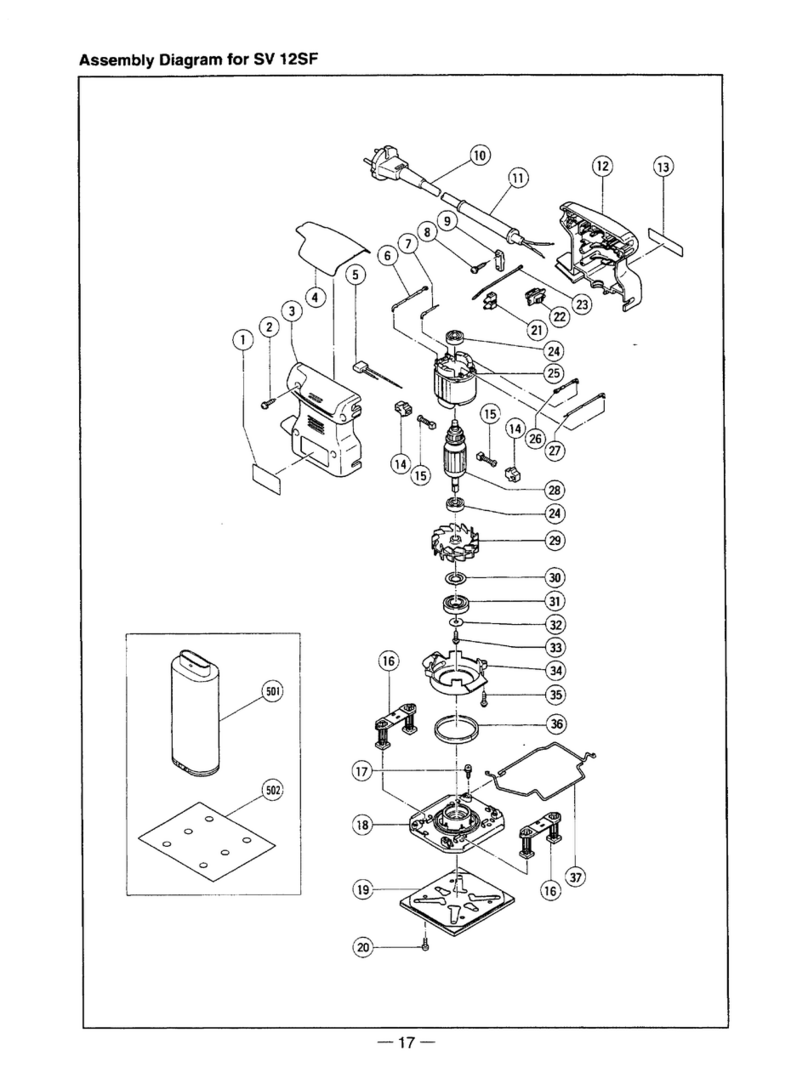

20

21

23

3

1

36

2517 26

12

16

15 13 4 18 19

14

22

11

29

30

27

32

