HCL Smart Band SM-FT-1000 Instruction Manual

TOOLING

©2009 HCL Fasteners

Operation, Parts and

Safety Manual

SM-FT-1000

Banding Tool

Suitable for Smart Band® 32mm (1¼”) 25mm (1”)

19mm (¾”) and Smart Tie™ 20mm (¾”)

READ ALL INSTRUCTIONS BEFORE OPERATING THIS

HCL PRODUCT

IMPORTANT – DO NOT DESTROY

It is the customer’s responsibility to have all operators

and servicemen read and understand this manual.

For additional copies please contact HCL.

Registered

NOVEMBER 2009

TOOLING

©2009 HCL Fasteners

Operation, Parts and

Safety Manual

1 Warning & Safety Instructions

2 Introduction

3 Operation

4 Tensioning Tables

5 Pressure Regulation

6 Maintenance

7 Adapting the Tool

8 Trouble Shooting

9 Parts List

NOVEMBER 2009

SM-FT-1000 Banding Tool

BANDING TOOLING

Warning Read these instructions carefully

Whilst the composite Smart Band® is considered significantly

safer than alternative metallic solutions, failure to follow these

instructions can still result in personal injury.

General safety considerations:

1. STRAP BREAKAGE HAZARD Smart Band® is free from sharp metallic edges however it is

important to understand that improper operation of the tool or

sharp corners on the load can result in strap breakage during

tensioning that could result in the following:

– A sudden loss of balance causing you to fall

– Both tool and strap flying violently towards your face

Failure to place the strap properly around the load, an unstable or

shifted load, could result in a sudden loss of strap tension during

tensioning. This could result in a sudden loss of balance causing

you to fall.

Positioning yourself in-line with the strap during tensioning, can

result in personal injury from flying strap or tool. When tensioning,

position yourself to one side of the strap and keep all bystanders

away.

2. TRAINING This tool must not be used by persons not properly trained

in its use. Be certain that you receive proper training from

your employer. If you have any questions contact your HCL

representative.

3. EYE INJURY HAZARD Failure to wear safety glasses with side shields can result in eye

injury or blindness. Always wear safety glasses with side shields

which conform to ANSI Standard Z87.1 or EN 166.

4. FALL HAZARD Maintaining improper footing and/or balance when operating the

tool can cause you to fall. Do not use the tool when you are in an

awkward position.

5. CUT HAZARD Although the Smart Band® is not metallic and therefore

significantly less likely to cause cuts to hands or fingers it is still

strongly recommended that the operator wear protective gloves.

6. NOISE HAZARD When using the pneumatic option, ear protection is

recommended.

7. TOOL CARE – Inspect and clean the tool daily. Replace all worn or broken

parts

– Lubricate all moving parts approximately every 50 hours of use

– On air powered tools always disconnect the pneumatic

connection to the tool when performing part removal and

replacement procedures. NEVER connect a pneumatic source to

a disassembled tool unless otherwise specified

– If used in sea water, wash off with fresh water after use.

8. WORK AREA Keep work areas uncluttered and well lit.

(for further information

see maintenance section)

SECTION 1

BANDING TOOLING

Introduction

SM-FT-1000 Banding Tool

Depending on set up, this power tool is designed

to assemble HCL Smart Band® 32mm (1¼”),

25mm (1”), 19mm (¾”) or Smart Tie™ 20mm (¾”)

Systems.

Follow the instructions described to achieve safe

operation.

