OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. Foreword . . . . . . . . . . . . . . . . . . . . . . . . 4

This manual . . . . . . . . . . . . . . . . . . . . . . 4

Important safety information . . . . . . . . . 6

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . 6

Spare part orders. . . . . . . . . . . . . . . . . . . 7

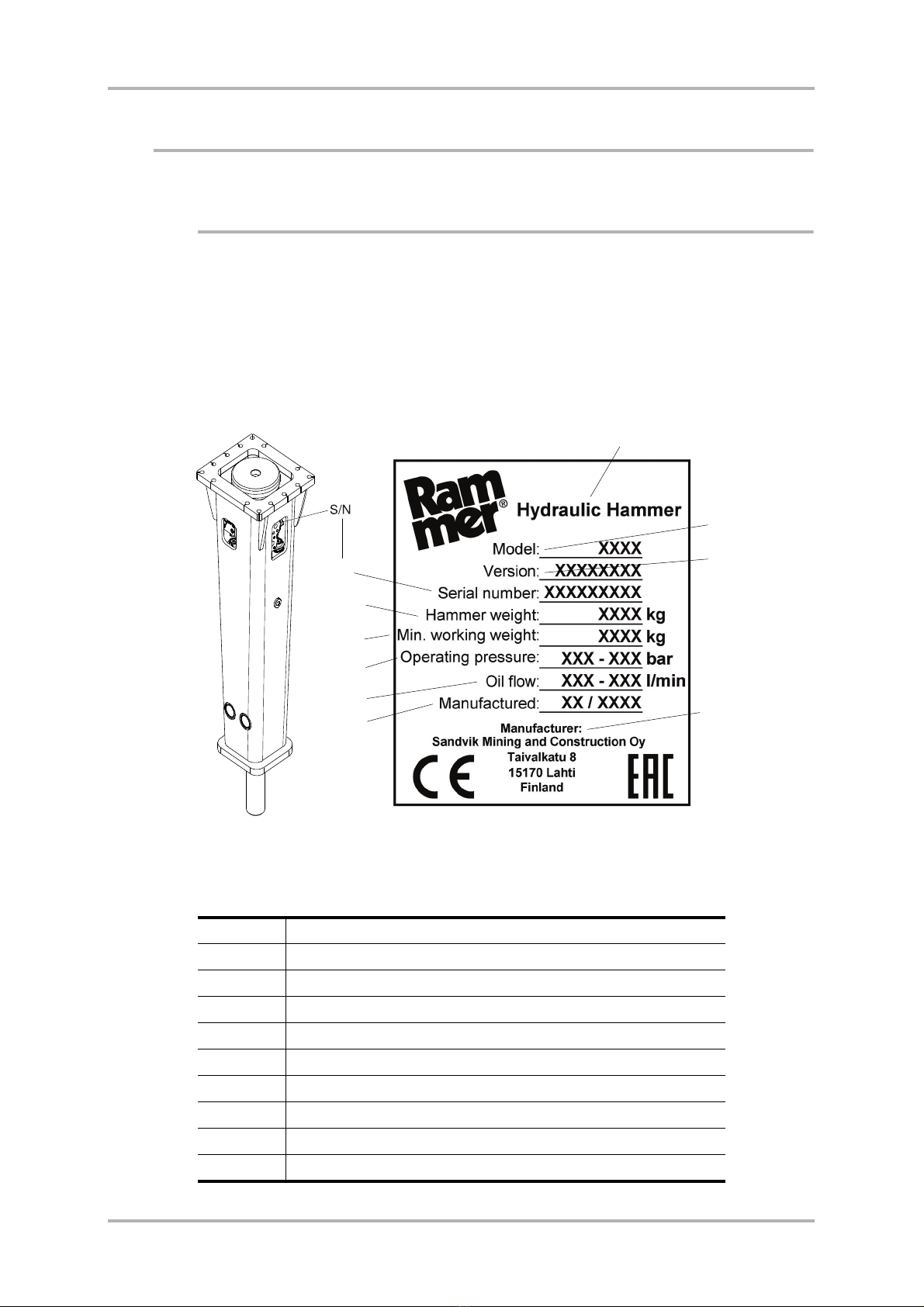

2. Product numbers. . . . . . . . . . . . . . . . . . . 8

Model and serial number . . . . . . . . . . . . 8

3. Product introduction. . . . . . . . . . . . . . . . 9

Overview. . . . . . . . . . . . . . . . . . . . . . . . . 9

Removal from package . . . . . . . . . . . . . . 9

Lifting instructions . . . . . . . . . . . . . . . . . 9

Main parts . . . . . . . . . . . . . . . . . . . . . . 13

Ramlube II . . . . . . . . . . . . . . . . . . . . . . 14

RD3 remote monitoring device . . . . . . . 14

Environmental protection and recycling

policy . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General safety . . . . . . . . . . . . . . . . . . . . 17

Safety instructions . . . . . . . . . . . . . . . . . 17

5. Operation . . . . . . . . . . . . . . . . . . . . . . . 26

Operating instructions. . . . . . . . . . . . . . 26

Daily operation . . . . . . . . . . . . . . . . . . . 29

Mounting and dismounting the hammer 36

Movement. . . . . . . . . . . . . . . . . . . . . . . 38

Special conditions of use . . . . . . . . . . . . 39

Storage . . . . . . . . . . . . . . . . . . . . . . . . . 39

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . 41

1. Hammer tool greasing. . . . . . . . . . . . . . 42

Recommended greases. . . . . . . . . . . . . . 42

Automatic greasing . . . . . . . . . . . . . . . . 43

Ramlube II . . . . . . . . . . . . . . . . . . . . . . 46

Adjusting the dose. . . . . . . . . . . . . . . . . 47

Manual greasing . . . . . . . . . . . . . . . . . . 49

2. Carrier hydraulic oil . . . . . . . . . . . . . . . 51

Requirements for hydraulic oil . . . . . . . 51

Oil cooler . . . . . . . . . . . . . . . . . . . . . . . 53

Oil filter . . . . . . . . . . . . . . . . . . . . . . . . 54

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . 57

