Heal Force Smart-NE Series Operation manual

Smart-NE Series

Water Purification System

Operation and Service Manual

Version:2004

Notice

If it is the first time for you to use our product, please carefully read this operating and maintenance

manual which will give you a lot of help. We take responsibility for regular maintenance and repair work

instead of consequences caused by improper operation.

The content of the publication is subject to change and/or updating without notice. The content of

this manual is only for reference use. The manufactory and the distributors shall not be responsible for

losses caused by incorrect description or misuse of this manual. The graphics contained in the manual

are as general representative which may have some errors compared to entity. But the description is

definitely match the function.

In accordance with copyright law, the company holds and retains the exclusive right to all the works.

Without written consent provided by company, any other organization or individual has no right to any

form of manual changes.

Preface

Thank you for using Smart-NE water purification system.

If you have any good suggestion, Please contact us, we will improve our products and after sale

service continuously.

Global Exclusive Agent: Healforce development (hongkong) Co. ltd. Tel: (00852)28987303

China Exclusive Agent: Nison Instrument (Shanghai) Co. ltd. Tel: (8621)62728646

Manufacture: Shanghai Canrex Analytic Instrument Co. ltd. Tel: (8621)50911997

ISO 9001 Certificate

I

Contents

Chapter 1 General............................................................................................................................1

1.1 Confirm the ordering products........................................................................................... 1

1.2 Safety information................................................................................................................ 1

1.3 System operating environment.......................................................................................... 1

1.4 warnings signal.....................................................................................................................1

Chapter 2 System Introduction....................................................................................................2

2.1 System principle................................................................................................................... 2

2.2 Technical features................................................................................................................ 2

2.3 Specifications for the system............................................................................................. 2

2.4 Diagram of the Smart-NE system......................................................................................3

Chapter 3 Instructions before installation................................................................................ 4

3.1 Check before installation.....................................................................................................4

3.2 Option spare parts............................................................................................................... 4

3.2.1 Pressure reducing valve CR-SP829.......................................................................4

3.2.2 Systematic data recording package CR-SP840................................................... 4

3.2.3 Enhanced pretreatment cartridge CR-SP102....................................................... 4

3.2.4 Water leakage sensor CR-SP846........................................................................... 4

Chapter 4 Installation..................................................................................................................... 5

4.1 Accessory installation of storage tank.............................................................................. 5

4.2 Pipeline connections............................................................................................................5

4.2.1 Feed pipeline and drain pipeline installations....................................................... 5

4.2.2 Pipeline connections between main unit and water tank.................................... 5

4.2.3 Pipeline connections between main unit and RWD............................................. 6

4.3 Signal cable connection...................................................................................................... 6

4.3.1 Level cable..................................................................................................................7

4.3.2 Pump power cable.....................................................................................................7

4.3.3 Cable connect between main unit and RWD........................................................ 7

4.4 Cartridge installation............................................................................................................7

4.4.1 Open the side door of the main unit....................................................................... 7

4.4.2 The position of the main components.................................................................... 7

4.4.3 Installation of pretreatment cartridge...................................................................... 8

4.4.4 Installation of purification cartridge(CR-SP303M)................................................ 8

Chapter 5 Parameter setting and operation........................................................................... 10

5.1 Control panel area............................................................................................................. 10

5.2 LCD display area................................................................................................................10

5.3 Symbols and graphics for LCD display...........................................................................10

5.4 Function Keypad................................................................................................................ 10

5.5 Operation.............................................................................................................................11

5.6 Parameters setting.............................................................................................................12

5.6.1 Alarm Settings.......................................................................................................... 12

5.6.2 Calendar setting.......................................................................................................14

5.6.3 Volume of taking product water setting................................................................ 14

5.6.4 Dispensing flow setting........................................................................................... 14

5.6.5 Ultra-pure water quality setting..............................................................................15

5.6.6 Unit selection............................................................................................................15

Chapter 6 Maintenance................................................................................................................ 16

6.1 Routine maintenance.........................................................................................................16

6.2 Periodic maintenance........................................................................................................16

6.3 Maintenance works and service works...........................................................................16

6.3.1 Pre-filter cleaning.....................................................................................................16

6.3.2 Into the maintenance settings................................................................................17

II

6.3.3 Pre-treatment replacement.................................................................................... 17

6.3.4 RO membrane replacement...................................................................................18

6.3.5 Purification cartridge replacement........................................................................ 20

6.3.7 Micro/Ultra-filter replacement.................................................................................21

6.3.8 Re-install the cartridges..........................................................................................22

6.4 System status check..........................................................................................................22

6.5 Obligate level setting......................................................................................................... 23

6.6 Data record of system....................................................................................................... 23

6.7 Restore factory settings.................................................................................................... 24

6.8 Main unit disinfection.........................................................................................................25

Chapter 7 Troubleshooting......................................................................................................... 27

7.1 No display............................................................................................................................27

7.2 Making RO water is too low..............................................................................................27

7.3 The pure water conductivity of Smart-NE is too high................................................... 27

7.4 Ultra-pure water resistivity is too low.............................................................................. 27

7.5 The flow rate of ultra-pure water is too low....................................................................27

Chapter 8 Order information...................................................................................................... 28

8.1 Consumable........................................................................................................................28

8.2 Option parts.........................................................................................................................28

Chapter 9 Appendix...................................................................................................................... 29

Appendix 1 Fuse replacement................................................................................................29

Appendix 2 Pressure reductor installation............................................................................ 29

Appendix 3 Inlet valve unit installation.................................................................................. 30

Appendix 4 Electrical connections......................................................................................... 30

1

Chapter 1 General

1.1 Confirm the ordering products

The manual is written for Smart-NE series water purification system

The content of the manual can lead users to installation, operation and maintenance of the

Smart-NE series water purification system

We strongly recommend our users to read and understand the content of the manual before

installation, operation and maintenance

You can easily find the model of the system in the nameplate at the back of the system.

1.2 Safety information

You must use the safety norms according to this manual before using the Smart-NE system,

especially water and power supply. It is necessary to refer to this manual when you install or operate the

Smart-NE system. Unqualified using environment will endanger the normal operation, or even damage

the whole system.

The installation, commissioning and maintenance of the equipment can only be completed by its

authorized agents. We did not responsible for duties and responsibilities if the equipment is

disassembled by unauthorized dealer or service personnel.

1.3 System operating environment

Indoor use

Avoid direct sunlight

Between 0-2000 meters altitude

Ambient temperature: 4-45℃

Operating Voltage: 220-230V AC 50/60Hz

Inlet pressure: 0.1-0.4MPA.

The fluctuation range of the main power supply can be 10% of the normal voltage.

Transient over-voltage power supply is grade 2.

There is an drains around the equipment(1 meters)

Adequate indoor ventilation

Mounting surface must be fixed, level, and not burning

Avoid direct sunlight

No heat source next to the equipment.

Be away from strong magnetic field.

1.4 warnings signal

Note alert you to pertinent facts and conditions, please read this operation and

service manual carefully before you operate the main system

Caution: Caution alert you to the possibility of damage to the equipment, and

water in pipe may spill out when the cartridge is installed OR replaced.

Danger: Danger alert to a possibility of personal injury.

Power supply must be firmly grounded

2

Chapter 2 System Introduction

2.1 System principle

Smart-NE Series is an advanced essential laboratory equipment, widely used in trace analysis,

diagnostics, toxicology, precision optics laboratories, as well as in hospital, research institute and other

water quality monitor department. The device adopted advanced modular design, CPU auto-control

technology, highly integrated water treatment equipment. It is the new generation of intelligent water

purification system with intellectual property.