SM-FT-1000 Banding Tool

WATERPROOF CASE

MAIN FITTING TOOL

REGULATOR

5M HOSE

WINDING HANDLE

TORQUE WRENCH

AIR RATCHET

W2300 / W2301

AIR RATCHET W2303

MANUAL CUTTER

SECTION 2

BANDING TOOLING

SM-FT-1000 Banding Tool

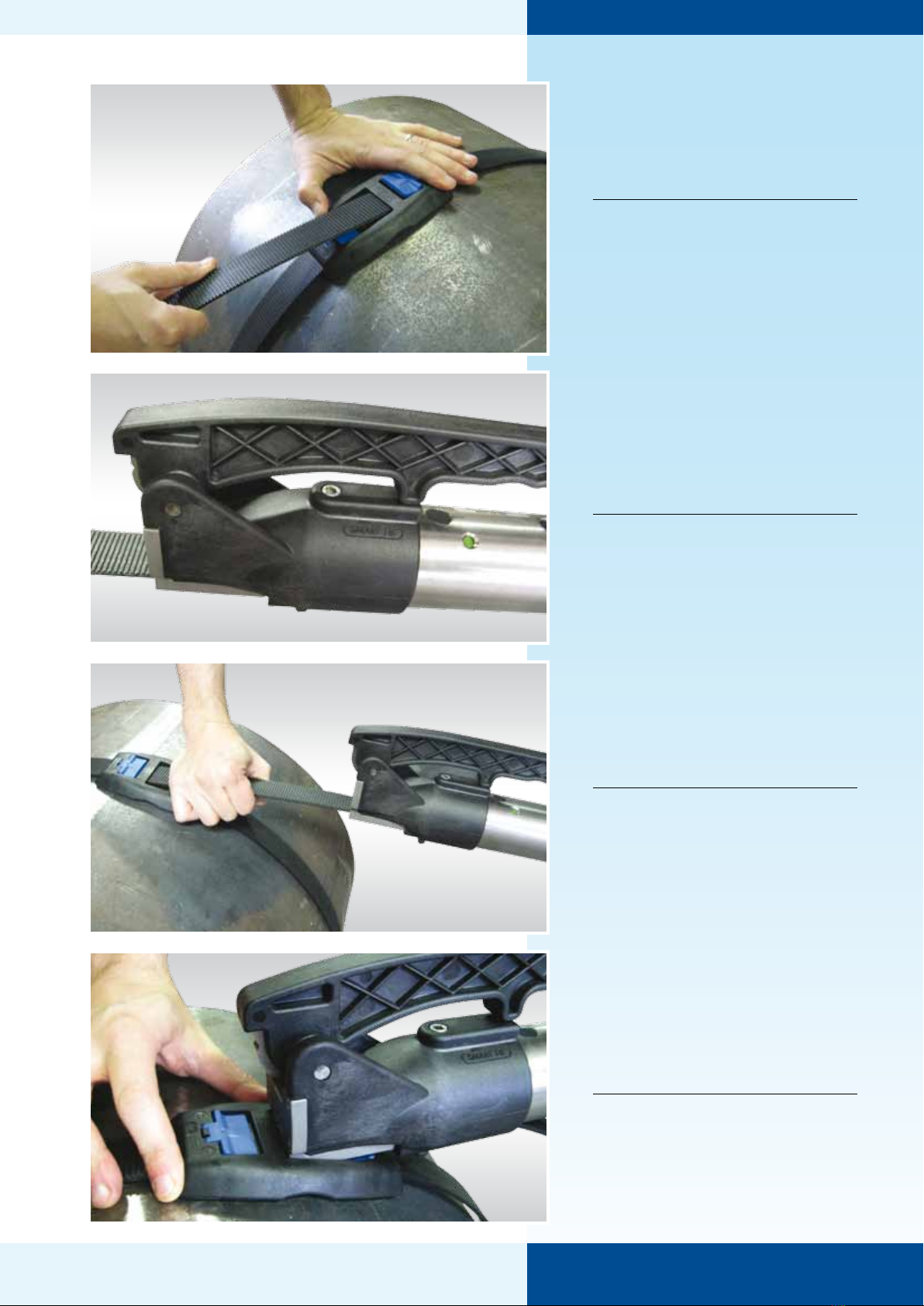

1

Insert band into fixed end of

the buckle

3

Wrap band around the

application

4

Insert band into other end of

buckle

Operation

Initial fitting and tightening

2

Pull back band to engage latch

WARNING – Ensure latch is

fully engaged with band before

tightening. Latch not fully engaged

could lead to premature failure of

system when tightening

TEETH ENGAGED

SECTION 3

BANDING TOOLING

SM-FT-1000 Banding Tool

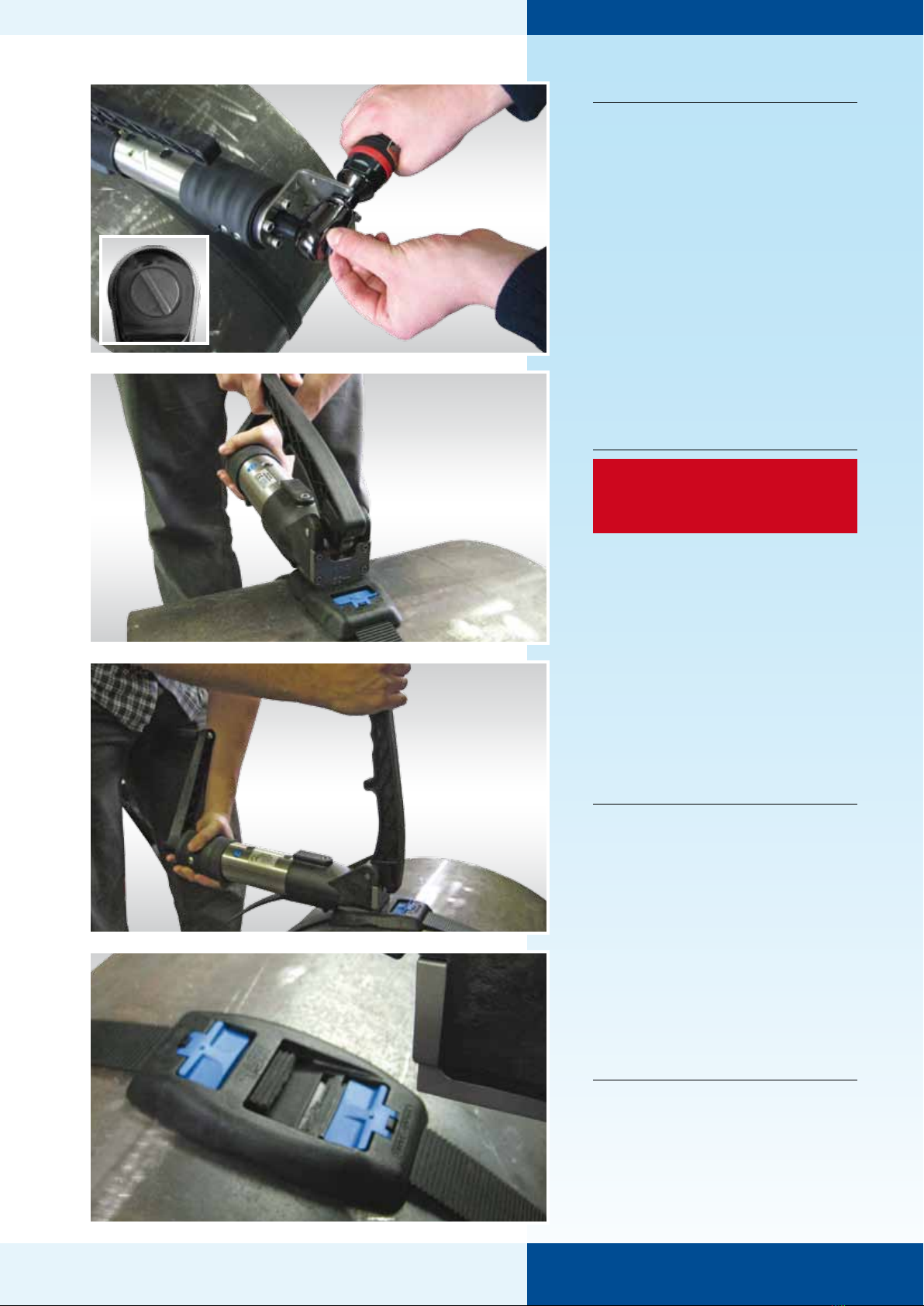

5

Pull band tight by hand, making

sure teeth are fully engaged

with band

6

Ensure that green marker is

showing

7

Insert tool onto band

8

Push tool up against buckle

SECTION 3

BANDING TOOLING

11

To gain high accuracy in tension

fit using torque wrench. Refer to

the tensioning tables to set the

correct torque

See torque wrench manual for

detailed operating instructions

NOTE – Torque wrench can be

used without handle using the

socket provided

12

For pneumatic tightening

attach air ratchet to the square

drive at the rear of the tool

and locate in torque reaction

bracket

See air ratchet manual for

detailed operating instructions

SM-FT-1000 Banding Tool

10

Wind handle clockwise until

band is tight. If red marker is

showing, wind handle anti-

clockwise until green, then

continue to tighten the band

GREEN MARKER -

Indicates tool is at

the start of its travel

RED MARKER –

Indicates tool is at the

end of its travel

SECTION 3

9

For manual tightening attach

handle to the square drive at

the rear of the tool

WARNING – Ensure tool does not

lift away from application

during tightening

WARNING – Do not operate the

Cutter during tightening

(see step 14)

....

