Page 2 Heat & Glo · Tiara I B & Tiara II B · 7010-149M August 1, 2008

Read this manual before installing or operating this appliance.

Please retain this owner's manual for future reference.

Congratulations

Congratulations on selecting a Heat & Glo gas appliance -

anelegantandcleanalternative towoodburningappliances.

TheHeat&Glogasapplianceyou have selected is designed

to provide the utmost in safety, reliability, and efficiency.

As the owner of a new appliance, you'll want to read and

carefully follow all of the instructions contained in this

Owner's Manual. Pay special attention to all Cautions and

Warnings.

ThisOwner'sManualshouldberetainedforfuturereference.

We suggest that you keep it with your other important

documents and product manuals.

The information contained in this Owner's Manual, unless

noted otherwise, applies to all models and gas control

systems.

Your new Heat & Glo gas appliance will give you years of

durable use and trouble-free enjoyment. Welcome to the

Heat & Glo family of gas appliance products!

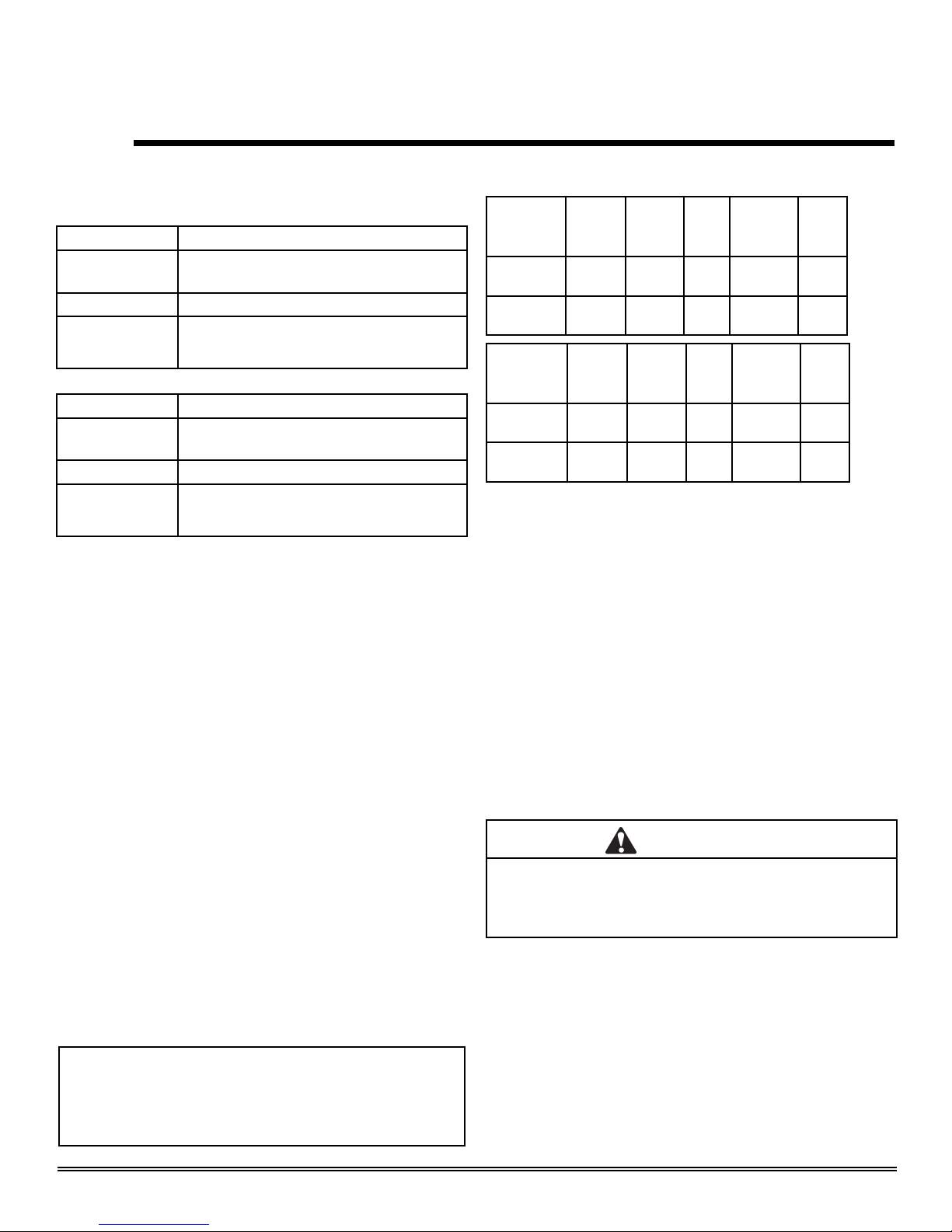

SAMPLE OF RATINGS LABEL

LOCATION: Hang tag attached to rear of appliance

Serial No.

