Healthy Climate Solutions HCC-14-23 User manual

IAQ - AIR FILTRATION

508028-01

12/2019

Supersedes 505,132M

HEALTHY CLIMATE®

MEDIA AIR CLEANER

INSTALLATION INSTRUCTIONS AND HOMEOWNER GUIDE FOR HEALTHY CLIMATE®

CABINETS MODELS HCC-14-23, HCC16-28, AND HCC20-28

THIS MANUAL MUST BE LEFT WITH THE OWNER

FOR FUTURE REFERENCE

Shipping and Packing List

Package 1 of 1 contains:

2 - Side panels

2 - Side rails

1 - Front panel

1 - Rear panel

1 - Door

8 - #8 screws

1 - Installation instructions

1 - Lennox logo label

1 - Warranty sheet

CAUTION

Sharp Edges Hazard.

Equipment sharp edges can cause injuries.

Use protective gloves when grasping equipment edges.

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury

or loss of life.

Installation and service must be performed by a licensed

professional HVAC installer (or equivalent) or a service

agency.

CAUTION

Risk of equipment damage and/or high energy usage.

Dirty air lters will cause high energy usage and/or

damage to the ventilation system.

Replace lters at recommended intervals.

General Information

The Healthy Climate®Media Air Cleaner is a cabinet with

electrostatically charged lter media to remove airborne

particles. Particle removal efciency increases as the Mini-

mum Efciency Reporting Value (MERV)* rating increases.

The highest removal efciency is seen when the Healthy

Climate Media Air Cleaners are equipped with Healthy

Climate Carbon Clean 16 MERV 16 lters. Unlike other

high efciency air cleaners, the Healthy Climate Media Air

Cleaners do not require any power source to operate.

The Healthy Climate®cabinet is shipped compact, and re-

quires minimal assembly. The cabinet can be installed on

the furnace/air handler horizontally, or vertically, at the top,

or at the bottom, depending on the application (see Page 4

for application diagrams). Healthy Climate®Media Filter will

last up to one year depending on conditions in the home.

The Healthy Climate Media Air Cleaner comes in three siz-

es (HCC14-23, HCC16-28 and HCC20-28).

The HCC14-23 cabinet is designed to house the following

lters:

• HCF14-11

• HCXF14-11

• HCF14-13

• HCF14-16

• HCXF14-16

2

The HCC16-28 cabinet is designed to house the following

lters:

• HCF16-11

• HCXF16-11

• HCF16-13

• HCF16-16

• HCXF16-16

The HCC20-28 cabinet is designed to house the following

lters:

• HCF20-11

• HCXF20-11

• HCF20-13

• HCF20-16

• HCXF20-16

Healthy Climate box cabinets and lters (box or expandable

media) are purchased separately.

*MERV rating is determined by testing according to

ASHRAE standard 52.2.

Required Tools

The following tools are required to attach the lter cabinet to

the furnace/air handler:

• Electric drill

• 1/4” (6mm) hex head tool

• Tin snips

• Screwdriver

• Rule/tape measure

• Gloves for sharp edge protection

• Foil tape

Rules for Safe Installation

1. Read this Owners Manual and Rules for Safe Operation

carefully. Failure to follow these rules and instructions

could cause a malfunction of filter or unsatisfactory

service.

2. Follow a regular service and maintenance schedule for

efcient operation.

3. Maximum static weight for cabinet - 400 lbs. (181 kg.)

Dimensions

Table 1. Dimensions - inches (mm)

Model# X Y Y1 Z Z1

HCC14-23 7

(179)

21-1/4

(540)

18-3/4

(476)

23

(584)

18-1/2

(470)

HCC16-28 7

(179)

17-1/4

(438)

14-3/4

(375)

28-1/2

(724)

24

(610)

HCC20-28 7

(179)

21

(533)

18-1/2

(470)

28-1/2

(724)

24

(610)

Dimenions subject to change without notice.