BANDING TOOLING

13

Refer to Section 4 Tensioning Tables to

set the correct pressure.

Hold down trigger on air ratchet. The

tool will stall when the system reaches

the correct tension. If red marker is

showing, simply reverse direction of

tool by turning knob on back of air

ratchet head (see inset). Wind tool back

until green, reverse direction again and

continue to tighten.

If required, further calibration can be

achieved with a torque wrench see

photo 11

14

WARNING – Ensure that the green

marker is showing before cutting

the band.

To remove the excess band,

simply take hold of the cutting

handle...

15

...and push upwards

16

Once cut remove tool from

buckle – Installed system

SM-FT-1000 Banding Tool

SECTION 3

BANDING TOOLING

SM-FT-1000 Banding Tool

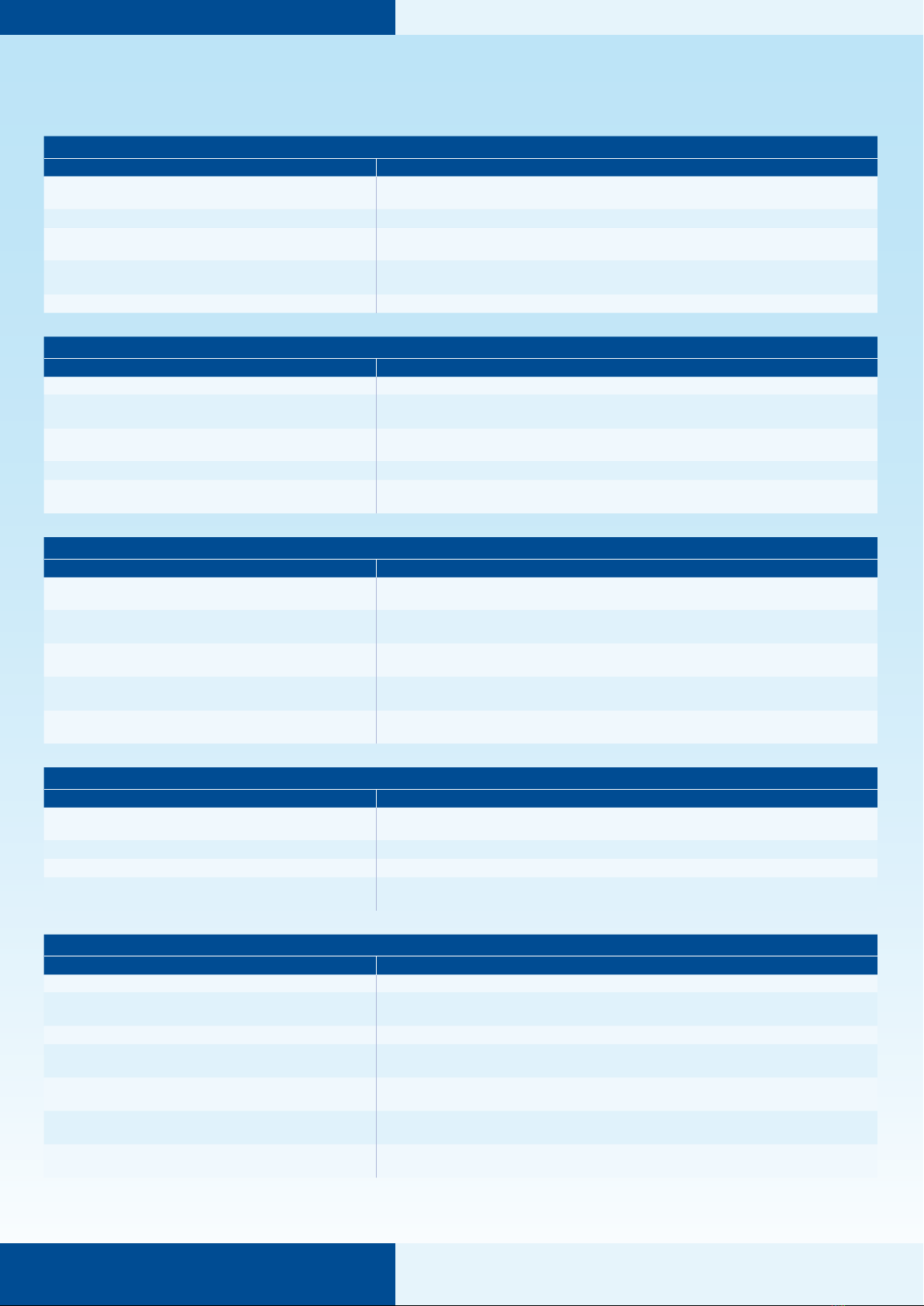

Tensioning Tables

WARNING – Do not exceed the maximum pressure or torque settings recommended for the