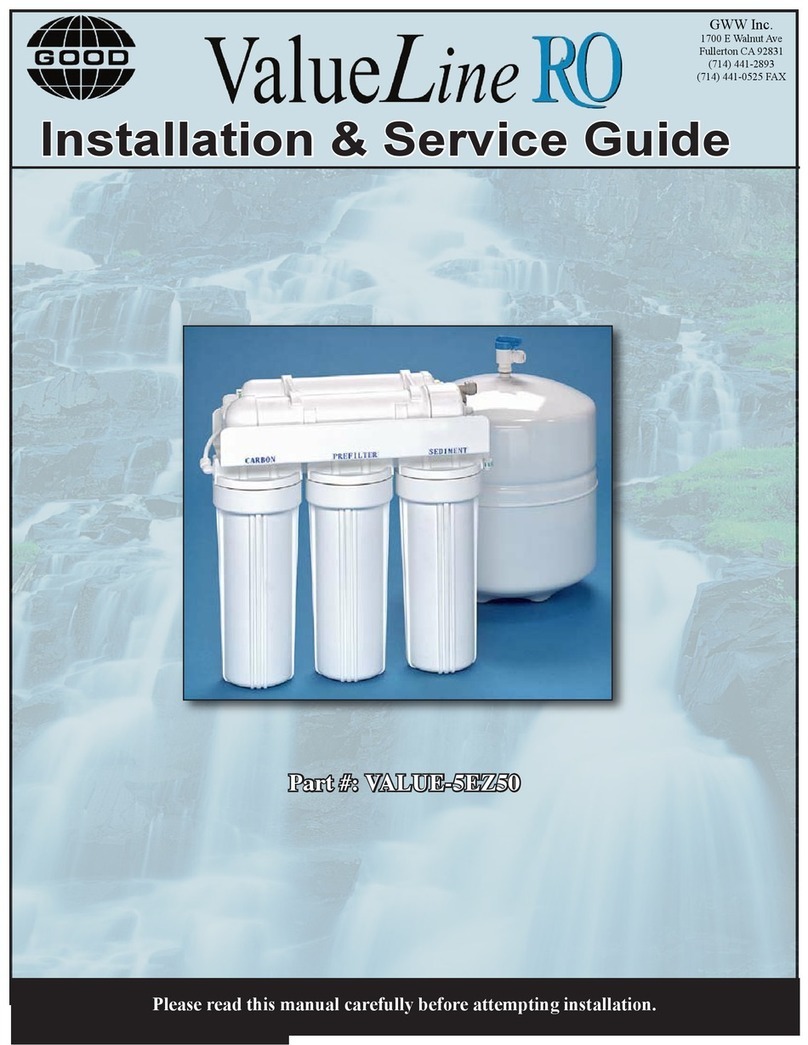

The feed water of Smart-NE system is ordinary tap water. The feed water is passing through the

multi-channel process of pretreatment cartridge, reverse osmosis cartridge, EDI, Ultra-purification

cartridge, UV sterilizer, Ultra-filter cartridge. The quality of ultrapure water can reach the resistivity of 18

MΩ.cm and eliminating bacteria.

2.2 Technical features

Product line is abundant, as many as a hundred variety, to meet individual needs.

Disposable integrated cartridge simplifies operation. It takes less time to replace any component

Modular design concept, including pretreatment cartridge, reverse osmosis, purification cartridge

Self-diagnostic microprocessor control system monitors major parameters and alarm to ensuring the

main system at optimize operation status.

Advanced CPU self-controlled technology can determine the configuration. The system will

shutdown automatically when the feed water is shortage and auto flush when the main system re-stared.

Double channel design for pure water and ultrapure water.

Special UV sterilizer control technology make the UV light work only when ultrapure water is

produced, thus can extend life time of UV lamp.

Interactive LCD display affords user optimum convenience, with indication on conductivity, resistivity,

temperature, operate mode, water tank level, volume dispense products water.

4-channel resistivity sensors, equipped with temperature compensation function, comprehensively

monitor system operation and water quality variation.

Two hours standby mode with various types of loop disinfection. Using hydrogen peroxide as

disinfectant to protect operator and filtration cartridge, and guarantee the quality of ultrapure water.

A special connection process is applied for the Smart-NE system, eliminating the risk of RO

membranes seepage when the main unit is in standby mode, ensuring the qualified water into the water

tank.

30Lor 60L storage tank with 5 level sensor, with optional air filter and UV sterilizer for water tank,

which provides flexible solutions for different water usage.

Adjustable level of water system start to making EDI water, keep the EDI water in the storage tank

fresh according to the user demand.

Volume dispense function (0.1-25L adjustable) or water producing amount according to your needs

PIN-coded access to software set points prevent unauthorized changes to operation or system

settings.

Remote water producing function (optional)

USB port allows for data collection and permanent record of water quality and system

parameters--essential for compliance with good laboratory practice guidelines.

With remote monitor software (option), you can remote the water system on the computer.

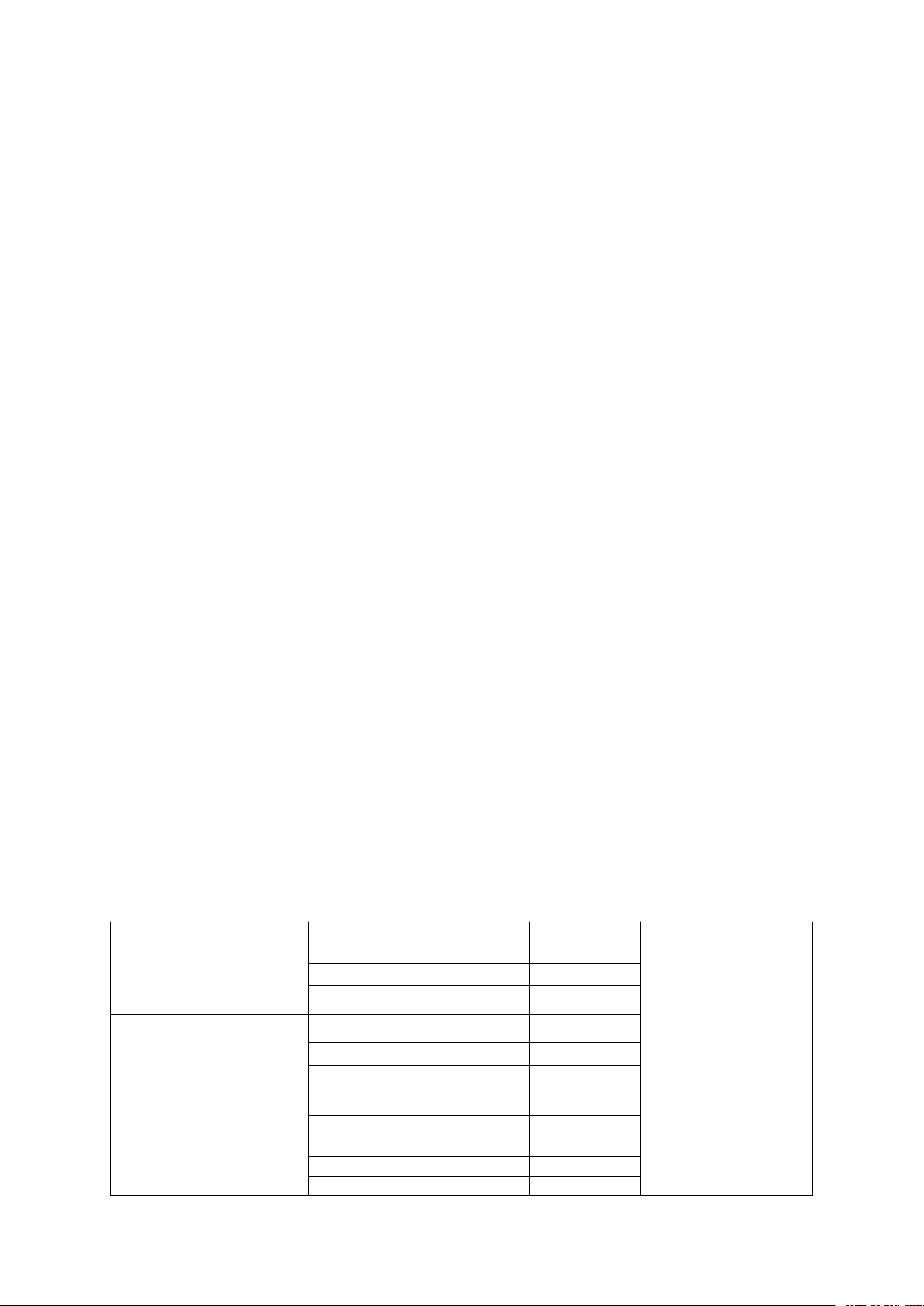

2.3 Specifications for the system

Feed water requirement

Conductivity μS/cm@25℃

<400

Note:

* The making

rate will be changed

with temperature

variation. (3% per

1℃)

** The feed

water TOC is less

than 1000ppb.

*** with 0.22um

final filter cartridge

**** with

Ultra-filter cartridge

Pressure MPa

0.1~0.4

Temperature ℃

5~40

Pure water

Ion rejection rate %@25℃

≥95

Bacteria remove %

>99

Make rate* L/H@25℃

25-30

High-pure water

resistivity MΩ.cm

>10

Make rate L/H

10-15

Ultra-Pure water

resistivity MΩ.cm

>18

TOC** ppb

1-10

Endotoxin*** Eu/ml

<0.001Eu/ml

3

Particles****(0.22μm)/ml

<1

Dispensing rate L/H

60-100

Power Consumption W

150

Weight kg

38

Storage tank

30L

Main System Dime. W*D*H

525*314*571

Storage Tank Dime.W*D*H

430*380*580

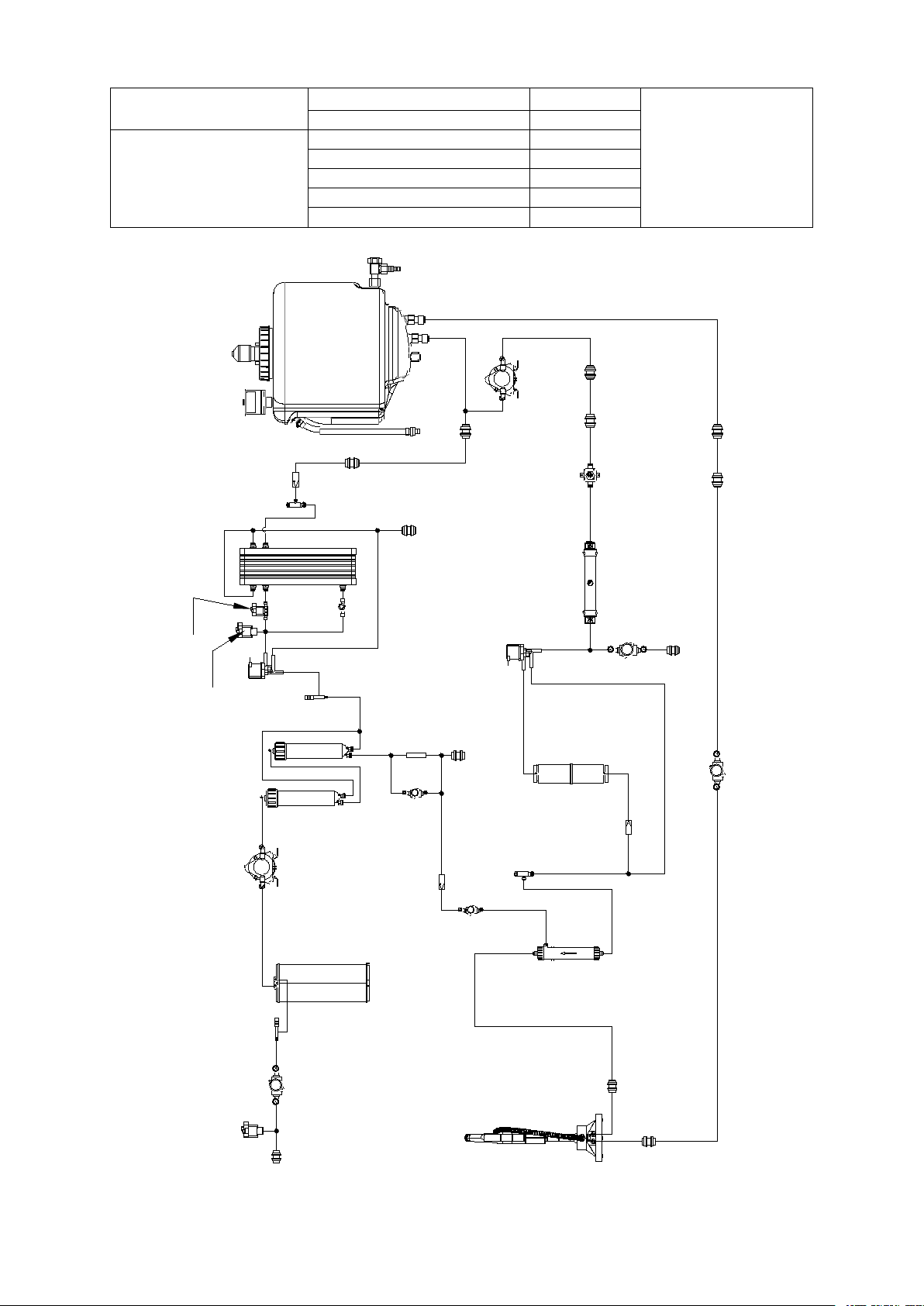

2.4 Diagram of the Smart-NE system

FEEDFEED

lowlow pressurepressure switch1switch1

solenoidsolenoid valveHvalveH

conductivityconductivity cell1cell1

pretreatmentpretreatment carteidgecarteidge

pump1pump1

reversereverse osmosisosmosiscartridgecartridge

flowflow controlcontrolvalve2valve2

solenoidsolenoid valveCvalveC

DRAIN1DRAIN1

conductivityconductivity cell4cell4

solenoidsolenoid valveBvalveB

OUTOUT

ININ

OUTOUT

ININ

pressurepressure reducingreducing valvevalve

solenoidsolenoid valveAvalveA

highhigh purepure waterwater

ultra-purificationultra-purification cartridgecartridge

resistivityresistivity cell3cell3

UFUF cartridgecartridge

solenoidsolenoid valveEvalveE

RWD1-1RWD1-1

RECREC RECREC

solenoidsolenoid valveDvalveD

checkcheck valve3valve3

solenoidsolenoid valveJvalveJ

checkcheck valve2valve2

DRAIN2DRAIN2

highhigh pressurepressure switchswitch

flowflow controlcontrolvalve1valve1

resistivityresistivity cell2cell2

pump2pump2

lowlow pressurepressure switch2switch2

RWD1-2RWD1-2

UVUV lamplamp

checkcheck valve1valve1

EDIEDI

waterwatertanktank

RWDRWD

4

Chapter 3 Instructions before installation

3.1 Check before installation

Users please ensure whether the product you received is your purchase before installation.

You had batter check all items according the packing list.

Whether the power site is close to the system.

Whether the feed water meets the requirements.

Whether the feed water pressure is normal.

Whether the feed water supply is nonstop.

Whether the feed water pipe has1/2″NPTF whorl connector.

Whether it is needed another frame for wall installation.

Whether the strength of the wall can bear the system (including tank full of water) weight.