28

37 5 8 9 7 10 6 2

31

35

33

34

24

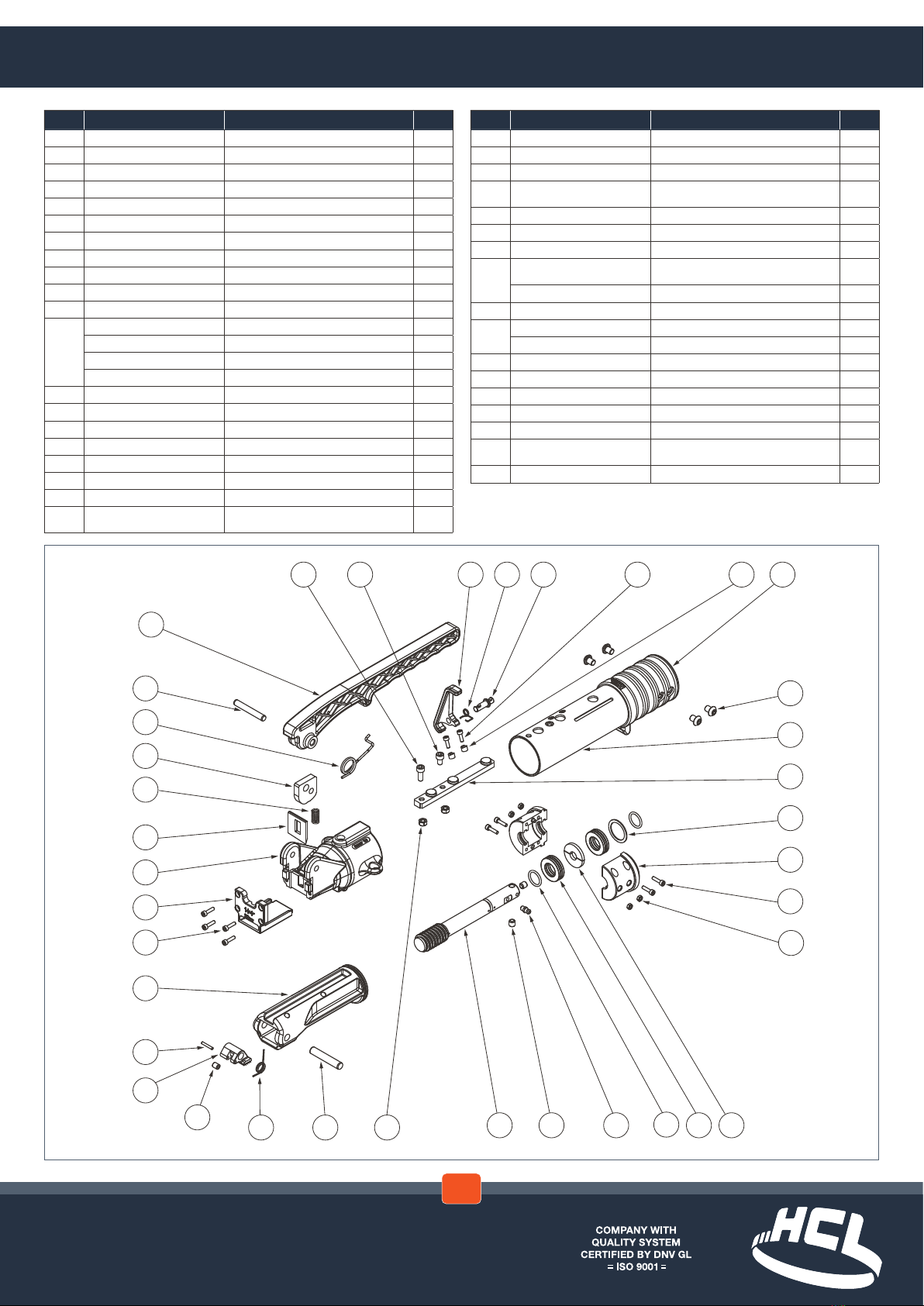

ITEM PART NUMBER DESCRIPTION QT Y.

