Heartland GENTRY GABLE VALUE Series User manual

Other Heartland Garden House manuals

Popular Garden House manuals by other brands

Mercia Garden Products

Mercia Garden Products 0628LOG181-V4 manual

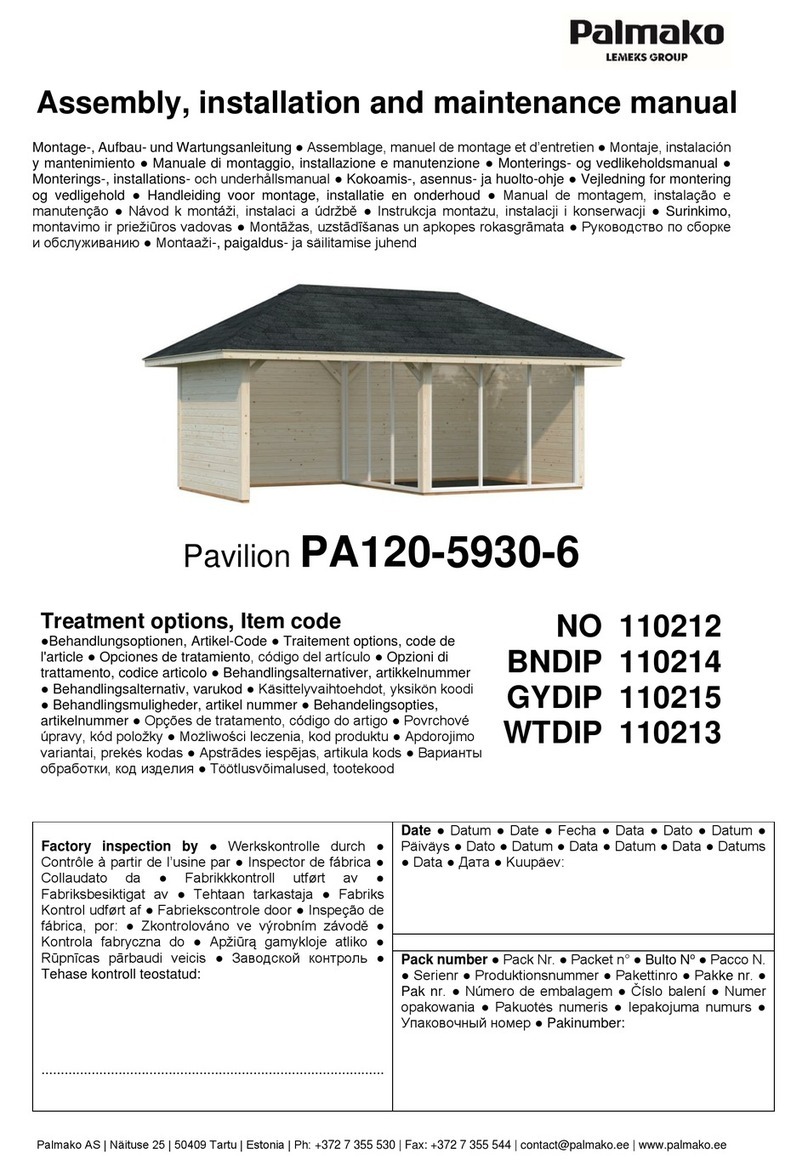

Lemeks

Lemeks Palmako PA120-5930-6 Assembly, installation and maintenance manual

Rion

Rion Hobby Gardener Assembly instructions

Gartenhaus-King

Gartenhaus-King Valery manual

Select

Select ISAAC E9682 Assembly manual

Mercia Garden Products

Mercia Garden Products 01DTSHPWOR1010DDOW-V4 General instructions

Palmako

Palmako Saale installation manual

Lemeks

Lemeks Palmako Kira EL16-3623 Assembly, installation and maintenance manual

Mercia Garden Products

