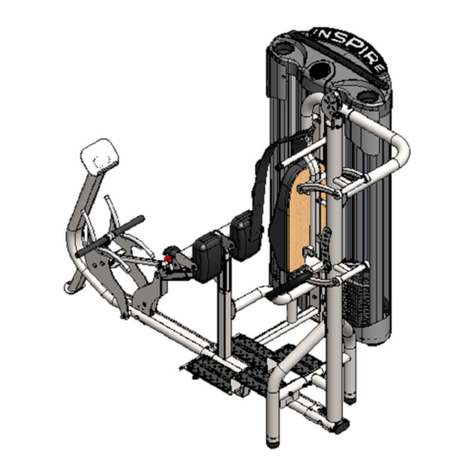

Health in motion INSPIRE Supplement

CONGRATULATIONS… You’ve just taken the first step to a healthier

and stronger body. This Dual Leg Extension/Curl machine by Inspire offers

the key to unlocking your body’s potential. Regular strength training on a

multi-gym has been shown to deliver a host of benefits including: increased

muscle tone, decreased body fat, improved energy levels, a reduction in

stress, and improved cardiac output. Once again, congratulations, you are

on your way to improving your self image, overall health, and quality of life.

BEFORE ASSEMBLING YOUR LEG EXTENSION/CURL

IMPORTANT: Read this entire manual before attempting to build or use

this Dual Leg Extension/Curl machine. This manual contains step by step

instructions for proper assembly.

Use the parts list included in this manual to verify that all parts are

accounted for before assembly. If any parts are missing, contact the dealer

of this Dual Leg Extension/Curl machine for replacement parts or call

Inspire at 877-738-1729.

Make sure that adequate room has been cleared before attempting to build

your Dual Leg Extension/Curl machine. A rubber mat is recommended for

use under your Dual Leg Extension/Curl machine to protect wood flooring or

carpeting from damage during assembly and usage. In a multi-use setting

or commercial setting, it is recommended that the machine be bolted to the

floor through the holes in the base plates.

This Dual Leg Extension/Curl machine is intended for indoor use only. Rust

can form on certain parts in a humid environment resulting in impaired

function.

Service of your Dual Leg Extension/Curl machine should only be preformed

by an authorized Inspire dealer. Service preformed by anyone else can

result in loss of warranty. If you need help finding an authorized dealer,

please contact us directly:

Inspire Fitness

255 Airport Circle

Suite 101

Corona, CA 92880

Ph: 877-738-1729

Fx: 714-738-1728

www.inspirefitness.com

TABLE OF CONTENTS

Section Description……………………………………………………. Page

Important Safety Instructions………………………………………. 1

Tools Required………………………………………………………………… 1

Parts & Hardware List……………………………………………………. 2

Cable Charts…………….……………………………………………………. 3

Assembly Instructions……………………………………………………. 5

Decal Reference……………………………………………………………… 25

Decal Placement…………………………………………………………….. 27

Training Tips…………………………………………………………………… 28

Maintenance Schedule…….……………………………………………… 30

Limited Warranty…………………………………………………………….. 31

Page 1

IMPORTANT SAFETY INSTRUCTIONS

Please read this entire manual and familiarize yourself with all decals and

warnings before using this Dual Leg Extension/Curl machine.

• WARNING! It is necessary to inspect this Dual Leg Extension/Curl

machine regularly to maintain safety and proper function. Please use the

maintenance schedule included towards the back of this manual.

Immediately replace any and all defective or worn parts. Pay special

attention to moving parts such as the cables and pulleys and connections

to accessories. See General Maintenance section for complete details.

• Use this Dual Leg Extension/Curl machine for its intended purpose as

described in this Operation Manual or the Exercise Book. Do not use

attachments not recommended by the manufacturer.

• Make sure bystanders are at least 5 feet away from the Dual Leg

Extension/Curl machine while it is in use.

• Keep children off the Dual Leg Extension/Curl machine at all times.

• Keep the Dual Leg Extension/Curl machine away from walls and clear of

any obstructions.