Whether the system’s height can clearly observe both LCD screen and keypad operations on control

panel.

Whether there is adequate space to substitute supplies and connecting pipe as well around and

behind the system.

Whether you have installed more than 1/2″ drains, not more than one meter far away from the

system, intended for discharging waste-water and water overflowing.

Whether the installment circumstances are consistent with the regulations.

Whether there is reserved space if you are going to install USB signal accessing your computer.

Whether there is reserved space if you are looking forward to having moving handle and pedal

switch installed.

3.2 Option spare parts

3.2.1 Pressure reducing valve CR-SP829

Please purchase this product additionally when the feed water pressure is too high(>0.4MPa).

This component can reduce pressure to 0.4Mpa below.

3.2.2 Systematic data recording package CR-SP840

It includes systematic data recording software and USB connecting signal. Using it, you can easily

have Smart-NE system and your computer connected, on which you can install and record you using

this recording system and water quality.

3.2.3 Enhanced pretreatment cartridge CR-SP102

Enhanced pretreatment cartridge is a multi-stage pretreatment module to removes the impurities in

tap water including suspended particulates, colloids, microorganisms, organics, chlorine and heavy

metals to ensure the following purification modules work properly.

3.2.4 Water leakage sensor CR-SP846

It will cut off systematic water supply in time when it breaks down or water leaks out, preventing

further leakage.

5

Chapter 4 Installation

It is important for the user to master installation and removal of quick connector. If user dose not

operate properly will lead to water leakage, quick connector damage and pipeline broken.

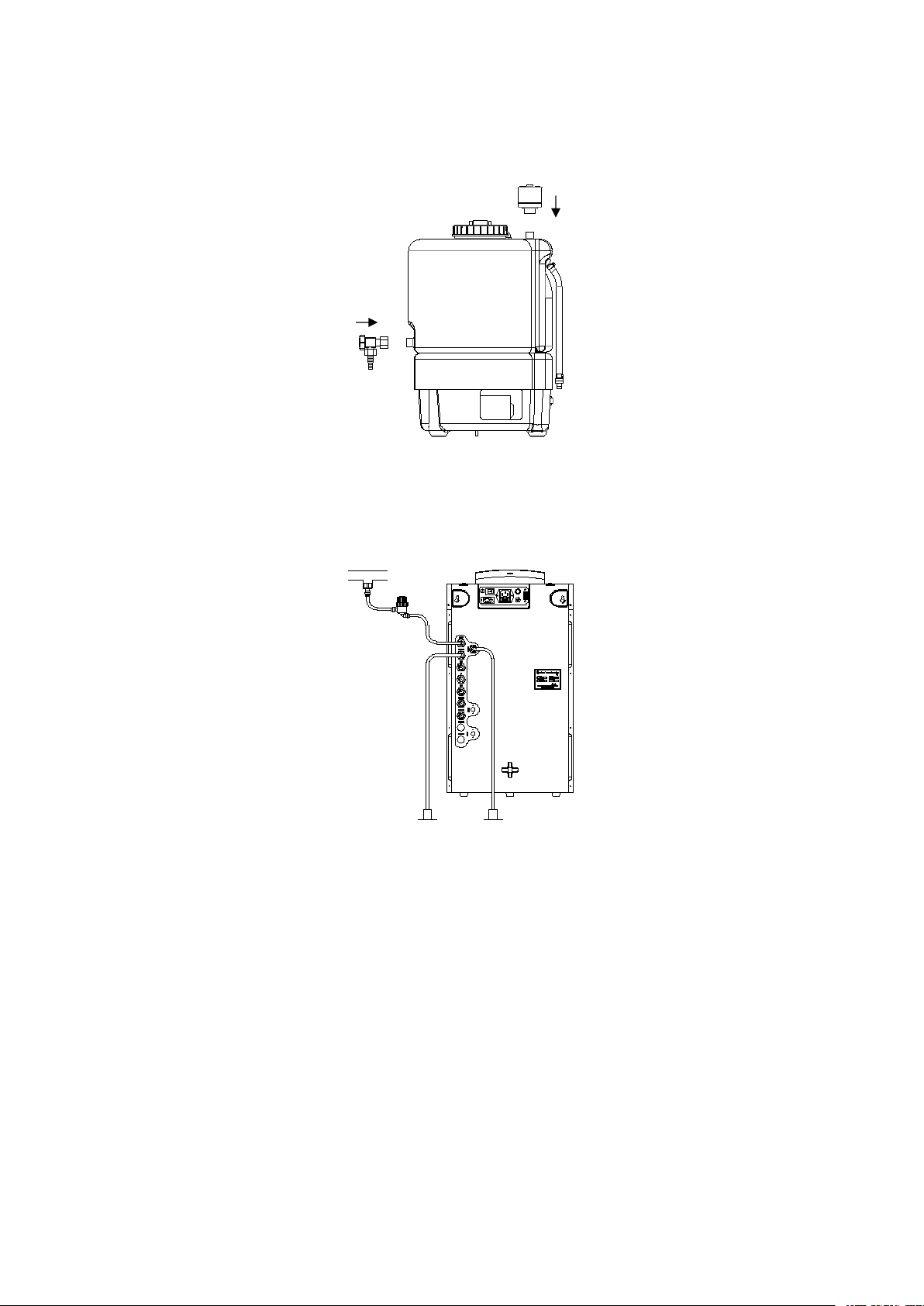

4.1 Accessory installation of storage tank

First to twine the 1/2’ NPTF outlet in the front of the storage tank with Teflon tape ,then get the RO

dispense valve connect to the outlet of storage, be sure the “O” ring and screw tight.

Get the air-filter and screw to the 1/2”NPTF outlet on the top of the storage tank according to the

clockwise sense, be sure not to screw tight.

4.2 Pipeline connections

4.2.1 Feed pipeline and drain pipeline installations

Before connecting the inlet pipe, make sure that the external water supply has been shut down to

prevent water supply pipe splashing around, resulting in unnecessary losses.

Get the quick connector and the tread sealing tape out. Wind the tread sealing tape around the 1 / 2

"NPTF connector (usually 3 to 4 laps) of pre-installed external water pipeline. And then screw on the

connector.

Cut a blue tube and prefilter, one end of the blue tube connects to the tap water connector, the other

end connects to the prefilter “in”.

Cut a blue tube, one end connects to the prefilter “outlet”, the other end connects into the “feed” at

the back of main unit.

Cut two black tubes, one ends of the tubes connect to the "DRAIN1"and “DRAIN2” at the back of

main unit, insert the other ends into the floor drain.