Mercia Garden Products 0644LOG186-V4 General instructions

Palmako

Palmako Roger FR44-5953-2 installation manual

Mercia Garden Products

Mercia Garden Products 03DTSHHP1206HGD4MW-V1 General instructions

Pergola kits USA

Pergola kits USA PREMIUM VINYL PAVILION Assembly manual

G21

G21 Boston 882 manual

Lemeks

Lemeks Palmako Grace PM56-4529 Assembly, installation and maintenance manual

Mercia Garden Products

Mercia Garden Products 03WES0808-V1 General instructions

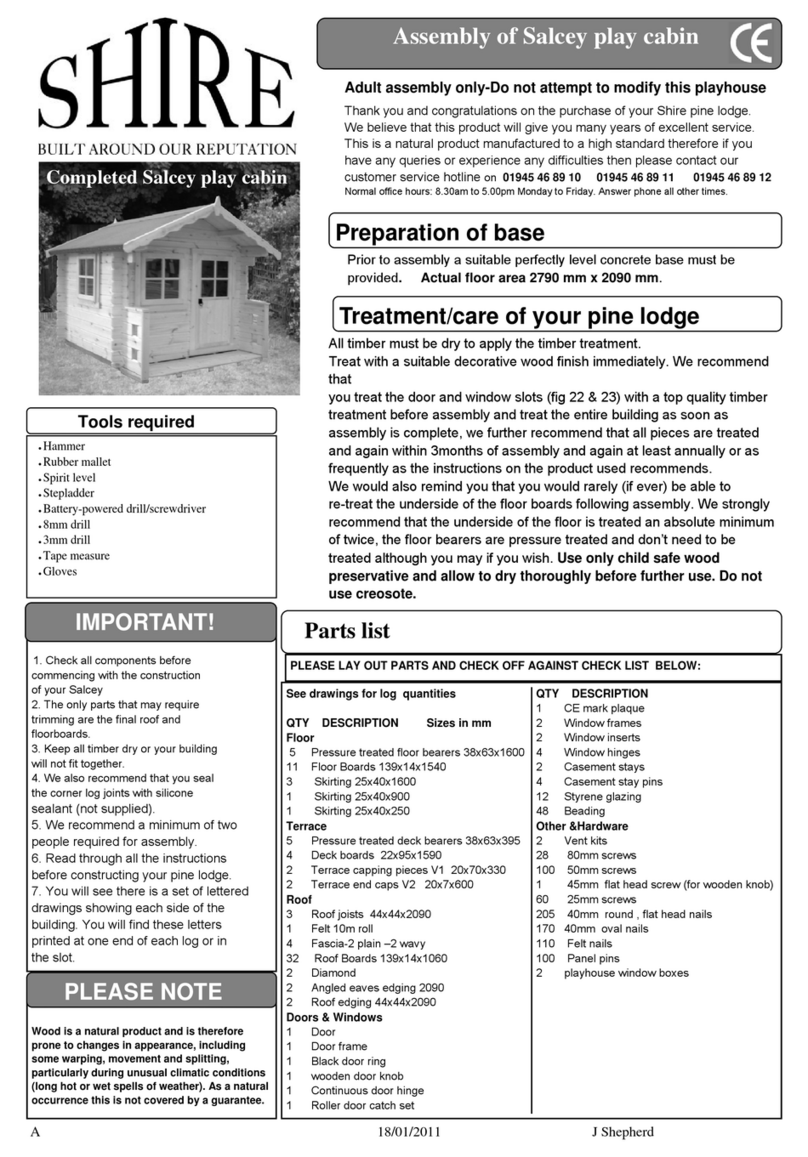

Shire

Shire Salcey Assembly

Mercia Garden Products

Mercia Garden Products 05DTMBPN0503DD-V1 Assembly instructions

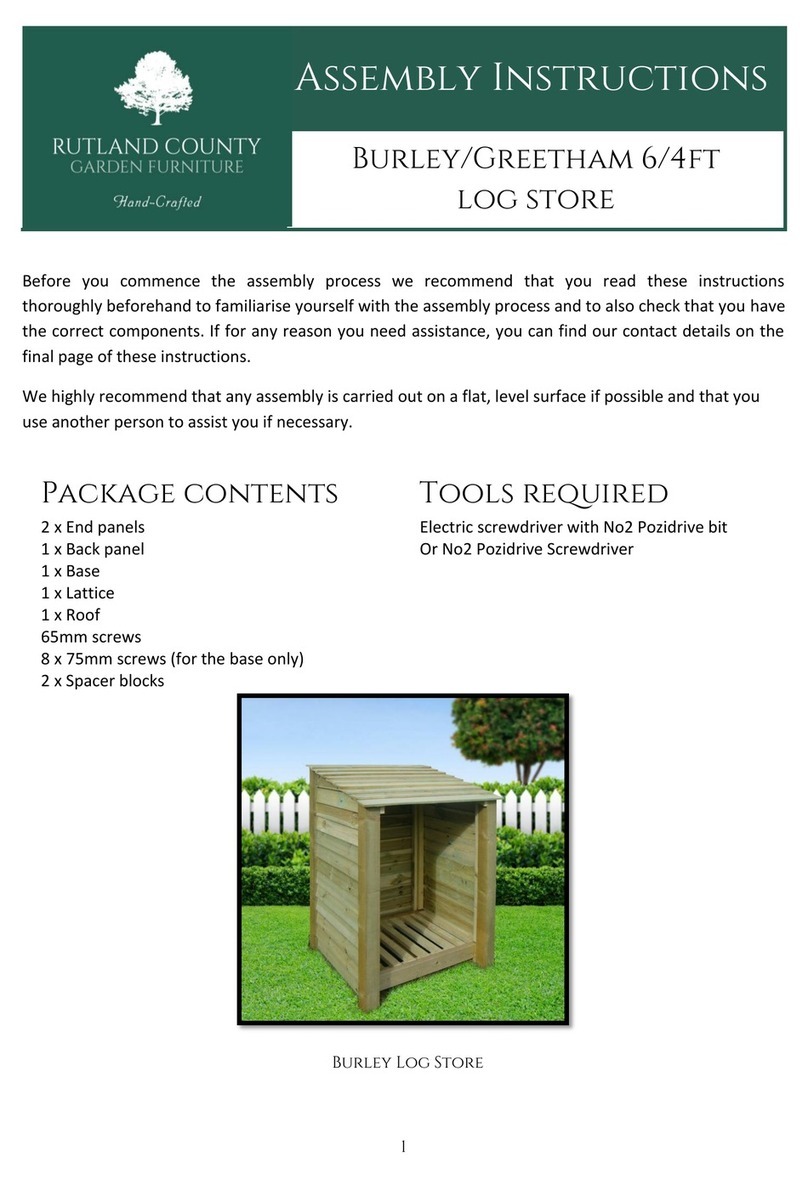

Rutland County

Rutland County Burley 6ft Assembly instructions