• Stop immediately if you experience shortness of breath, pain, or dizziness

during your workout. Inspire strongly recommends consulting your

doctor before starting an exercise program.

TOOLS REQUIRED FOR ASSEMBLY

• Metric socket set (including 16mm, 17mm, 18mm, and 19mm sockets)

• Metric wrenches (16mm, 17mm, 18mm, and 19mm)

• 4mm, 5mm, and 6mm Allen wrenches (supplied in hardware pack)

• Adjustable wrench

• Philips screwdriver

Page 2

Item Parts Description Qty Qty Rec'd Item Hardware Description Qty Qty Rec'd

1Main Frame 1 1 M10 x 25 Hex Bolt 9

2Guide Cable Support 1 2 M10 x 95 Hex Bolt 2

3Upright 1 1 3 M10 x 75 Hex Bolt 6

4Base Frame 1 4 M10 x 65 Hex Bolt 8

5Left Pivot Frame 1 5 M10 x 70 Hex Bolt 8

6Right Pivot Frame 1 6 M10 x 125 Hex Bolt 3

7Brace 1 7 M10 x 50 Threaded Hex Bolt 3

8Seat Frame 1 8 M10 x 100 Hex Bolt 4

9Right Handle 1 9 M10 x 90 Hex Bolt 4

10 Left Handle 110 M8 x 20 Hex Bolt 2

11 Top Weight/Selector Stem 211 M12 x 135 Hex Bolt 1

12 Rubber Donut 412 M10 x 85 Hex Bolt 2

13 Top Weight Stop Assembly 213 M8 x 40 Hex Bolt 8

14 Guide Rods 414 M10 x 20 Flat Head Screw 2

15 Upper Pulley Mount, Left 115 M8 Cap Screw 4

16 Upper Pulley Mount, Right 116 M10 x 50 Hex Bolt 9

17 Back Attachment Frame 117 M10 x 70 Flat Head Bolt 1

18 Seat Frame Extension 118 M8 x 100 Hex Bolt 1

19 Cam 419 M10 x 25 Button Head Bolt 3

20 L/R Pivot Arm 220 M6 x 12 Button Head Bolt 10

21 Selector Plate 221 M8 x 12 Button Head Bolt 7

22 Pulley Cover Plate 2

23 Cable Connector 222 M10 Flat Washer 105

24 Head Pad 123 Plastic Washer 4

25 Back Pad 124 Oilite Bushing 4

26 Thigh Pad 125 M12 Bushing 2

27 Seat Pad 126 M8 Flat Washer 27

28 Rear Shroud Plate Support 127 Shim Washer 2

29 Metal Shroud Placard Left 128 1/2" Long Step Bushing 2

30 Metal Shroud Placard Right 129 M6 Flat Washer 10

31 Left Metal Shroud Plate 130 M10 Large OD Flat Washer 2

32 Right Metal Shroud Plate 131 M12 Flat Washer 2

33 Upper Metal Shroud 132 Wave Washer 2

34 Lower Metal Shroud 1

35 Fabric Shroud 133 M12 Locknut 1

36 Rubber Cup 234 M10 Locknut 46

37 Rubber Tablet Holder 135 M8 Locknut 9

38 Molded Top Cap 136 Rectangular Key 2

39 Guide Rod Lube 137 Cable End 2

40 Touch-up Paint 138 Shaft Collar 2

39 Aluminum Endcap 2

41 3 1/2" Pulley 640 Weight Pin 2

41 4 mm Allen Wrench 1

42 5 mm Allen Wrench 1

43 6 mm Wrench 1

DUAL LEG EXTENSION/CURL PARTS & HARDWARE LIST

Page 3

Page 4

ASSEMBLY INSTRUCTIONS

Page 5

Step 1: Attach Upright 1 to the Main Frame using: 2 - M10 x 25 Hex Bolts

2 - M10 x 95 Hex Bolts

6 - M10 Flat Washers

2 - M10 Locknuts

NOTE: Wrench Tighten Now.