Model Name

Test Lab &

Report No.

Manufactured

Date

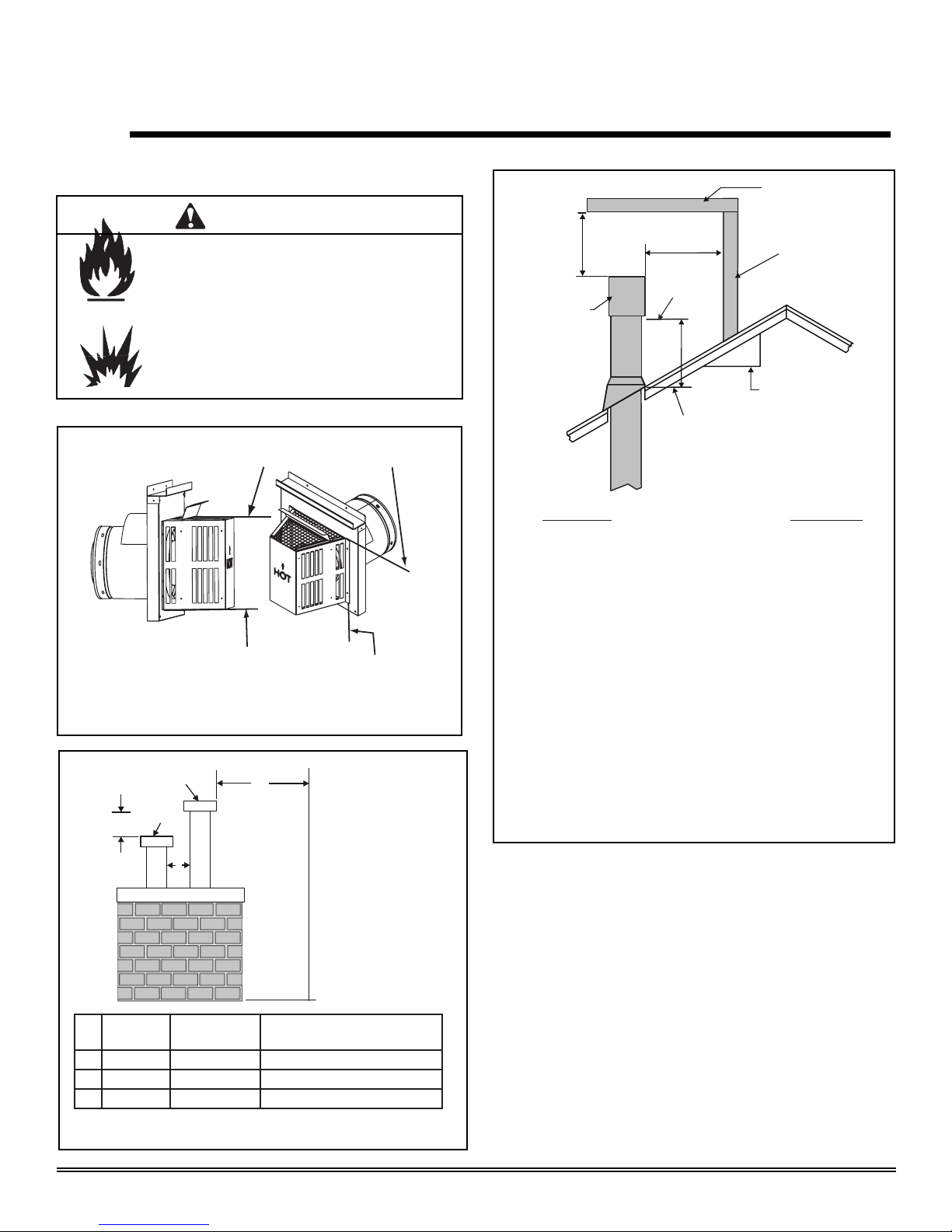

MINIMUM CLEARANCES TO COMBUSTIBLES / ESPACE MINIMUM AUX COMBUSTIBLES

Minimum clearances required from combustible construction for all appliance surfaces. / Espaces minimum exigés de la

construction combustible aux surfaces de l’appareil.