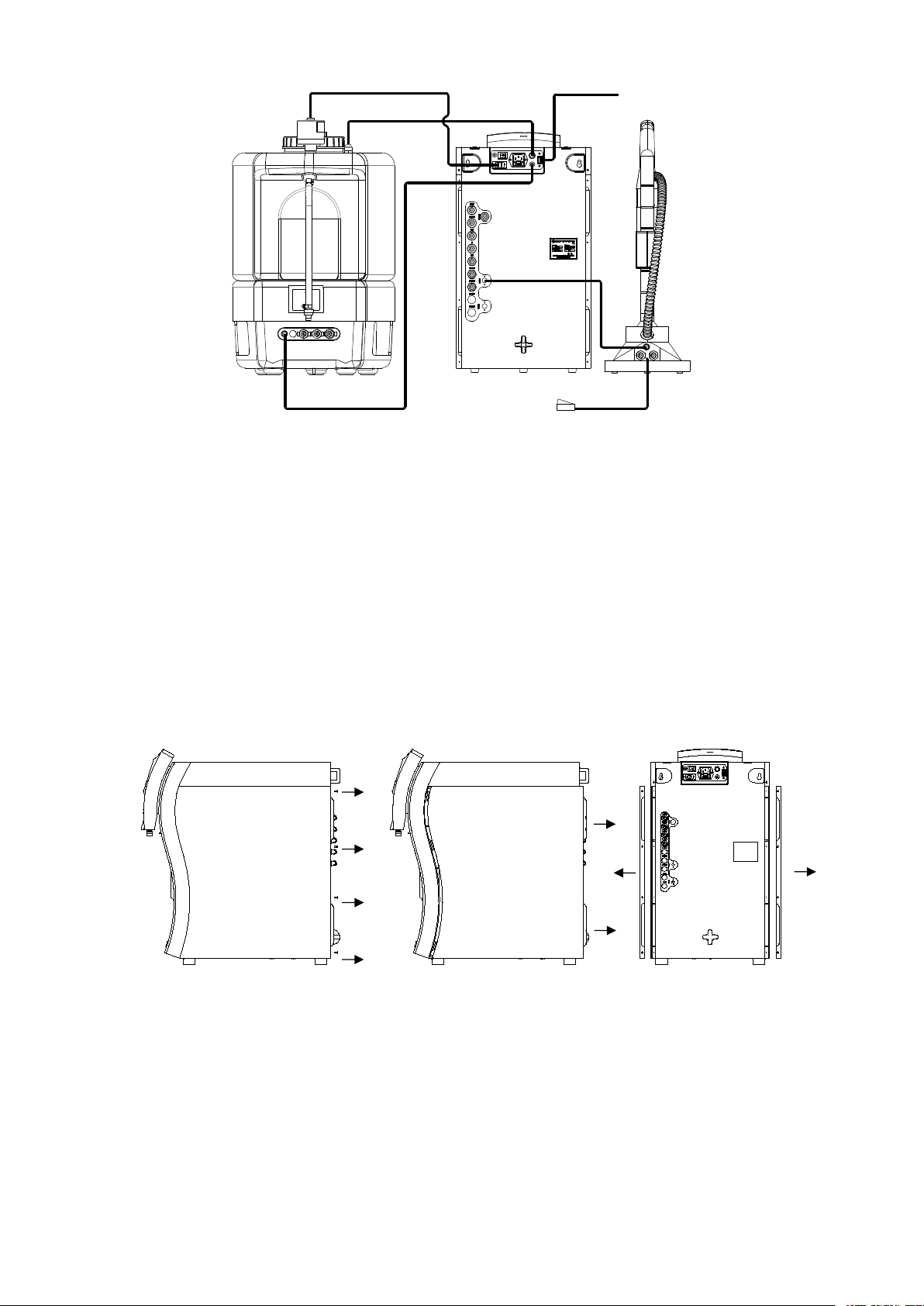

4.2.2 Pipeline connections between main unit and water tank

Water supply pipe

Prefilter

Floor drain

6

Cut a white tube, insert one end of the tube into the "OUT" on the back of main unit, and the other

end into the "IN" on the back of storage tank.

Cut a white tube, insert one end of the tube into the "IN" on the back of main unit, and the other end

into the "OUT" on the back of storage tank.

Cut a white tube, insert one end of the tube into the "REC" on the back of main unit, and the other

end into the "REC" on the back of storage tank.

Get a transparent tube (DN12mm,2m), one end of the tube connect to the air check valve at the

back of storage tank with clamp fitting, the other end into the external drainage pipes which have been

pre-installed.

4.2.3 Pipeline connections between main unit and RWD

Get a white tube, insert one end of the tube into the "RWD1-1" on the back of main unit, and the

other end into the one of the connectors on the back of RWD.

Get a white tube, insert one end of the tube into the "RWD1-2" on the back of main unit, and the

other end into the one of the connectors on the back of RWD.

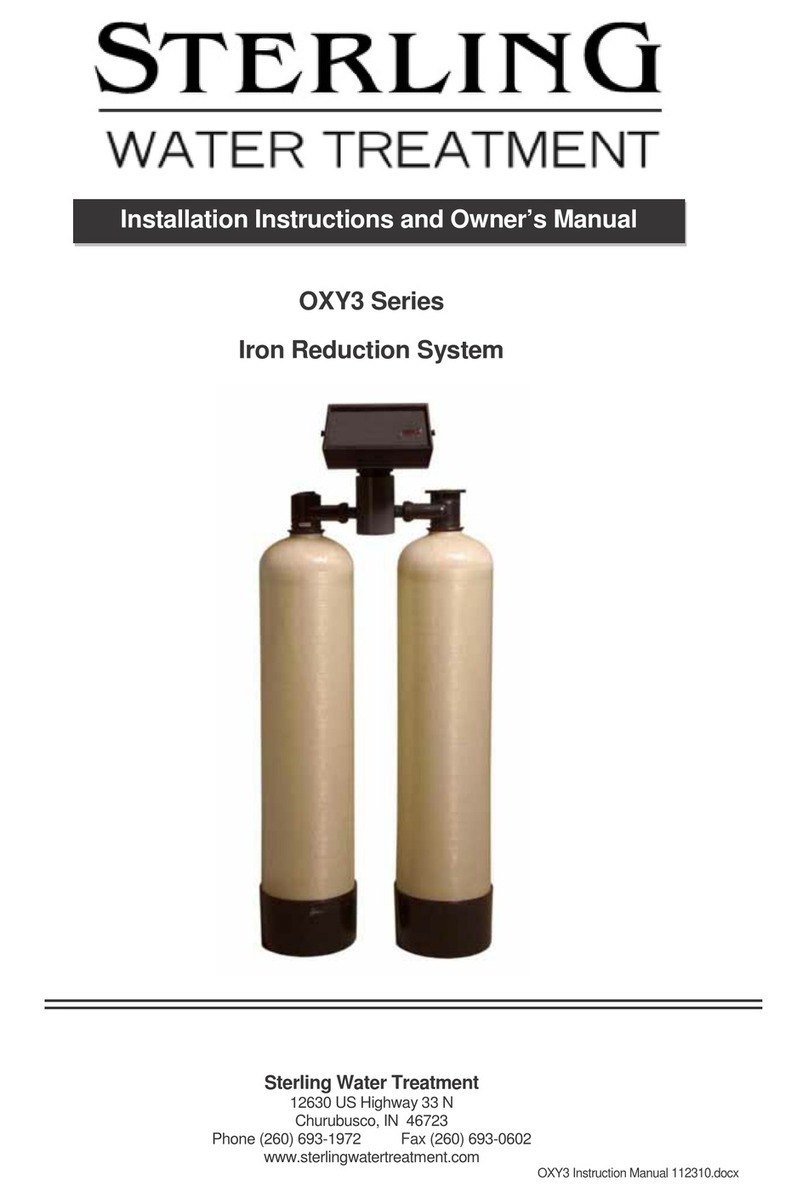

4.3 Signal cable connection

1 power switch

2 power supply socket

3 level sensor socket

4 USB socket

5 tank pump socket

6 tank UV socket

Floor drain

1

2

3

5

6

4

7

4.3.1 Level cable

Connect the seven core signal cable on the top of the water storage tank to the level sensor socket

on the back of the main unit.

4.3.2 Pump power cable

Get the three core signal cable, one end connect to three core socket at the back of main unit, the

other end connect to the three core socket at the back of storage tank base.

4.3.3 Cable connect between main unit and RWD

Get the PS/2 signal cable, one end connects to the “RWD1” at the back of the main unit, the other

end connects to the PS/2 socket at the back of the remote water dispenser.

4.3.4 Main power supply cable

Make sure that the system switch status is "OFF" the switch should be in the "O"

Put the power cord plug into the power supply socket.

Insert the other end of the power cord into the external power supply outlet.