Step 2: Attach Guide Cable Support to Main Frame

and Upright 1 using: 4 - M10 x 75 Hex Bolts

8 - M10 Flat Washers

4 - M10 Locknuts

NOTE: Finger Tighten Only.

4 - M10 x 75 Hex Bolts

8 - M10 Flat Washers

4 - M10 Locknuts

Step 2

Step 1

2 - M10 x 25 Hex Bolts

2 - M10 x 95 Hex Bolts

6 - M10 Flat Washers

2 - M10 Locknuts

Main Frame

Upright 1

Guide Cable

Support

Page 6

Step 3: Attach the Base Frame to Upright 1 using: 2 - M10 x 125 Hex Bolts

4 - M10 Flat Washers

2 - M10 Locknuts

NOTE: Finger Tighten Only.

Step 4: Attach the Left Pivot Frame to the Base Frame using: 3 - M10 x 65 Hex Bolts

6 - M10 Flat Washers

3 - M10 Locknuts

NOTE: Finger Tighten Only.

2- M10 x 125 Hex Bolts

4- M10 Flat Washers

2- M10 locknuts

Step 3

Base Frame

Upright 1

Step 4

3 - M10 x65 Hex Bolts

6 - M10 Flat Washers

3 - M10 locknuts

Left Pivot Frame

Page 7

Step 5: Attach the Right Pivot Frame to Base Frame

and Brace to Upright 1 using: 3 - M10 x 65 Hex Bolts

1 - M10 x 70 Hex Bolts

8 - M10 Flat Washers

4 - M10 Locknuts

NOTE: Finger Tighten Only.

Step 6: Attach Seat Frame to Base Frame using: 4 - M10 x 25 Hex Bolts

8 - M10 Flat Washers

4 - M10 Locknuts

NOTE: Finger Tighten Only.

3 - M10 x65 Hex Bolts

1 - M10 x70 Hex Bolts

8 - M10 Flat Washers

4 - M10 locknuts

Step 5

Base Frame

Upright 1

Step 6

4 - M10 x25 Hex Bolts

8 - M10 Flat Washers

4 - M10 locknuts

Seat Frame

Brace

Right Pivot

Frame

Page 8

Step 7: Attach Left Handle and Right Handle to

Seat Frame using: 3 - M10 x 125 Hex Bolts

6 - M10 Flat Washers

3 - M10 Locknuts

NOTE: Finger Tighten Only.

Step 8: Attach Left Handle and Right Handle to

Seat Frame using: 4 - M10 x 100 Hex Bolts

8 - M10 Flat Washers

4 - M10 Locknuts

NOTE: Wrench Tighten Steps 2 –8 Now.

3 - M10 x 125 Hex Bolt

6 - M10 Flat Washer

3 - M10 locknuts

Step 7

Left Handle

Seat Frame

Right Handle

Step 8

4- M10 x 100 Hex Bolt

8 - M10 Flat Washer

4 - M10 locknuts

Page 9

Step 9: Insert two Guide Rods into the holes in the bottom tube of the Main Frame. Carefully tilt the

Guide Rods back away from the machine. Slide one Rubber Donut into each guide Rod. Slide ten

Weight Plates onto the Guide Rods. Make sure the recessed area on the front of the weight plate

is facing towards the front of the machine. Slide Top Weight/Selector Stem onto the Guide Rods.

Slide the Top Weight Stop Assembly onto the Guide Rods making sure the rubber pad is facing

down. Attach the Upper Pulley Mount, Top Weight Stop Assembly, and Guide Rods to the Main

Frame Using:

1 - M10 x 75 Hex Bolt

2 - M10 x 90 Hex Bolts

6 - M10 Flat Washers

3 - M10 Locknuts

NOTE: Finger Tighten Only. 1 - M8 x 20 Hex Bolt

1 - M8 Flat Washer

Step 9

M8 x 20 Hex Bolt

1 - M10 x 75 Hex Bolt

2 - M10 x 90 Hex Bolts

6 - M10 Flat Washers

3 - M10 Locknuts

1 - M8 x 20 Hex Bolt

1 - M8 Flat Washer

Guide Rods

Upper Pulley

Mount, Left

Weight

Plates

Rubber

Donuts

Top Weight/Selector Stem

Top Weight

Stop Assembly

Main Frame

Bottom of weight

plate has three feet

Front of weight plate has recessed

area for the number sticker

Page 10

Step 10: Insert two Guide Rods into the holes in the bottom tube of the Main Frame. Carefully tilt the

Guide Rods back away from the machine. Slide one Rubber Donut into each guide Rod. Slide ten

Weight Plates onto the Guide Rods. Make sure the recessed area on the front of the weight plate

is facing towards the front of the machine. Slide Top Weight/Selector Stem onto the Guide Rods.

Slide the Top Weight Stop Assembly onto the Guide Rods making sure the rubber pad is facing

down. Attach the Right Upper Pulley Mount, Top Weight Stop Assembly, and Guide Rods to the

Main Frame Using:

1 - M10 x 75 Hex Bolt

2 - M10 x 90 Hex Bolts

6 - M10 Flat Washers

3 - M10 Locknuts

NOTE: Finger Tighten Only. 1 - M8 x 20 Hex Bolt

1 - M8 Flat Washer

Step 10

M8 x 20 Hex Bolt

1 - M10 x 75 Hex Bolt

2 - M10 x 90 Hex Bolts

6 - M10 Flat Washers

3 - M10 Locknuts

1 - M8 x 20 Hex Bolt

1 - M8 Flat Washer

Upper Pulley

Mount, Right

Top Weight

Stop Assembly

Main Frame

Guide Rods

Weight

Plates

Rubber

Donuts

Top Weight/

Selector Stem

Bottom of weight

plate has three feet

Front of weight plate has recessed

area for the number sticker

Page 11

Step 11: Attach Back Adjustment Frame to

Seat Frame using: 1 - M12 x 135 Hex Bolts

2 –M12 Bushing

2 - M12 Flat Washers

1 - M12 Locknuts

NOTE: Wrench Tighten Now.

Step 12: Attach Seat Frame Extension to

Seat Frame using: 2 - M10 x 25 Hex Bolts

2 - M10 x 85 Hex Bolts

8 - M10 Flat Washers

4 - M10 Locknuts

NOTE: Wrench Tighten Now.

1 - M12 x 135 Hex Bolt

2- M12 Bushings

2 - M12 Flat Washer

1 - M12 locknut

Step 11

Seat Frame

Back Attachment Frame

Step 12

2 - M10 x 25 Hex Bolt

2 - M10 x 85 Hex Bolt

8 - M10 Flat Washer

4 - M10 locknuts

Seat Frame

Extension

Page 12

Step 13: Attach Cams to Both Left and Right

Pivot Arm using: 8 – M8 x 40 Hex Bolts

16 – M8 Flat Washers

8 – M8 Locknuts

NOTE: Wrench Tighten Now.

Step 14: Attach Left Pivot Arm to Left Pivot Frame and

Right Pivot Arm to Right Pivot Frame.

8 - M8 x 40 Hex Bolt

16 - M8 Flat Washer

8 - M8 locknuts

Step 13

L/R Pivot Arm

Cam

Right Pivot Frame

Left Pivot Frame

Step 14

Page 13

Step 15: First, slide the Shim Washer onto the shaft against the bearing, then insert the Rectangular Key

into the slot in the Shaft as shown. Loosen the Cap Screws on the Shaft Collar so that the

Selector Plate can slide over the Shaft of the Right Pivot Arm. Align the keyway in the Shaft

Collar with the rectangular key and push the Selector Plate against the Shim Washer. Slide Wave

Washer onto Shaft, then the Right Arm Assembly. Attach the Aluminum Endcap to the shaft with

the M10 x 20 Flat Head Screw. Finally, reattach the bottom half of the Shaft Collar with the M6

Cap Screws. Tighten both screws evenly and tightly. There will be a small gap between the two

halves of the Shaft Collar when fully tightened.