1. Routine maintenance . . . . . . . . . . . . . . 58

Overview. . . . . . . . . . . . . . . . . . . . . . . . 58

Inspection and maintenance by the

operator . . . . . . . . . . . . . . . . . . . . . . . . 58

Inspection and maintenance by the

dealer . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Maintenance intervals in special

applications. . . . . . . . . . . . . . . . . . . . . . 60

Other maintenance procedures . . . . . . . 60

2. Changing the tool . . . . . . . . . . . . . . . . . 61

Wear limits and lubricants for tool

removal . . . . . . . . . . . . . . . . . . . . . . . . . 61

Removal of tool . . . . . . . . . . . . . . . . . . 61

Installation of tool. . . . . . . . . . . . . . . . . 62

3. Lower tool bushing . . . . . . . . . . . . . . . 64

Wear limits and lubricants for lower tool

bushing. . . . . . . . . . . . . . . . . . . . . . . . . 64

Removal of lower tool bushing. . . . . . . 64

4. Troubleshooting. . . . . . . . . . . . . . . . . . 65

The hammer operates irregularly but the

blow has full power . . . . . . . . . . . . . . . 65

The hammer operates irregularly and blow

has no power . . . . . . . . . . . . . . . . . . . . 65

Impact rate slows down . . . . . . . . . . . . 65

The hammer does not stop or has

run-on . . . . . . . . . . . . . . . . . . . . . . . . . 66

Oil overheats . . . . . . . . . . . . . . . . . . . . 66

Recurrent tool failure . . . . . . . . . . . . . . 67

Automatic greasing device Ramlube II

problems. . . . . . . . . . . . . . . . . . . . . . . . 67

Further assistance . . . . . . . . . . . . . . . . . 68

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . 69

1. Hammer specifications . . . . . . . . . . . . . 70

Technical specifications . . . . . . . . . . . . 70

Main dimensions . . . . . . . . . . . . . . . . . 71

Mounting bracket specifications. . . . . . 72

RD3 Technical specifications . . . . . . . . 73

2. Tool specifications . . . . . . . . . . . . . . . . 74

3. CE mark and EC Declaration of

Conformity . . . . . . . . . . . . . . . . . . . . . 75

Important information concerning the

remote monitoring device and data

privacy . . . . . . . . . . . . . . . . . . . . . . . . . 76