4.4 Cartridge installation

4.4.1 Open the side door of the main unit

Unscrew the screw of the side door with a screwdriver.

Pull the handle of the side door with both hands, forced back to pull the a side door out of 10mm ~

13mm.

Carry out the side door.

4.4.2 The position of the main components

Water tank

Foot control

Remote water dispenser

Main unit

8

A Pretreatment cartridge

B RO cartridge

C UV light

D EDI

E Ultrapure cartridge

F MF/UF cartridge

4.4.3 Installation of pretreatment cartridge

Confirm the system is power off.

Pretreatment cartridge is installed in the right chamber of Smart-NE system.

Get the pretreatment cartridge from the box (make sure number is correct for the CR-SP101M),

open the vacuum bag, remove protection cover for the inlet and outlet of pretreatment cartridge. Make

sure there is a black “O” ring in the inlet and outlet, which is in the bottom of the hole.

Use pure water to make the black "O" rings wet. Do not use lubricants for lubrication, such as

glycerol or Vaseline or other lubricant.

Place the square tenon at the low of the pretreatment into the corresponding square hole on the

main unit.

Push the joint at the up of the pretreatment cartridge to the main unit. Make sure the "O"-rings of

pretreatment cartridge can be completely sealed with the joints.

There is locking plate connected with nylon line on the joints of main unit. Insert the locking plate

into the slot of metal bar.

Pretreatment cartridge installation is complete.

4.4.4 Installation of purification cartridge(CR-SP303M)

Open the front door of the main unit

A

C

F

D

E

A

B

D

9

Press and pull the latch at the top of the front door, to remove the front door (press down about 3mm,

do not press down hardly which may cause deformation or even fracture bayonet).

Open the front door of the system. Please refer to this chapter.

Open the front door, the cabinet of ultra-purification cartridges has upper and lower latch.

Take out the purification cartridge from the box (make sure number is correct for the CR-SP303M),

open the vacuum bag, remove protection cover for the port of cartridge. Make sure there is a black “O”

ring in the ports, which is in the right position.( should be close to the inlet and outlet inside the convex

shoulder). If the position is not right, Please adjust it to the right position.

Wet the "O"-rings with ultra-pure water. Do not use lubricants for lubrication, such as glycerol or

Vaseline or other lubricant.

Push the purification cartridge firmly into place, Both the top and bottom ports of the cartridge have

to be fully seated.

Place the latch as origin. Make sure that both the top latch and bottom latch are fully closed. Each

latch should “click” when it is fully closed.

Install the front door as this chapter. The purification cartridge installation is completed