1 - M10 x 20 Flat Head Screw

1 – Aluminum Endcap

1 – Rectangular Key

1 - Wave Washer

1 – Shim Washer

2 – M8 Cap Screws

NOTE: Wrench Tighten Now.

1 - M10 x20 Flat Head Screw

1 - Aluminum Endcap

1 - Rectangular Key

1- Wave Washer

1 - Shim Washer

2 – M8 Cap Screws

Step 15

Right Pivot Handle

Right Pivot Arm

Rectangular Key

Shim

Washer

Wave

Washer

Selector Plate

Cap Screws

Right Arm

Assembly

Shaft Collar

Keyway in

Shaft Collar

Page 14

Step 16: First, slide the Shim Washer onto the shaft against the bearing, then insert the Rectangular Key

into the slot in the Shaft as shown. Loosen the Cap Screws on the Shaft Collar so that the

Selector Plate can slide over the Shaft of the Left Pivot Arm. Align the keyway in the Shaft Collar

with the rectangular key and push the Selector Plate against the Shim Washer. Slide Wave

Washer onto Shaft, then the Left Arm Assembly. Attach the Aluminum Endcap to the shaft with

the M10 x 20 Flat Head Screw. Finally, reattach the bottom half of the Shaft Collar with the M6

Cap Screws. Tighten both screws evenly and tightly. There will be a small gap between the two

halves of the Shaft Collar when fully tightened.

1 - M10 x 20 Flat Head Screw

1 - Aluminum Endcap

1 - Rectangular Key

1 - Wave Washers

1 - Shim Washer

NOTE: Wrench Tighten Now. 2 – M8 Cap Screws

1 - M10 x20 Flat Head Screw

1 - Aluminum Endcap

1 - Rectangular Key

1- Wave Washer

1 - Shim Washer

2 – M8 Cap Screws

Step 16

Left Pivot Handle

Left Pivot Arm

Rectangular Key

Shim

Washer

Wave

Washer

Selector Plate

Shaft Collar

Cap Screws

Keyway in

Shaft Collar

Left Arm

Assembly

Page 15

Step 17: Route end of Weight Stack Cable up and over Pulley 1, then over and down Pulley 2. Attach the

Slotted Cable Bolt to the end of the cable, screw on Jam Nut, and thread the Cable Bolt

completely into the Selector Stem. Fully tighten the Jam Nut now. Next, thread the Right

Arm Cable Bolt with Jam Nut into the Cable Connector five turns so you can see the bolt through

the inspect holes in the Cable Connector. Fully tighten the Jam Nut now. Route Cable down

under Pulley 3, through the Base Frame to the first opening in the tube. Carefully pull the cable

out of the Base tube towards Pulley 5. Feed the Cable around Pulley 5 and attached the Cable

End, Oilite Step Bushings, Plastic Washers to Right Pivot Arm using one M10 x 50 Hex bolt, two

M10 Flat Washers, and one M10 Locknut. Be sure the Cable is in the Pulley groove between the

Pulley 5 and the cable retainer tab on the bottom of the bracket. Attach the Special Pulleys 6 &

7 and Pulley Cover Plate to the Right Pivot Frame using two M10 x 50 Hex Bolts, four M10 Flat

Washers, and two M10 Locknuts.

Note: Be sure the Cable is in-between the grooves of the two Special Pulleys 6 & 7.

3 - M10 x 50 Hex Bolt 3 - M10 Locknut 2 - Oilite Bushings

6 - M10 Flat Washers 1 - Cable End 2 - Plastic Washers

Step 18: Install Pulley 4 into Base Frame using:

1 - M10 x 50 Hex Bolt 2 - M10 Flat Washers 1 - M10 Locknut.