Smart Tie™ or Smart Band® system being applied

Pressure Conversion Triangle

MPa

(N/mm2)

Psi

(lb/in2)Bar

x 0.1x 0.006895

x 10x 145.03

x 0.06895

x 14.503

Recommended setting for each system

Smart Tie™

System Width Maximum Recommended Input 1System Force 2

(mm) / (inch)

Torque Wrench 3Air Ratchet

W2303

Air Ratchet

W2300 / W2301

Max. during

Fitting

Min. Final

Retention

Torque (Nm) Pressure (MPa) Pressure (MPa) (N) (N)

PP (Polyproylene) 20 / ¾– 0.3 – 1500 700

PA66 (Nylon 66) 20 / ¾– TBC – TBC TBC

PA11 (Nylon 11) 20 / ¾– 0.3 – 2600 1700

POM (Acetal) 20 / ¾– 0.35 – 3400 1800

Smart Band® System Width Maximum Recommended Input 1System Force 2

Head Material Band Material (mm) / (inch)

Torque Wrench 3

13042

Air Ratchet

W2303

Air Ratchet

W2300 / W2301

Max. during

Fitting

Min. Final

Retention

Torque (Nm) Pressure (MPa) Pressure (MPa) (N) (N)

Standard Buckle – see photo above

PA66 (Nylon 66) POM (Acetal) 25 / 1 8 0.33 – 5600 2000

Hybrid Buckle – see photo above

PA11GF

(Nylon 11 Glass Filled)

PA11GF

(Nylon 11 Glass Filled) 19 / ¾13 0.45 – 8200 3400

POM (Acetal) POM (Acetal) 19 / ¾11 0.40 – 7100 3000

PA66 (Nylon 66) PA66 (Nylon 66) 19 / ¾14 0.50 – 8600 3700

PA11GF

(Nylon 11 Glass Filled)

PA11GF

(Nylon 11 Glass Filled) 25 / 1 14 0.45 – 9200 4500

PA11 (Nylon 11) PA11 (Nylon 11) 25 / 1 12 0.40 – 7100 4000

PA11GF

(Nylon 11 Glass Filled)

PA11GF

(Nylon 11 Glass Filled) 32 / 1¼30 – 0.45 17500 8000

POM (Acetal) POM (Acetal) 32 / 1¼22 – 0.35 13500 5000

1] IMPORTANT – Tightening force may need to be reduced depending upon application and environment

2] The larger the diameter, the closer the final retention will be to the maximum tension induced upon fitting

3] Using the torque wrench increases the repeatability accuracy

Standard Buckle

Hybrid Buckle

SECTION 4

BANDING TOOLING

SM-FT-1000 Banding Tool

Pressure

Regulation

1 Pressure Regulator Gauge

2 Air Filter – 3/8” BSP female

input

3 Pressure Regulator Knob

4 Air Lubricator

5 Lubrication Dial

6 Lubrication Fill-point

7 Lockable Shut-Off Valve

8 5m hose

4

5 6 7

8

3 Pressure Regulator

To set required pressure, pull down Pressure

regulator knob until orange band appears,

then twist until dial shows required pressure,

finally, click knob back up until orange band

disappears.

7 Lockable Shut-Off Valve

Set Lockable shut-off valve to ‘SUP.’ to supply

air to the tool. To shut-off the air supply to the

tool and dump the excess pressure in the hose

to atmosphere, set Lockable shut-off valve to

‘EXH.’ (this enables safe removal of the hose).

Air Lubricator

To fill lubricator, remove black cap

using 5mm Allen key and fill to

between the maximum and minimum

oil levels. See air ratchet manual for

suitable oils. Ensure lubricator dial is

set to ‘2’ at all times.