10

Chapter 5 Parameter setting and operation

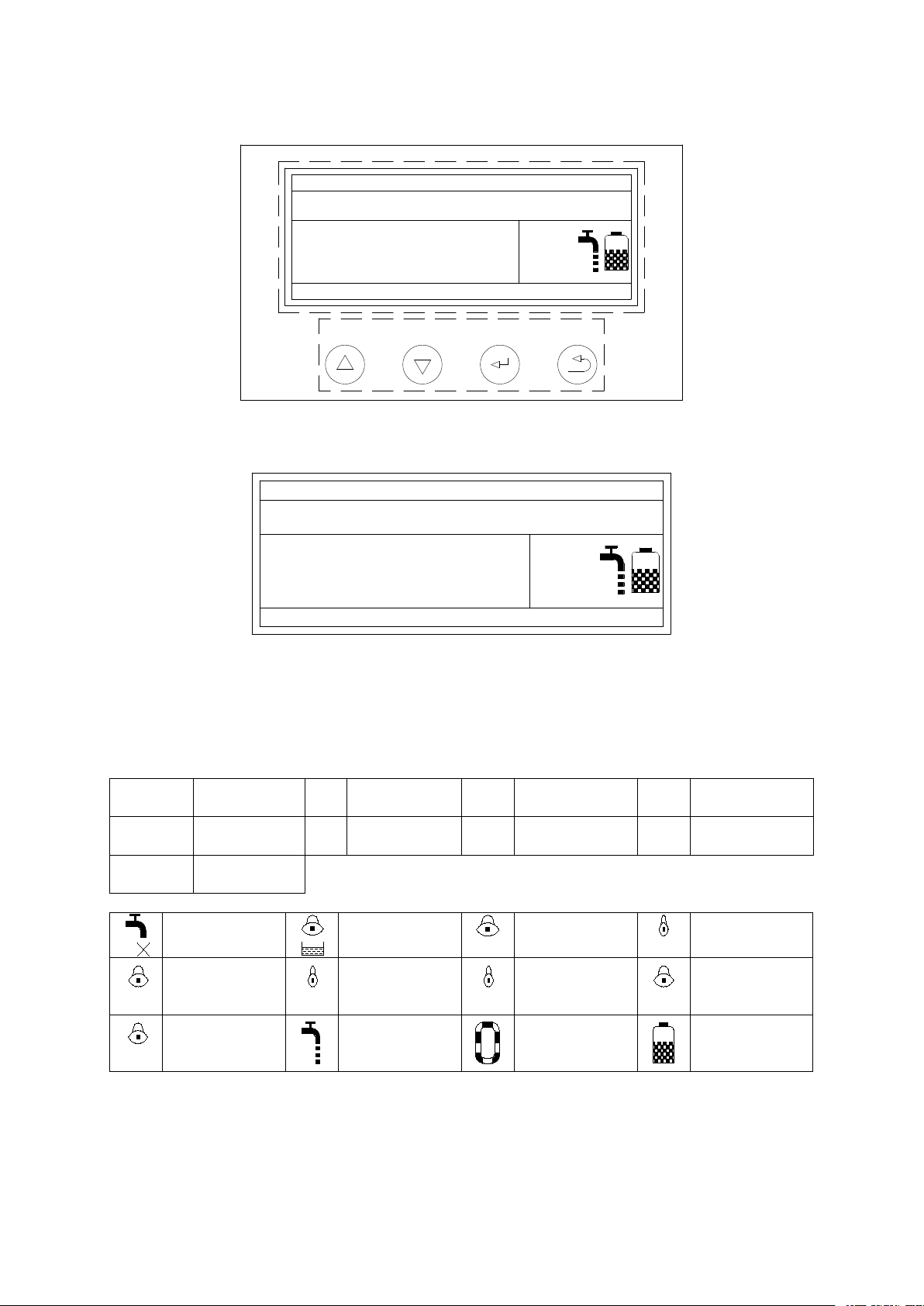

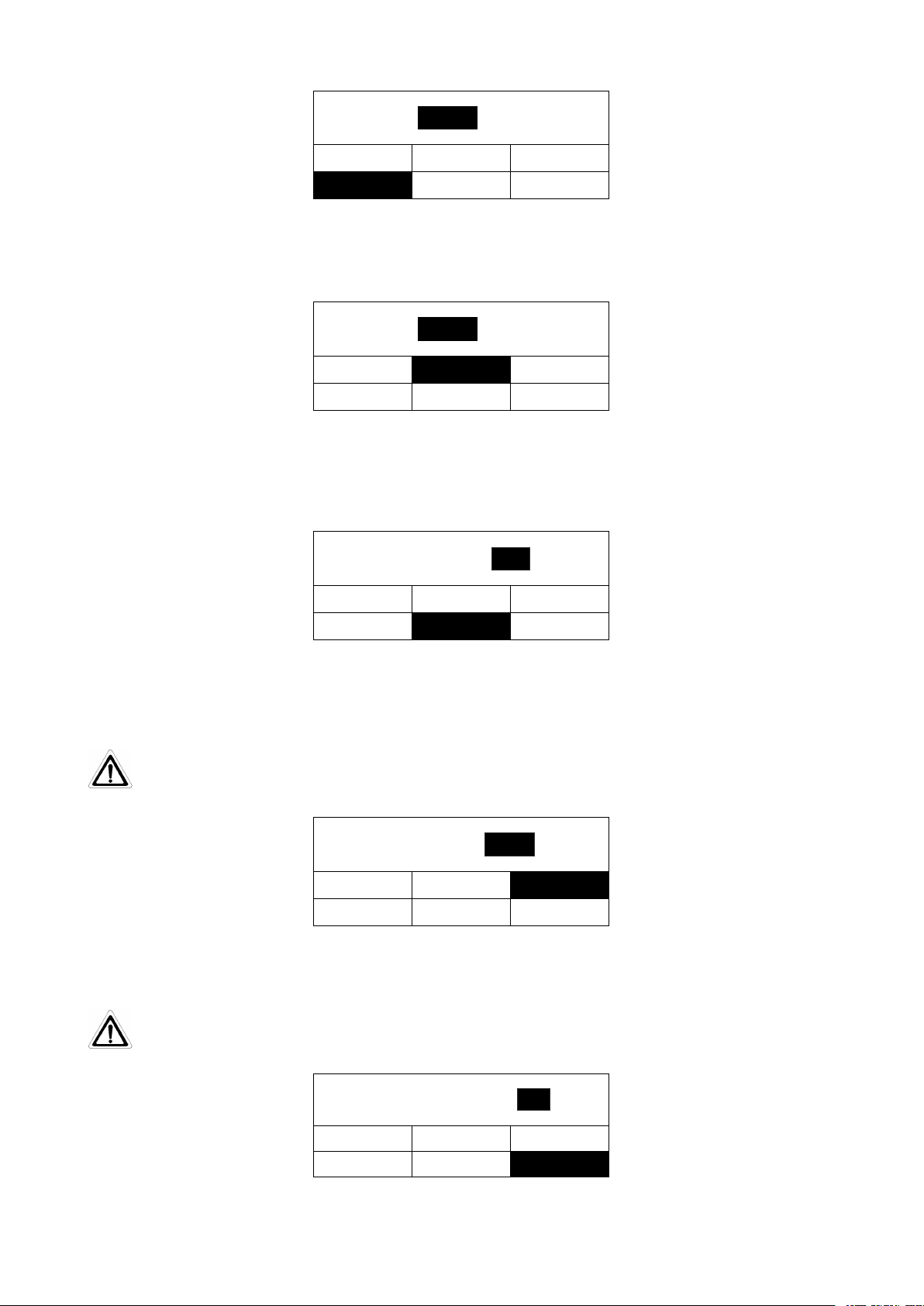

5.1 Control panel area

DISP.DISP. FlushFlush StopStop M enuM enu

Smart-NE

Ultra-water Dispensing

25.0°C

08:00 20/09/2016

UP: 18.2 MΩ·cm

Vol Disp: OFF

A: dashed box for the LCD display area.

B: dashed box for the function keypad board.

5.2 LCD display area

Smart-NE

Ultra-water Dispensing

25.0°C

08:00 20/09/2016

UP: 18.2 MΩ·cm

Vol Disp: OFF

A: system model and the current temperature display .

B: current status

C: product water quality and Volume dispense status.

D: date and feed water conductivity.

E: graphic for display status.

5.3 Symbols and graphics for LCD display

symbols

FEED

Feed water

conductivity

RO

Pure water

conductivity

UP

Products

resistivity

DS

deionization

rate

PF

Pretreatment

cartridge

UF

Ultra-filter

UV

UV lamp

Vol.

Disp

Fixed Volume

Dispensing

EDI

EDI water

resistivity

graphics

Without feed

water

System

leakage

FE

Feed water

low quality

PF

Pretreatment

failure

RO

RO failure

UF

Ultra-filter

failure

UV

UV light failure

DI

Purification

cartridge

failure

DS

RO failure

Ultrapure

water

producing

Ultrapure

water recycle

Tank level

5.4 Function Keypad

There are 4 function keypads in the system: DISP./▲, Flush/▼, Stop/and Menu/.

DISP./▲

Dispense product water, adjusting keypad at the menu mode.

Flush/▼

Flush cartridges, adjusting keypad at the menu mode.

Stop/

Stop current operation, confirmation keypad at the menu mode.

Menu/

Parameter setting.

A

B

A

B

C

D

E

11

5.5 Operation

Turn on feed water supply. Ensure that all the pipe connecting parts have no leaking. Switch on the

power supply at the back of the main unit.

After the main unit is powered on, LCD will display a welcome message, which is followed by the

current state of the system. The system will remain in flushing status about 1 minute.

Smart-NE

System Flushing...

25.0°C

08:00 20/09/2016

1:001:00

The lack of water warning will show in the right of display area when the pressure of feed water is

too low or no feed water. The main unit will stop to standby status. The main unit will re-start to flush

automatically when the water comes again, as shown below:

When the flushing process of main unit is finished, the system will automatically enter the water

producing state. The Smart-NE will flush automatically RO membrane before and after producing EDI

water. The system also shows water conductivity.

Smart-NE

EDI water making

25.0°C

20/09/2016

RO: 10.0 μs/cm

EDI: 15.2 MΩ.cm

FEED: 400μs/cm

When the storage tank of Smart-NE system is full , the system will enter the standby mode

automatically.

Standby

25.0°C

IdealIdeal forfor lablab

08:00 20/09/2016

Smart-NE

Press "Disp. / ▲" keypad you can take the high pure water.

Ensure that the pure water at least 20% of the Smart-NE water tank(water level 1).

Smart-NE

HP-water Dispensing

25.0°C

08:00 20/09/2016

Ideal for lab

Vol Disp: OFF

Press "Stop/" keypad to stopping take product water. The LCD displays the next system state.

Smart-NE has manual flush function for RO membrane cartridge, press the "Flush / ▼" to flush RO

membrane cartridge manually for 1 minute. At this time the LCD display of the main unit is the same as

flushing mode from the beginning.

Press the "Stop / "keypad to stop flushing operation. LCD will display the next current-status.

You can take ultrapure water with the remote water dispenser. If the quality of current ultrapure

water can not meet the requirement of original setting (ie 16.0MΩ.cm), the system will automatically

enter recycling mode to improve the water quality. And if the water quality reaches the set value, the

main unit starts to produce ultra-pure water.

When the Smart-NE system is in the standby state, the ultrapure water in the loop will automatically

recycle for 5 minutes every 2 hours, which will guarantee the quality of ultrapure water to the setting

requirement.

12

Smart-NE

25.0°C

08:00 20/09/2016

Cycling...Cycling...

Standby

5.6 Parameters setting

Press "Menu" keypad to enter the menu

语言 LANGUAGE

ENGLISH

中文

Press "Disp./▲" or "Flush/▼" keypad to select "ENGLISH". Press the "Stop /" keypad to confirm

the setting and to the next level.

Password: 85

Press or hold down the "Disp. / ▲" or "Flush / ▼" keypad to enter the correct password. The default

password is 85. Enter the password, press the "Stop / " keypad to confirm the entry of next menu level.

If the password input is error, the system will be directly reset.

Parameter

setting

Service

setting

Press the "disp. / ▲" "Flush / ▼" keypad to select "Parameter setting". Press the "Stop / " keypad

to enter the parameter setting level

After entering the parameter setting menu, you can see the contents of the setting are: Alarm

settings, Calendar, Product conductivity unit, Volume of water dispense,

AlarmAlarm settingsetting

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

5.6.1 Alarm Settings

After entering the parameter setting menu, press the "Disp. / ▲" or "Flush / ▼" keypad to select

"Alarm setting". Press the "Stop / " keypad to confirm the settings menu to enter the alarm category

including various settings.