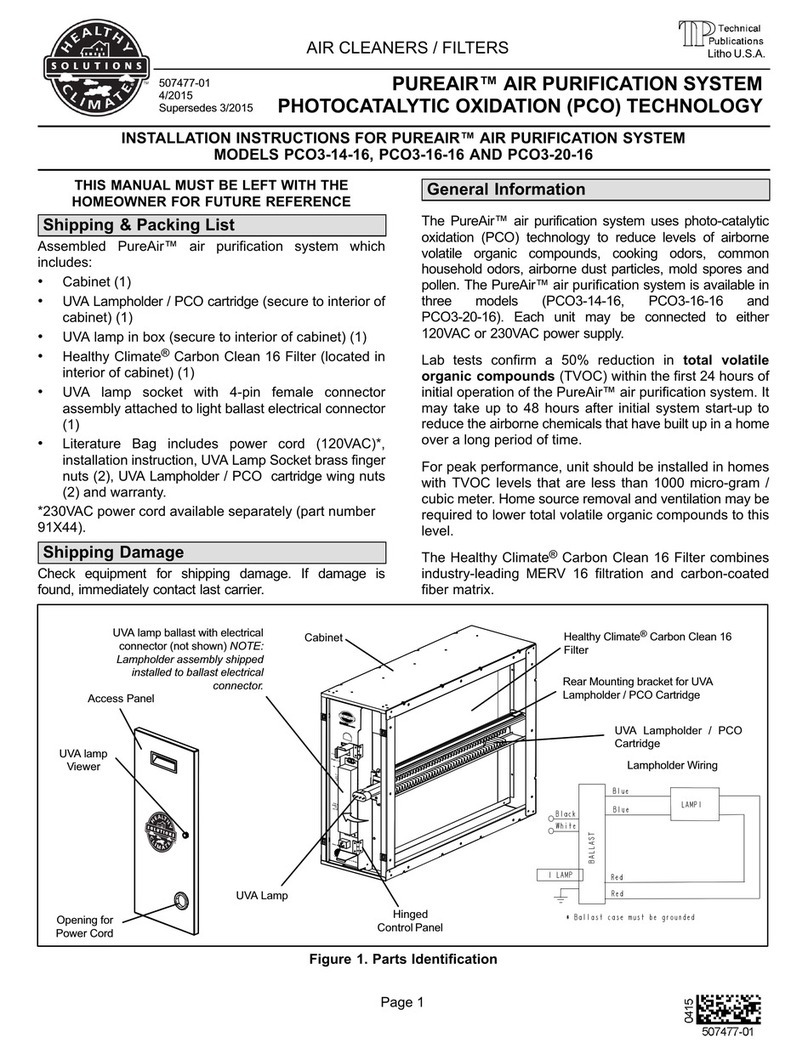

Figure 1. Dimensions

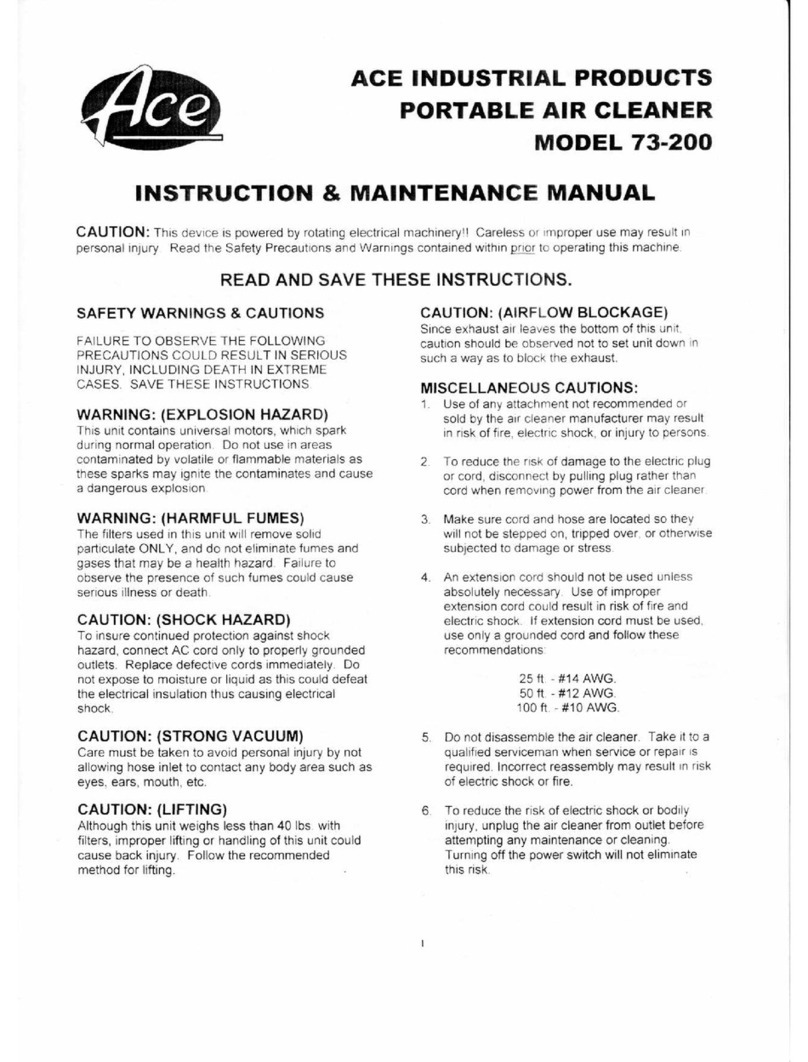

Unpacking

The cabinet must be unpacked and assembled prior to use.

Refer to the following gure to ensure all the necessary

components are included before assembling.