5 6

IMPORTANT – Input pressure should be greater than

0.6 MPa but less than 1.0 MPa

– Input hose size should be ½” and above

SECTION 5

1

23

Ensure Pressure Dial

on Ratchet Wrench

is set to ‘HI’ at all

times

Maintenance

SM-FT-1000 Banding Tool

BANDING TOOLING

1 Wind the square drive clockwise until red marker is

showing

2 Tap square drive on rear of tool to ensure rear housing is

as far forward as possible. This will aid the removal of the

bolts

3 Remove M8 Buttonhead screws (4x) using 5mm Allen key

RED MARKER

TOOL BACK

For maintenance of air ratchets please

see manufacturers manual

SECTION 6

4 Remove internal sub-assembly

5 Wind the square drive anti-clockwise to remove threaded

shaft from internal housing. Thoroughly clean all parts.

Apply Silicone grease to male and female threads as

shown

6 Remove M4 Capscrews and Full nuts (4x each) from split

housing. Thoroughly clean all parts

7 Apply Silicone grease to thrust washers and split housing

as shown

8 Remove M6 Capscrew and slide front assembly off main

body. Thoroughly clean all parts

9 Grease Cam and blade as shown

BANDING TOOLING

SM-FT-1000 Banding Tool

Adapting

the Tool

Every fitting tool can be adapted to fit

the following sizes of Smart Band:

32mm (1¼”), 25mm (1”) & 19mm (¾”)

Example of a 19mm (¾”)

Adaptation Kit

SECTION 7

Changing the Pawl

5 Remove pin from housing

6 Remove old pawl and insert new pawl

7 Re-fit pin. Reassemble tool as reverse of disassembly

Changing the Front Plate & Blade

1 Ensure cutting handle is in the down position. Remove

Capscrews (4x) using 3mm Allen Key and remove old front

plate

2 Remove existing blade and insert spring into new blade

3 Reassemble tool as reverse of disassembly

1-4 Repeat steps 1-4 in Section 6, Maintenance

NOTE – Take care to reinsert spring in correct

orientation.

SM-FT-1000 Banding Tool

BANDING TOOLING SECTION 8

Trouble Shooting

Symptom 1: Inadequate Band Tension

Possible Cause Solution

1. Tool has hit rear stop (red marker showing) Wind square drive anti-clockwise until green marker is showing. Then continue tightening the

band (Refer to Section 3, Operation; steps 10 & 13)

2. Input torque incorrect (Hand tool) Set Torque Wrench to correct torque (Refer to Section 4, Tensioning Tables)

3. Input pressure incorrect (Air tool) Check supply pressure. Set regulator to correct pressure. Set Air Ratchet to ‘HI’ (Refer to Section 4,

Tensioning Tables and Section 5, Pressure Regulation)

4. Torque reaction bracket incorrect or not in use Fit torque reaction bracket to rear of fitting tool. Ensure that air ratchet fits tightly into bracket

(Refer to Section 3, Operation; steps 12 & 13)

5. Tool requires servicing Service fitting tool (Refer to Section 6, Maintenance)

Symptom 2: Tool does not grip Band

Possible Cause Solution

1. Excess band tail too short Remove band and replace with a longer length

2. Pawl housing not fully forward (green marker not showing) Wind square drive anti-clockwise until green marker is showing. Then continue tightening the

band (Refer to Section 3, Operation; steps 10 & 13)

3. Pawl teeth dirty or clogged Remove internal sub-assembly from tool and clean pawl teeth (Refer to Section 6, Maintenance;

steps 1-4)

4. Incorrect pawl fitted Remove pawl and replace with correct size for band (Refer to Section 7, Adapting the Tool)

5. Pawl stuck in position Remove internal sub-assembly from tool and un-stick pawl (Refer to Section 6, Maintenance;

steps 1-4)

Symptom 3: Band does not feed through Tool

Possible Cause Solution

1. Blockage in tool, e.g. band Remove internal sub-assembly or front sub-assembly as required, then clear blockage (Refer to

Section 6, Maintenance, steps 1-4 & 8)

2. Pawl stuck in position Remove internal sub-assembly from tool and un-stick pawl (Refer to Section 6, Maintenance;

steps 1-4)

3. Pawl Housing not fully forward (green marker not showing) Wind square drive anti-clockwise until green marker is showing (Refer to Section 3, Operation;

steps 10 & 13)

4. Blade stuck down Remove and clean blade. Front end may need to be removed. Be careful that blade does not

spring out (Refer to Section 7, Adapting the Tool)

5. Incorrect front end is fitted Remove internal sub-assembly from tool and un-stick pawl (Refer to Section 6, Maintenance;

steps 1-4)