UFUF lifelife

UVUV lifelife FeedFeed

RORO

DSDS

PFPF

lifelife : 400h400h 500h500h 600h600h

PFPF lifelife

Alarm time setting for pretreatment failure

In this menu level the maintenance interval for the pre-treatment cartridge ,it must be reset after

exchanged ,the manufacture setting is 400 hour, the user can press “Disp./▲,Flush/▼” keypad to select

one of the 400,500,600hour according to the tap water quality. Press the “Stop/” keypad to confirms the

setting and switches to the next menu level.

Select alarm time UV lamp failure

13

UVUV lifelife

PFPF lifelife UFUF lifelife

FeedFeed

RORO

DSDS

UVUV

lifelife : 6000h6000h 8000h8000h

4000h4000h

In this menu level the maintenance interval for the UV oxidator of main system must be reset after

exchanging the UV lamp. the manufacture setting is 4000hour for UV lamp life time, the user can press

“Disp./▲,Flush/▼” keypad to select one of the 4000,5000,6000,hour according to the user desire. Press

the “Stop/” keypad to confirms the setting and switches to the next menu level.

Micro-filter failure time alarm options

UVUV lifelife

PFPF lifelife UFUF lifelife

FeedFeed

RORO

DSDS

UFUF

lifelife : 6000h6000h 8000h8000h

4000h4000h

In this menu level the maintenance interval for the Micro-filter Cartridge life time of main system

must be reset after exchanging the cartridge. the manufacture setting is 4000hour for Micro-filter

Cartridge life time, the user can press “Disp./▲,Flush/▼” keypad to select one of the 4000,5000,6000

hour according to the user de sire. Press the “Stop/” keypad to confirms the setting and switches to the

next menu level.

Feed water quality alarm setting

PFPF lifelife UFUF lifelife RORO

DSDS

FeedFeed WaterWater

Alarm-HAlarm-H :

UVUV lifelife

μs/cmμs/cm

400400

FeedFeed

The limit of the feed tap water conductivity can be adjusted by the user. If the adjusted limit will be

overstepped it will decrease the life time of Pre-treatment cartridge, RO membrane and purification

cartridge. the manufacture setting is 400us/cm, the user can press “Disp./▲,Flush/▼” keypad to

adjusting according to the user desire. Press the “Stop/” keypad to confirms the setting and switches to

the next menu level.

When setting the value, please refer to the actual water quality. Only to eliminate the alarm for

feed water. If the feed water quality is poor, the overall performance and lifetime of each

module will be affected.

Pure water quality alarm settings

PFPF lifelife UFUF lifelife

FeedFeed DSDS

RORO

Alarm-HAlarm-H :

UVUV lifelife

μs/cμs/c

RORO

20.020.0

The limit of the RO water conductivity can be adjusted by the user. if the adjusted limit will be

overstepped it will decrease the life time of purification cartridge. the manufacture setting is 20us/cm, the

user can press “Disp./▲,Flush/▼” keypad to adjusting according to the user desire. Press the “Stop/”

keypad to confirms the setting and switches to the next menu level

If this value is set too large, then the performance and lifetime of the ultrapure water purification

cartridge will be affected.

Alarm settings for reverse osmosis desalting rate

PFPF lifelife UFUF lifelife

FeedFeed

RORO

DSDS

Alarm-LAlarm-L :

UVUV lifelife

%

DSDS

9090

The limit of the desalting rate of the RO membrane can be adjusted by the user. The display of the

14

system shows the alarm message “Ds light” if the adjusted limit will be overstepped (manufacture’s

setting is 90%). press “Disp./▲,Flush/▼”keypad to increases or decreases the value, press the Stop/”

keypad to confirm the setting and switches to the next menu level.

This value should not be set too low, otherwise the pure water quality will be affected. If the quality

of inlet water is too poor, Please set high value for higher pure water requirement. Value setting range:

50 to 99.

5.6.2 Calendar setting

After entering the parameter setting menu, press “Disp./▲” or “Flush/▼”keypad to select the

"Calendar" function.

CalenderCalender

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

In this menu level the user want to change the timer in maim system ,you can be press the

“Disp./▲,Flush/▼”keypad to set the correct date and time according to the mention of the display. Press

the “Stop /” keypad to confirms the setting and switches to the next menu level.

YearYear

MonthMonth

9

HourHour

1212 MinuteMinute

3030

DateDate

2020

20162016

YearYear

20162016

5.6.3 Volume of taking product water setting

After entering the parameter setting menu , press “Disp./▲” or “Flush/▼”keypad to select the

"Volume of water" function.

VolumeVolume ofof waterwater

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

Press "Stop / " keypad to enter the volume of taking water setting interface.

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

Volume:Volume: OFFOFF

In this menu level the user can be adjusted fixed quantity of take water from 0.1L to 25L, or No

limit(off) , the manufacture setting is No limit(OFF), the user can press “Disp./▲,Flush/▼” keypad to

adjusting according to the user desire. Press the “Stop/” keypad to confirms the setting and switches to

the next menu level

5.6.4 Dispensing flow setting

By setting this parameter, user can calibration the accuracy of fixed quantity of taking water such as

1L or 5L.

After entering the parameter setting menu ,Press the “Disp./▲”or “Flush/▼”keypad to select the

"Dispense flow" function.

DispensingDispensing flowflow

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

Press the “Stop/” keypad to confirms the setting and switches to the next menu level.

15

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

DispensingDispensing

flowflow : L/mL/m

1.501.50

Note: Suggestion the user had batter to calibrating fixed quantity every half month.

5.6.5 Ultra-pure water quality setting

After entering the parameter setting menu according to this chapter, press “Disp./▲”or

“Flush/▼”keypad to select the "Prod. Resis." function.

ProductProduct resistivityresistivity

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

Press “Stop/”keypad to enter the water quality parameters setting interface.

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

Prod.Prod.

Resis.Resis. : MΩMΩ·cmcm

16.016.0

The limit of the resistivity of the ultra pure water from purification cartridge can be adjusted by the

user. the manufacture setting is 16.00MΩ.cm, if the resistivity of product water is lower than limit ,the

product water will be recycling in main system , the product water ‘s resistivity of user’ taken is higher

than the limit. the user can press “Disp./▲,Flush/▼” keypad to adjusting according to the user desire.

Press the “Stop/” keypad to confirms the setting and switches to the next menu level.

5.6.6 Unit selection

By setting this parameter, user can choose to the unit form of the ultrapure water, MΩ.cm or μS/cm.

After entering the parameter setting menu according to this chapter, press “Disp./▲”or

“Flush/▼”keypad to select the "Prod. Unit." function.

ProductProduct unitunit

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

Press "Stop / " button to confirm the unit selection interface.

AlarmAlarm

settingsetting CalenderCalender Prod.Prod.

unitunit

VolumeVolume

ofof waterwater Prod.Prod.

Resis.Resis. Disp.Disp.

flowflow

Prod.Prod.

unitunit : μs/cmμs/cm

MΩ·cmcm

In this menu level the user can select the display unit of product water , the user can press

“Disp./▲,Flush/▼” keypad to selecting one of “MΩ.cm” “or us/cm” according to the user desire. Press

the “Stop/Enter” keypad to confirms the setting and switches to the next menu level.

Table of contents

Other Heal Force Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Pentair

Pentair EZ-RO 200/2G-BL Installation & operation guide

PureEffect

PureEffect ULTRA-WHW installation instructions

Simple Water Service

Simple Water Service 7QCRO Installation, operation & service

Weller

Weller Zero Smog TL Translation of the original instructions

Sterling

Sterling OXY3 Series Installation instructions and owner's manual

AAF

AAF TM4 Installation, operation and maintanance instructions