Component List

A 1 - Rear Frame

B 1 - Front Frame

C 1 - Door

D 2 - Side Rail

E 2 - Side Panel

B

C

D

E

A

Figure 2. Unpack

3

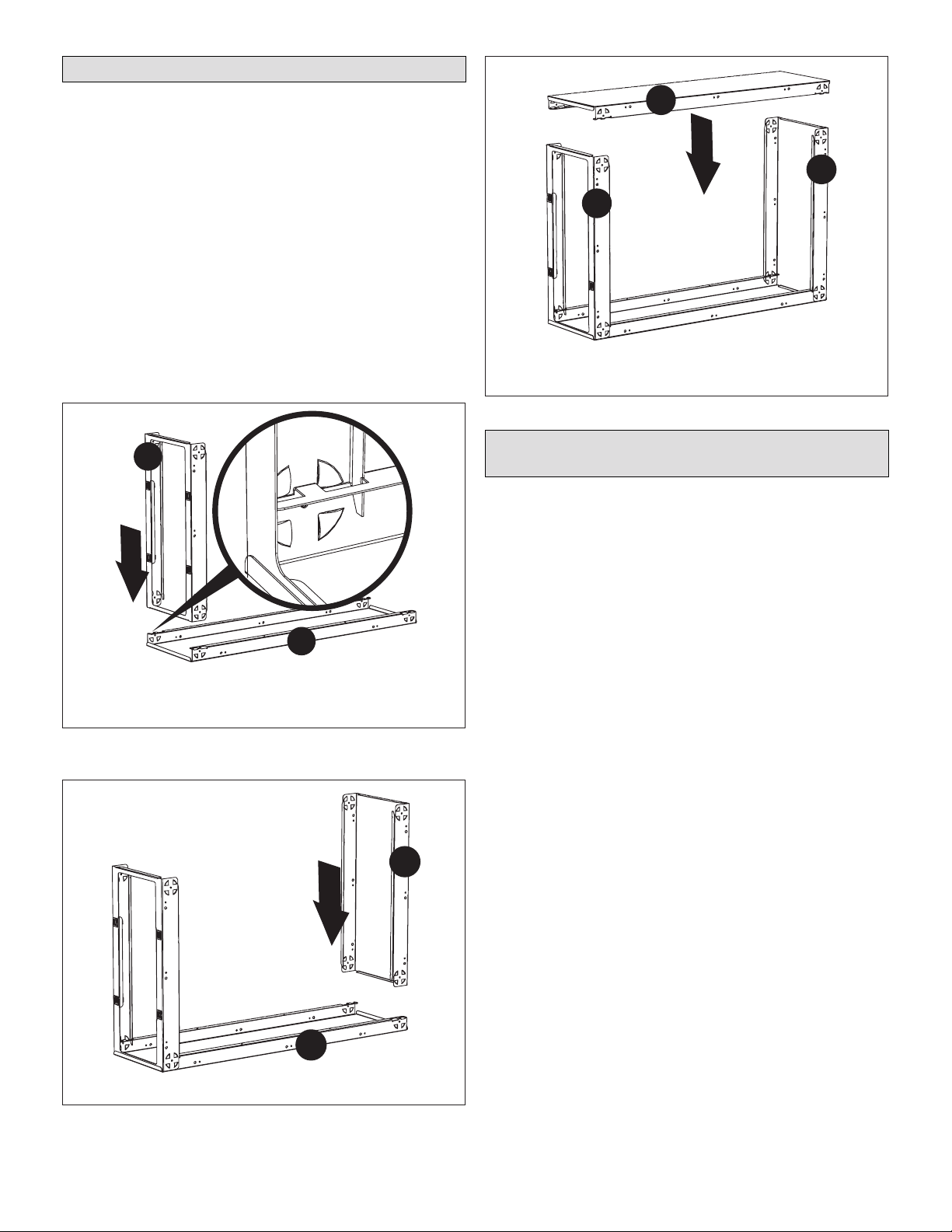

Assembly the Cabinet

The cabinet sections are designed to lock together. Align

the edges as shown in Figure 3 on page 3. It may be

necessary to apply force to snap the tight pieces together.

1. Remove front frame B from door C.

2. Place side panel E on a rm surface. Align and insert

front frame B into one end of side panel E (see fFigure

3 on page 3). Firmly press down until each corner

has snapped into place.

3. Align and insert rear frame A into side panel E (see

Figure 4 on page 3).

4. Align and insert remaining side panel E into front frame

B and rear frame A. Firmly press down until each corner

has snapped into place (see Figure 5 on page 3).

NOTE: Side rails (D) are attached to the cabinet after the

cabinet is installed on the Furnace/Air Handler (see

Figure 13 on page 6).

E

B

Snap front frame B into side panel E. Parts interlock as

shown in detail illustration.

Figure 3. Assemble Front Frame (B) to

Side Panel (E)

E

A

Snap rear frame A into side panel E.

Figure 4. Assemble Rear Frame (A) to

Side Panel (E)

E

B

A

Snap remaining side panel E into front frame B and

rear frame A.

Figure 5. Assemble Remaining Side Panel (E)

Use of Healthy Climate Media Air Cleaner

for Construction Filtration