Symptom 4: Tool does not cut or it is too difficult to cut

Possible Cause Solution

1. Blockage in tool, e.g. band Remove blade and/or front end as required, then clear blockage (Refer to Section 7, Adapting the

Tool)

2. Cam not lubricated (blade may also make ‘screeching’ noise) Grease cam and blade (Refer to Section 6, Maintenance; step 9)

3. Blade worn or damaged Replace or re-sharpen blade (Refer to Section 7, Adapting the Tool)

4. Incorrect blade or front end is fitted Remove blade and/or front end and replace with correct size for band (Refer to Section 7,

Adapting the Tool)

Symptom 5: Smart Band Failure during fitting

Failure Mode & Possible Cause Solution

1. Band/Buckle breaks due to incorrect input torque or pressure Set correct input torque or pressure (Refer to Section 4, Tensioning Tables)

2. Buckle breaks due to incorrect tool positioning during fitting Ensure tool is correctly positioned in buckle. Do not lift tool away from application during

tightening (Refer to Section 3, Operation; steps 8-9)

3. Band breaks due to repeated relaxing and re-tightening Only tighten the band once (Refer to Section 3, Operation; step 10)

4. System breaks due to cutting whilst in tension (green

marker not showing)

Do not operate cutter during tightening (Refer to Section 3, Operation; step 14)

5. Band pulls out of fixed end of buckle Ensure that latch is fully engaged with band before tensioning (Refer to Section 3, Operation;

step 2)

6. Buckle breaks due to being positioned in mid-air or around

too small a radius

Position Buckle on suitable radius (Refer to Banding Products Technical Booklet; Section 2.2

Technical – Installation Design)

7. Band breaks due to being positioned around too small a

radius

Position Band on suitable radius (Refer to Banding Products Technical Booklet; Section 2.2

Technical – Installation Design)

BANDING TOOLING

Parts List

SM-FT-1000 Banding Tool

SECTION 9

1

2

3

4 5

6

7

8

9

10 11 12

13 14 15

16

17 18 19

20

21

22

23

24

25

26

27

28

29

30 31

32

ITEM PART NUMBER DESCRIPTION QTY.

1 BHS_M8X10_SS BUTTONHEAD SCREW, SKT HD,

M8x10LG, SS 4

2 BLB_3_7_3_SS BEARING, BALL ROLLER, 3IDx7ODx3LG 2

3 CPS_M4X16_SS CAPSCREW, SKT HD, M4x16LG, SS 8

4 CPS_M6X10_SS CAPSCREW, SKT HD, M6x10LG, SS 1

5 CPS_M6X16_SS CAPSCREW, SKT HD, M6x16LG, SS 1

6 NUT_HEX_M4_SS NUT, FULL, HEXAGON, M4, SS 4

7 NUT_NYLOC_HEX_M6_SS NUT, NYLOC, HEXAGON, M6, SS 2

8 ORG_01872X262 O-RING, 18.72IDx2.62CS, NITRILE 70A 2

9 PRT1044 PLUNGER, BALL SPRING 1

10 PRT1002 HOUSING, MAIN BODY 1

11 PRT1003 GRIP, OVERMOULDED, FITTING TOOL 1

12 PRT1004 GUIDE 1

13 PRT1035 HOUSING, PAWL 1

14

PRT1036 PAWL, 32mm 1

PRT1040 PAWL, 25mm 1

PRT1040 PAWL, 19mm 1

15 PRT1037 PIN, Ø10x54LG 1

16 PRT1038 PIN, Ø3x20LG 1

17 PRT1039 SPRING, TORSION 1

18 PRT1041 MAIN SHAFT, THREADED 1

19 PRT1045 HOUSING, THRUST BEARING 2

20 PRT1046 HOUSING, CUTTING BLADE 1

ITEM PART NUMBER DESCRIPTION QTY.