Date of Manufacture / Date du Manufacturier

2008 2009 2010 Feb Mar Apr May Jun Jul Aug Sep Oct Nov DecJan

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER L’ÉTIQUETTE Made in U.S.A. / Fait Aux États-Unis 7010-150

A. Side of stove top to side wall 8-1/2" (216mm) D

u côté du poêle au côté du mur

B. Rear of stove to back wall 1/4" (6mm)

Le contrôle arrière au mur arrière

C. Corner of stove top to side wall 3/8" (9mm) Du coin du dessus du po

êle au mur de côté

D. Minimum Alcove Height 54" (1372mm) Ha

uteur minimum du plancher au plafond

E. Maximum Alcove Depth 36" (914mm) P

rofondeur maximum de l'alcove

F. Minimum Alcove Width 40" (1016mm)

Largeur minimum de l'alcove

G. Stove to Ceiling Clearance 27" (686mm) Le po

êle au dégagement de plafond

H. Top of Pipe to Combustible 1-1/2" (38mm) Le sommet de tuyau à combustible

Side of Pipe to Combustible 1" (25mm) Le côté de tuyau à combustible

Inside Outside Cornerwall Vent 9" (229mm) À l'intérieur de conduit de mur de coin extérieur

Right and left sides of appliance are determined when facing the front of appliance. / Les

côté gauches et droits de

l'appareil sont d

éterninés lorsque vous

êtes en face de l'appareil.

G-Alcove

A

F

de l'alcôve

90° off top up & out ceiling

clearance 90° du sommet en

haut et hors le degagement de

plafond

A

B

E

A A

G

D

H

"A" measurement is from stove top,

not side /

"A"mesure est du

sommet de poêle, pas le côté

HEARTH: A non-combustible hearth pad is not required. However, the floor beneath the stove must be stable, level, and strong

enough to support the stove without a tipping hazard. / CHEMINÉE: Un coussinet non-combustible de cheminée n’est pas

exigé. Cependant, le plancher en dessous du poêle doit être droit, à niveau et assez fort pour supporter le poêle sans le

hasard de basculer.

C

C

0-2000 FT’ 0-2000FT

Input Rate on “HI” (BTU/Hr) 31,000 30,000 Puissance Évaluée à “HI” (BTU/Hr)

Input Rate on “LO” (BTU/Hr) 22,000 23,000 Puissance Évaluée à “LO” (BTU/Hr)

Maximum Output (BTU/Hr)** 20,943 21,519 Puissance Maximum (BTU/Hr**

Main Burner Orifice .106 .063 Orifice du Brûleur Principal

Minimum Inlet Pressure

(Inches W.C.)

4.5” 11” Pression Minimum de la Valve (pouces W.C.)

Maximum Inlet Pressure

(Inches W.C.)

7.0” 14” Pression Maximum de la Valve (pouces W.C.)

M

anifold Pressure on

“HI”

(Inches W.C.)

3.5” 10” Pression du Collecteur d’ Échappement à “HI” (pouces W.C.)

**Max Venting, Blower On **Ventilation Maximum, Ventilateur Allumé

For use with Propane

Usage Au Gaz Propane

For use with Natural Gas

Usage Au Gaz Naturel

APPROVED FOR CANADA AND USA TO: ANSI Z21.88-2002 / CSA 2.33-02 Vented Gas Fireplace Heaters, and applicable sections of UL307b Gas Burning HeatingAppliances for Manufactured Homes and Recreational

Vehicles, CAN/CGA 2.17-M91 Gas Fired Appliances for use at High Altitudes. This appliance is manufactured for operation with Natural Gas. For conversion to propane Manufacturer's instructions must be used. This

appliance may be installed in a bedroom or bedsitting room; in Canada remote thermostat installation is required.

APPROUVÉ-POUR LE CANADA ET LES ÉTATS-UNIS: ANSI-Z21.88-2002 / CSA 2.33-02 Fournaises au Gaz avec Ventilation, et les sections applicable de UL 307b Appareils de Chauffage Au Gaz our les Maisons Mobiles et les

Vehicules Motoriss, CAN/CGA 2.17-M91 Gas Fired Appliances for use at High Altitudes. Cet appareil est manufactur pour l'operation avec le Gaz Naturel. Pour une conversion au gaz propane les pices du Manufacturier et ses

instructions doivent tre utilises. Cet appareil peut tre utilis dans une chambre à coucher ou salle de sjour, au Canada, l'installation d'un thermostat à distance est exige.

FAN TYPE VENTED CIRCULATOR / VENTILATEUR CIRCULATOIRE

Optional Blower Kit #GFK-160A

/

Le Souifleur Optionel Kit #GFK-160A

120Vac, 60Hz., 12 Amperes or less (ou moins)

Route power cord away from unit. /

Éloignez le fil électrique de l'appareil.

Do not route

power cord under or over stove. /

Ne pas faire passer le fil électrique au dessus ou en dessous de l'appareil.

SAMPLE

VENTED GAS FIREPLACE HEATER

NOT FOR USE WITH SOLID FUEL

Serial No / Numéro du

Report No. / Rapport Numéro

061-S-43b-5 FOURNAISE AU GAZ AVEC VENTILATION

NE PAS UTILISER AVEC LE COMBUSTIBLE SOLIDE

MODEL / MODÈLE: TIARA I (B)

A division of Hearth & Home Technologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044

007

O-T

Tested and

Listed by

Portland

Oregon USA

OMNI-Test Laboratories, Inc.

CUS

Barcode