Healthy Climate Media Air Cleaners may be used for l-

tering heated or cooled air of buildings or structures under

construction if the following conditions are met to ensure

proper operation:

DO NOT USE THE UNIT FOR CONSTRUCTION FILTRA-

TION UNLESS ALL OF THE FOLLOWING CRITERIA

ARE MET:

• Cabinet and furnace or air handler must be in their -

nal location. The vent system must be permanently in-

stalled per these installation instructions.

• Refer to furnace or air handler installation instructions

for any additional construction use criteria. All furnace

or air handler construction use criteria must also be met.

• Supply and return air ducts must be provided and

sealed to the furnace or air handler. Return air must be

terminated outside of the space where the furnace or air

handler is installed.

• Healthy Climate MERV 11 or greater air lters must be

installed in the system and must be regularly inspect-

ed and maintained during construction. Filters must be

changes when operating more than 0.1” WC static pres-

sure over initial static pressure at operating airow.

• Air lters must be replaced upon construction comple-

tion.

FILTER LIFE MAY BE SHORTENED WHEN USED IN

STRUCTURES UNDER CONSTRUCTION. FILTER MUST

BE REPLACED UPON CONSTRUCTION COMPLETION.

EQUIPMENT MAY EXPERIENCE PREMATURE COM-

PONENT FAILURE AS A RESULT OF FAILURE TO FOL-

LOW THE THESE INSTALLATION INSTRUCTIONS.