21

PRT1047 FRONT END, CAST, 32mm 1

PRT1053 FRONT END, CAST, 25mm 1

PRT1054 FRONT END, CAST, 19mm 1

22

PRT1048 BLADE, CUTTING, 32mm 1

PRT1056 BLADE, CUTTING, 25mm 1

PRT1057 BLADE, CUTTING, 19mm 1

23 PRT1049 SPRING, COMPRESSION 1

24 PRT1050 LEVER, CUTTING MECHANISM 1

25 PRT1051 CAM, ROLLER 1

26 PRT1052 PIN, Ø8x55LG 1

27 PRT1059 WASHER, FLAT, 12IDx35ODx4LG 1

28 PRT1059 BOLT, SQUARE DRIVE 1

29 SSS_M8X35_CUP_PT_SS SKT SETSCREW, M8x35LG, CUP

POINT, SS 1

30 THB_20_35_2 BEARING, THRUST, NEEDLE ROLLER,

20IDx35ODx2LG 2

31 WAS_FLAT_20_35_1 WASHER, FLAT, 20IDx35ODx1LG 4

32 WAS_WAVE_2670_3432_124 WASHER, WAVE SPRING,

26.70IDx34.32ODx1.24LG 1

* Items 14, 21 & 22 are either 19mm, 25mm or 32mm options

Your attention is drawn to the following:

HCL warrants that a new HCL banding tool will operate per functional specifications for a period of sixty (60) days after the date of

shipment to the owners place of business. Normal wearing parts, as outlined in the Operations, Parts & Safety manual, are also covered

by a sixty (60) day warranty unless, in HCL’s judgement, these parts have been subjected to abnormal or extreme usage. HCL’s sole

liability hereunder will be to repair or replace, without charge, F.O.B. HCL, Bath UK, any tool which proves to not operate per functional

specifications within the stated period. HCL reserves the right to replace any tool which proves not to operate per functional specifications

with a new or like-new tool of the same model, if in HCL’s judgement such replacement is appropriate. Any new replacement or like new

replacement tool provided to an owner will carry a full sixty (60) day warranty. Any warranty repaired tool will carry a warranty for the

balance of time remaining on the initial sixty (60) day warranty. This warranty will be extended to compensate for the time the tool is in

HCL’s possession for warranty repairs.

This warranty is void as to any tool which has been:

a) subjected to mis-use, misapplication, accident damage, or repaired with other than genuine HCL replacement parts.

b) improperly maintained, or adjusted, or damaged in transit or handling.

c) used with improperly filtered, regulated, unlubricated air.

d) in HCL’s opinion, altered in a way that affects or detracts from the performance of the tool.

HCL MAKES NO WARRANTY, EXPRESSED OR IMPLIED, RELATING TO MERCHANTABILITY, FITNESS OR OTHERWISE EXCEPT AS STATED

ABOVE AND HCL’S LIABILITY AS ASSUMED ABOVE IS IN LIEU OF ALL OTHERS ARISING OUT OF OR IN CONNECTION WITH THE USE

AND PERFORMANCE OF THE TOOL. IT IS EXPRESSLY UNDERSTOOD THAT HCL SHALL IN NO EVENT BE LIABLE FOR ANY INDIRECT OR

CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, DAMAGES WHICH MAY ARISE FROM LOSS OF ANTICIPATED PROFITS OR

PRODUCTION, SPOILAGE OF MATERIALS, INCREASED COSTS OF OPERATION OR OTHERWISE.

Considerable effort has been made to ensure that this product conforms to our high quality standards. However, should you

experience any difficulties, please contact your Sales representative providing samples and the serial code specified on the tool.

Declaration

of Conformity

Name of manufacturer: HCL Fasteners Ltd

Address of manufacturer: First Avenue, Westfield Industrial Estate, Radstock, Bath BA3 4BS, UK

Telephone: +44 (0)1761 417714

Email [email protected]

I hereby declare that the following machinery complies with all the Essential Health and Safety

Requirements of the Machinery Directive 89/392/EEC as amended.

Machinery description: Banding tool for tensioning the HCL Smart Band® 32 mm (1¼”),

25mm (1”), 19mm (¾”) or Smart Tie™ 20mm (¾”) Systems

Type: Banding Tool SM-FT-1000

Serial No:

Transposed Harmonised European Standards used:

BS EN 12100 – 1&2:2003 Safety of Machinery – Basic concepts, general principles for design

prEN 983 Safety requirements for fluid power systems and components –

Pneumatics

EN 349 : 1993 Safety of Machinery – Minimum gaps to avoid crushing of parts of the

human body

BS EN 792-10 Hand-held non-electric power tools – Safety requirements – Part 14:

Compression power tools

HCL Fasteners Limited, Registered Office: First Avenue, Westfield Industrial Estate, Radstock, Bath, BA3 4BS United Kingdom.

Tel: +44 (0)1761 417714 Fax: +44 (0)1761 417710 www.hclfasteners.com

Other manuals for Smart Band SM-FT-1000

1

Table of contents

Other HCL Tools manuals