1 PRT1002 HOUSING, MAIN BODY 1

2 PRT1003 GRIP, OVERMOULDED, FITTING TOOL 1

3 PRT1004 GUIDE 1

4 NUT_NYLOC_HEX_M6_SS NUT, NYLOC, HEXAGON, M6, SS 2

5 CPS_M6X10_SS CAPSCREW, SKT HD, M6x10LG, SS 1

6 PRT1341 SPACER, PIVOT PIN PROTOTYPE 2

7 PRT1340 PIN, PIVOT 1

8 PRT1339 CLASP, CUT PREVENTION 1

9 PRT1342 SPRING, TORSION 1

10 CPS_M4X12_SS CAPSCREW, SKT HD, M4x12LG, SS 2

11 PRT1035 HOUSING, PAWL 1

12*

PRT1036 PAWL, 32mm 1

PRT1055 PAWL 19mm SMART BAND 1

PRT1297 PAWL 20mm SMART TIE 1

PRT1338 PAWL 32mm SMART TIE 1

13 PRT1037 PIN, Ø10x54LG 1

14 PRT1038 PIN, Ø3x20LG 1

15 PRT1039 SPRING, TORSION 1

16 PRT1502 BEARING 1

17 PRT1041 MAIN SHAFT, THREADED 1

18 THB_20_35_10_SS BEARING, THRUST, BALL, 20IDx35ODx10LG 2

19 PRT1058 WASHER, FLAT, 12IDx35ODx4LG 2

20 WAS_WAVE_2670_3432_124 WASHER, WAVE SPRING,

26.70IDx34.32ODx1.24LG 1

ITEM PART NUMBER DESCRIPTION QT Y.

21 PRT1045 HOUSING, THRUST BEARING 2

22 NUT_HEX_M4_SS NUT, FULL, HEXAGON, M4, SS 4

23 CPS_M4X16_SS CAPSCREW, SKT HD, M4x16LG, SS 4

24 ORG_01872X262_BS116_N70A O-RING, BS116, 18.72IDx2.62CS, NITRILE 70A 2

25 SSS_M8X8_CUP_SS SKT SETSCREW, M8x8LG, CUP POINT, SS 2

26 GN_M6_STRAIGHT_SS GREASE NIPPLE, STRAIGHT, SS 1

27 PRT1046 HOUSING, CUTTING BLADE 1

28 PRT1295 FRONT END, CAST, 32mm, CHAMFERED SLOT 1

PRT1296 FRONT END, CAST, 19mm & 20mm 1

29 CPS_M4X16_SS CAPSCREW, SKT HD, M4x16LG, SS 4

30 PRT1048 BLADE, CUTTING, 32mm 1

PRT1057 BLADE, CUTTING 19mm & 20mm 1

31 PRT1049 SPRING, COMPRESSION 1

32 PRT1050 LEVER, CUTTING MECHANISM 1

33 PRT1051 CAM, ROLLER 1

34 PRT1052 PIN, Ø8x55LG 1

35 PRT1503 HANDLE RETURN SPRING 1

36 BHS_M8X10_SS BUTTONHEAD SCREW, SKT HD, M8x10LG, SS 4

37 CPS_M6X16_SS CAPSCREW, SKT HD, M6x16LG, SS 1

*Item 12 is either Smart® Tie 20mm (¾˝), Smart® Tie 32mm (1¼˝), Smart® Band 19mm (¾˝) or

Smart® Band 32mm (1¼˝) option.

Items 28 & 30 are either 19mm or 32mm options (20mm Smart® Tie tool uses 19mm option).

Servicing - Parts List

4.3

Considerable effort has been made to ensure that this product conforms to our high quality standards. However, should you

experience any diculties, please contact your Sales representative providing samples and the serial code specied on the tool.

Name of manufacturer: HCL Fasteners Ltd

Address of manufacturer: Clamping House, First Avenue, Westeld Industrial Estate, Radstock,

Bath BA3 4BS, UK

Telephone: +44 (0)1761 417714

Email: [email protected]

Machinery description: Banding tool for tensioning the HCL Smart® Tie 20mm (¾˝),

Smart® Tie 32mm (1¼˝), Smart® Band 19mm (¾˝) Hybrid & Compact or

Smart® Band 32mm (1¼˝) Hybrid & Compact Systems

Tool Size: Smart® Tie 20mm (¾˝)

Smart® Tie 32mm (1¼˝)

Smart® Band 19mm (¾˝) Hybrid & Compact

Smart® Band 32 mm (1¼˝) Hybrid & Compact

Serial No:

HCL – UK & Rest of the World

Tel: +44 (0)1761 417714

Fax: +44 (0)1761 417710

HCL – North America

Tel: +1 281-717-1145

Fax: +1 281-717-1146

Email: [email protected]

Visit www.hclfasteners.com to view our complete range of products.

March 2021

©HCL Fasteners. All Rights Reserved.

Other manuals for Smart Band SM-FT-1000

1

Table of contents

Other HCL Tools manuals