4

FAILURE TO FOLLOW THIS INSTALLATION INSTRUC-

TIONS VOIDS THE MANUFACTURER’S EQUIPMENT

LIMITED WARRANTY. LENNOX DISCLAIMS ALL LIA-

BILITY IN CONNECTION WITH INSTALLER’S FAILURE

TO FOLLOW THE ABOVE INSTALLATION INSTRUC-

TIONS.

NOTWITHSTANDING THE FOREGOING, INSTALLER IS

RESPONSIBLE FOR CONFIRMING THAT THE USE OF

CONSTRUCTION HEAT OR COOLING IS CONSISTENT

WITH THE POLICIES AND CODES OF ALL REGULAT-

ING ENTITIES.

ALL SUCH POLICIES AND CODES MUST BE ADHERED

TO.

Applications

Up-ow Furnace/Air Handler

Cabinet is installed horizontally beneath the furnace/air

handler. Return air enters from the bottom (see following

gure).

RETURN

DUCT

SUPPLY

DUCT

Figure 6. Up-ow Furnace/Air Handler

Down-ow Furnace/Air Handler

Cabinet is installed horizontally in the return air duct just

bove the furnace/air handler.

RETURN

DUCT

SUPPLY

DUCT

Figure 7. Down-ow Furnace/Air Handler

Up-ow Furnace (up to 4 ton application)

Cabinet is installed vertically and return air enters the fur-

nace side inlet.

RETURN

DUCT

SUPPLY

DUCT

Figure 8. Up-ow Furnace (up to 4 ton)

5

Up-ow Furnace (5-ton application)

Option 1—Install Return air base, part numbers 98M60,

98M58. HCC20-28 Cabinet is installed vertically and return

air enters the furnace side inlet.

RETURN

DUCT

SUPPLY

DUCT

OPTIONAL

RETURN

AIR BASE

Figure 9. Up-ow Furnace (5 ton, Option 1)

Option 2—Over cut top edge of side return opening by 1”

to 15” x 23”. HCC20-28 Cabinet is installed vertically and

return air enters the furnace side inlet.

OVERCUT TOP

EDGE BY 1”

15”

23”

Figure 10. Up-ow Furnace (5 ton, Option 2)

Horizontal Furnace/Air Handler

Cabinet is installed vertically in the return air duct near the

furnace/air handler.

RETURN DUCT

SUPPLY DUCT

Figure 11. Horizontal Furnace/Air Handler

Installation

Cabinet Installation

The following is a typical installation of the cabinet with an

up-ow furnace (see Figure 8 on page 4).

1. Position the cabinet alongside the furnace with the

access door opening facing outward.

2. Align the cabinet opening with the opening on the

furnace. (For 5 ton application, use option 1 or 2 [see

Figure 9 on page 5 and Figure 10 on page 5).

3. Secure the cabinet to the furnace using sheet metal

screws in the pre-drilled cabinet mounting holes (see

gure 12).

4. Use a butt joint to attach the duct to the upstream side

of the cabinet.

NOTE: If necessary, use sheet metal turning vanes to

improve air movement through an elbow in the duct.

5. Connect the next section of the duct. If necessary, use

a properly sized wooden block to support a duct elbow.

6. Use foil tape to seal all duct joints. This prevents dust

from entering the air stream.

7. Insert side rails (D) into the cabinet and use the provided

screws to secure them to the cabinet at both the top and

bottom (see gure 13).

8. Slide the lter into the rail and secure the cabinet door

(see gure 14).

WARNING

Risk of Carbon Monoxide

poisoning.

Can cause injury or death.

Do not operate without Filter

Cabinet door in place. Operation

of this equipment without the

Filter Cabinet door in place may

cause exhaust fumes to be drawn

into occupied spaces.

CABINET

FURNACE

RETURN

DUCT

Figure 12. Attach Cabinet to Furnace and Duct

6

Insert two side rails (D) into cabinet and secure with provided

screws to top and bottom of cabinet.

CABINET

FURNACE

RETURN

DUCT

SIDE

RAILS

Figure 13. Install Side Rails

FILTER

DUCT

DOOR

Figure 14. Insert Filter and Attach Door

This manual suits for next models

2

Table of contents

Other Healthy Climate Solutions Air Cleaner manuals