1 - M10 x50 Hex Bolt

2- M10 Flat Washer

1- M10 Locknut

3 - M10 x 50 Hex Bolt

6 - M10 Flat Washer

3 - M10 Locknut

1 - Cable End

2 - Oilite Bushings

2 - Plastic Washers

Step 17

Step 18

Thread bolt completely into selector

stem and tighten jam nut

Selector Stem

Cable

Jam Nut

Right Upper

Pulley Mount

Pulley 3

Pulley 5

Right Pivot

Arm

Pulley 2

Pulley 1

Pulleys 6 & 7

Pulley Cover Plate

Pulley 4

Right Pivot Frame

Plastic

Washer

Oilite Bushing

Inspect Hole

Right Arm Cable

Weight

Cable

Page 16

Step 19: Route end of Weight Stack Cable up and over Pulley 8, then over and down Pulley 9. Attach the

Slotted Cable Bolt to the end of the cable, screw on Jam Nut, and thread the Cable Bolt

completely into the Selector Stem. Fully tighten the Jam Nut now. Next, thread the Left Arm

Cable Bolt with Jam Nut into the Cable Connector five turns so you can see the bolt through the

inspect holes in the Cable Connector. Fully tighten the Jam Nut now. Route Cable down under

Pulley 10, through the Base Frame to the first opening in the tube. Carefully pull the cable out of

the Base Frame towards Pulley 12.Feed the Cable around Pulley 12 and attached the Cable End,

Oilite Step Bushings, Plastic Washers to Left Pivot Arm using one M10 x 50 Hex bolt, two M10

Flat Washers, and one M10 Locknut. Be sure the Cable is in the Pulley groove between the

Pulley 12 and the cable retainer tab on the bottom of the bracket. Attach the Special Pulleys 13

& 14 and Pulley Cover Plate to the Left Pivot Frame using two M10 x 50 Hex Bolts, four M10 Flat

Washers, and two M10 Locknuts.

Note: Be sure the Cable is in-between the grooves of the two Special Pulleys 13 & 14.

3 - M10 x 50 Hex Bolt 3 - M10 Locknut 2 - Oilite Bushings

6 - M10 Flat Washers 1 - Cable End 2 - Plastic Washers

Step 20: Install Pulley 11 in Base Frame and Cable Retainer Bolts to Base Frame using:

1 - M10 x 70 Hex Bolt 2 - M10 x 65 Hex Bolt 4 - M10 Flat Washer

2 – ½” long Step Bushings 3 - M10 Locknut

3 - M10 x 50 Hex Bolt

4 - M10 Flat Washer

3 - M10 Locknut

1 - Cable End

2 - Oilite Bushings

2 - Plastic Washers

Step 19

Step 20

1 - M10 x 70 Hex Bolt

2 - M10 x 65 Hex Bolt

4 - M10 Flat Washer

2 - 1/2" long Step Bushings

3- M10 Locknut

Thread bolt completely into selector

stem and tighten jam nut

Selector Stem

Cable

Jam Nut

Left Upper Pulley Mount

Base Frame

Left Pivot Frame

Pulley 9

Pulley 8

Inspection

Hole

Left Pivot Arm

Pulley 10

Pulley 12

Pulley 11

Pulley 13 & 14

Left Arm Cable

Weight

Cable

Page 17

Step 21: Attach Head pad to Back pad Adjustment

Frame using: 1 - M10 x 70 Hex Bolt

1 – M10 x 70 Flat Head Bolt

1 – M10 Flat Washer

NOTE: Wrench Tighten Now.

Step 22: Attach Back pad to Back pad Adjustment

Frame using: 1 - M10 x 70 Hex Bolt

1 – M10 x 25 Hex Bolt

2 – M10 Flat Washer

NOTE: Wrench Tighten Now.

1 - M10 x 70 Hex Bolt

1- M10 x 70 Flat Head Bolt

1- M10 Flat Washer

Step 21

Head Pad

Back Pad Adjustment Frame

Back Pad

Step 22

1 - M10 x 70 Hex Bolt

1 - M10 x 25 Hex Bolt

2 - M10 Flat Washer

Table of contents

Other Health in motion Fitness Equipment manuals